Underground water-sealing cave depot system, and oil storage method of underground water-sealing cave depot

A groundwater and cavern technology, which is applied in the field of underground water-sealed caverns for oil storage and underground water-sealed cavern systems, can solve problems such as high operating costs, oil and gas seepage, complex process control, etc., to improve safety and reliability , reduce construction costs, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

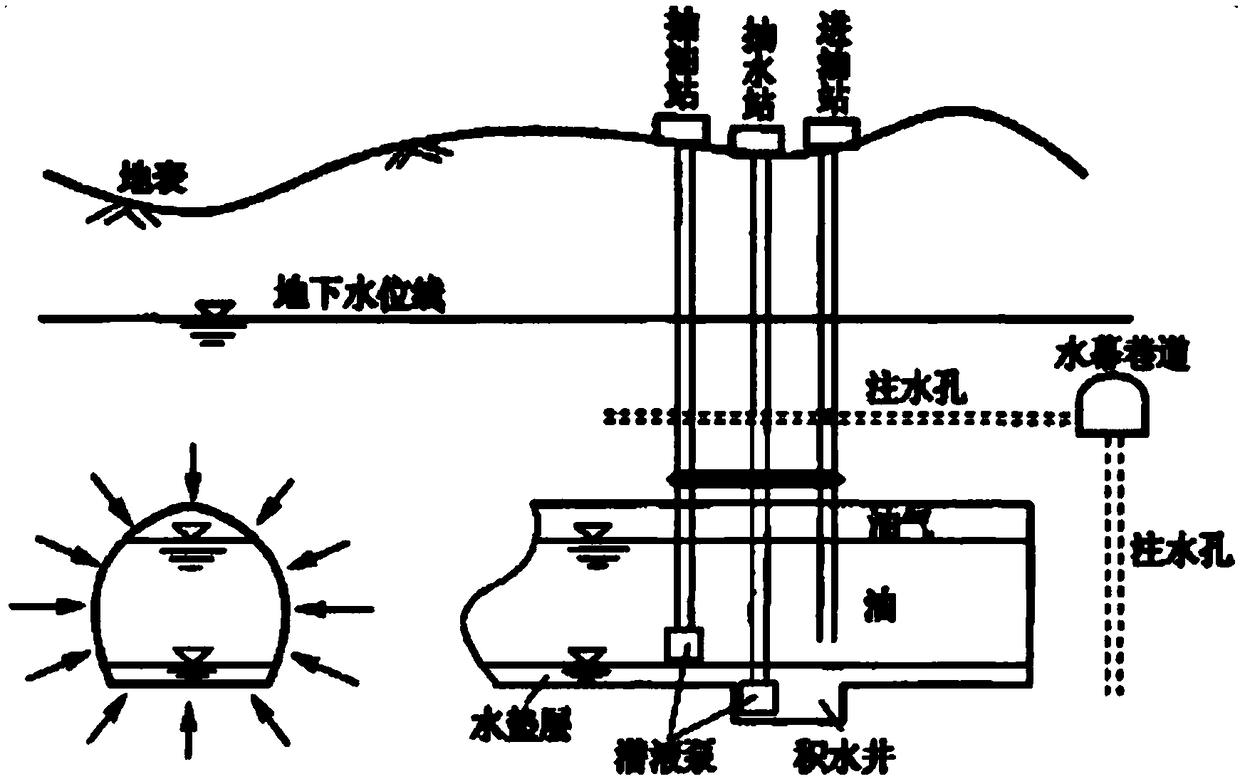

