Vacuum train gas insulation type access device

A kind of train and vacuum technology, applied in the directions of stations, transportation and packaging, railway car body parts, etc., can solve the problems of reduced efficiency, large friction, waste of manpower, etc., to reduce energy consumption, reduce friction, and save labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

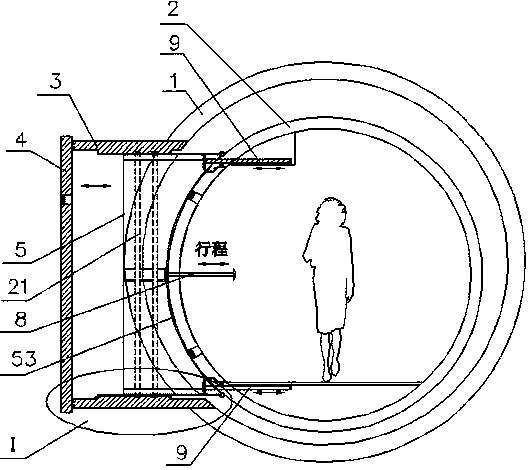

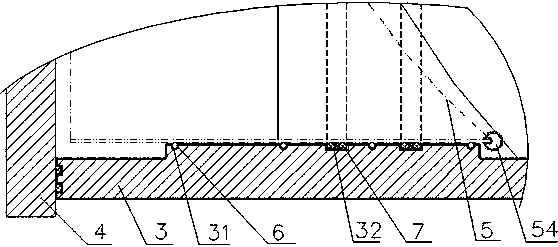

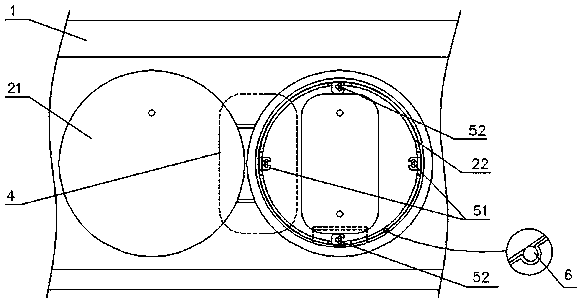

[0026] Such as Figure 1~Figure 4 Shown: a vacuum train air barrier entry and exit device, including a vacuum pipeline 1 and a train 2 located in the vacuum pipeline 1, the vacuum pipeline 1 is connected with a fixed passage 3, and the fixed passage 3 is provided with a tunnel door 4; One end is connected with a telescopic air baffle 5; a sliding structure is provided between the air baffle 5 and the fixed channel 3 to facilitate the movement of the air baffle 5. The sliding structure is a ball mechanism.

[0027] This embodiment has the following advantages: (1) the fixed channel and the air shield are arranged on the vacuum pipeline instead of the train, which can reduce the weight of the train and simplify the structure; (2) it is easy to manufacture and install, and the installation is more firm; (3 ) The tunnel door is moved outwards and installed on a fixed channel, which simplifies the structure of the tunnel door compared to being directly installed on a vacuum pipe; ...

Embodiment 2

[0043] The difference from Embodiment 1 is that the sliding structure of this embodiment is a roller mechanism. The roller mechanism includes a plurality of rollers, and the rollers are fixed on the fixed channel at intervals through roller seats.

[0044] Other structures are with embodiment 1.

Embodiment 3

[0046] The difference from Example 1 is that a plurality of first grooves are arranged at intervals on the opposite side of the fixed channel and the air baffle, and the first grooves of the fixed channel and the first grooves of the air baffle are alternately arranged, and the balls set in the first groove.

[0047] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com