A wooden perforated sound-absorbing panel with built-in heating material

A sound-absorbing board and wood technology, applied in the field of building decoration materials, can solve the problems of no heating composite function, single function, unstable laying quality, etc., and achieve the effects of simple laying, increased heat dissipation area, and good sound absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

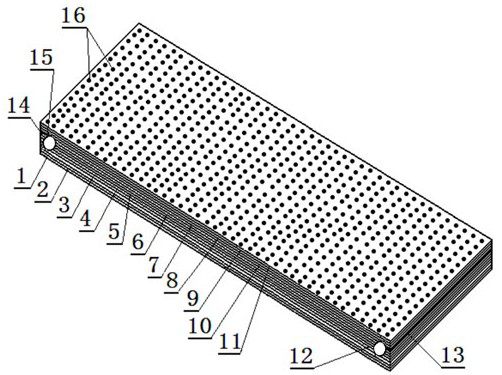

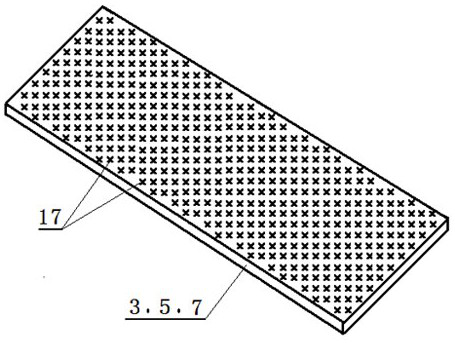

[0027] A wooden perforated sound-absorbing panel with a built-in heating material, which is provided with a base plate 2, a single plate A4, an electric heating plate 6, a single plate B8, and a panel 10, and the base plate 2, the single plate A4, the electric heating plate 6, the single plate B8, and the panel 10 are sequentially connected by adhesive layer A3, adhesive layer B5, adhesive layer C7, and adhesive layer D9 under pressure. The bottom plate 2, veneer A4, and veneer B8 are respectively provided with cross holes, and the upper and lower plates are dislocated and glued. , after cold pressing, hot pressing, and stress balance, the finished product is made.

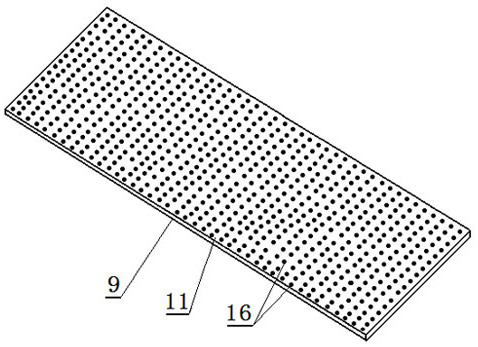

[0028] Further, the panel 10 is uniformly provided with heat-radiating and sound-absorbing plate microholes 16 , and a protective film layer 11 is provided on the surface of the panel 10 .

[0029] Further, the base plate 2 is a medium density fiberboard, and the bottom surface of the base plate 2 is provided with...

Embodiment 2

[0036] A wooden perforated sound-absorbing panel with a built-in heating material, which is provided with a base plate 2, a single plate A4, an electric heating plate 6, a single plate B8, and a panel 10, and the base plate 2, the single plate A4, the electric heating plate 6, the single plate B8, and the panel 10 are sequentially connected by adhesive layer A3, adhesive layer B5, adhesive layer C7, and adhesive layer D9 under pressure. The bottom plate 2, veneer A4, and veneer B8 are respectively provided with cross holes, and the upper and lower plates are dislocated and glued. , after cold pressing, hot pressing, and stress balance, the finished product is made.

[0037] Further, the panel 10 is uniformly provided with heat-radiating and sound-absorbing plate microholes 16 , and a protective film layer 11 is provided on the surface of the panel 10 .

[0038] Further, the bottom plate 2 is eucalyptus plywood, and the bottom surface of the bottom plate 2 is provided with a mo...

Embodiment 3

[0045] A wooden perforated sound-absorbing panel with a built-in heating material, which is provided with a base plate 2, a single plate A4, an electric heating plate 6, a single plate B8, and a panel 10, and the base plate 2, the single plate A4, the electric heating plate 6, the single plate B8, and the panel 10 are sequentially connected by adhesive layer A3, adhesive layer B5, adhesive layer C7, and adhesive layer D9 under pressure. The bottom plate 2, veneer A4, and veneer B8 are respectively provided with cross holes, and the upper and lower plates are dislocated and glued. , after cold pressing, hot pressing, and stress balance, the finished product is made.

[0046] Further, the panel 10 is uniformly provided with heat-radiating and sound-absorbing plate microholes 16 , and a protective film layer 11 is provided on the surface of the panel 10 .

[0047] Further, the bottom plate 2 is eucalyptus plywood, and the bottom surface of the bottom plate 2 is provided with a mois...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com