Method for producing a three-dimensional object and stereolithography machine

A technology of stereolithography and three-dimensional objects, which is applied to the processing of accessories of main materials, manufacturing tools, and additive manufacturing. It can solve the problems of increasing the total size of the machine and prolonging the total processing time of three-dimensional objects. The effect of overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

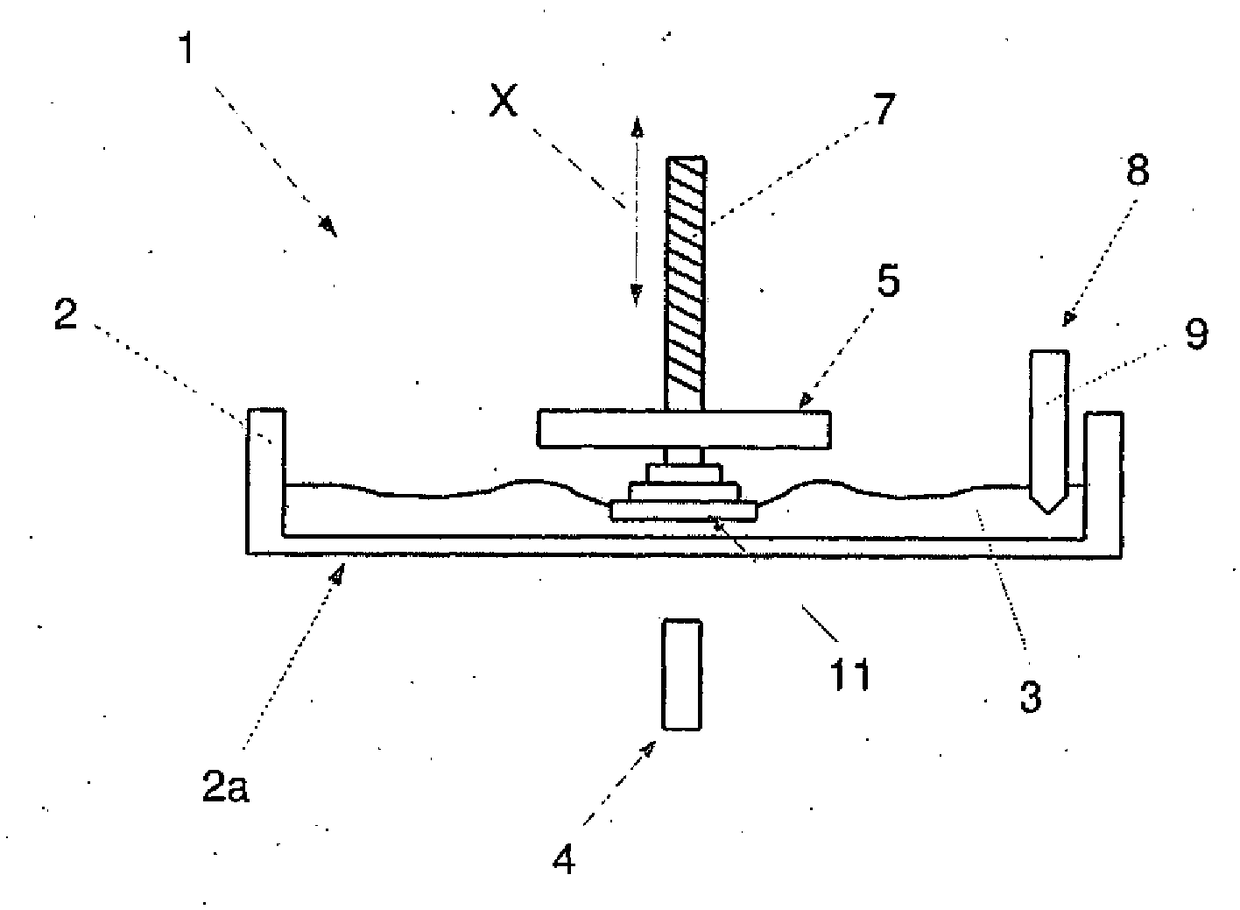

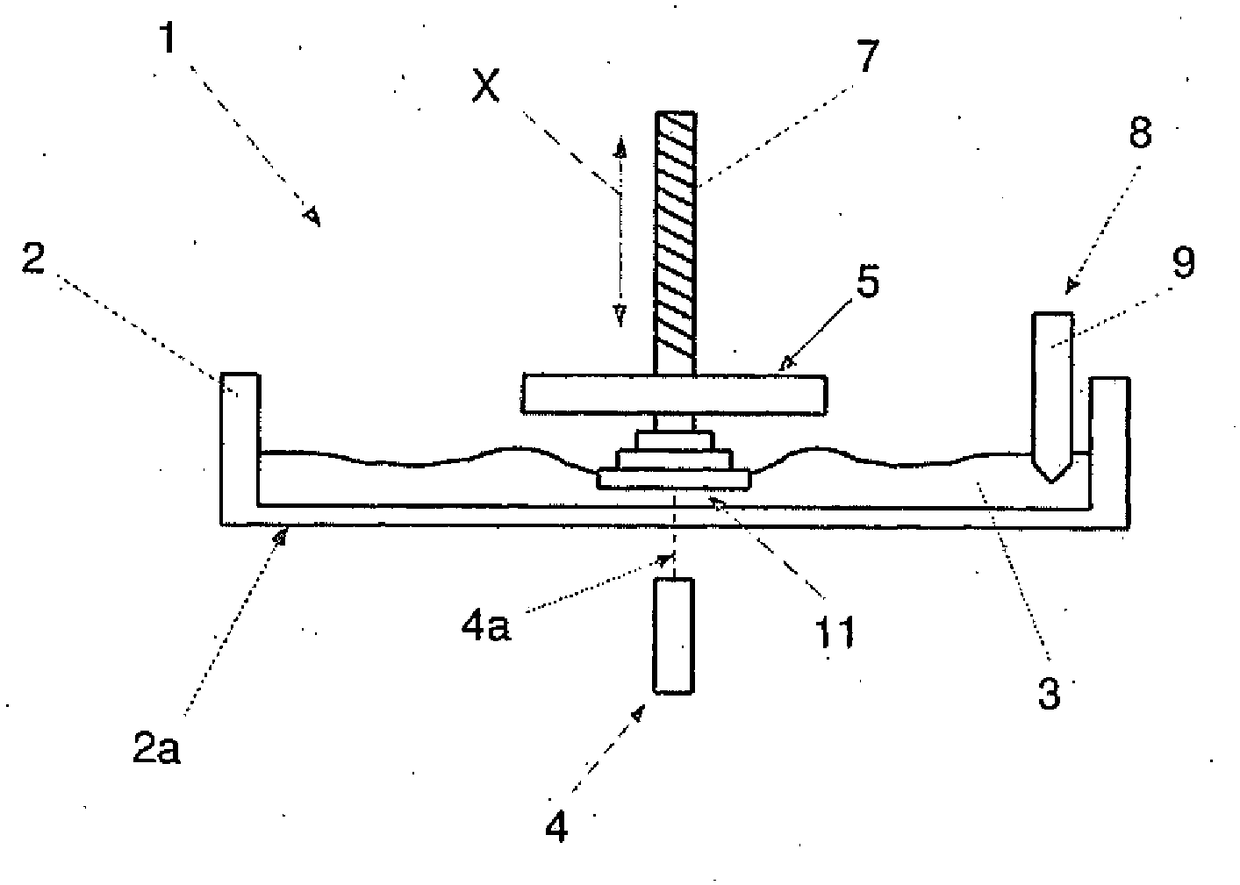

