Manufacturing method of thin film transistor and manufacturing method of display substrate and display device

A technology of a thin film transistor and a manufacturing method, which is applied to the manufacturing of thin film transistors and the field of display devices, can solve problems such as instability, changes in the performance of thin film transistors, and drive failure of thin film transistors, and achieves the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limit the present invention.

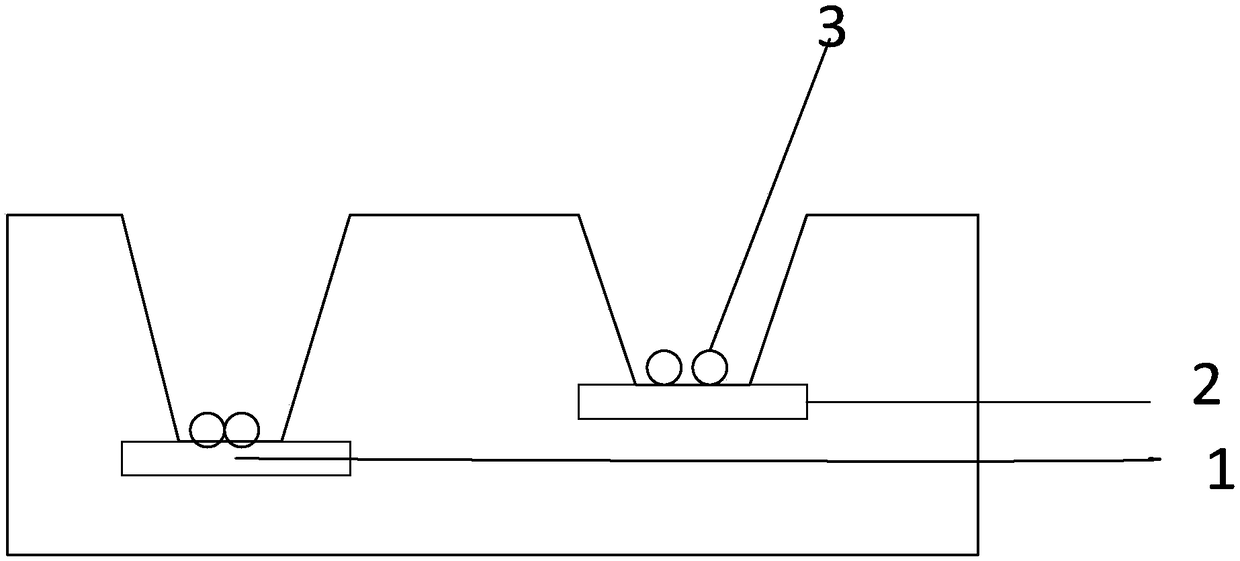

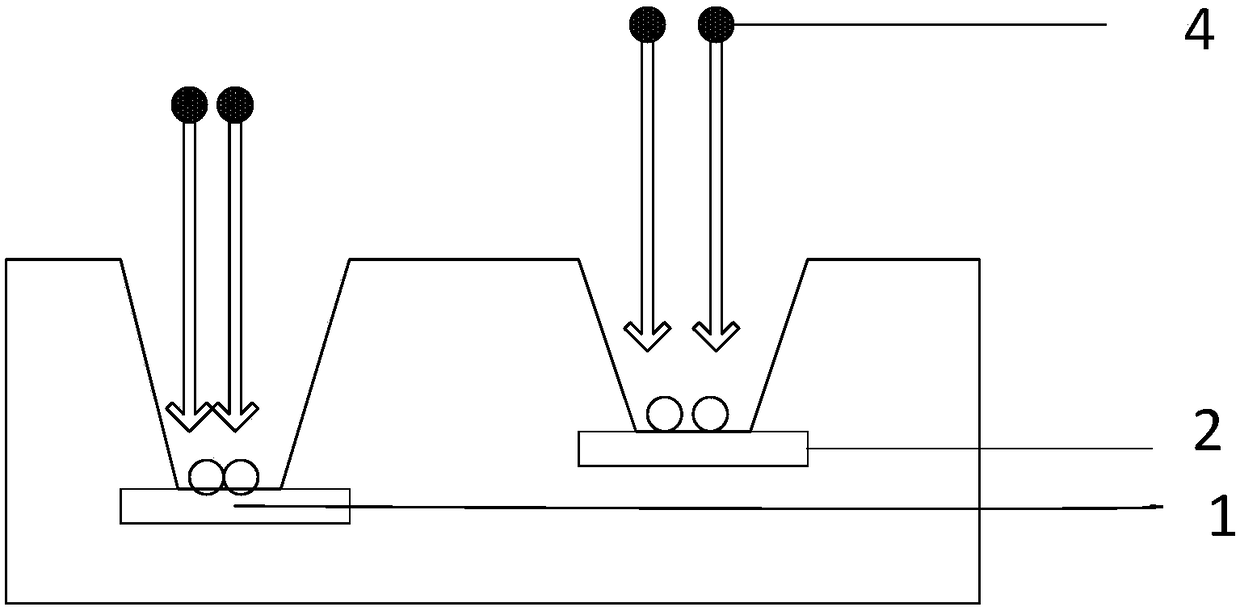

