Photosensitive resin composition, preparation method thereof, and method of producing printed circuit board

A technology of photosensitive resin and composition, which is applied in the direction of printed circuit manufacturing, printed circuit, and secondary treatment of printed circuit, etc., and can solve the problems of increasing storage cost and storage risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preferred embodiment of the present invention also provides a method for preparing the above-mentioned photosensitive resin composition, which includes the following steps:

[0036] Step 1: In parts by weight, 100 parts of epoxy acrylate, 10-50 parts of acrylate monomer, 5-15 parts of photoinitiator, 1-5 parts of colorant, 10-40 parts The acrylate oligomer and 10-50 parts of the oxazoline compound are mixed with a solvent to prepare a mixture;

[0037] Step 2: Stir the mixture to dissolve the epoxy acrylate, acrylate monomer, colorant, acrylate oligomer and oxazoline compound in the solvent, so as to prepare the photosensitive resin composition.

[0038] In this embodiment, the solvent is butanone. It can be understood that the content of the solvent can be changed according to actual needs, as long as each component can be dissolved therein.

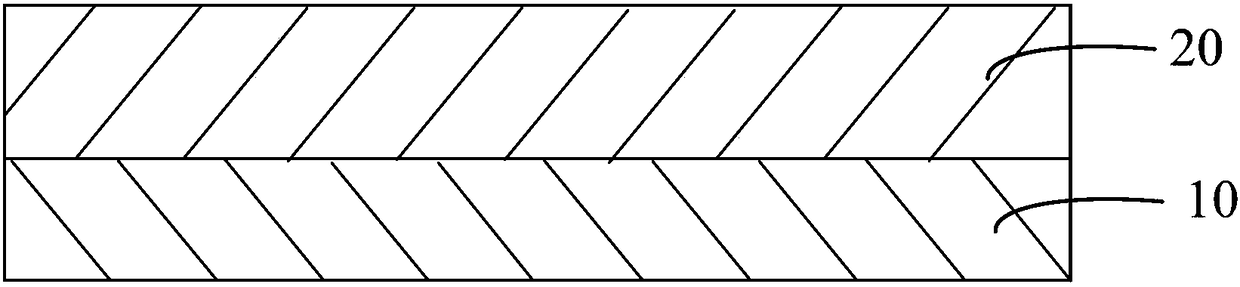

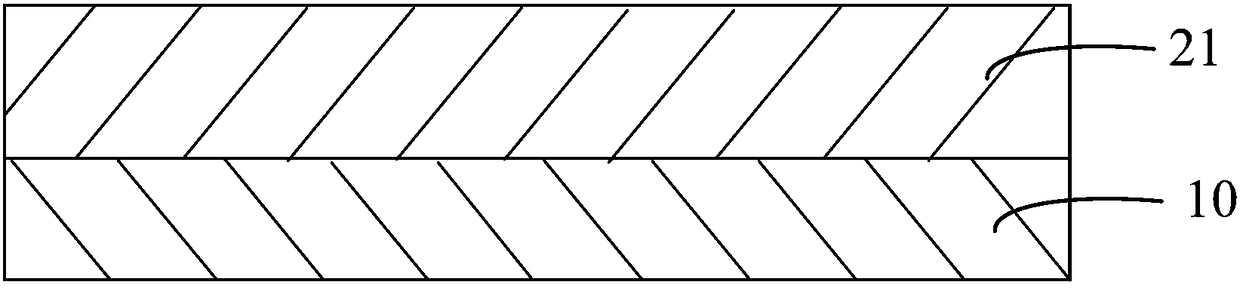

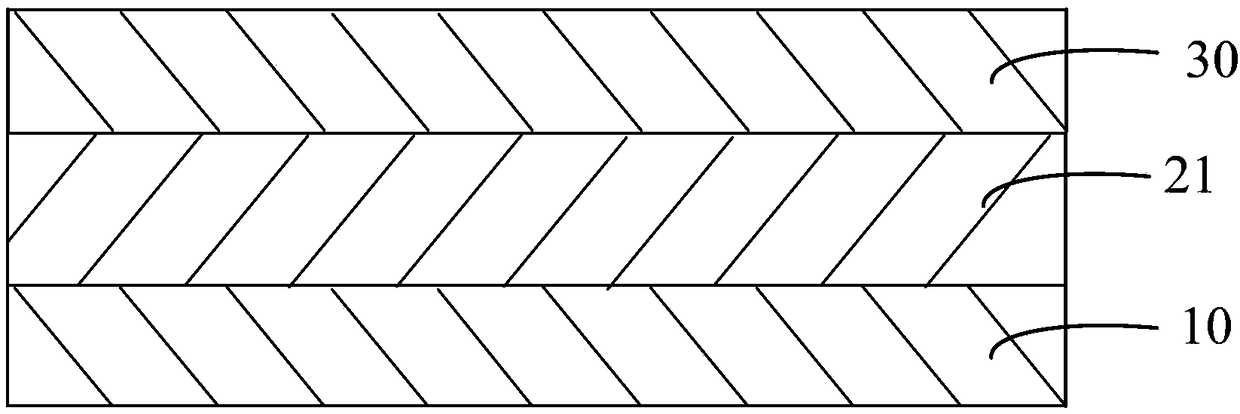

[0039] see Figure 1 to Figure 5 , a preferred embodiment of the present invention also provides a printed circuit board 1...

Embodiment 1

[0053] In parts by weight, add 100 parts of epoxy acrylate (molecular weight is 10000g / mol, acid value 100mgKOH / g), 40 parts of TMP (3PO) TA, 15 parts of aliphatic polyurethane in a 500ml reaction bottle Acrylate, 8 parts of photoinitiator, 2 parts of colorant, 30 parts of butanone, 10 parts of oxazoline compound and 0.5 part of triphenylphosphine, stir until each component is dissolved in butanone, Thus, the resin composition was prepared.

Embodiment 2

[0055] In parts by weight, 100 parts of epoxy acrylate (molecular weight is 10000g / mol, acid value 100mgKOH / g), 20 parts of TMP (3PO) TA, 30 parts of aliphatic polyurethane are successively added in a 500ml reaction bottle Acrylate, 8 parts of photoinitiator, 2 parts of colorant, 30 parts of butanone, 20 parts of oxazoline compound and 1 part of triphenylphosphine, stir until each component is dissolved in butanone, Thus, the resin composition was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com