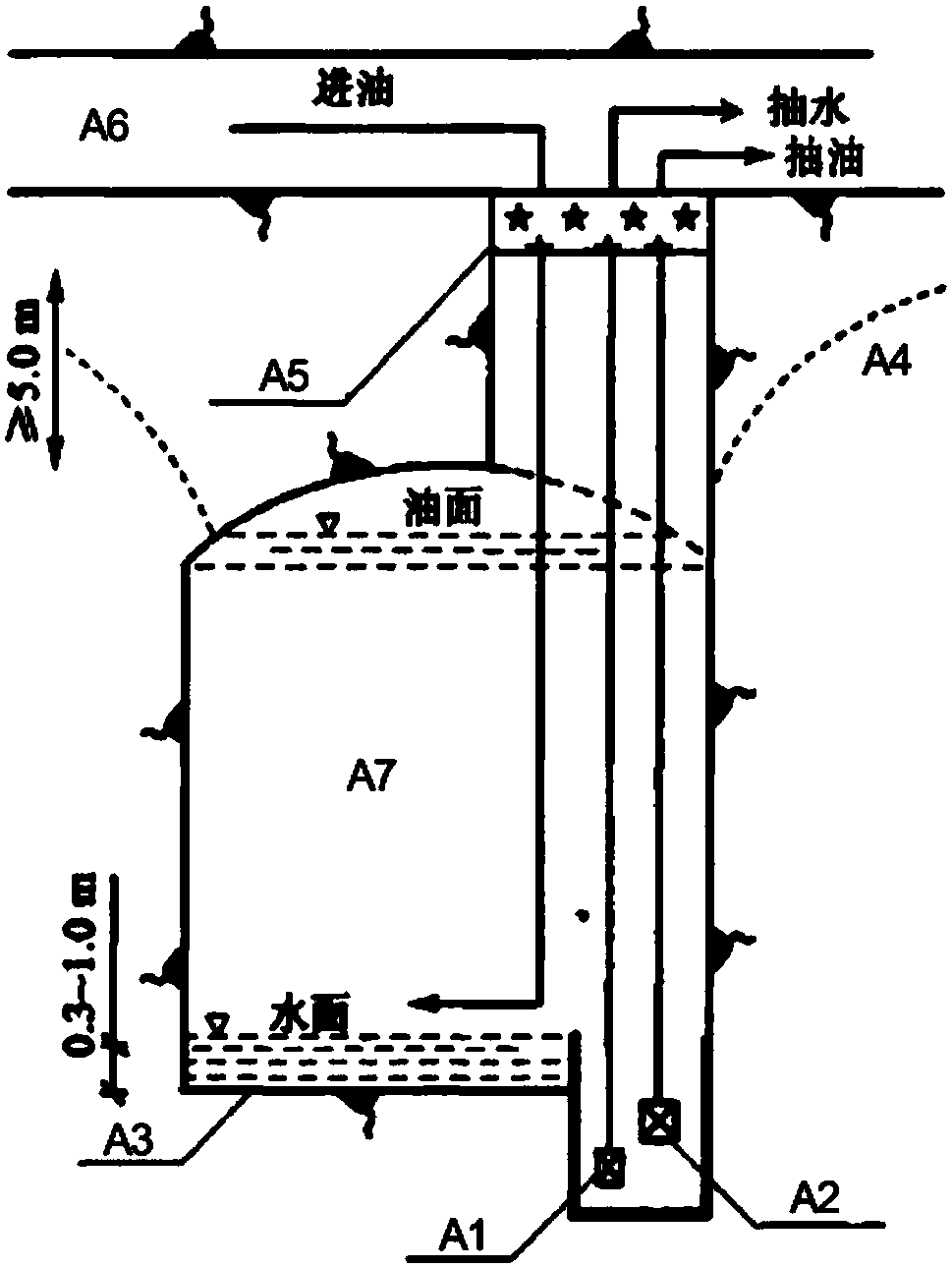

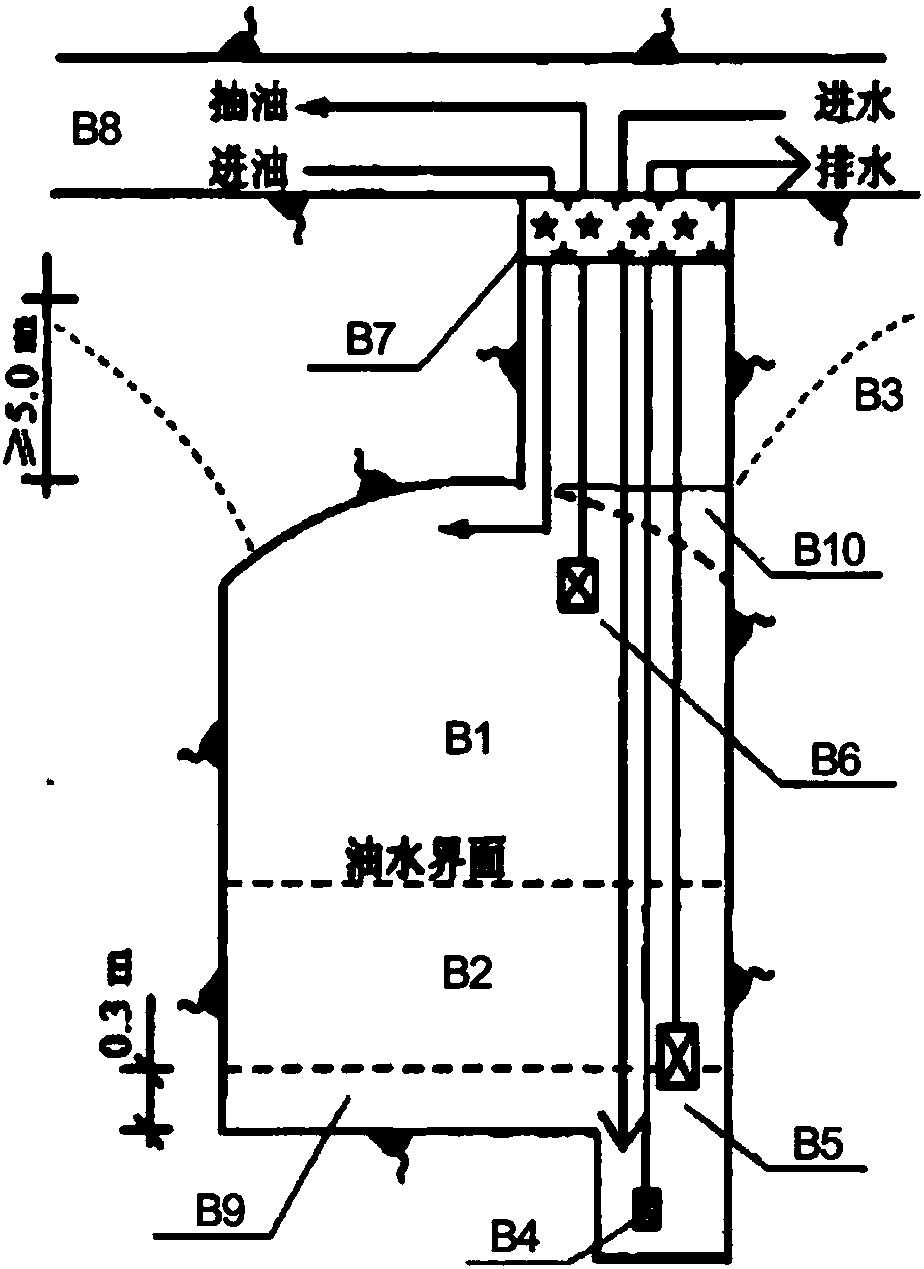

[0066] This embodiment describes in detail an underground water-sealed cavern system and an oil storage method using the underground water-sealed cavern system.

[0067] see Figure 4 and 5 , the underground water-sealed cavern system in this embodiment includes: several oil storage caverns C8, a pressure regulating air chamber C1 is arranged above each of the oil storage chambers C8, and the bottom elevation of the pressure regulating air chamber C1 is greater than the top elevation of the oil storage chamber C8; each of the pressure regulating air chambers C1 communicates with each of the corresponding oil storage chambers C8 through a connecting channel C2; the top of the pressure regulating air chamber C1 is connected to a The gas shaft is provided with a reinforced concrete sealing cover C10 in the gas shaft, and is provided with a gas inlet and outlet pipe C15 passing through the reinforced concrete sealing cover C10; an adjustable opening is installed on the gas inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com