[0029] The embodiment of the present invention discloses a method for manufacturing a thin film transistor, which includes the steps of forming an active layer and the step of forming an insulating layer covering the active layer, and the manufacturing method further includes: After forming the via holes exposing the active layer by patterning, the exposed surface of the active layer is treated with plasma to remove organic impurities and / or oxides on the surface of the active layer.

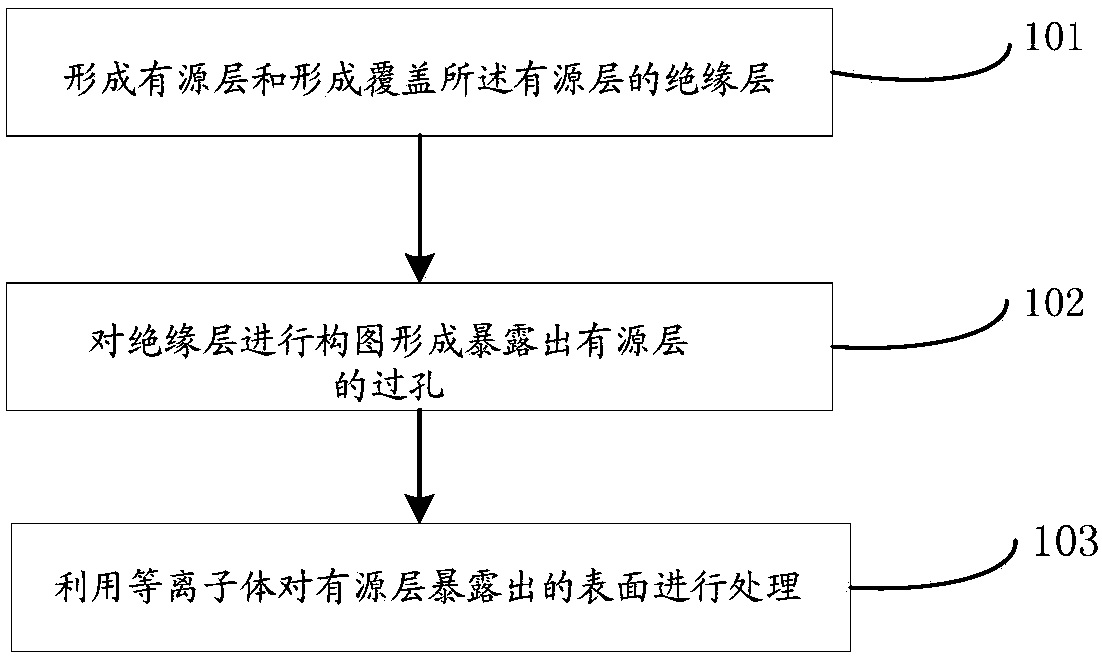

[0030] The manufacturing method of the thin film transistor of the present invention can be found in figure 1 A brief flowchart is shown. The manufacturing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com