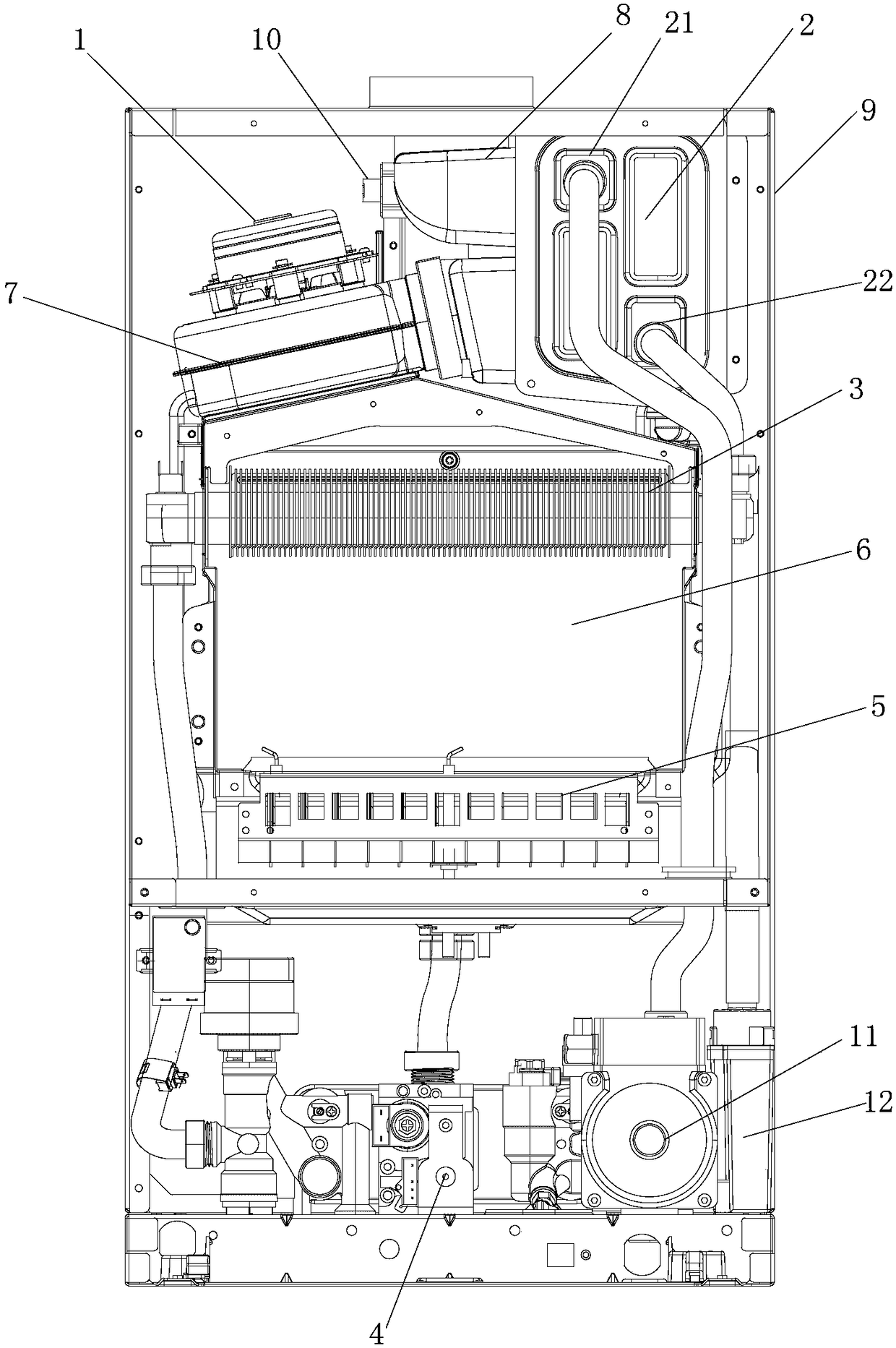

Condensation type gas heating stove

A gas heating, condensing technology, applied in air heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of waste of resources, low efficiency, poor condensation effect of waste heat recovery devices, etc., to avoid energy waste, high energy consumption, etc. efficiency, the effect of improving the efficiency of condensation and utilization of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

