Vehicle and power device thereof

A technology of power plant and installation position, applied in power plant, pneumatic power plant, electromechanical device, etc., can solve the problems of displacement, poor heat dissipation, and the parts to be lubricated cannot be lubricated continuously.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

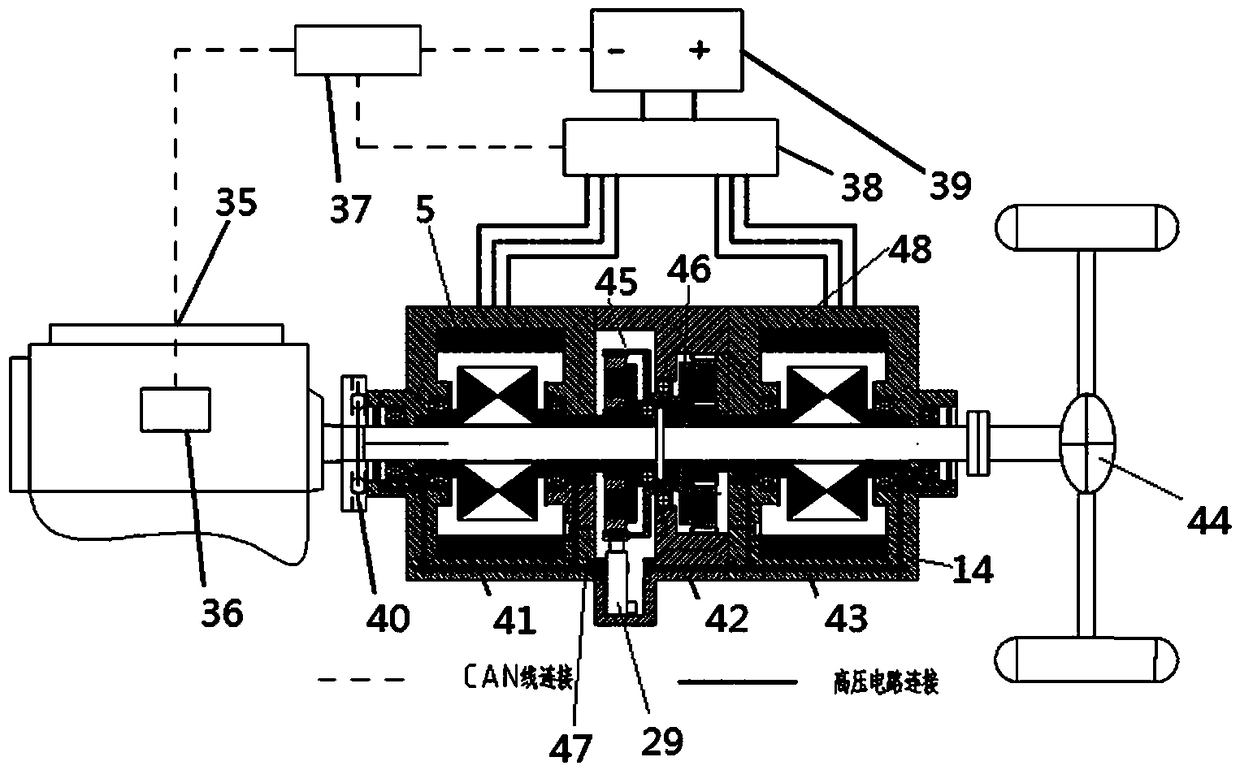

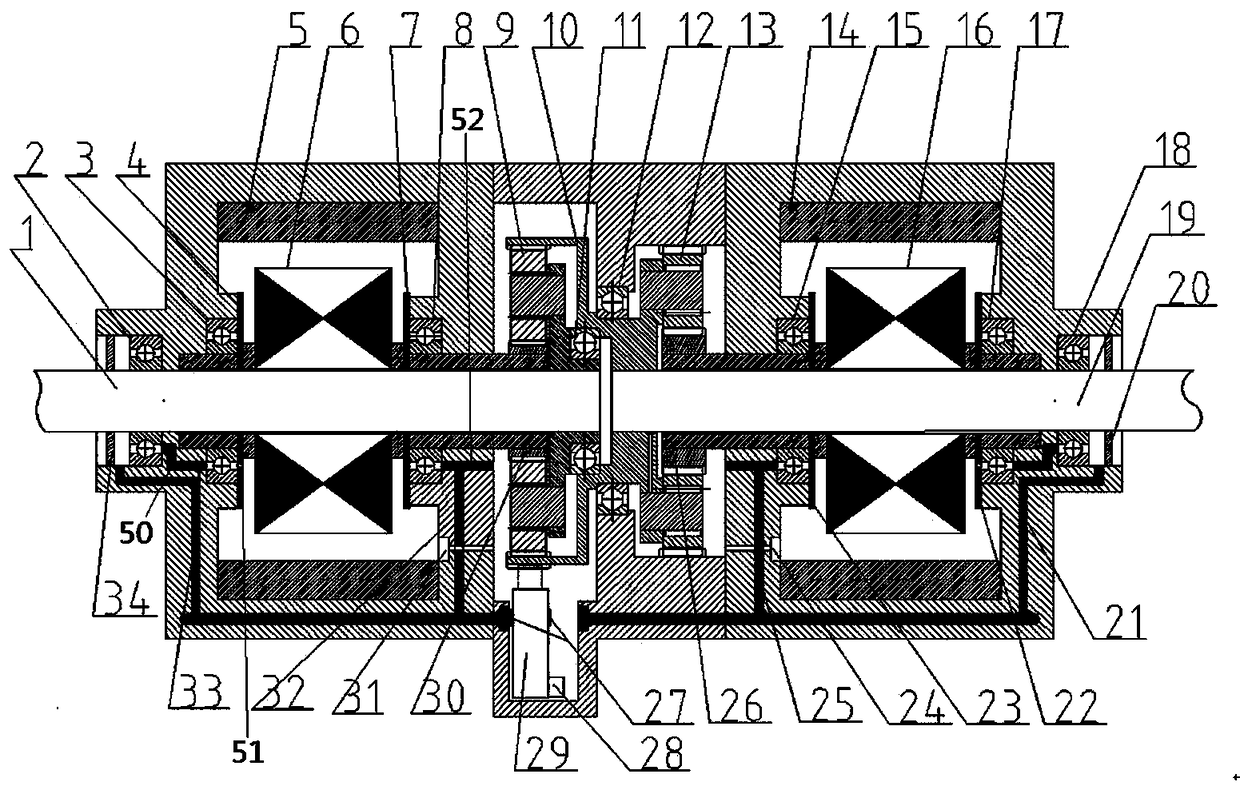

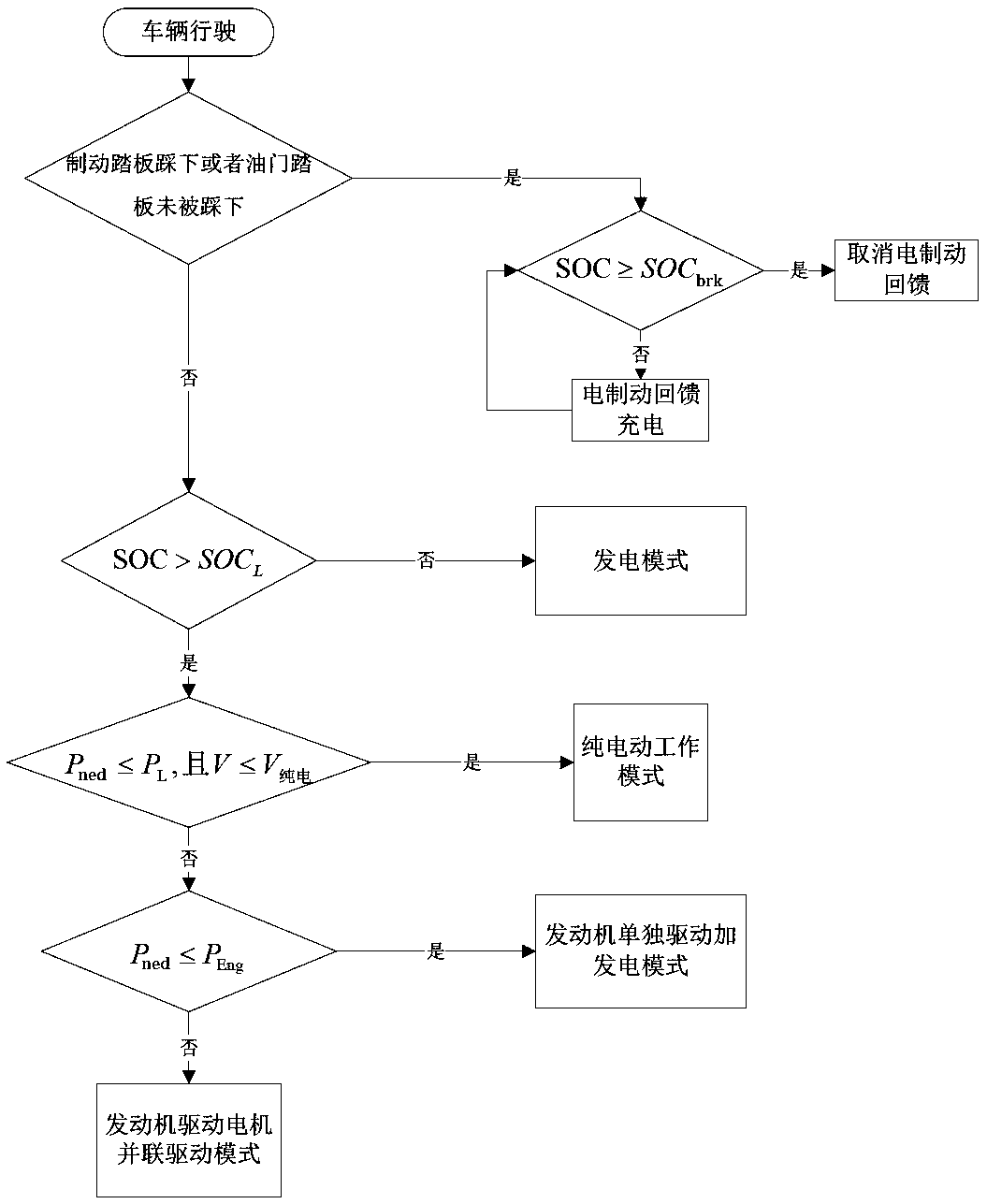

[0047] Examples of vehicles are Figure 1~3 Shown: including the vehicle frame and the power system arranged on the vehicle frame, the power system in this embodiment is a parallel hybrid system, the vehicle frame belongs to the prior art, and its structure will not be described in detail here. The series hybrid power system includes an engine 35 and a power unit, and the power unit includes a device housing, which is composed of a first motor housing 41, a planetary row housing 42, and a second motor housing 43 arranged in front and rear , wherein the rear end cover of the first motor housing and the front end cover of the second motor respectively form the first barrier 47 and the second barrier 48, and the two barriers separate the device housing into the first motor chamber, the planetary row chamber and the second motor chamber, the first motor chamber is provided with the first motor 5, the planetary row chamber is provided with the first planetary row 45 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com