Combustion chamber with combustion area adjusted on basis of inlet swirl rectifying support plates, and special support plates thereof

A technology of rectifying support plate and combustion chamber, applied in the field of combustion chamber, can solve the problems of unfavorable fuel oil uniformity, reasonable distribution, reliability of low fuel consumption rate, difficult diffusion and mixing, etc., so as to improve the distribution of oil mist field and strengthen oil Effects of mist blending, accelerated breakup and atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

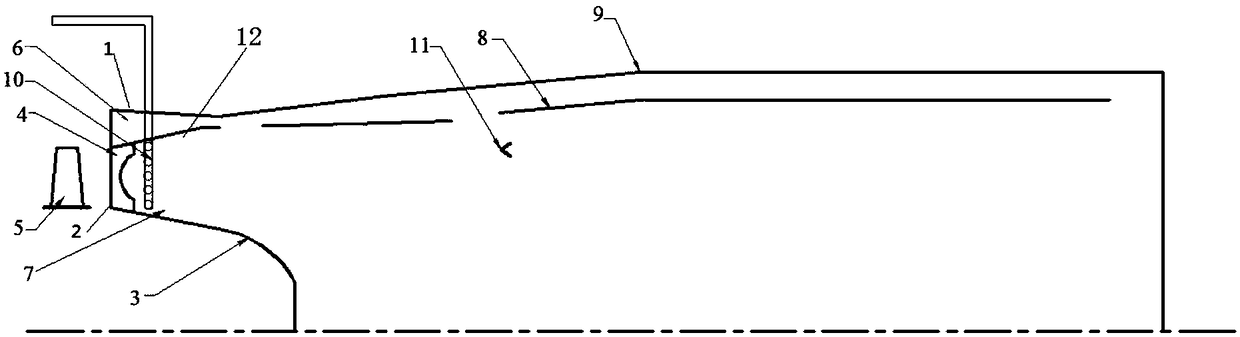

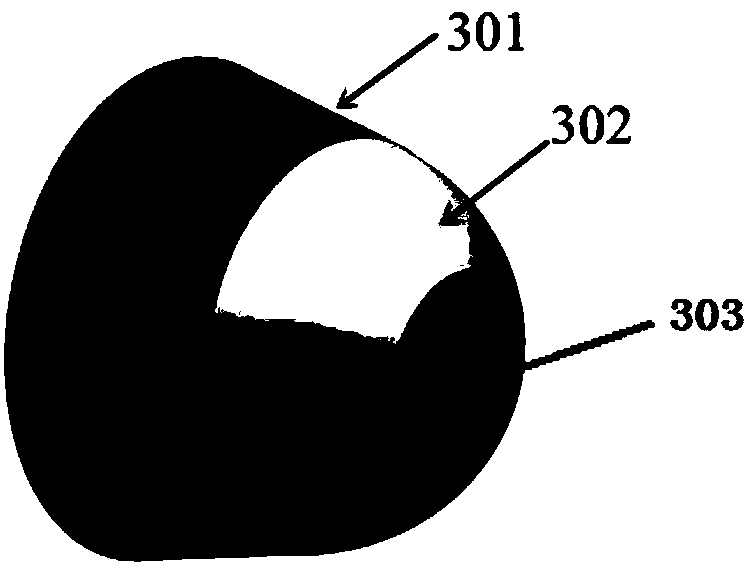

[0032] Such as figure 1 As shown, a combustion chamber according to the present invention includes an outer casing 1, an inner casing 2, a center cone 3, a fuel injection system, a heat shield 8, a cylinder body 9 and a flame stabilizer 11 on duty, located in the inner casing The shunt ring 12 between the casing and the outer casing; the shunt ring is arranged around the inner casing in a concentric manner, and the outer casing is arranged on the periphery of the shunt ring in a concentric manner; a number of swirl rectifiers are fixed between the shunt ring and the inner casing. support plate 4. The distance between the inner casing and the splitter ring is set to H, the distance H between the inner casing and the splitter ring is 1:7 to the diameter of the combustion chamber, and the diameter of the combustion chamber is the diameter of the cylinder 9.

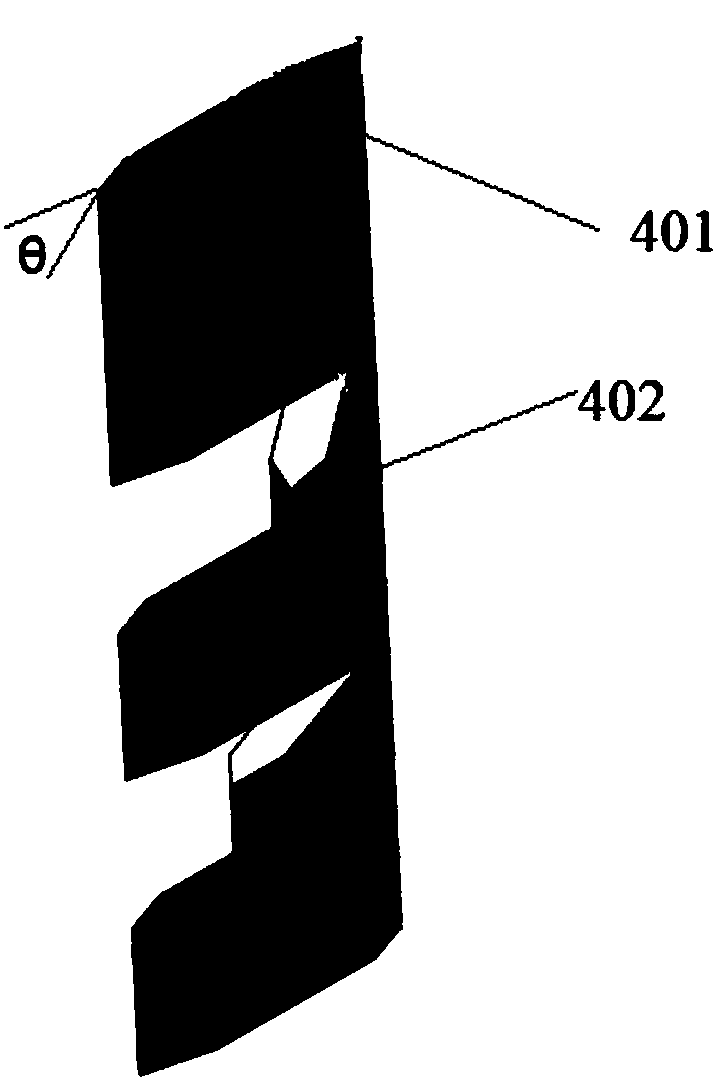

[0033] The swirl rectifying strut includes a side portion 401 and six blades 402 connected to the side portion. Each blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com