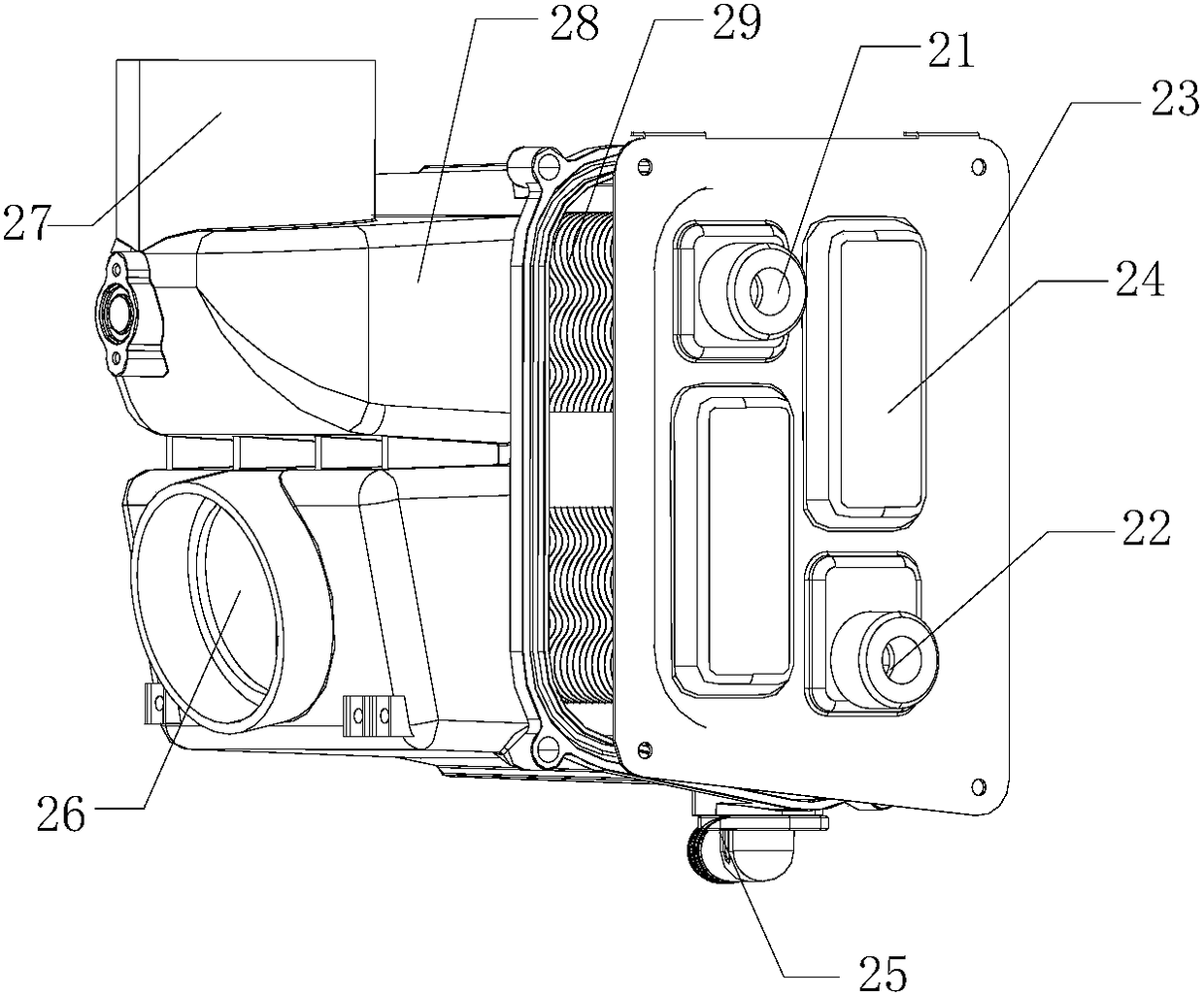

[0061]The waste heat recovery device 2 includes an outer shell, a condensation chamber formed in the outer shell, and a heat exchange device arranged in the condensation chamber. The heat exchange device has a first channel water inlet 21 and a second channel water outlet 22. The heat exchange device includes multiple stainless steel heat exchange tubes arranged side by side and stainless steel fins 29 fixed on the stainless steel heat exchange tubes. The outer casing includes a main casing 28 and a side cover 23 fixed to the main casing 28 by screws. The side cover 23 is provided with a water box 24 that is punched from the inside of the outer casing to the outside of the outer casing to form a convex water box. Two adjacent tubes of the stainless steel heat exchange tubes are connected to the water box 24 on one side of the side cover 23 for diversion of the water flow in the heat exchange device.

[0062] The heat exchange tubes and fins are made of stainless steel. Specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com