AFM(atomic force microscope)-based method for testing surface roughness of aggregate

An atomic force microscope and surface roughness technology, applied in the field of construction, can solve problems such as errors, and achieve the effect of good accuracy, simple method and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: A method for testing aggregate surface roughness based on AFM mirror

[0042] The aggregate is limestone.

[0043]1) To prepare the AFM sample of limestone aggregate, cut the limestone into a 5cm x 5cm x 0.5cm thick specimen, and use sandpaper to polish it to eliminate the macroscopic texture caused by cutting. AFM samples of limestone aggregates see figure 1 .

[0044] 2) The Demension icon type AFM equipment from Bruker, Germany is used. The specifications of the AFM instrument are shown in Table 1, and the selected probe models and test parameters are shown in Tables 2 and 3.

[0045] Table 1 Demension icon type AFM instrument parameters

[0046]

[0047] Table 2 Probe Models and Parameters

[0048]

[0049] Table 3 AFM test parameters of aggregates

[0050]

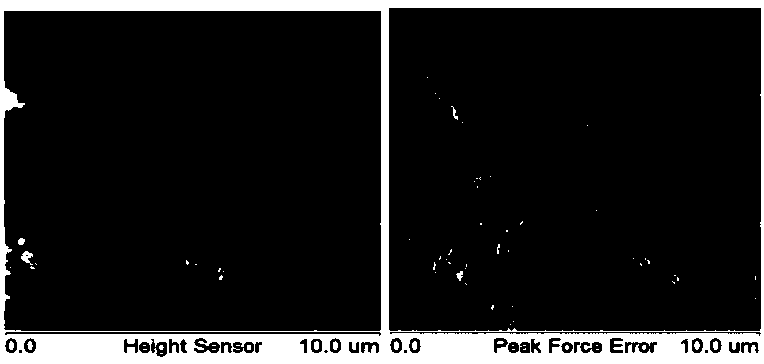

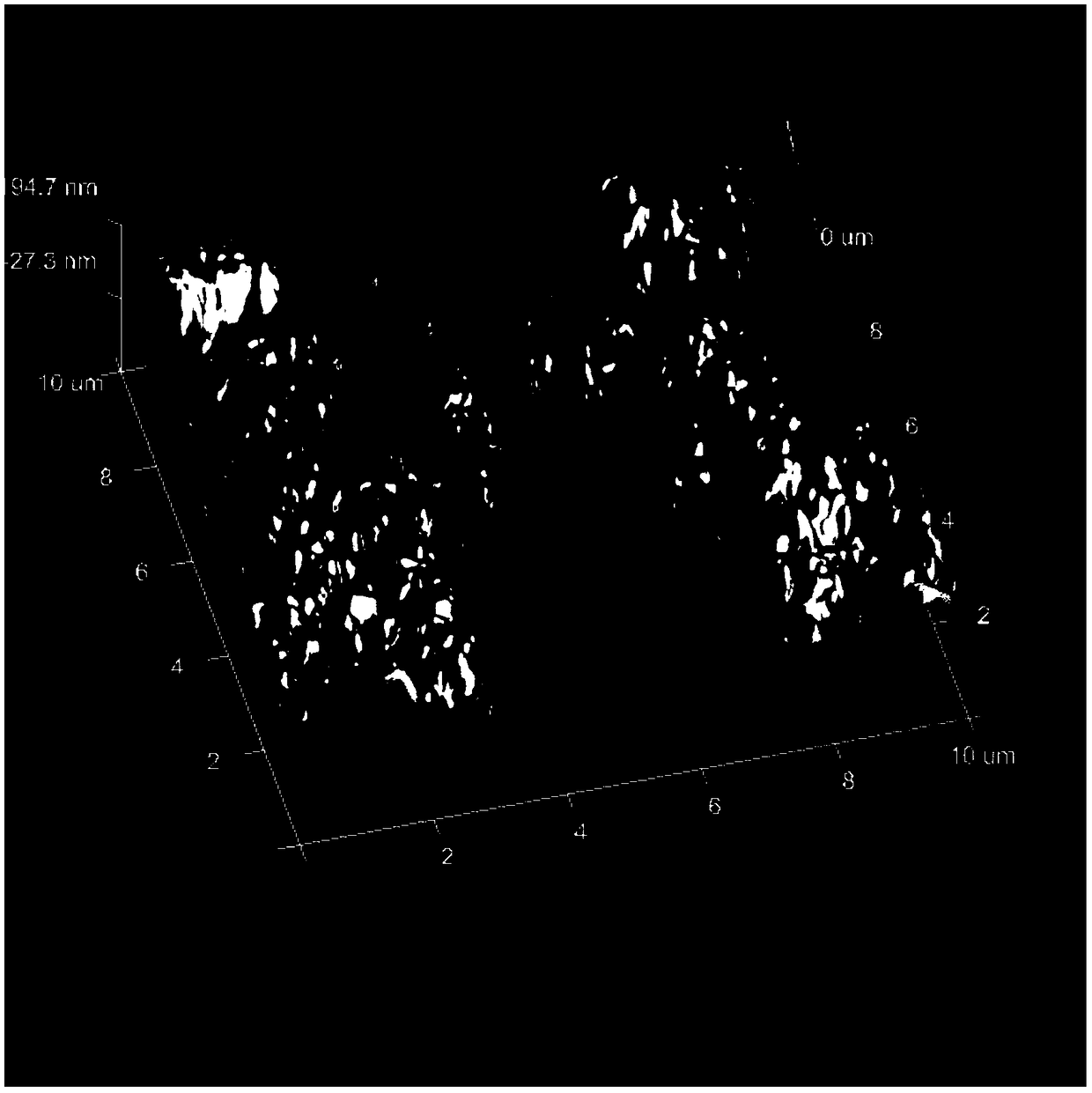

[0051] 3) Topography of limestone aggregates, Figure 2~3 They are the two-dimensional topography map, phase map and three-dimensional topography map of limestone aggregates below 1...

Embodiment 2

[0067] Embodiment 2: A method for testing aggregate surface roughness based on AFM mirror

[0068] The aggregate is basalt.

[0069] 1) To prepare AFM samples of basalt aggregates, cut the basalt into 5cm x 5cm x 0.5cm thick specimens, and polish them with sandpaper to eliminate the macroscopic texture caused by cutting. For AFM samples of basalt aggregates see Figure 4 .

[0070] 2) Demension icon type AFM equipment from Bruker, Germany.

[0071] Instrument index is identical with embodiment 1.

[0072] 3) Topography of basalt aggregates, Figure 5-6 They are the two-dimensional topography map, phase map and three-dimensional topography map of basalt aggregates under 10 μm, respectively.

[0073] 4) Verify the effectiveness of basalt aggregate Ra, see Table 6.

[0074] Table 6 Ra of basalt

[0075]

[0076] 5) Discriminative verification. The independent sample t-test in SPSS is used to conduct discriminative verification of the surface roughness of basalt aggregat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com