Full-automatic feed stirrer

A fully automatic, mixer technology, used in mixer accessories, feed, mixers with rotating mixing devices, etc., can solve the problems of long mixing time, uneven mixing, etc., achieve uniform and fast mixing, save time and energy, and operate convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is realized through the following technical solutions:

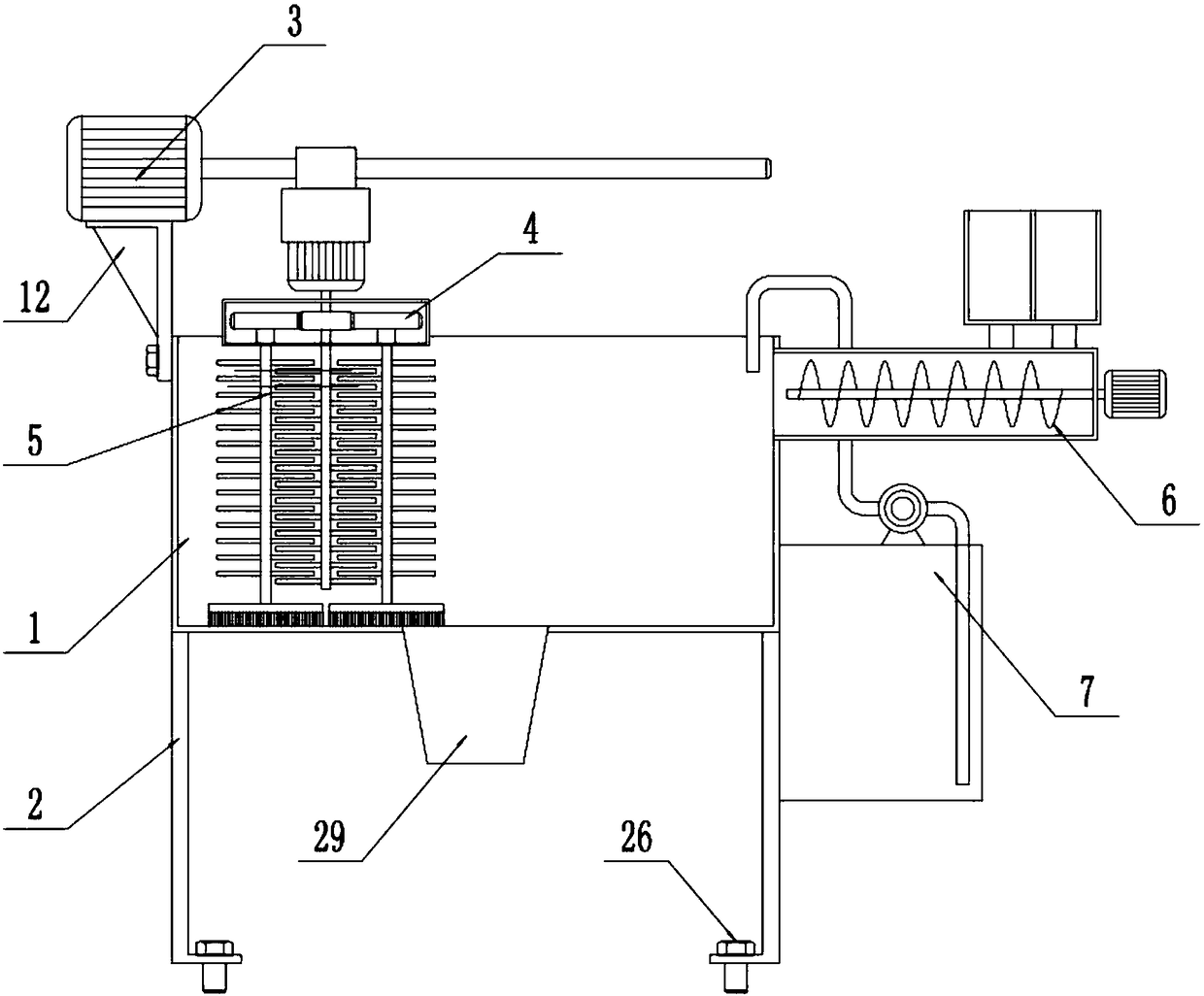

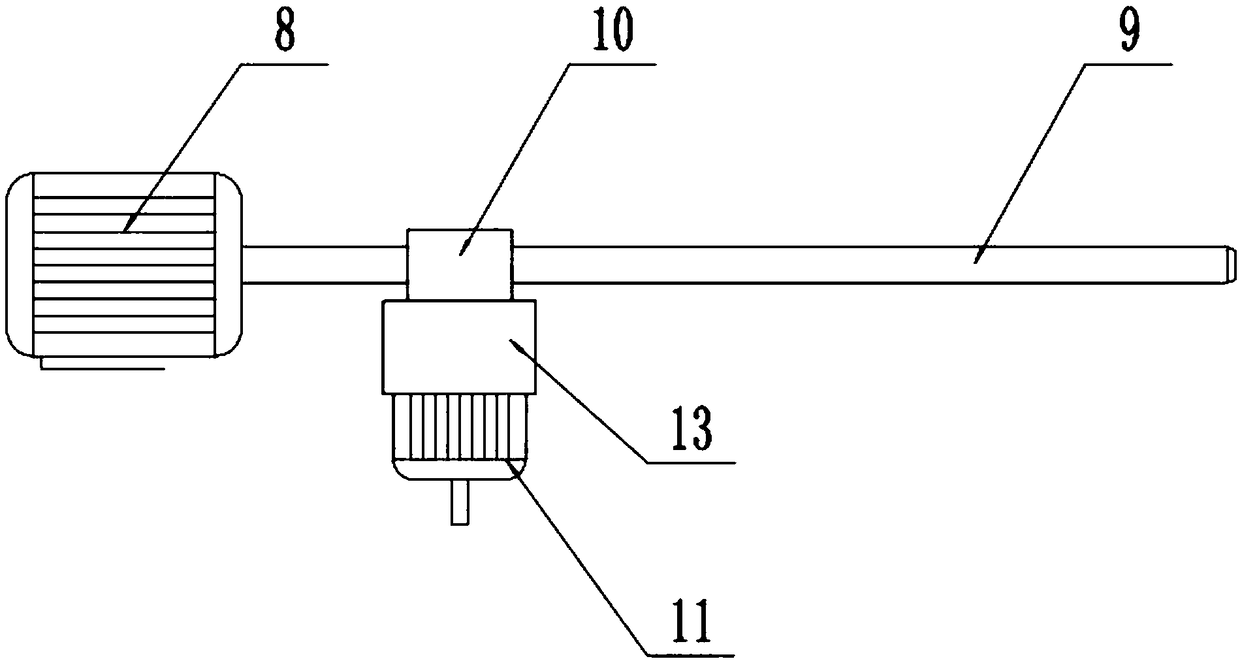

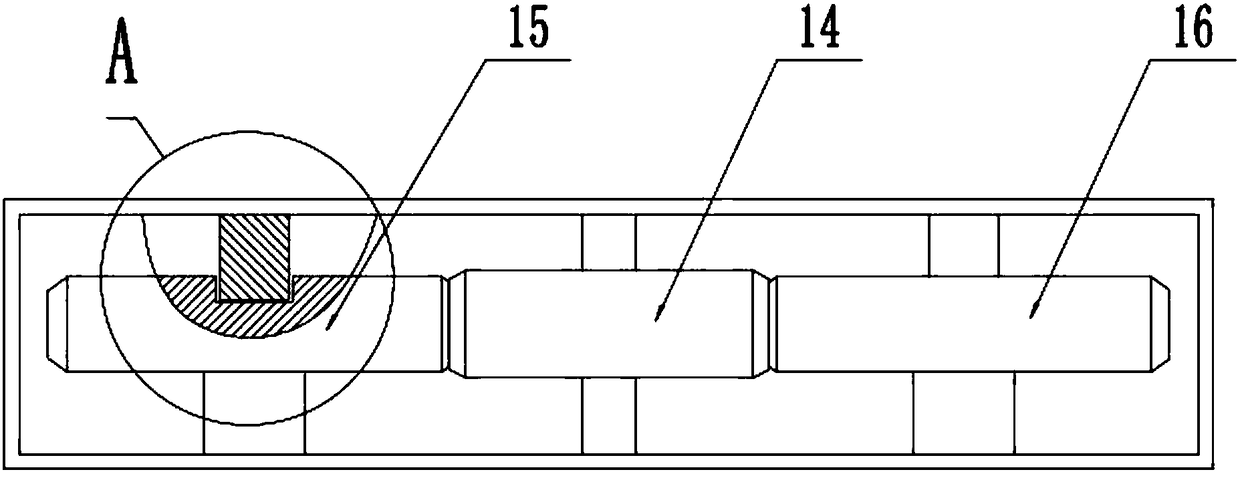

[0021] A fully automatic feed mixer, comprising a box body 1, a frame 2, a power mechanism 3, a transmission mechanism 4, a stirring mechanism 5 and a feeding mechanism 6, the frame 2 is fixed on the bottom of the box body 1, and the power mechanism 4 Set above the box body 1, the stirring mechanism 5 is connected to the power mechanism 4 through the transmission mechanism 4, the feeding mechanism 6 is arranged on the outside of the box body 1, and the power mechanism 3 includes a first motor 8, a lead screw 9, Lead screw nut 10 and second motor 11, described first motor 8 is arranged on the outside of box body 1 by fixture 12, and described lead screw 9 is arranged on the output end of first motor 8, and described lead screw nut 10 and The leading screw 9 is mated and connected, and the leading screw nut 10 is fixedly connected with the second motor 11 through a connector 13; the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com