Flexible electronic device module, article and manufacturing method thereof

An electronic device, bending technology, applied in the field of bendable electronic device modules, can solve the problems of lack of fatigue resistance and mechanical reliability, increased stress level of covering components, stress concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

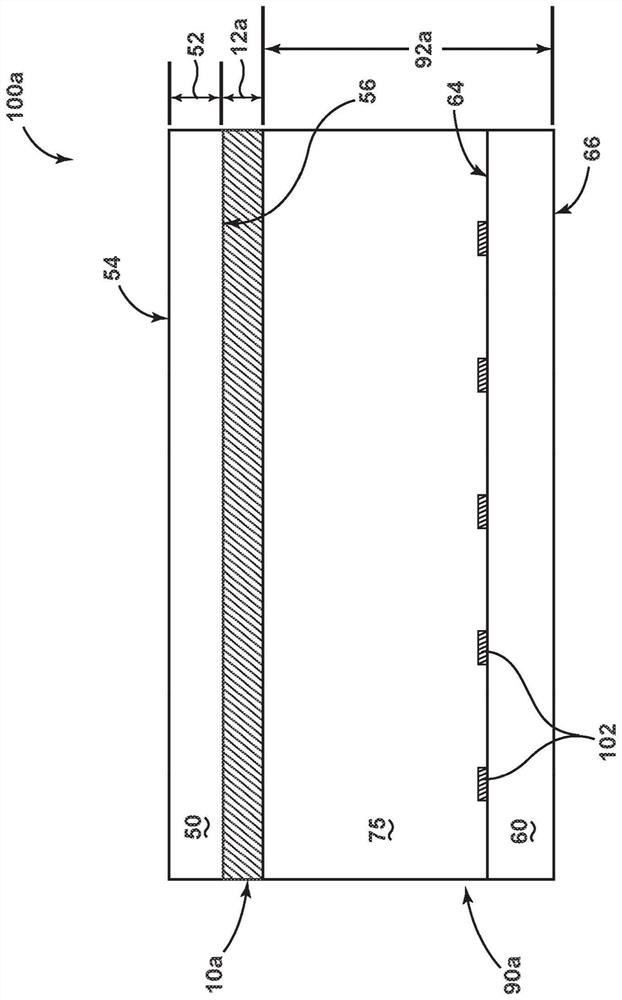

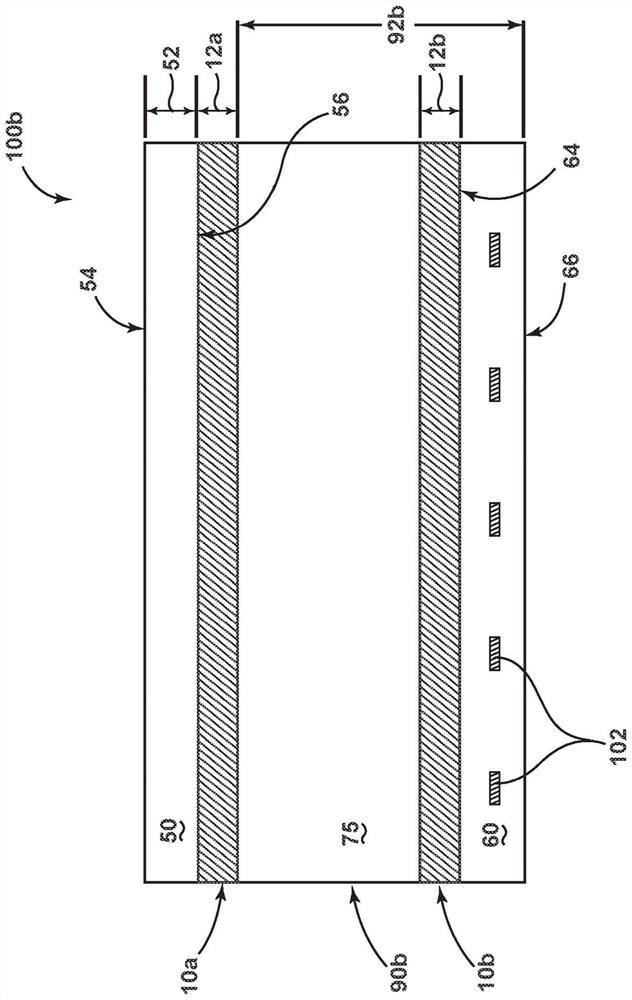

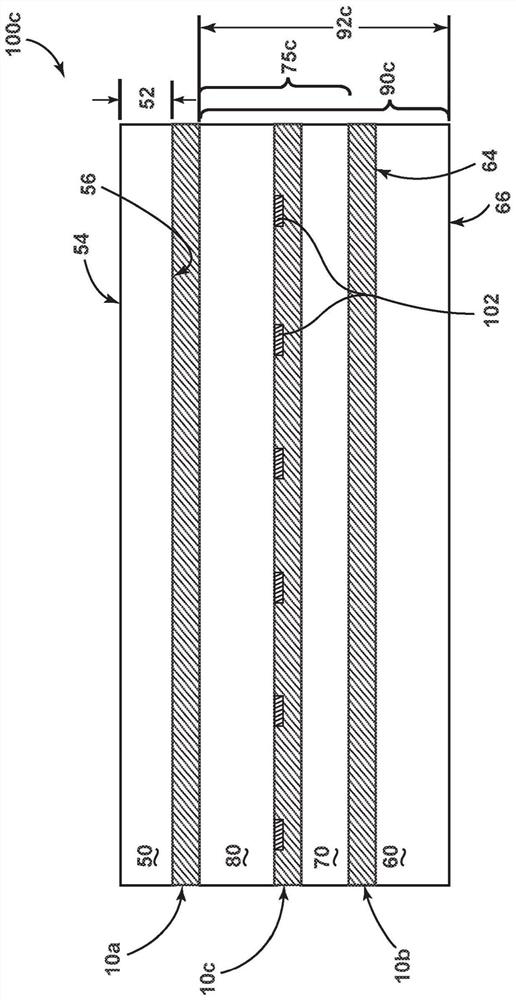

[0034] Reference will now be made in detail to the embodiments of the claims, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts. Ranges can be expressed herein as from "about" one particular value, and / or to "about" another particular value. When such a range is expressed, another embodiment includes from the one particular value and / or to the other particular value. Similarly, when values are expressed as approximations, by use of the prefix "about," it will be understood that the particular value forms another embodiment. It should also be understood that the endpoints of each range are meaningful in relation to and independent of the other endpoint.

[0035] Among other features and benefits, the bendable electronics modules and articles of the present disclosure (and their methods of manufacture) provide mechanical reliability at small ben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com