Full servo control material-box-type collecting and accumulating device

A servo control and accumulation technology, applied in the field of integrator, can solve the problems such as the speed cannot reach the surface line speed, the lack of automatic feeding equipment, and the low production efficiency, etc., to achieve the effect of improving the accumulation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

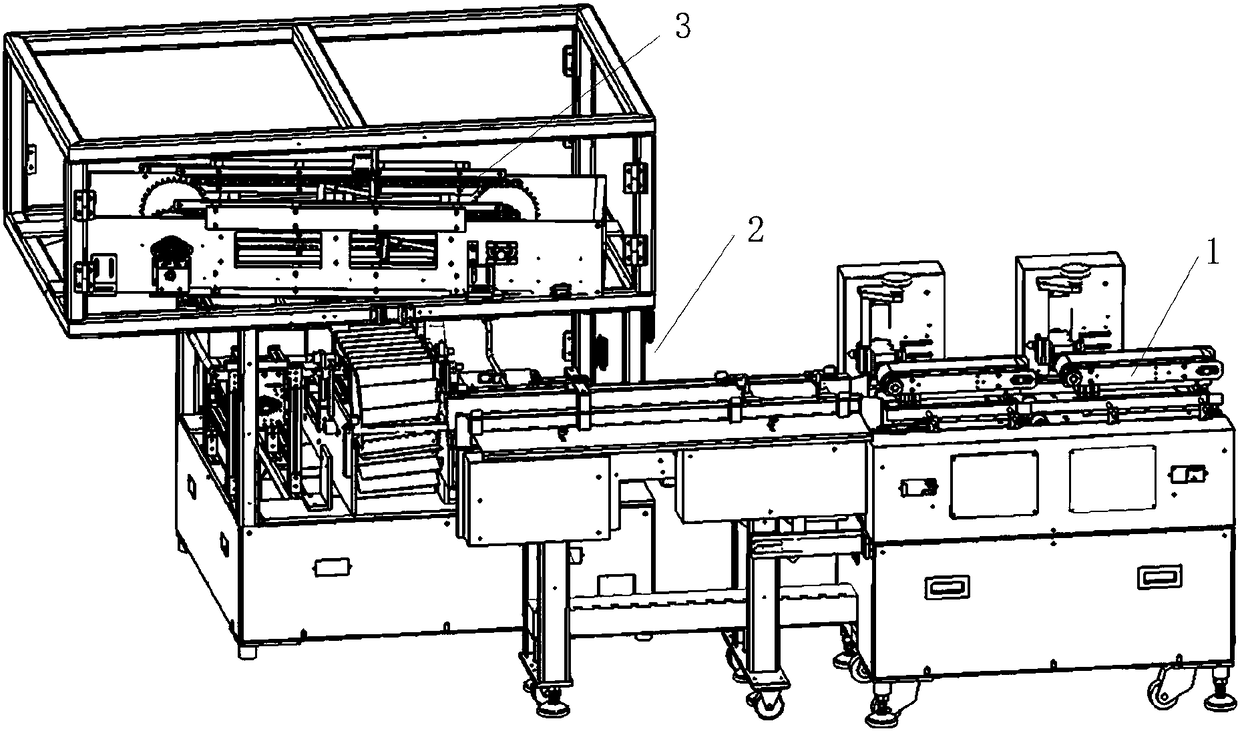

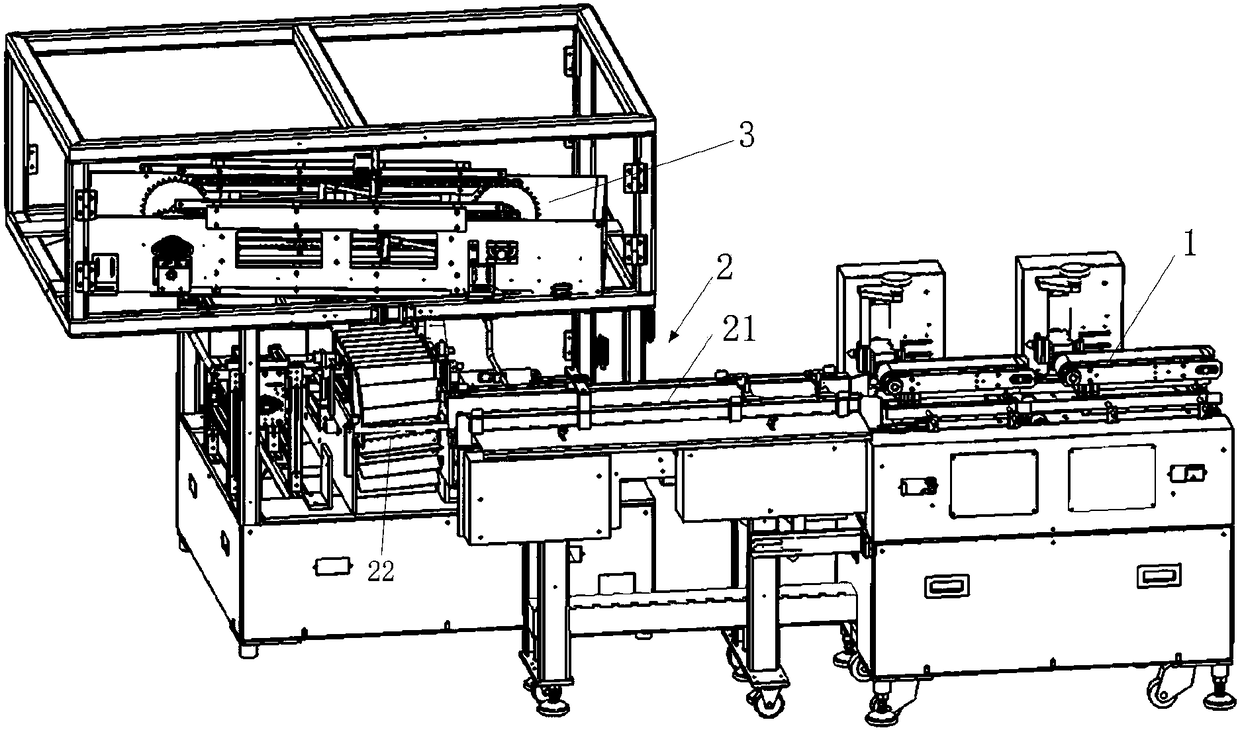

[0034] figure 1 It is a fully servo-controlled cassette type accumulator, which includes a feeding mechanism 1, a fast conveying mechanism 2, a material shifting mechanism 3 and a conveying auxiliary mechanism 4; the feeding mechanism 1 conveys the instant noodles to the rapid conveying