HUD front windshield detection device and method

A front windshield and detection equipment technology, which is applied in the direction of measuring devices, optical instrument testing, optical performance testing, etc., can solve the problems of mass production product quality inspection and other problems, and achieve the effect of eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

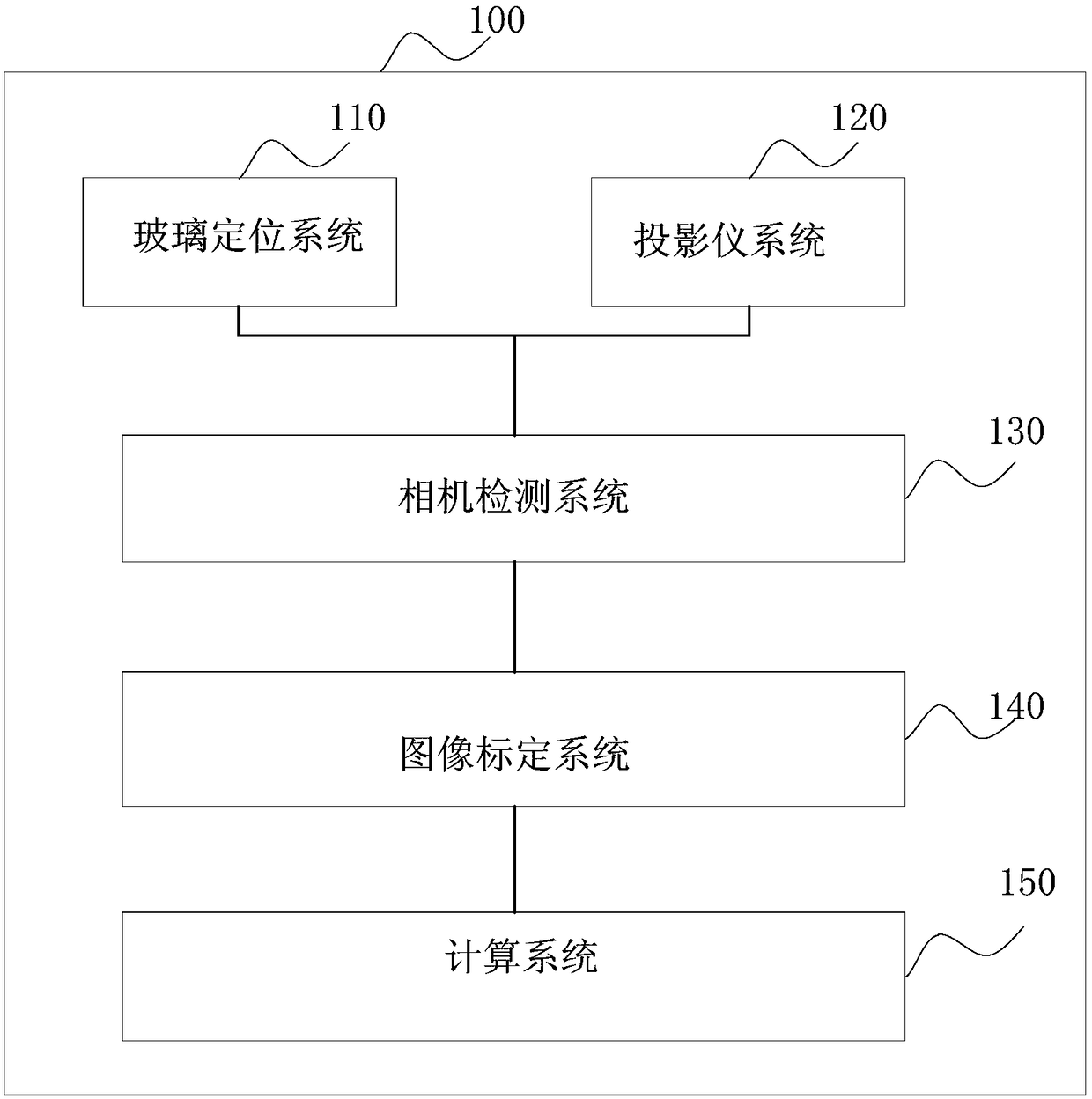

[0025] figure 1 It is a schematic structural diagram of a HUD windshield inspection device 100 provided in Embodiment 1 of the present invention, including a glass positioning system 110 , a projector system 120 , a camera inspection system 130 , an image calibration system 140 , and a computing system 150 .

