Filtering material electret equipment and method

A filter material and electret technology, applied in the direction of filter separation, separation methods, chemical instruments and methods, etc., can solve the waste of resources, can not be used to manufacture a variety of different filter materials, etc., to achieve the effect of eliminating waste and polarization Robust, compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

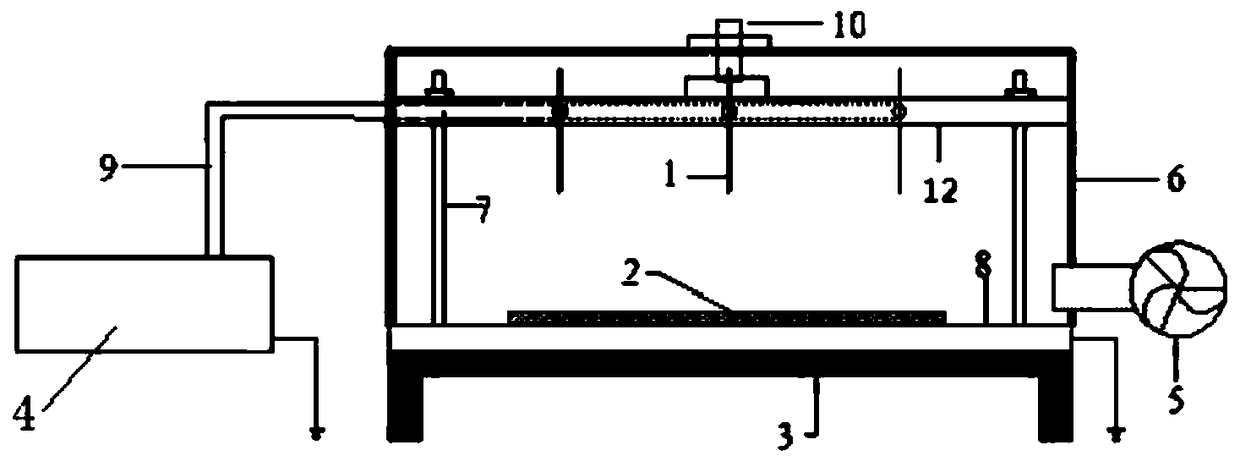

[0042] Such as figure 1 As shown, the temperature control heating device 3 is placed on the ground as a whole, and its upper space is completely covered by the insulating cover 6 . The insulating cover 6 can also cover the temperature control heating device 3 as a whole.

