Clamping device for hydrogen detector sensor handle

A clamping device and detector technology, which is applied to workpiece clamping devices, heat treatment equipment, furnaces, etc., can solve the problems of cumbersome bundling operations, easy loosening of the hydrogen detector sensor clamping device, and inability to meet the needs of on-site use. , to achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

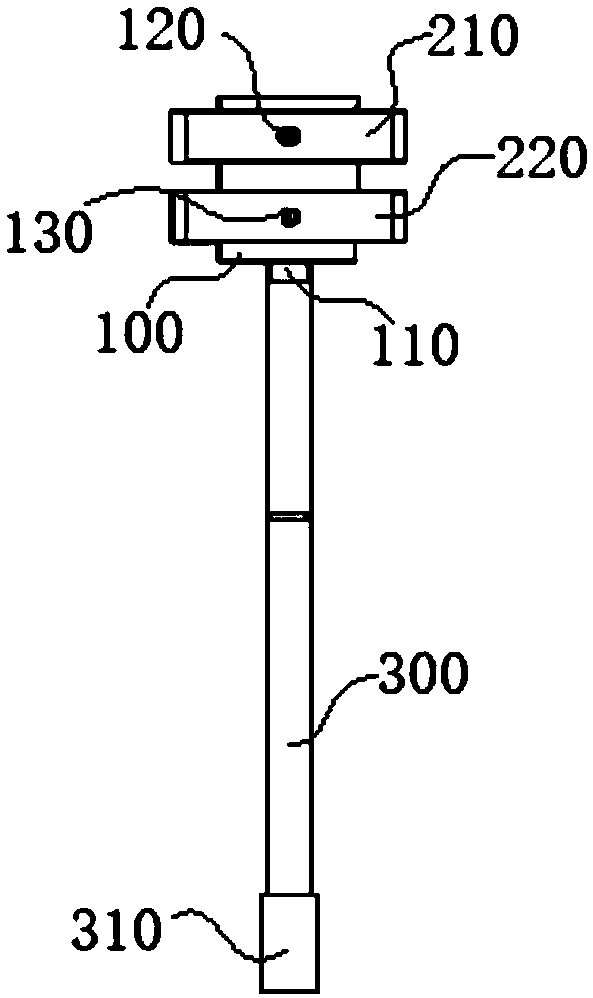

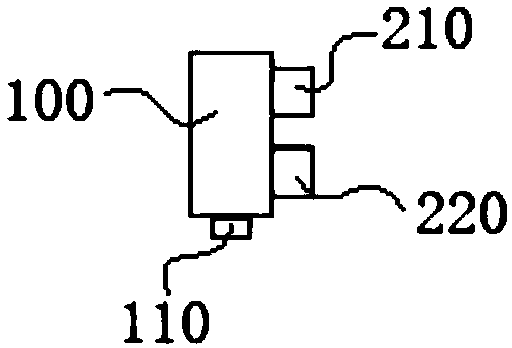

[0035] Such as Figure 1-Figure 3 As shown, a hydrogen detector sensor handle clamping device in this embodiment includes a clip base 100, an upper clip 210, a lower clip 220 and a telescopic rod 300, wherein the upper clip 210 and the lower clip 220 are respectively connected to the The upper and lower ends of the clip base 100 are connected, and the telescopic rod 300 is connected with the bottom end of the clip base 100 . Among them, the telescopic rod 300 can conveniently and quickly adjust the length of the rod, which can meet the height requirements of different positions on site. In this embodiment, the telescopic rod 300 can adopt a variety of existing conventional telescopic structures in the industry, which will not be described in detail here. For example, a multi-stage tubular structure can be used, and the expansion and contraction through pin holes and pins can be used. In this embodiment, the structure of the lower clip 220 is the same as that of the upper clip...