mechanism 2. The mechanism 2 conveys the instant noodles from the feeding mechanism 1 to the feeding mechanism 3. The feeding mechanism 3 transfers the instant noodles from the fast conveying mechanism 2 according to the requirement of multiple bags at a time, and the auxiliary conveying mechanism 4 transfers the feeding mechanism 3 The instant noodles that have been removed at one time are transported to the conveyor belt of the packaging machine.

[0035]

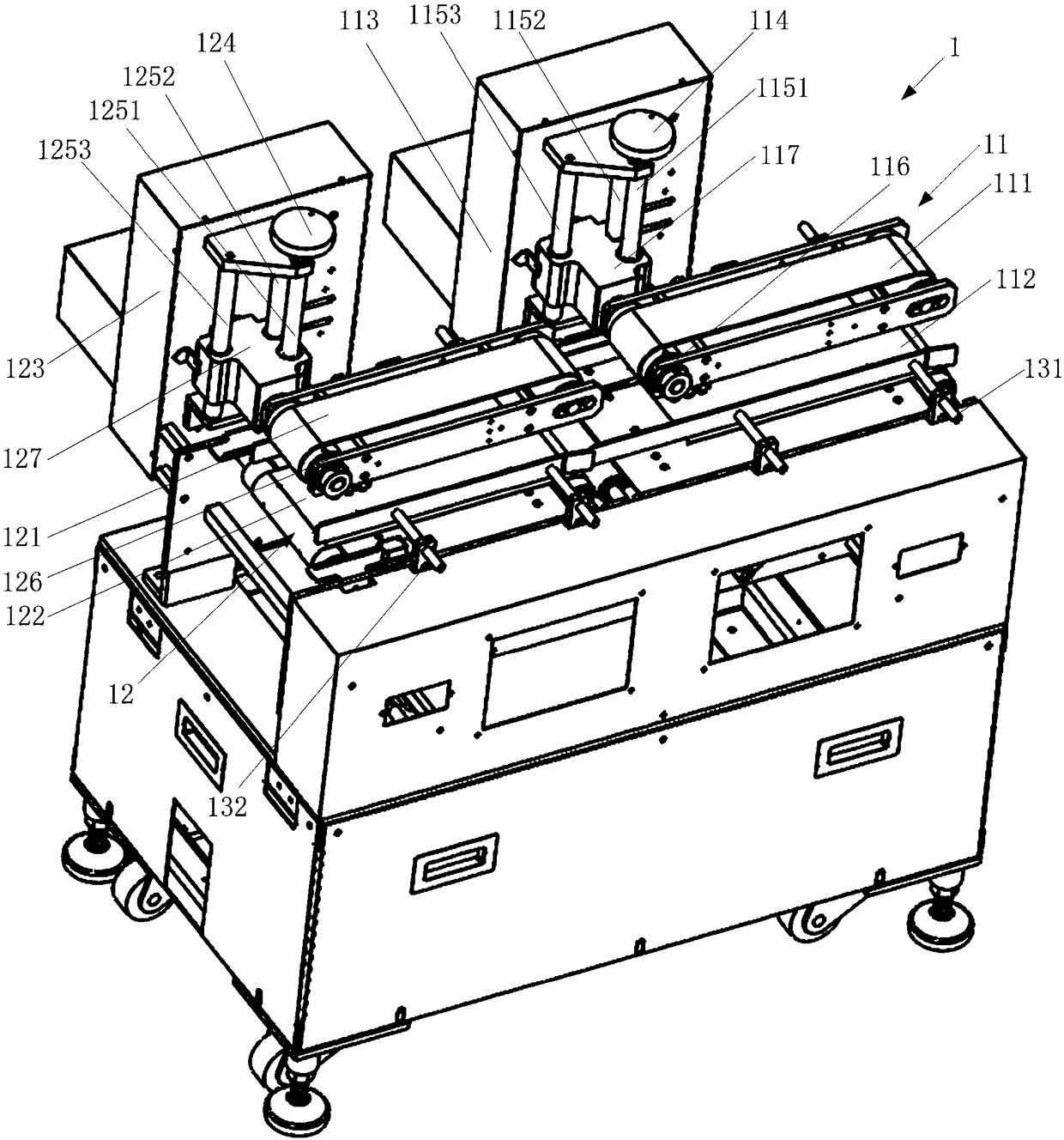

[0036] figure 2 It is a structural diagram of the feeding mechanism 1, which includes two sponge surface-ejecting belt conveyors 11 (the first sponge surface-ejecting belt conveyor) and a sponge surface-ejecting belt conveyor 12 (the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com