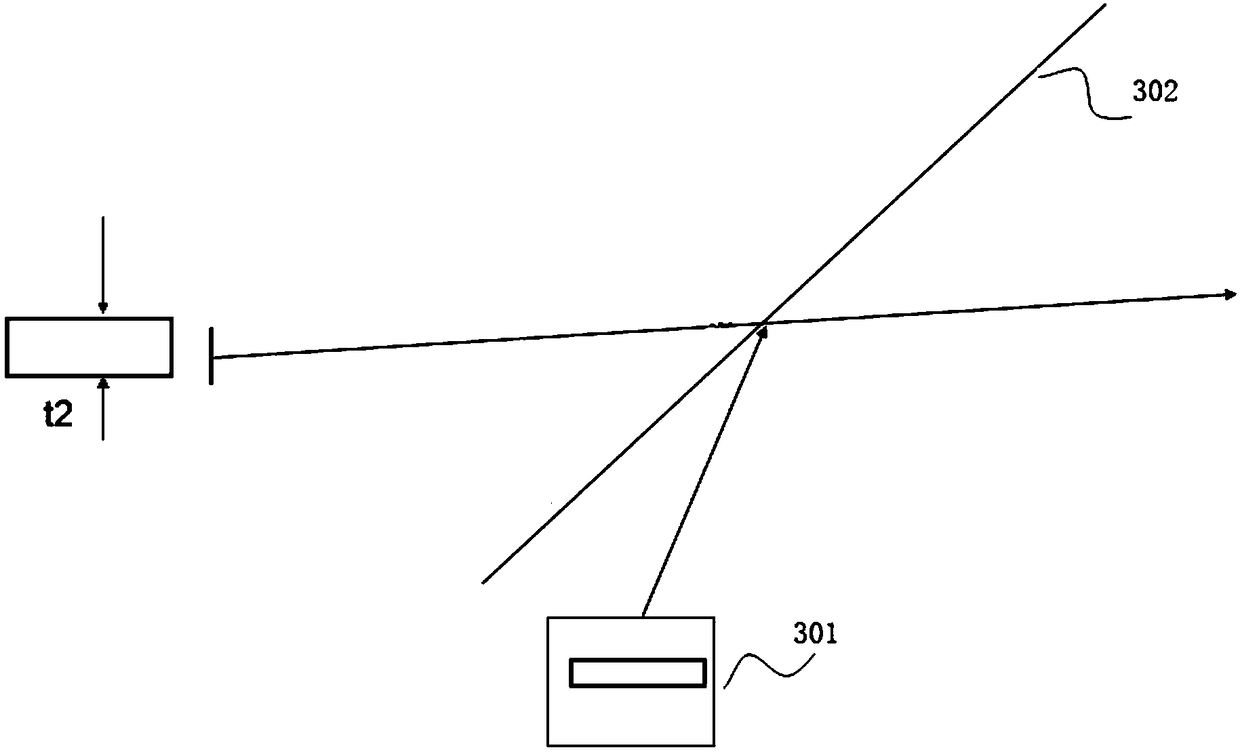

[0026] Wherein, the glass positioning system 110 is used for fixing the reflective component and the front windshield of the HUD to be tested based on the vehicle loading positioning method. Specifically, the installation and fixing method of the front windshield in a real car is simulated, and the reflection component and the front windshield of the HUD to be tested are fixed. The reflection component is used to separate the virtual image so as to measure the geometric size of the main image. Wherein, the reflective component can be a reflective surface part consistent with the inner surface of the HUD glass to be tested, such as a reflector, or a front glass with the ...

