Two-line structure light-based online welding seam forming visual detection method

A line-structured light and visual detection technology, applied in the field of computer vision, can solve problems such as roughness evaluation and affecting the accuracy of welding quality evaluation, and achieve the effect of improving calibration accuracy and 3D reconstruction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

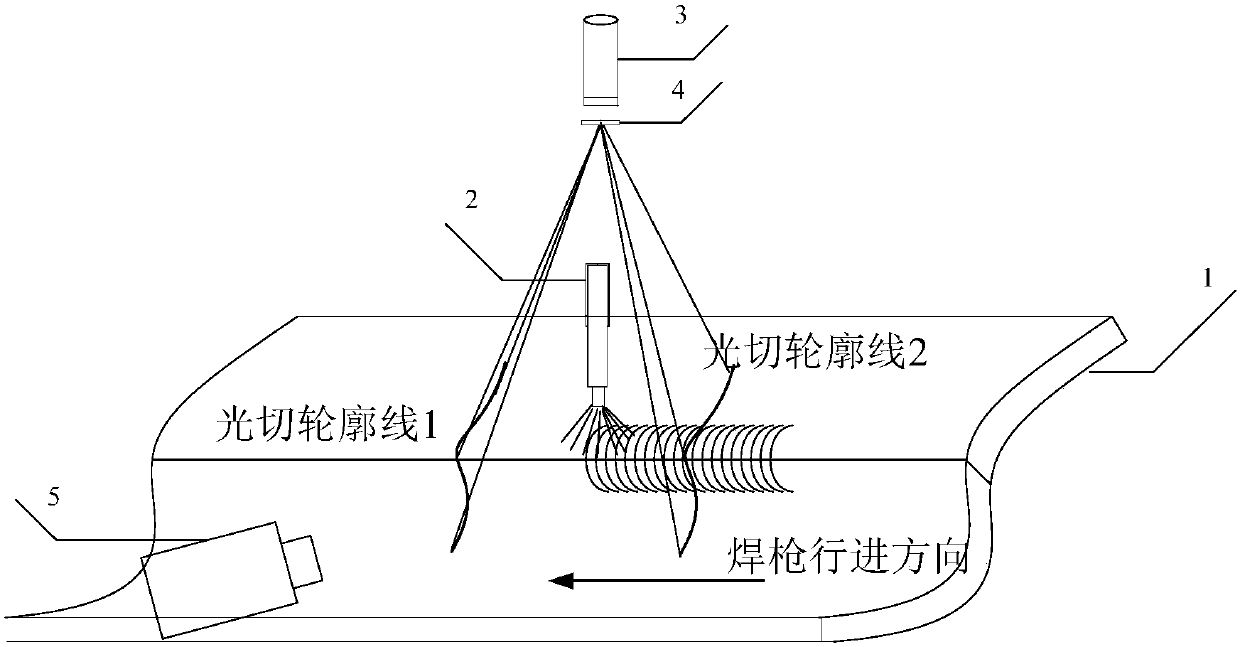

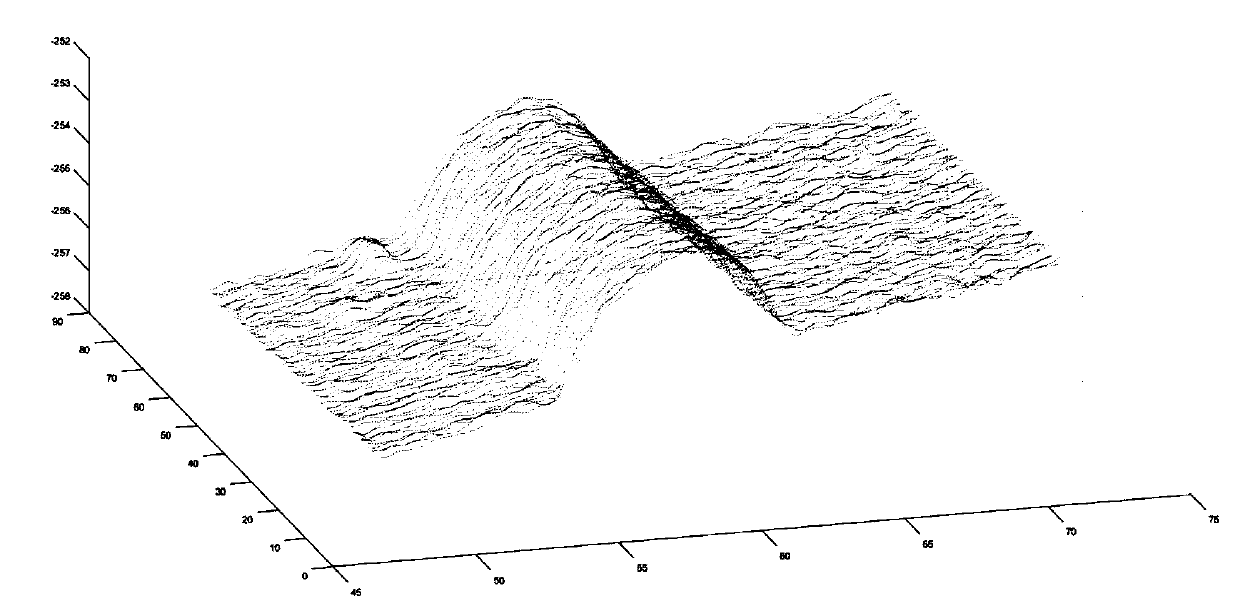

[0035] as attached figure 1 As shown, the online weld forming visual inspection method based on two-line structured light of the present invention includes a motherboard 1, a welding torch 2, a laser 3, a laser beam splitter 4, and a CCD camera 5; the laser 3 is placed vertically with the