Manufacturing method of indoor wood floor

A technology for floors and bottom plates, which is applied in the field of indoor floor preparation. It can solve the problems of simple steps, no antibacterial and mildew-proof performance of the floor, and single product functions, and achieve the effects of convenient spraying, strong product functionality, and guaranteed work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

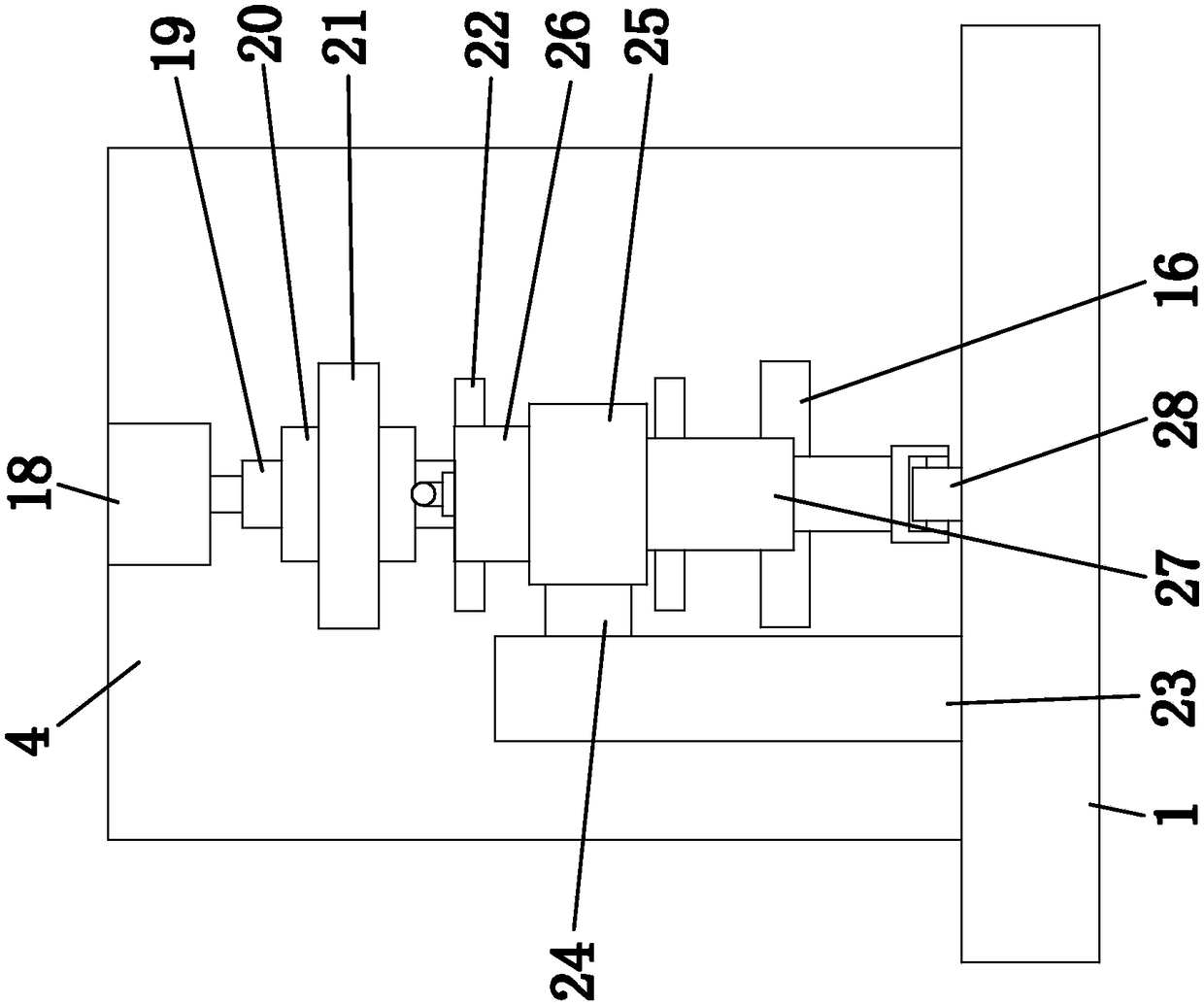

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0029] The preparation method of this indoor floor comprises the steps:

[0030] a. In parts by weight, weigh: 70-80 parts of polyester resin, 3.5-5.8 parts of crosslinking agent, 0.12-0.15 parts of catalyst, 2-8 parts of antibacterial agent, 1-5 parts of antifungal agent and 40- 60 parts are put into the blender, and protective coating is obtained; In the present embodiment, take by weighing: 74 parts of polyester resins, 3.9 parts of crosslinking agents, 0.13 parts of catalysts, 3 parts of antibacterial agents, 2 parts of antifungal agents and solvents 50 parts are put into the blender, and protective coating is obtained; Cross-linking agent, catalyzer, antifungal agent and solvent all adopt the existing product that can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com