Embodiment 2

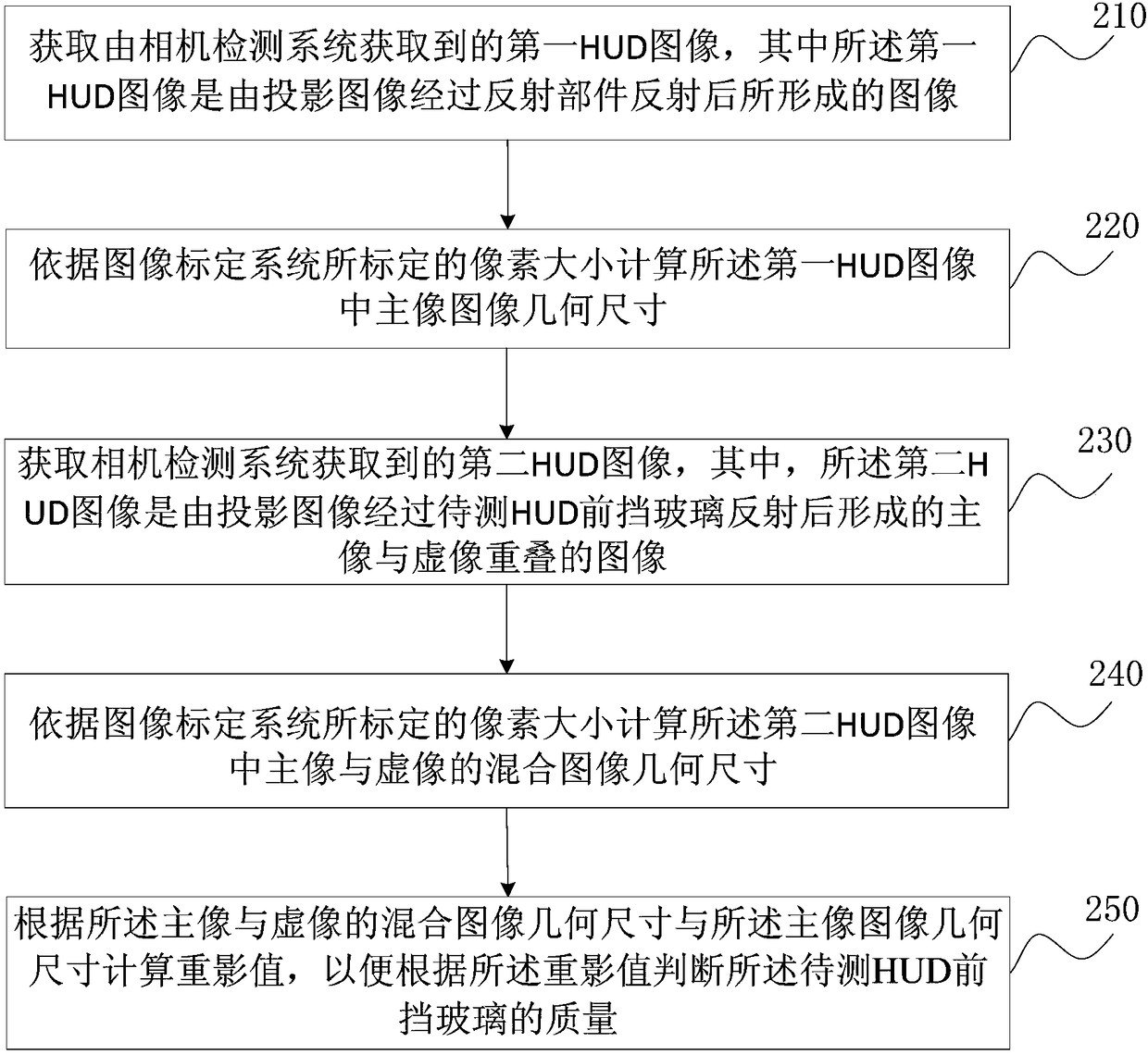

[0034] figure 2 It is a schematic flowchart of a method for detecting a HUD windshield provided by Embodiment 2 of the present invention. This embodiment is applicable to the situation of detecting the quality of the HUD front windshield, and the method may be performed by a HUD front windshield detection device, which specifically includes the following steps:

[0035] Step 210, acquire a first HUD image acquired by the camera detection system, wherein the first HUD image is an image formed by reflecting a projected image through a reflective component.

[0036]The reflection component is fixed on the inspection fixture based on the glass positioning system, so as to reflect the projected image to form the first HUD image. The first HUD image is used to calculate the geometric dimensions of the main image, and depending on the selection of the reflective component, the first HUD image can be a single main image or an image in which the main image is separated from the virtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com