Raw material preparation device for sewage treatment

A technology for sewage treatment and raw materials, applied in chemical/physical processes, dissolution, mixers, etc., can solve problems such as insufficient mixing, adhesion, and affecting the preparation of raw materials for sewage treatment, and achieve the effect of avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

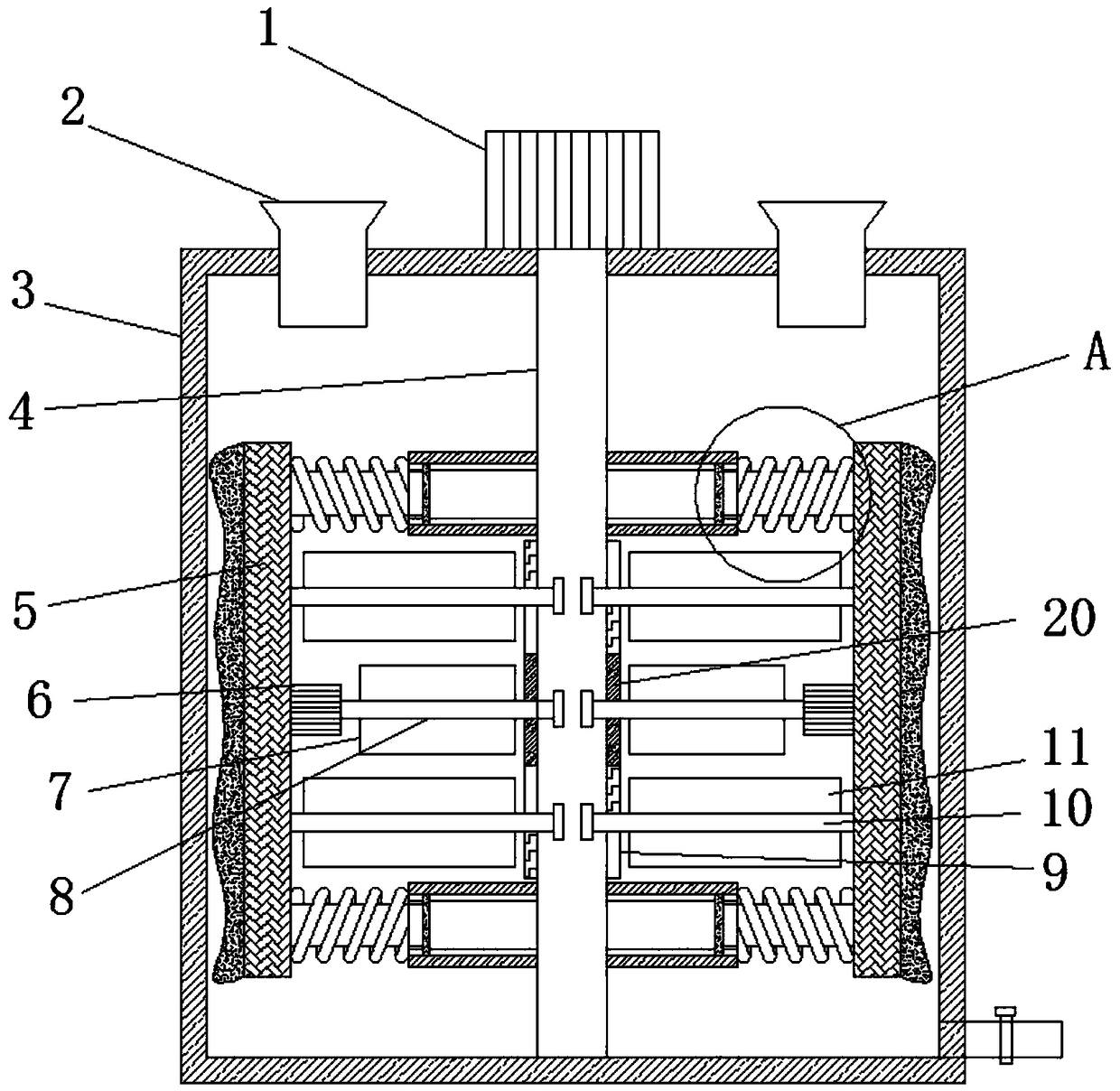

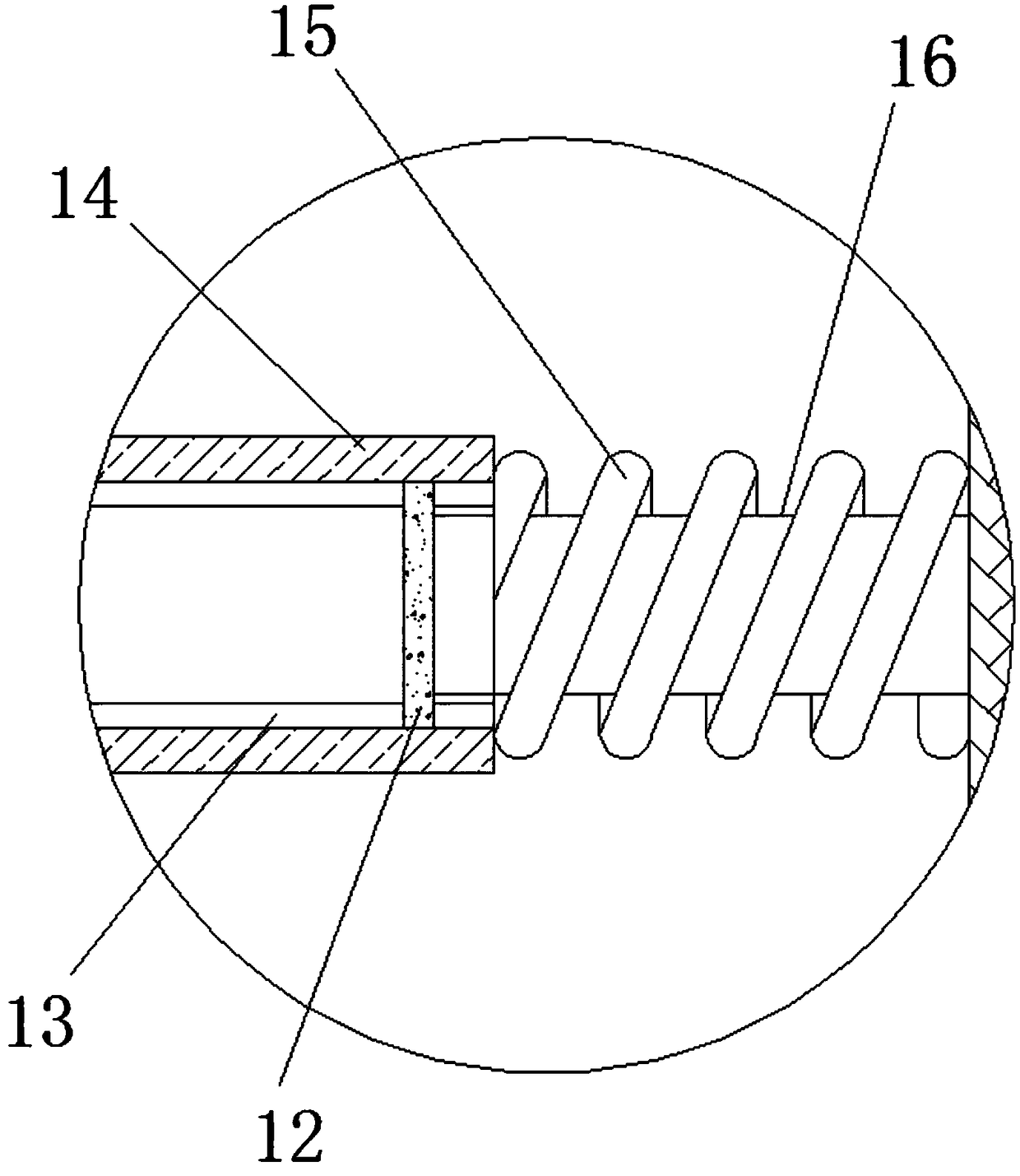

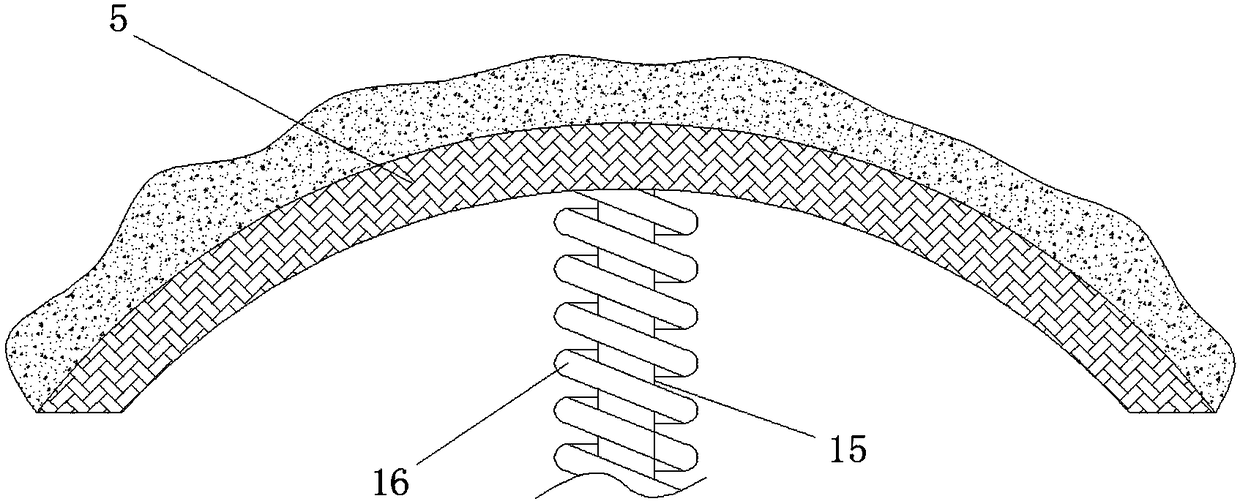

[0024] Embodiment: When the present invention is used, the raw materials for sewage treatment are poured into the housing 3 through the feed port 2, and when poured in, the prepared raw materials are piled up at the blanking plate 19, and are weighed by the electronic weighing board 18. When it reaches a certain weight, the electronic weighing board 18 transmits the signal to the controller, and the controller transmits the signal to the solenoid valve 17, so that the solenoid valve 17 is opened, and the raw materials are entered into the housing 3, and then the second Rotating motor 6 makes the second rotating motor 6 drive driving rod 8, driving wheel 20, driven rod 10, driven wheel 9, the first stirring plate 7 and the second stirring plate 11, make it stir the preparation raw material, prepare The raw materials are mixed evenly, and the first rotating motor 1 is started at the same time, so that it drives the rotating plate 4 and the cleaning plate 5 to rotate, and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com