Substrate support assembly with deposited surface features

A countertop, ceramic technology, applied in the field of substrate support components, can solve the problem of particle pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

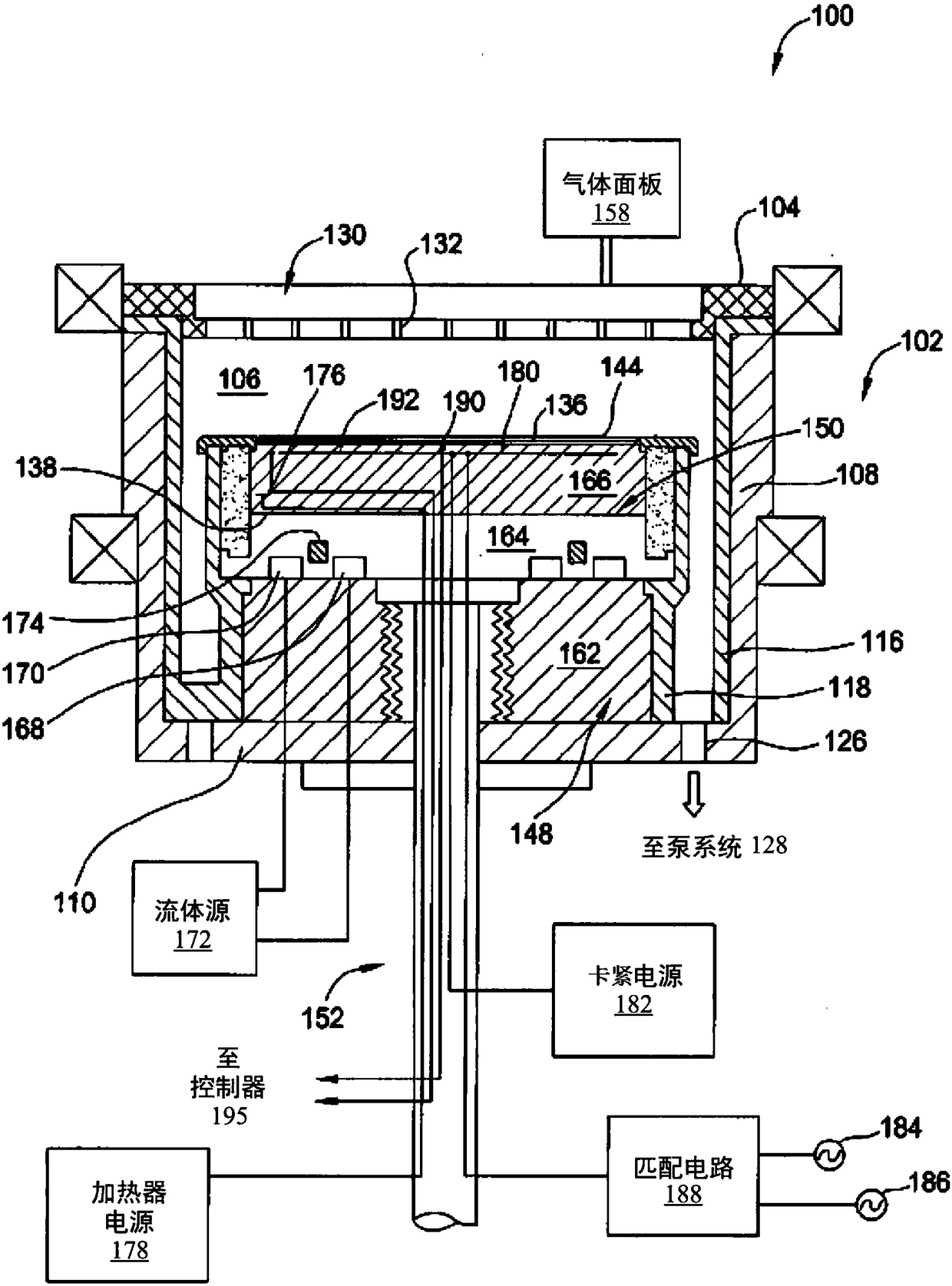

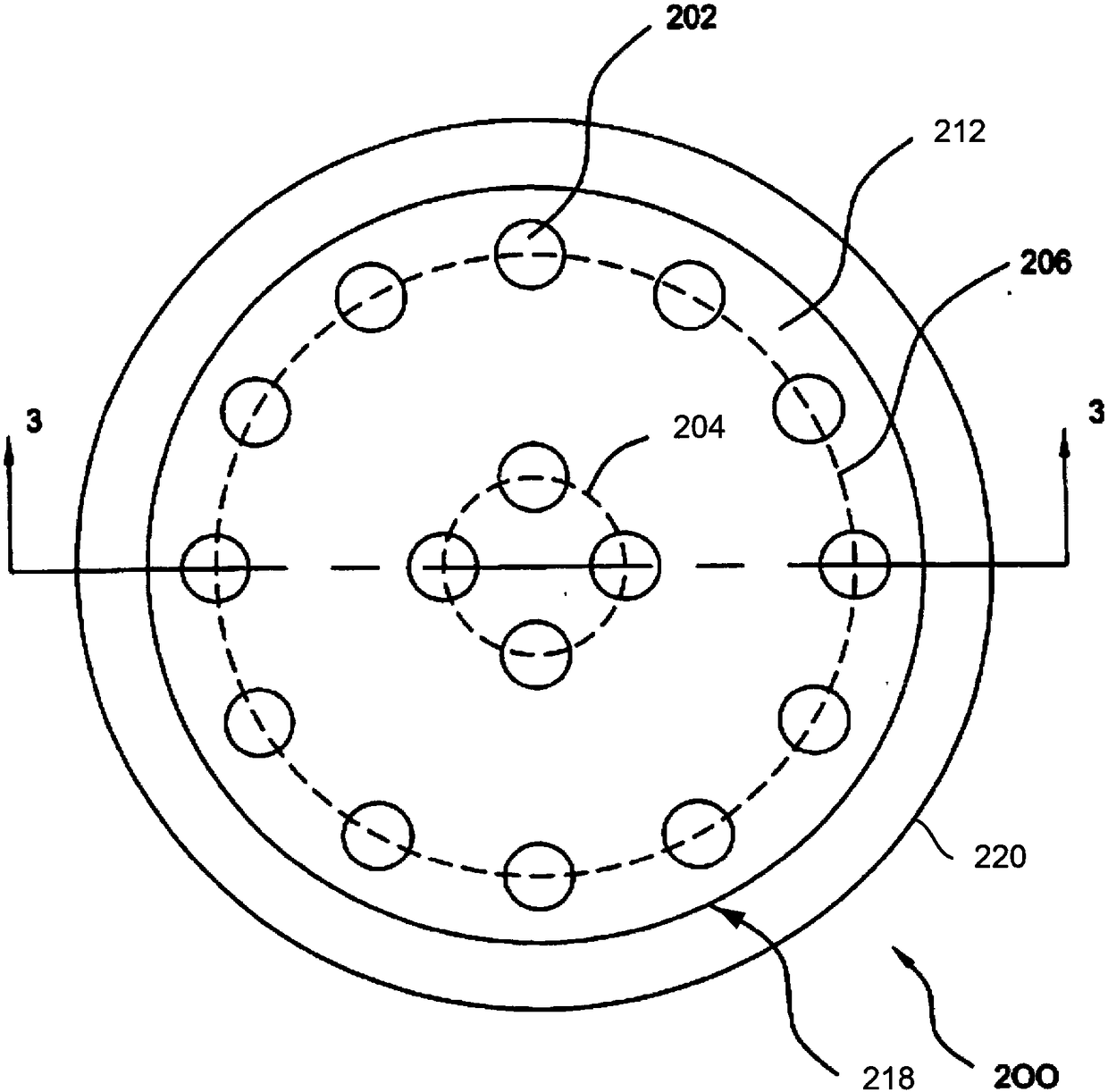

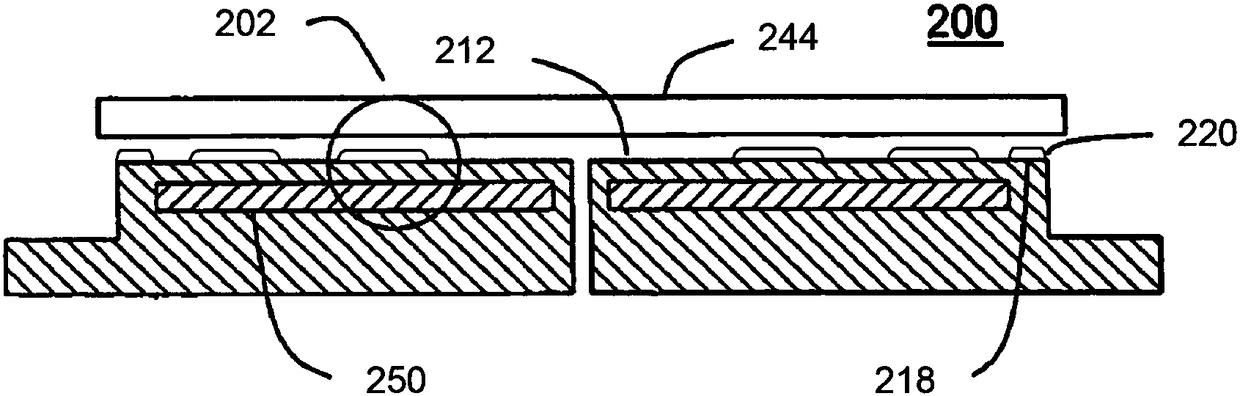

[0016] Embodiments of the present invention provide a substrate support assembly (eg, an electrostatic chuck) having a deposition table with rounded edges. Embodiments also provide a substrate support assembly having a protective ceramic coating formed over a ceramic body of the substrate support assembly. The protective ceramic coating can provide plasma corrosion resistance for protecting the ceramic body. Mesa can be deposited on top of the protective ceramic coating and also be resistant to plasma corrosion.

[0017] In one embodiment, an electrostatic chuck includes a thermally conductive base (eg, a metal or metal alloy base) and a ceramic body (eg, an electrostatic puck) bonded to the thermally conductive base. A protective ceramic coating serving as a protective layer covers the surface of the ceramic body, and a number of elliptical (eg circular) mesas are disposed over the protective ceramic coating. In one embodiment, an electrostatic chuck is fabricated by first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com