Hangar electric door system and driving method thereof

A hangar electric door and door panel technology, applied in the direction of windows/doors, door/window applications, door/window accessories, etc., can solve the problems of hangar doors that cannot be used normally, and achieve compact structure, stable transmission, and reduced friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

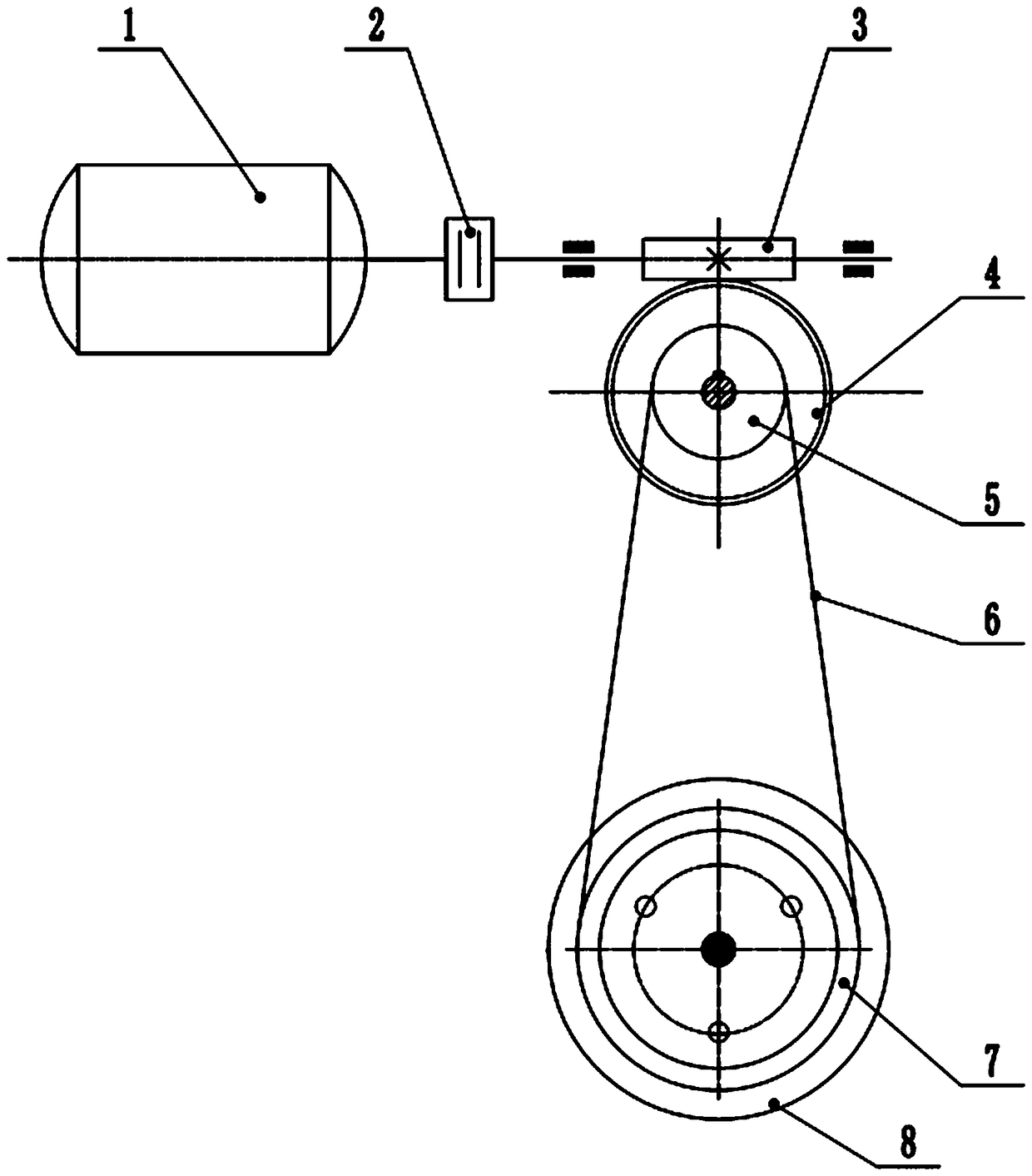

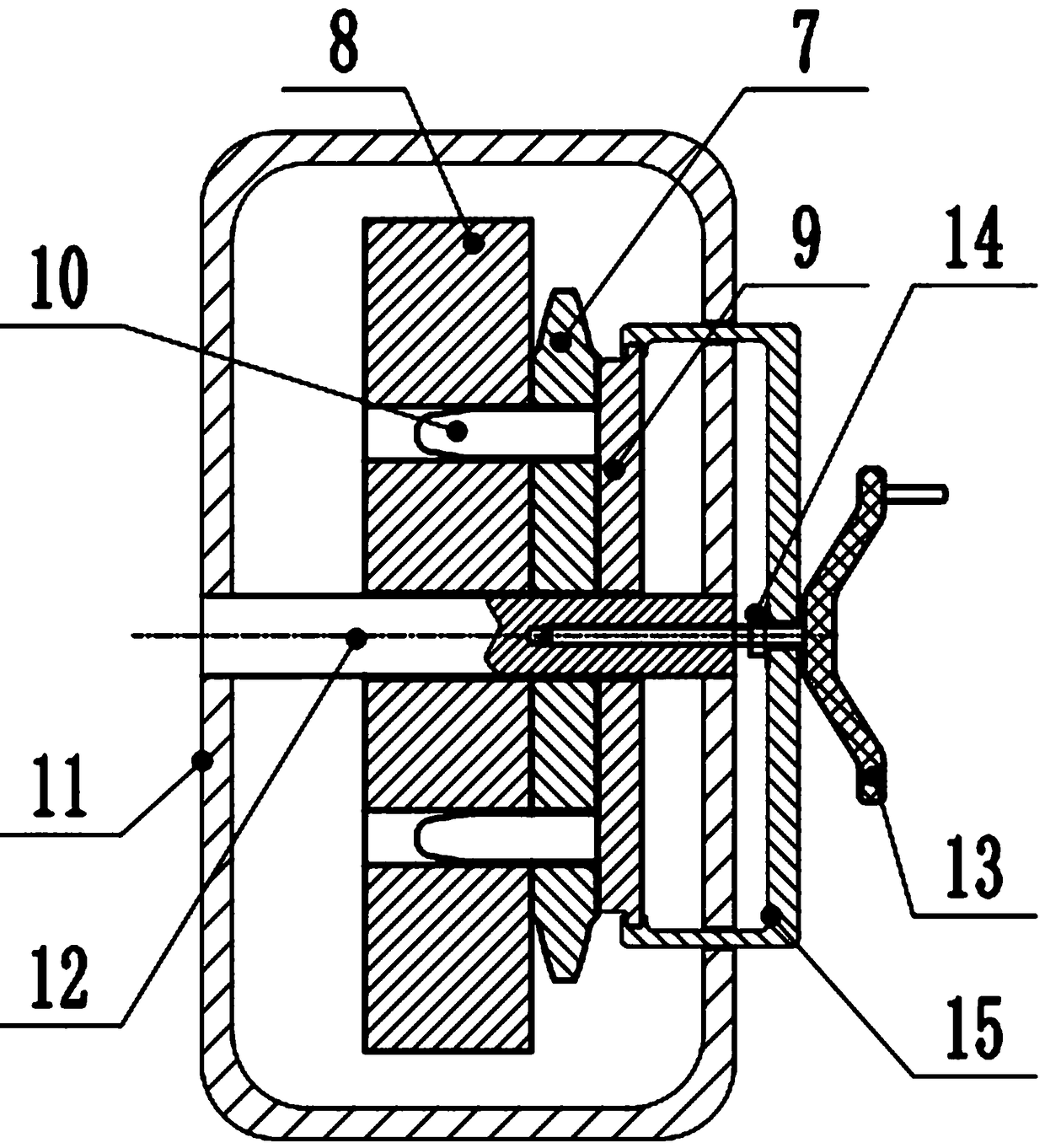

[0023] Such as figure 1 , a hangar electric door system, including a door panel and a track, the bottom of the door panel is provided with a box 11, the box 11 is fixedly installed with a wheel shaft 12, and the wheel shaft 12 is installed in a rotating manner with the track Matching rail wheel 8.

[0024] The system also includes a motor 1, a transmission wheel and a clutch wheel 9. The transmission wheel is mounted on the wheel shaft 12 in a rotational manner, and the clutch wheel 9 is sleeved on the wheel shaft 12 to realize the circumferential rotation and the axial direction relative to the wheel shaft 12. move.

[0025] The motor 1 drives the transmission wheel to rotate through a transmission mechanism; the transmission mechanism may be transmission devices such as gears and synchronous belts. The present embodiment preferably adopts the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com