Reciprocating type dust removal device and method used after PCB drilling

A dust removal device and reciprocating technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problem that PCB holes cannot be identified or misjudged, the cleaning process is cumbersome, and the holes are easy to clean. Residual dust and other problems, to achieve a thorough cleaning effect, shorten the processing cycle, and solve the effect of scratching the board surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a reciprocating dust removal device after drilling a PCB. The dust removal device is used to automatically clean the dust and debris on the surface of the PCB board and the hole after drilling. The dust removal device includes a reciprocating type connected in sequence. The dust removal mechanism, the drilling cleaning mechanism, the flap cooling mechanism, the hole position accuracy testing mechanism and the automatic plate receiving machine, the reciprocating dust removal mechanism is connected with a dust removal and feeding manipulator, and the hole position accuracy testing mechanism is connected with a test feeding manipulator .

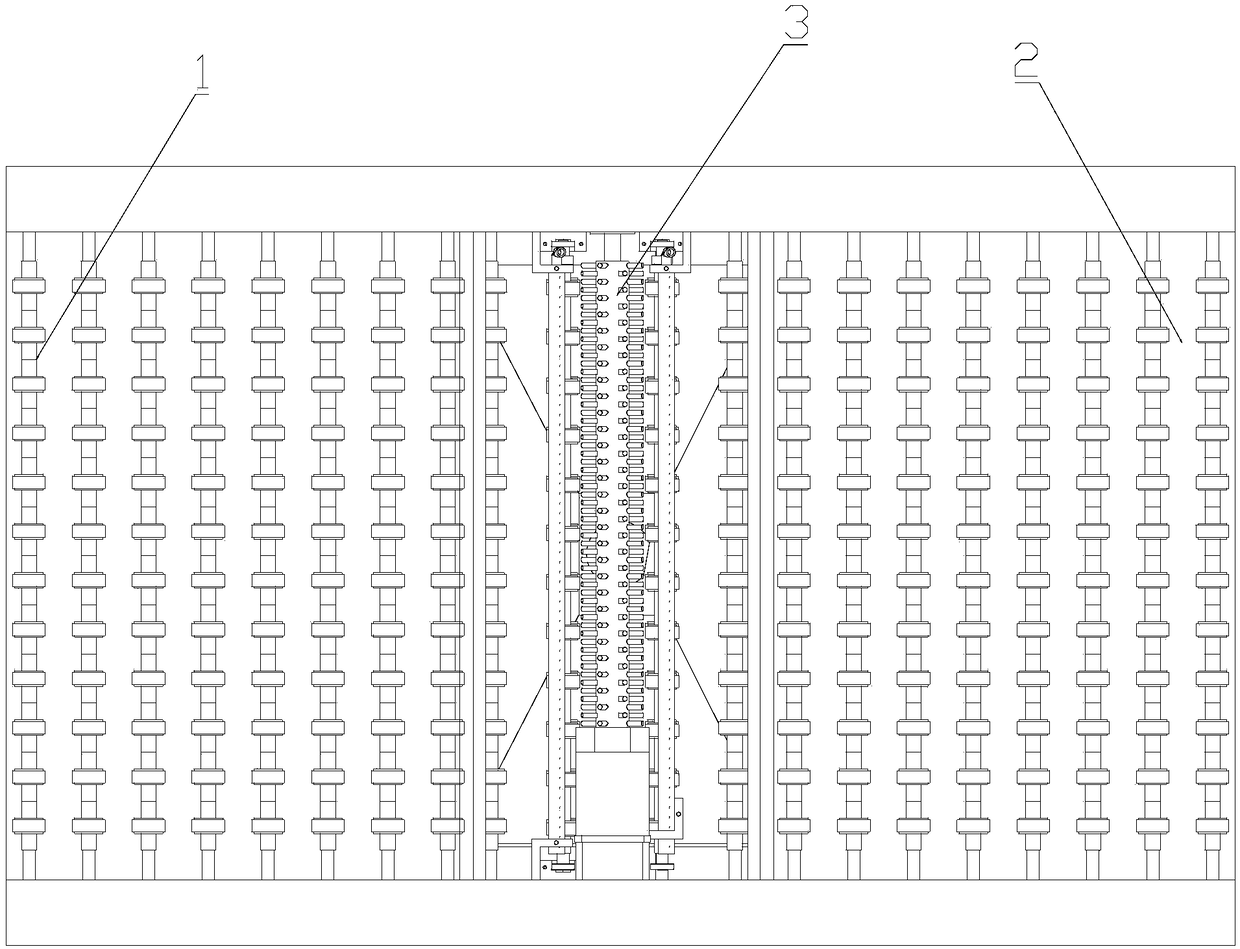

[0032] The reciprocating dust removal mechanism adopts a method of large air flow, high air pressure and fast dust suction, which can instantly remove the dust and debris on the surface of the PCB board and in the hole after drilling, specifically, such as figure 1 As shown, the reciprocating dust removal mechani...

Embodiment 2

[0046] This embodiment provides a reciprocating dust removal device after drilling a PCB. The dust removal device is used to automatically clean the dust and debris on the surface of the PCB board and the hole after drilling. The dust removal device includes a reciprocating type connected in sequence. The dust removal mechanism, the drilling cleaning mechanism, the flap cooling mechanism, the hole position accuracy testing mechanism and the automatic plate receiving machine, the reciprocating dust removal mechanism is connected with a dust removal and feeding manipulator, and the hole position accuracy testing mechanism is connected with a test feeding manipulator .

[0047] The reciprocating dust removal mechanism adopts a method of large air flow, high air pressure and fast dust suction, which can instantly remove the dust and debris on the surface of the PCB board and in the hole after drilling, specifically, such as figure 1 As shown, the reciprocating dust removal mechani...

Embodiment 3

[0061] This embodiment provides a reciprocating dust removal device after drilling a PCB. The dust removal device is used to automatically clean the dust and debris on the surface of the PCB board and the hole after drilling. The dust removal device includes a reciprocating type connected in sequence. The dust removal mechanism, the drilling cleaning mechanism, the flap cooling mechanism, the hole position accuracy testing mechanism and the automatic plate receiving machine, the reciprocating dust removal mechanism is connected with a dust removal and feeding manipulator, and the hole position accuracy testing mechanism is connected with a test feeding manipulator .

[0062] The reciprocating dust removal mechanism adopts a method of large air flow, high air pressure and fast dust suction, which can instantly remove the dust and debris on the surface of the PCB board and in the hole after drilling, specifically, such as figure 1 As shown, the reciprocating dust removal mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com