Embodiment 2

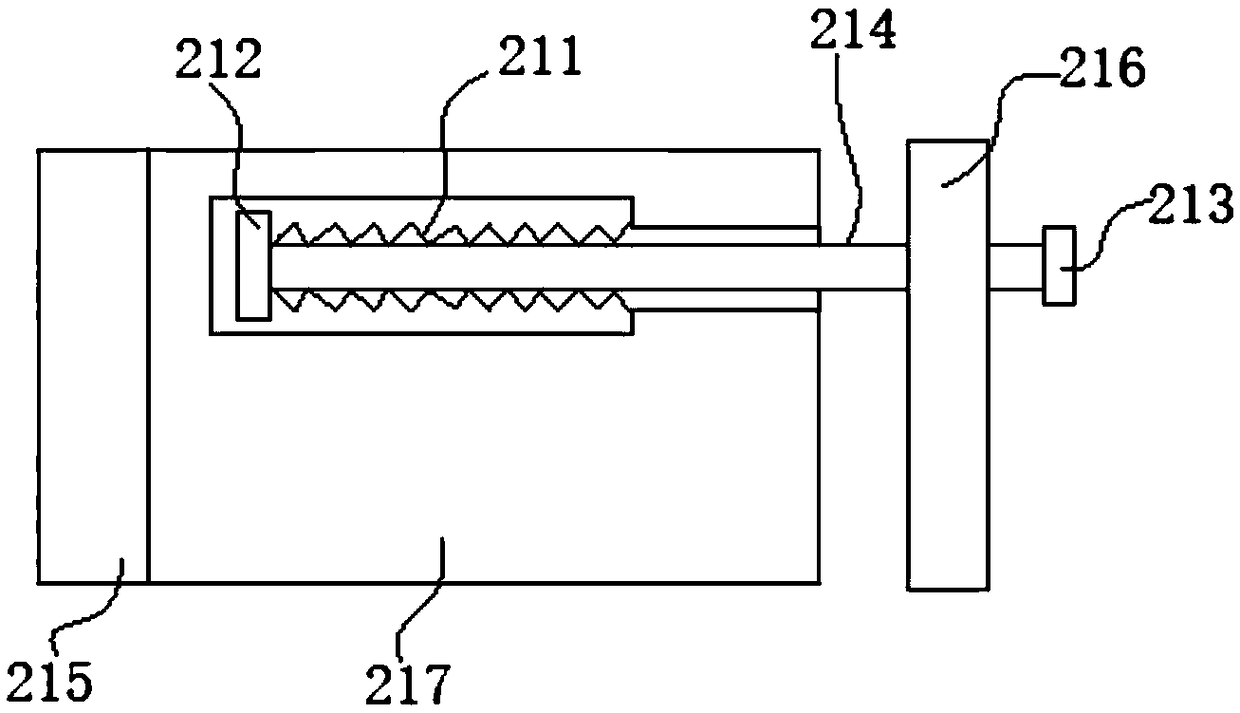

[0040] The basic structure of the hydrogen detector sensor handle clamping device of this embodiment is the same as that of Embodiment 1. Further, a return spring 211 is arranged in the adjustment hole in this embodiment, and one end of the return spring 211 is connected to the blocking part 212 for reset. The other end of the spring 211 is connected with the inner wall of the adjustment hole. Specifically, in this embodiment, the return spring 211 is sheathed on the outside of the pull rod 214 . One end of the pull rod 214 and the return spring 211 is connected to the blocking portion 212 to form a whole, and the other end of the return spring 211 is specifically fixed on the right side end wall of the large aperture section of the adjustment hole, as image 3 As shown in the middle position, pull the right baffle plate 216 to the right, that is, drive the pull rod 214 to move horizontally to the right side synchronously, and the blocking part 212 will move horizontally to th...

Embodiment 3

[0042] A hydrogen detector sensor handle clamping device of this embodiment has the same basic structure as that of Embodiment 2. Furthermore, a bolt hole is provided in the right side plate 216 of this embodiment, and a bolt hole corresponding to the bolt hole is provided at the right end of the pull rod 214. Cooperating threads, and the pull rod 214 passes through the bolt hole and is fixed by the nut 213. When installing, screw the threaded section at the right-hand side of the pull rod 214 into the bolt hole to the right, and fix it by the nut 213; The way of threaded connection is convenient and quick to use, and it is convenient for the disassembly and installation of the right side plate 216; secondly, by setting the nut 213, the clamping width of the upper clip 210 can be further fine-tuned, specifically, it can be clamped on the right side plate 216 After holding the sensor handle, lock the nut 213 to the left on the right side plate 216, which helps to further enhanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com