Self-adaptive control system for performing air conveying on fragile materials

A technology of self-adaptive control and wind conveying, applied in the fields of application, cigarette manufacturing, food science, etc., can solve the problems of high energy consumption, low material utilization rate, high shredding rate of cut tobacco, reduce operating costs, reduce energy consumption, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

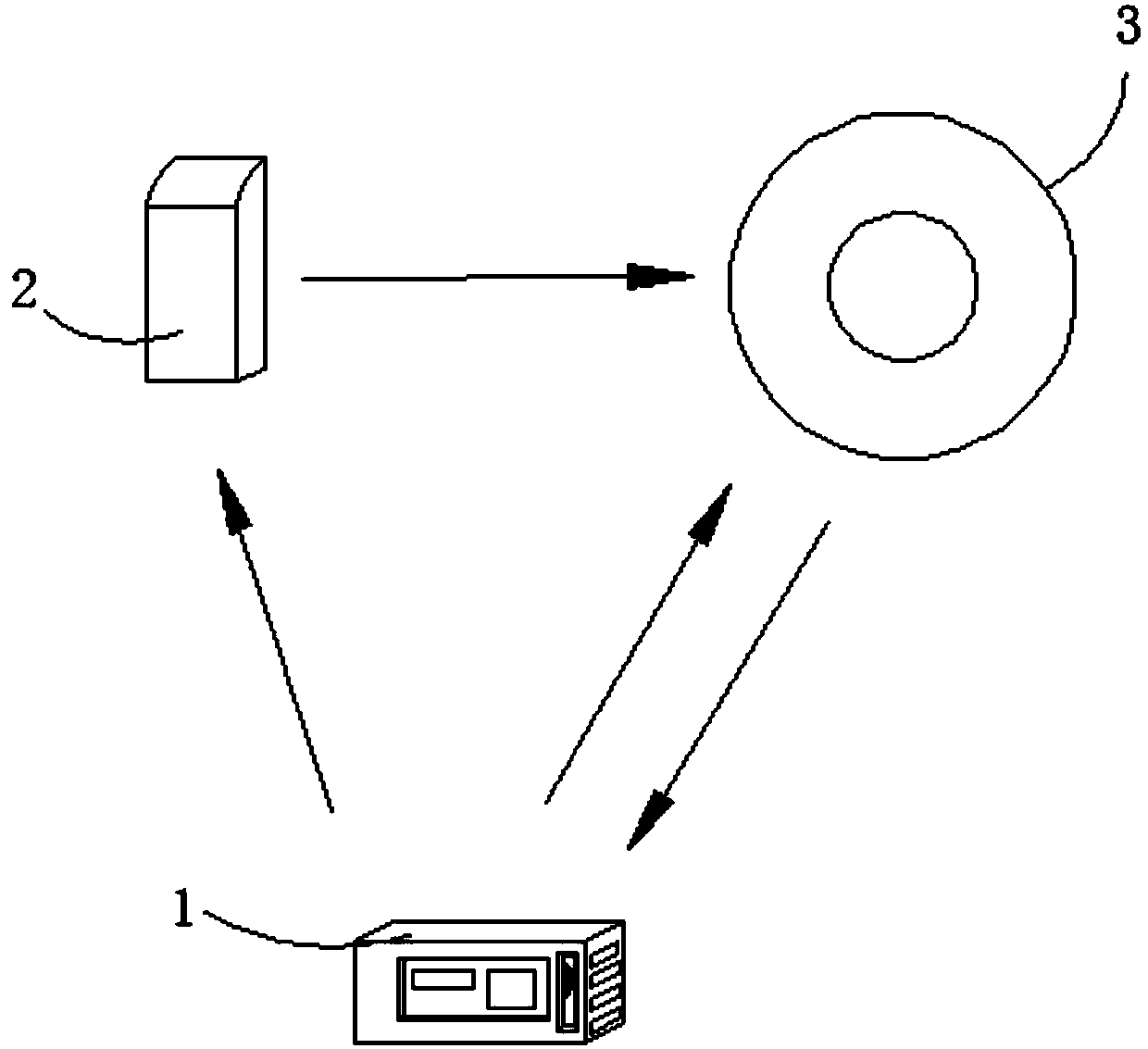

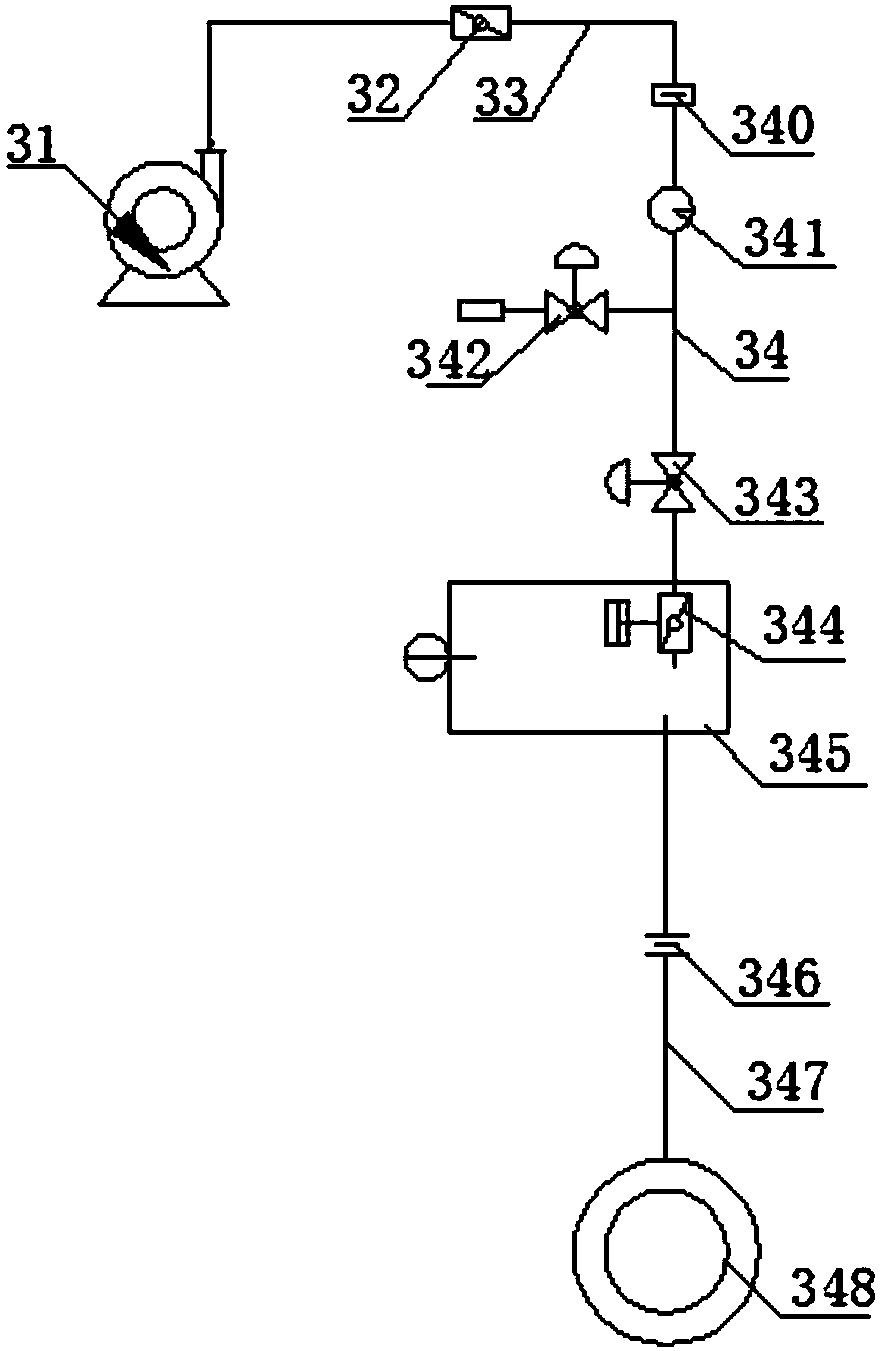

[0031] Embodiment 1 of the present invention provides an adaptive control system for wind conveying fragile materials, such as figure 1 As shown, the system includes a PLC intelligent controller 1, a smart power saver 2 and a delivery device 3 electrically connected to each other; as figure 2 As shown, the conveying device 3 includes a centrifugal fan 31 electrically connected to the smart power saver 2, and the output end of the centrifugal fan 31 is connected to a first wrapping machine 345 through a conveying pipeline, and the conveying pipeline includes a The main pipeline 33 connected with the centrifugal fan 31 and the first branch pipeline 34 connected with the first crimping machine 345, the main pipeline 33 communicates with the first branch pipeline 34; on the first branch pipeline 34 From one end close to the first crimping machine 345 to one end close to the main pipeline 33, a first pneumatic regulating butterfly valve 343, a first pneumatic regulating valve 342,...