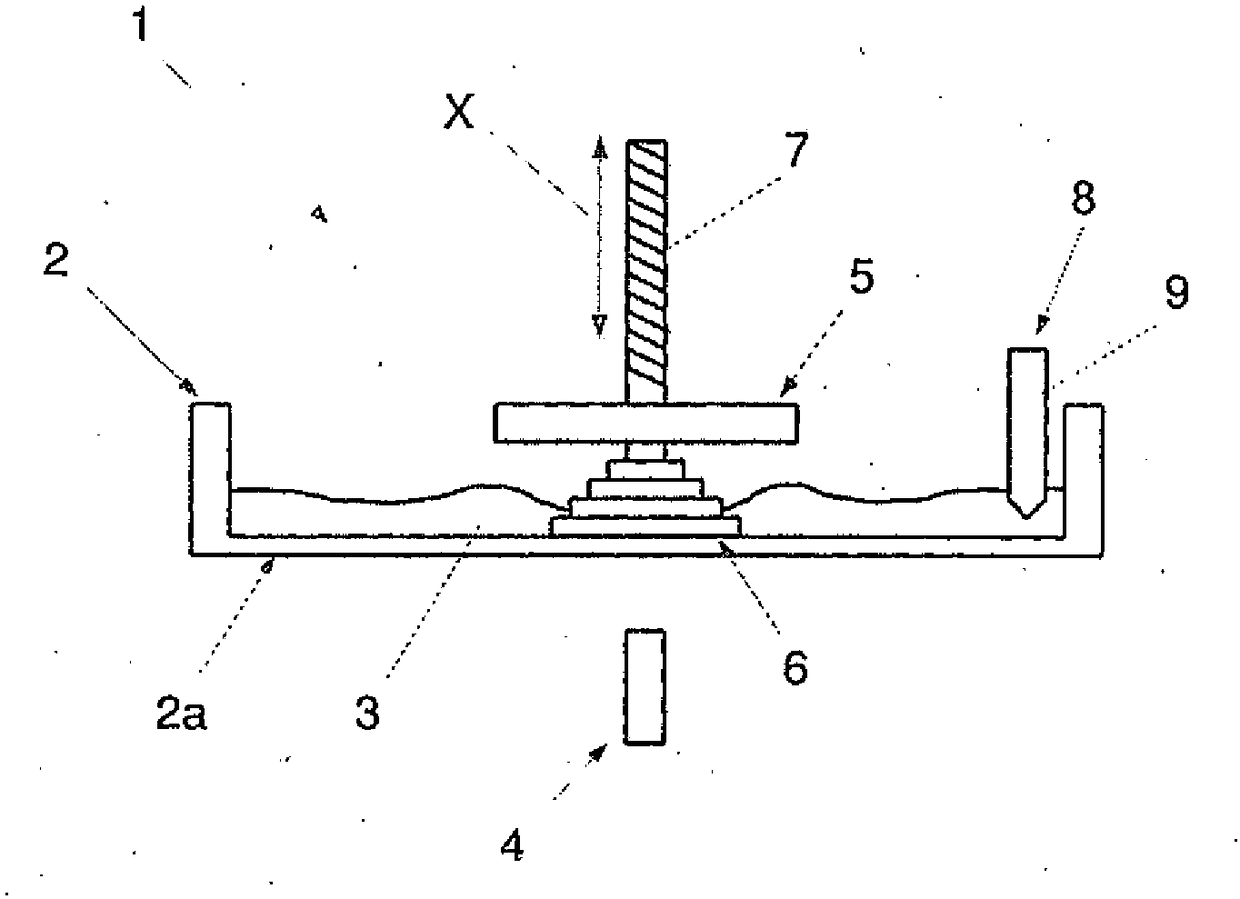

[0046] referenced by figure 1 The method of the invention is described by a stereolithography machine generally indicated by 1, comprising a container 2 containing a fluid substance 3 suitable for solidification by exposure to predetermined radiation 4a.

[0047] From now on, the term "fluid substance" refers to a substance suitable for distribution in the container 2 such that its surface assumes a substantially planar shape, eg like that of a liquid or pasty substance.

[0048] The fluid substance 3 is preferably but not necessarily a photopolymer liquid resin and the predetermined radiation is light radiation.

[0049]In particular, said resin is of the so-called "hybrid" type comprising particles of ceramic or other material capable of increasing the mechanical resistance of the resin once it has set.

[0050] However, the methods and machines of the present invention may be used with any type of fluid substance that is capable of solidifying after exposure to the predet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com