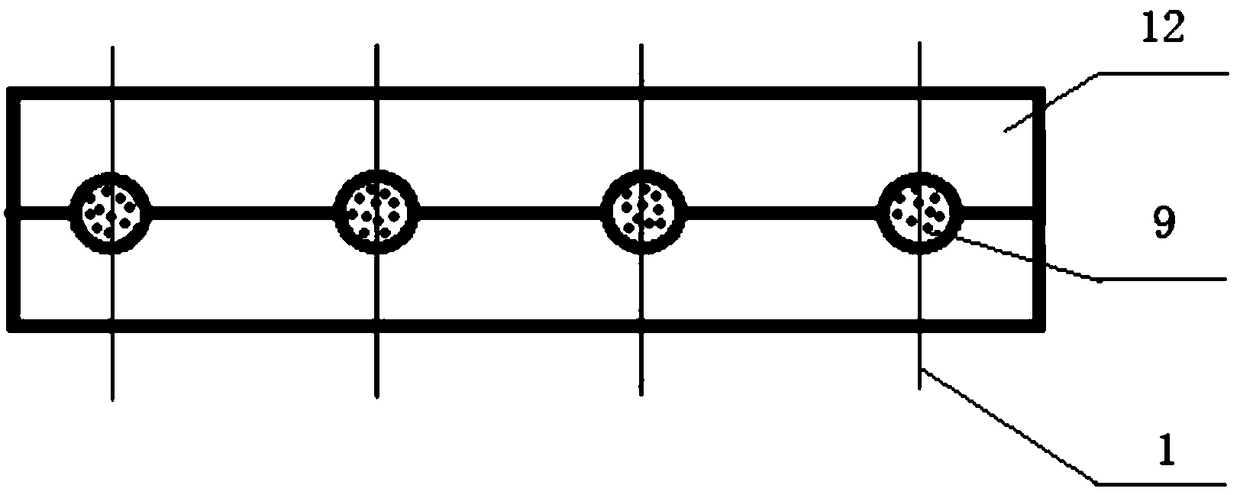

[0043] Most of the voltage-applying devices are arranged in the insulating cover 6, and the DC high-voltage power supply 4 is arranged outside and connected to the needle electrode 1 through the high-voltage wire 9, and the DC high-voltage power supply 4 is also grounded. The DC high-voltage power supply 4 has a voltage regulation range of 0kV-30kV, and has the functions of breakdown power cutoff and overcurrent power cutoff.

[0044] A plate electrode 8 is arranged on the temperature control heating device 3, and the plate electrode 8 is grounded. figure 1 The middle support rod 7 is fixed to the plate electrode 8 , and may actually be fixed to the temperature control heating device 3 or the insulating co...

Embodiment 2

[0056] S1, raw material 2 is PTFE (Poly tetrafluoroethylene, polytetrafluoroethylene) needle felt, PTFE is placed on the metal plate electrode 8, the insulating cover 6 is closed, and the distance between the needle electrode 1 and the plate electrode 8 is adjusted to 2cm;

[0057] S2, turn on the temperature control heating device 3, heat the PTFE to make its surface temperature reach 300°C;

[0058] S3, turn on the DC high-voltage power supply 4, the voltage between the needle electrode 1 and the plate electrode 8 is 15kV, and the electret time is 2 / 3h;

[0059] S4, turn off the temperature control heating device 3, keep the DC high-voltage power supply 4, turn on the cooling fan 5, reduce the surface temperature of PTFE to room temperature, and obtain the finished product;

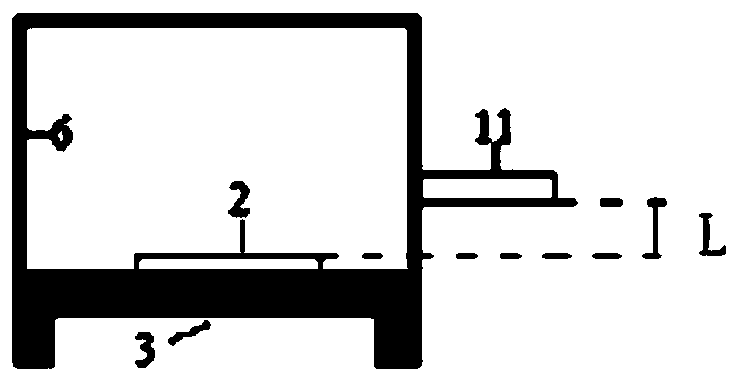

[0060] S5, pull out the plate electrode 8 from the insulating cover 6, and use the surface potential detector 11 to detect the quality of the finished product,

[0061] If qualified, take out the finis...

Embodiment 3

[0064] S1, raw material 2 is P84 (polyimide) filter material, place P84 on the metal plate electrode 8, close the insulating cover 6, adjust the distance between the needle electrode 1 and the plate electrode 8 to 2cm;

[0065] S2, turn on the temperature control heating device 3, and heat P84 to make its surface temperature reach 350°C;

[0066] S3, turn on the DC high-voltage power supply 4, the voltage between the needle electrode 1 and the plate electrode 8 is 18kV, and the electret time is 1.5h;

[0067] S4, turn off the temperature control heating device 3, keep the DC high-voltage power supply 4, turn on the cooling fan 5, reduce the surface temperature of P84 to room temperature, and obtain the finished product;

[0068] S5, pull out the plate electrode 8 from the insulating cover 6, and use the surface potential detector 11 to detect the quality of the finished product,

[0069] If qualified, take out the finished product;

[0070] If unqualified, repeat S1-S5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com