Color coated plate coiling roller achieving convenient coiling

A sheet and color-coating technology, which is applied in the field of color-coated sheet rewinding, can solve problems such as easy loosening and low winding efficiency, and achieve the effects of neat winding process, stable coils, and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

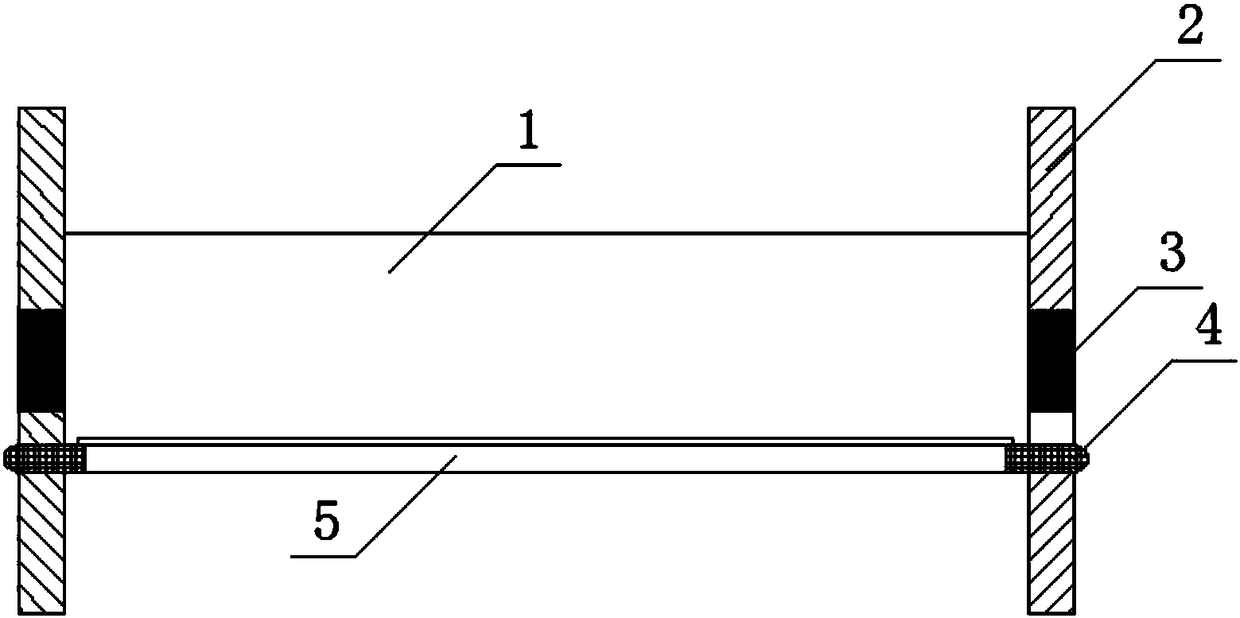

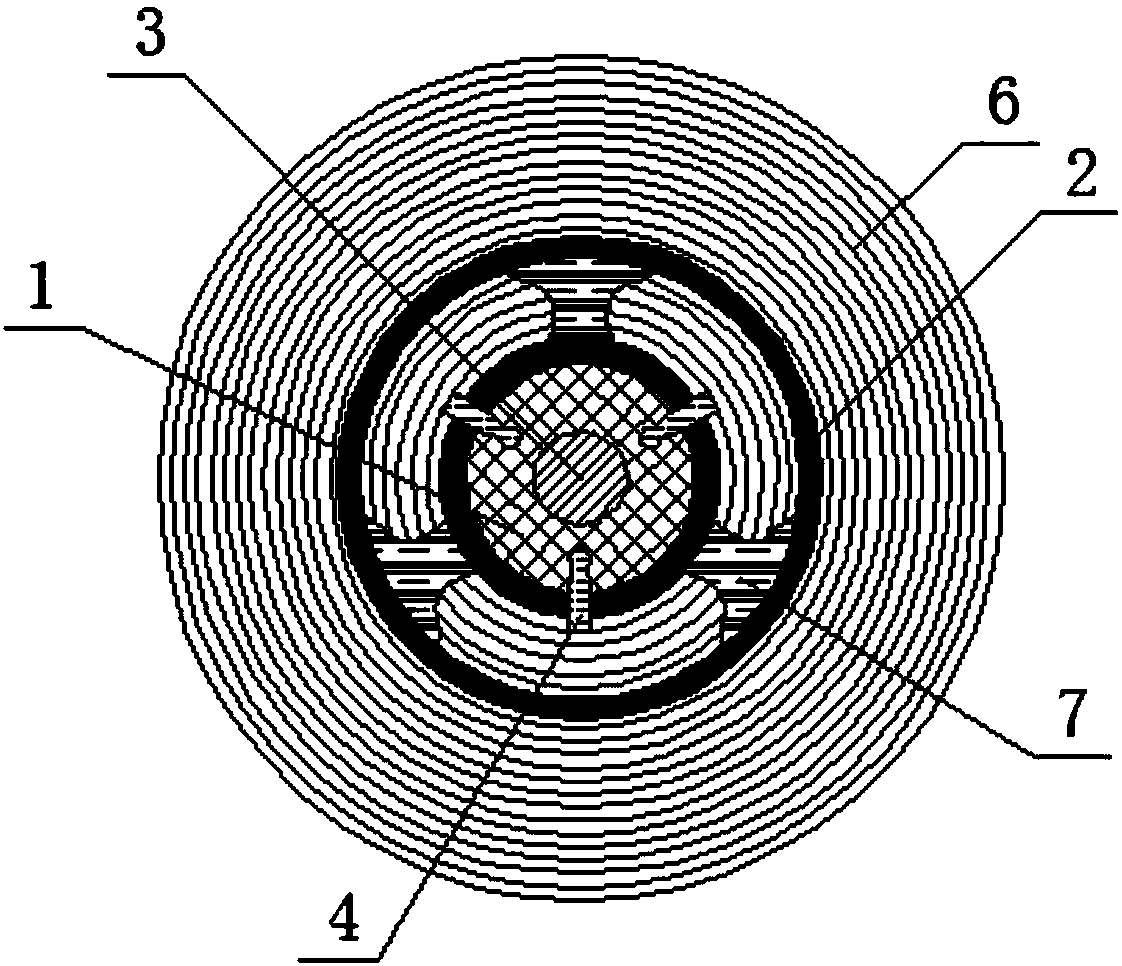

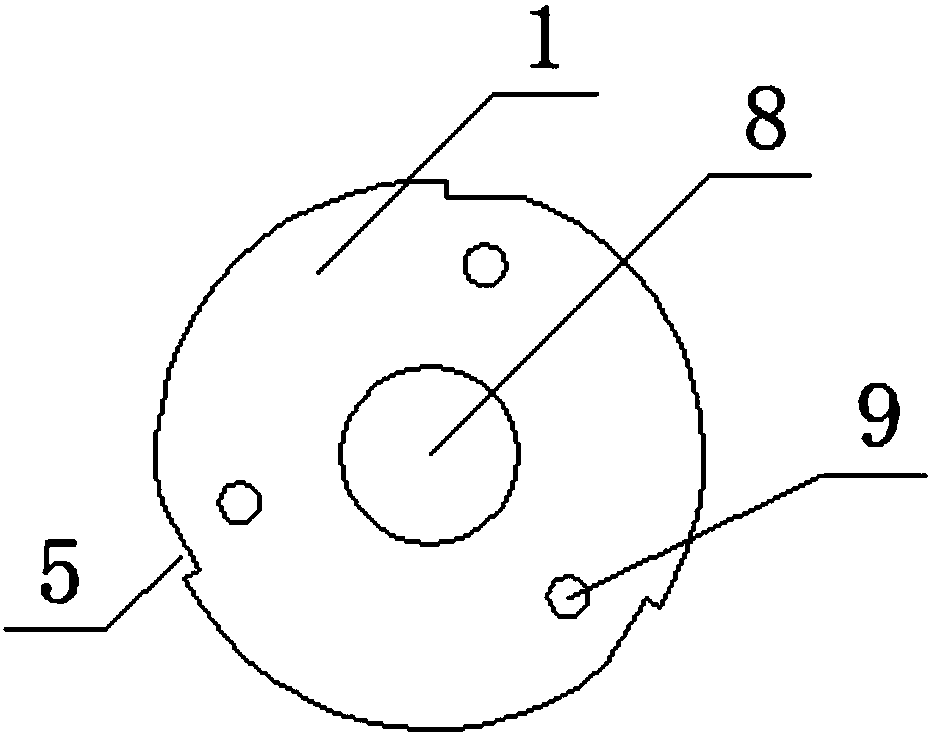

[0019] refer to Figure 1-4 , a color-coated plate reel that is easy to roll, including a roller 1, a pressing sheet 10 and a shaft pin 11, side rails 2 are installed at the left and right ends of the roller 1, and a roller 3 is installed inside the side rail 2, and the roller The outer surface of 1 is provided with a fixing groove 5, and the two ends of the fixing groove 5 are installed with a fixed pressure piece 4, the fixed pressure piece 4 includes a pressure piece 10 and a shaft pin 11, and the inside of the drum 1 is provided with a built-in hole 8, and the inside of the drum 1 Presser installation holes 9 are arranged at the left and right ends, the roll mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com