Integrated layer etch system with multiple type chambers

A chamber and etching technology used in the field of integrated layer etching systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

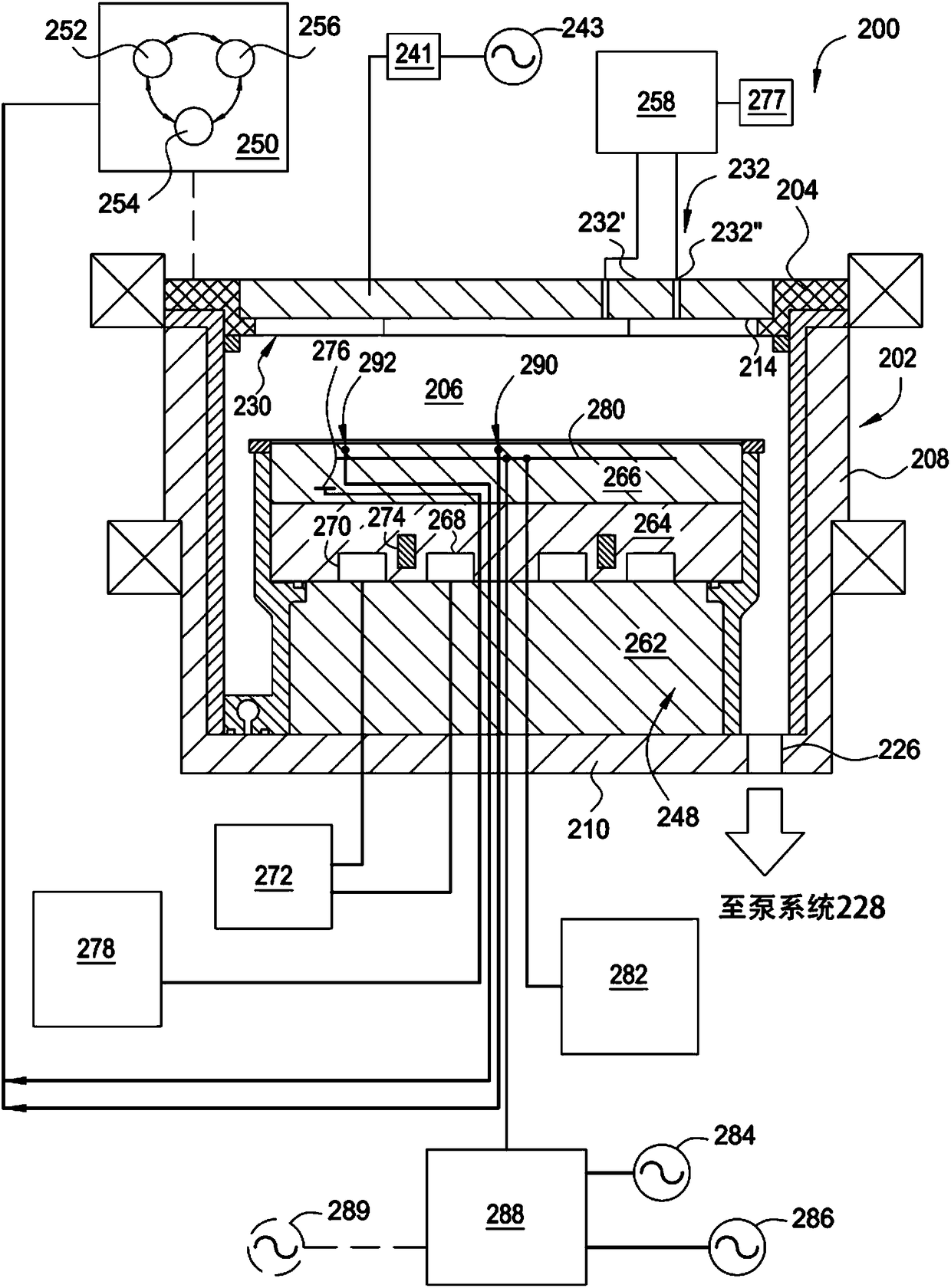

[0016] figure 1 A processing chamber 100 is illustrated according to one example. The processing chamber 100 may be configured to remove material from a layer of material disposed on a surface of a substrate. The processing chamber 100 is particularly useful for performing plasma assisted dry etch processes.

[0017] The processing chamber 100 includes a chamber body 112 that defines a processing region 141 . The cover assembly 123 is disposed on the top end of the chamber body 112 and limits the processing area 141 . The support assembly 180 is disposed below the lid assembly 123 and at least partially within the chamber body 112 .

[0018] The chamber body 112 includes a slit valve opening 114 formed in a sidewall of the chamber body 112 to provide access to a processing region 141 of the processing chamber 100 . The slit valve opening 114 is selectively opened and closed by a gate (not shown) to allow access to the processing region 141 of the chamber body 112 by a wafe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com