A kind of three-layer water retention type environmental biodegradable film and preparation method thereof

A biodegradable and water-retaining technology, which is applied in botany equipment and methods, chemical instruments and methods, layered products, etc., can solve problems such as soil impact, and achieve an effect that is not easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

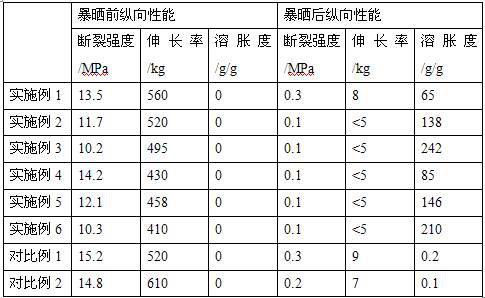

Examples

Embodiment 1

[0030] A three-layer water-retaining environmental biodegradable film, which includes an upper film, a middle film and a lower film; the upper film

[0031] The film raw materials include the following components: 0.02kg iron stearate, 0.2kg barium stearate, 0.2kg phenyl salicylate, 0.2kg2,6-di-tert-butyl p-cresol, 5kg low-density polyethylene 2426H, 94.38kg linear low density polyethylene 7042;

[0032] The raw materials of the middle layer film include the following components: 0.01kg iron stearate, 0.1kg barium stearate, 0.05kg 2,6-di-tert-butyl p-cresol, 30kg sodium polyacrylate, 69.84kg linear low density polyethylene 7042.

[0033] The raw materials of the lower film include the following components: 0.2kg of iron stearate, 5kg of low-density polyethylene 2426H, and 94.8kg of linear low-density polyethylene 7042.

[0034] A preparation method of a three-layer water-retaining type environmental biodegradable film, comprising the steps of:

[0035] (1) Put the raw materi...

Embodiment 2

[0041] Upper layer: 0.02kg iron stearate, 0.2kg barium stearate, 0.2kg phenyl salicylate, 0.2kg 2,6-di-tert-butyl-p-cresol, 5kg low-density polyethylene 2426H, 94.38kg linear low-density polyethylene Vinyl 7042.

[0042] Middle layer: 0.05kg iron stearate, 0.2kg barium stearate, 0.1kg 2,6-di-tert-butyl-p-cresol, 50kg sodium polyacrylate, 49,65kg linear low density polyethylene 7042.

[0043] Lower layer: 0.2kg iron stearate, 5kg low density polyethylene 2426H, 94.8kg linear low density polyethylene 7042.

[0044] The preparation method of this embodiment is the same as that of Example 1, wherein the thickness of the upper film is 5 microns, the thickness of the middle film is 7 microns, and the thickness of the lower film is 3 microns.

Embodiment 3

[0046] Upper layer: 0.02kg iron stearate, 0.2kg barium stearate, 0.2kg phenyl salicylate, 0.2kg 2,6-di-tert-butyl-p-cresol, 5kg low-density polyethylene 2426H, 94.38kg linear low-density polyethylene Vinyl 7042.

[0047] Middle layer: 0.2kg iron stearate, 0.4kg barium stearate, 0.2kg 2,6-di-tert-butyl-p-cresol, 90kg sodium polyacrylate, 9.2kg linear low density polyethylene 7042.

[0048] Lower layer: 0.2kg iron stearate, 5kg low density polyethylene 2426H, 94.8kg linear low density polyethylene 7042.

[0049] The preparation method of this embodiment is the same as that of Example 1, wherein the thickness of the upper film is 5 microns, the thickness of the middle film is 7 microns, and the thickness of the lower film is 3 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com