welding motherboard 1 , the laser beam splitter 4 and the laser device 3 are placed together, and the laser beam splitter 4 produces two parallel laser lines, which are irradiated on the welding mother board 1, respectively located at the front and rear positions of the welding torch 2; the CCD camera 5 selects a suitable angle, Ensure that two parallel laser lines can be observed. According to attached figure 1 A device for visual inspection of online forming welds, comprising the following steps:

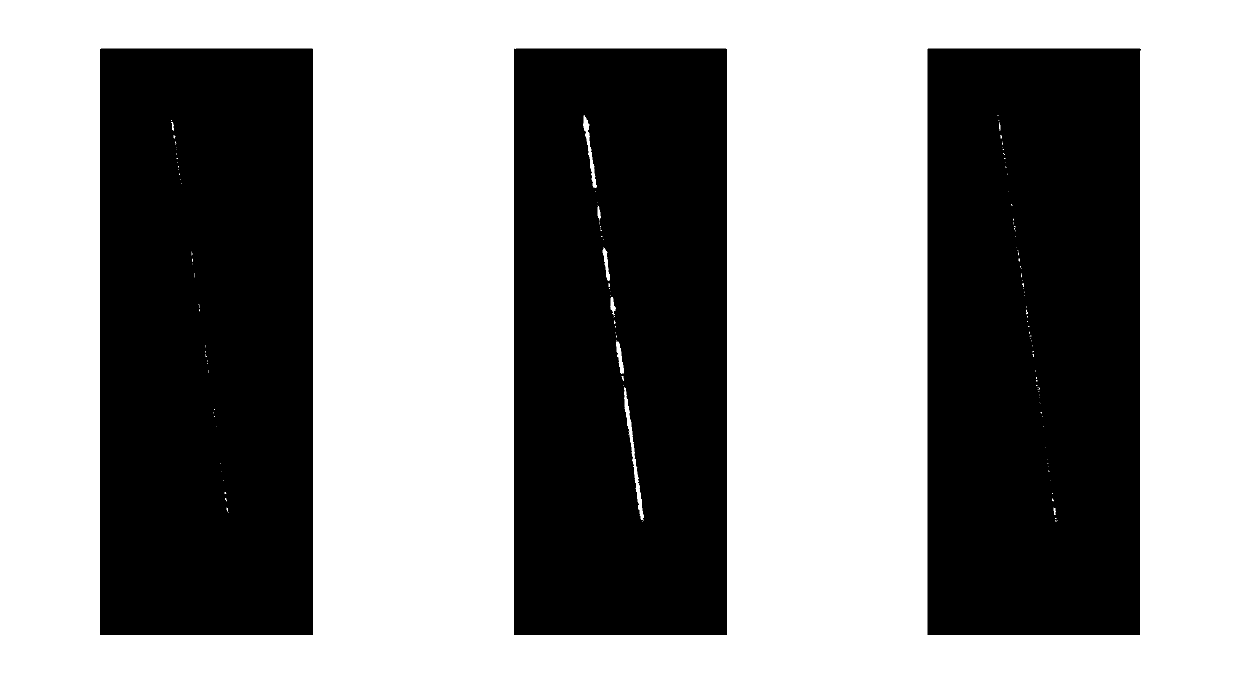

[0036] Step 1: Select the checkerboard as the calibration plate, select two modes of high exposure time and low exposure time, and shoot the line structured light in the same calibration image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com