Embodiment 2

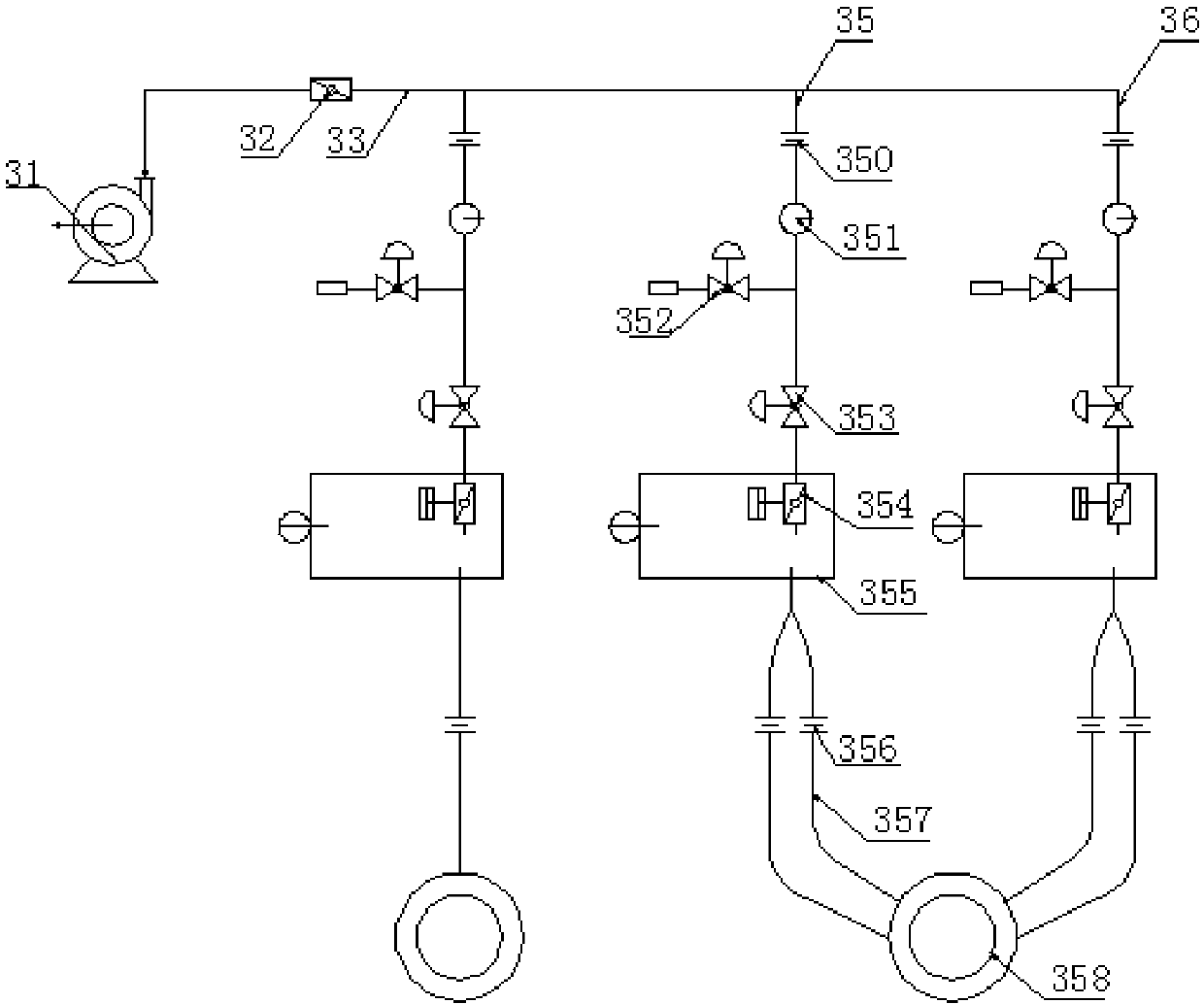

[0035] The self-adaptive control system for wind conveying fragile materials provided by Embodiment 2 of the present invention is basically the same as Embodiment 1, the difference is that please refer to image 3 As shown, the end of the main pipeline 33 away from the centrifugal fan 31 and the valve 32 is connected with a second branch pipeline 35 and a third branch pipeline 36; the end of the second branch pipeline 35 away from the main pipeline 33 is connected with Second crimping machine 355; described second branch pipe 35 is provided with the second pneumatic regulating butterfly valve 353, the second pneumatic regulating valve 352, the second pneumatic regulating butterfly valve 353, the second pneumatic regulating valve 352, the second pneumatic regulating butterfly valve 353 from one end near the second crimping machine 355 to one end near the main pipeline 33. Two pressure transmitters 351 and a third flow meter 350; the second branch pipe 35 is connected with the se...

Embodiment 3

[0038] The self-adaptive control system for wind conveying fragile materials provided by Embodiment 3 of the present invention is basically the same as Embodiment 2, the difference is that please refer to Figure 4Shown, described main pipeline 33 is connected with the 4th branch pipeline 37 far away from one end of centrifugal blower 31 and valve 32; Described 4th branch pipeline 37 is connected with the 4th crimping machine 375 away from one end of described main pipeline 33; The fourth branch pipeline 37 is sequentially provided with a fourth pneumatic regulating butterfly valve 373, a fourth pneumatic regulating valve 372, and a fourth pressure transmitter 371 from the end close to the fourth wrapping machine 375 to the end close to the main pipeline 33. and the fifth flow meter 370; the fourth branch pipe 37 is connected with the fourth wrapping machine 375 through a fourth pneumatic shut-off valve 374; the fourth wrapping machine 375 is connected to the fourth wrapping ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com