Prefabricated double-energy consumption recoverable square steel tube concrete composite column and installation method thereof

A prefabricated and combined column technology, applied in columns, piers, pillars, etc., can solve the problems of insufficient integrity of CFST composite columns, save building space and construction costs, avoid waste, and avoid stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

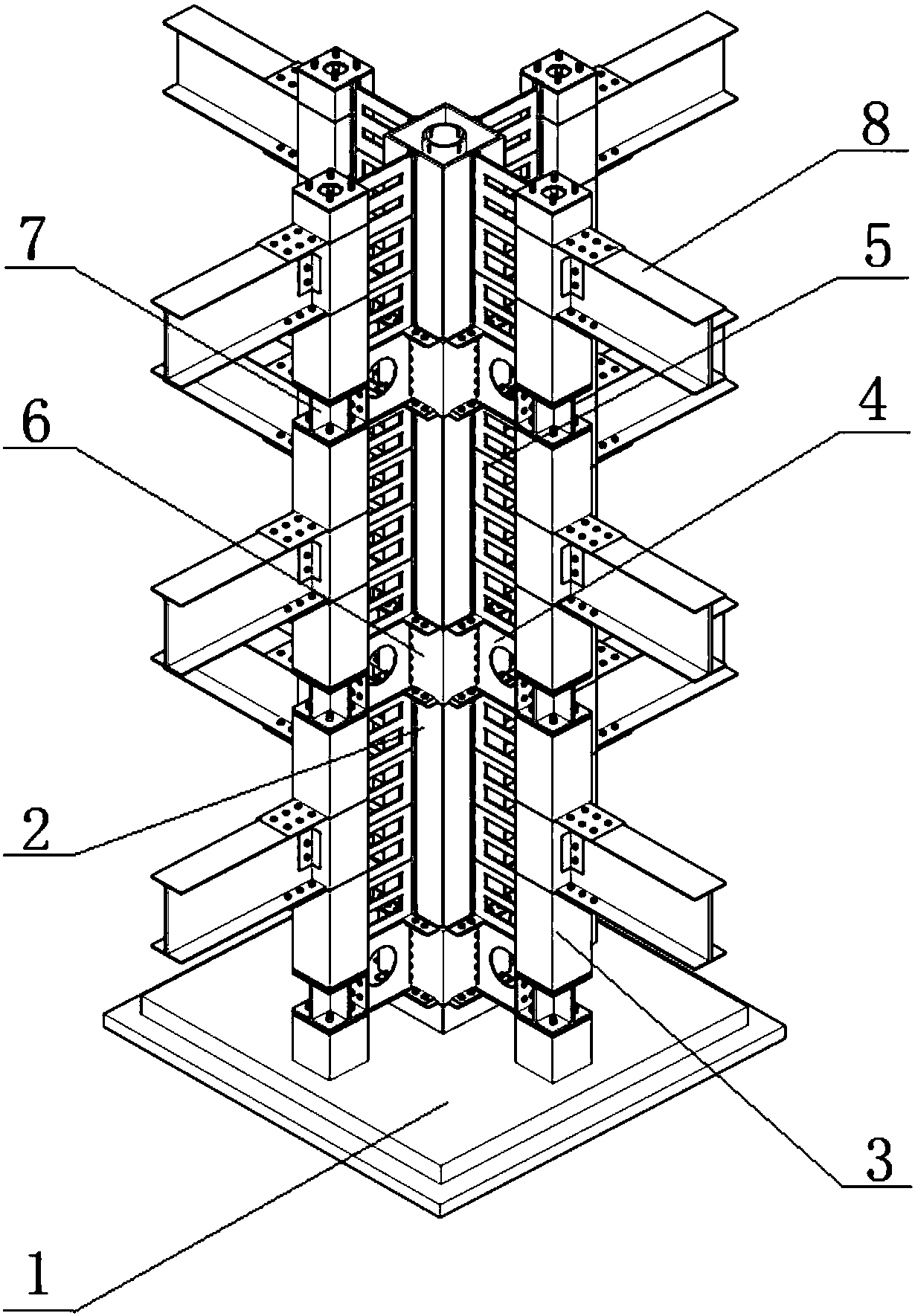

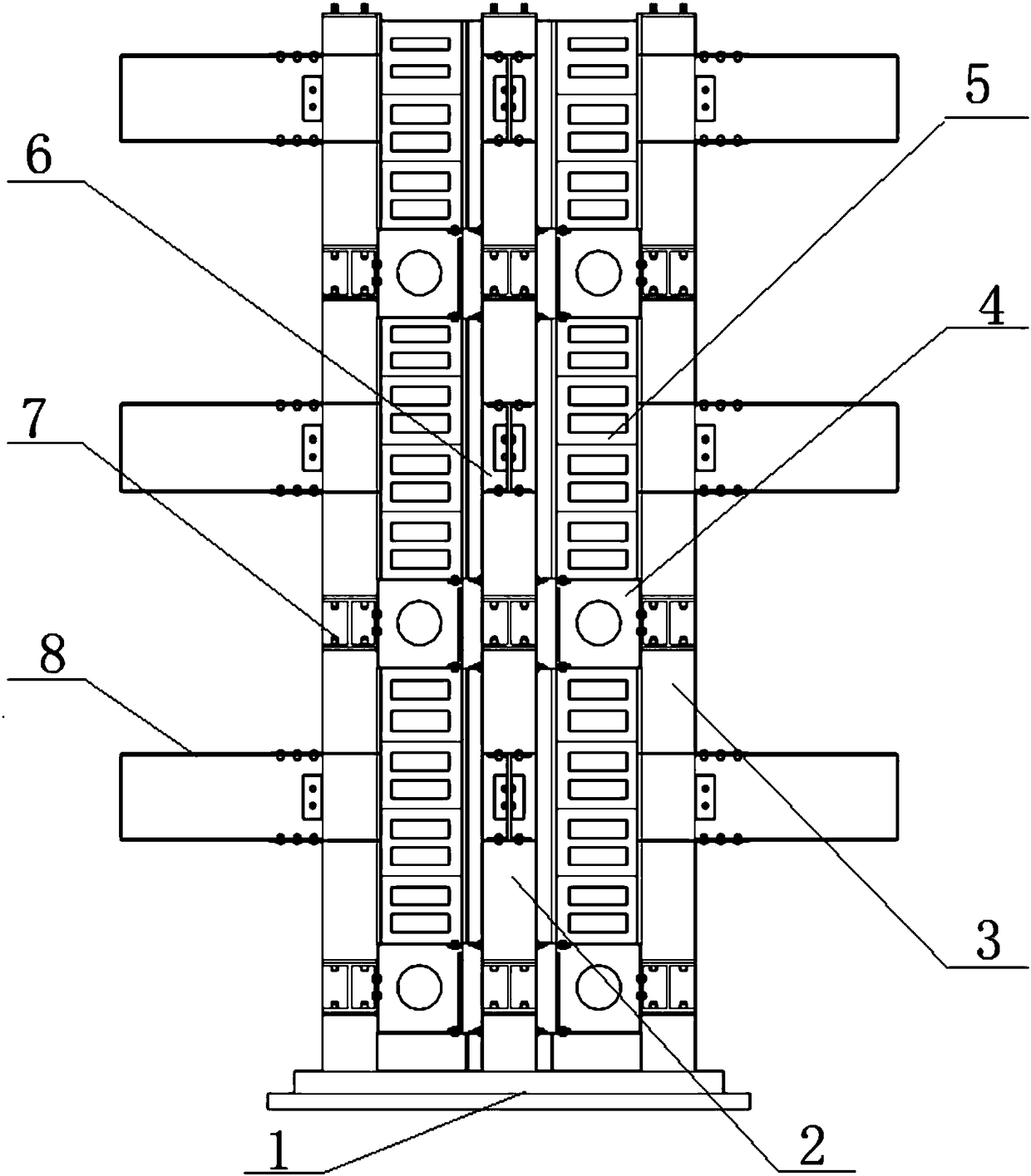

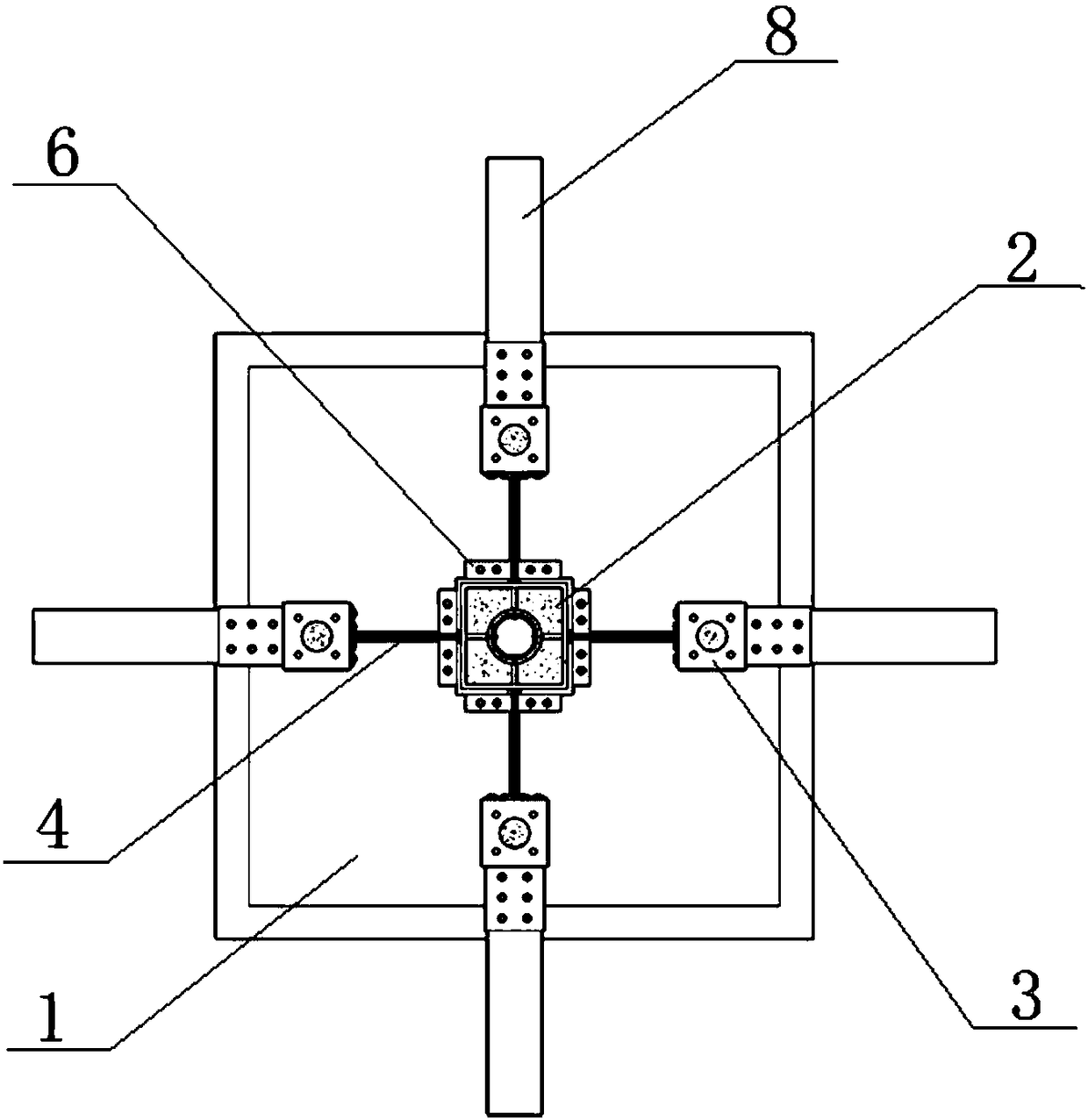

[0060] Such as figure 1 , 2 As shown in and 3, the assembled double energy consumption recoverable square concrete-filled steel tube composite column of the present invention includes type I column 2 (assembled outer square inner circular steel tube concrete column, type II column 3 (assembled self-restoring square steel tube concrete column) column), energy-dissipating connecting steel plate 5 and platform energy-dissipating connecting piece 4. The present invention is the first to create energy-dissipating connecting steel plate as the connecting member between combined columns, while ensuring the connection performance and integrity between the combined columns, in order to ensure the energy-consuming connecting The steel plate is the first to consume energy and needs to weaken the strength of the member. Therefore, a rectangular hole is opened in the web part to make it firstly destroyed by the earthquake, resulting in tearing damage, consuming earthquake energy, and avoid...

Embodiment 2

[0083] In the above-mentioned embodiment 1, one type I column 2 and four type II columns 3 are combined by using the platform energy-dissipating connector 4 and the energy-dissipating connecting steel plate 5 . It should be noted in this embodiment 2 that the combination of the type I column 2 and the type II column 3 is various, and is not limited to the combination mentioned in this embodiment.

[0084] Such as Figure 13 and 14 As shown, one type I column 2 is combined with three type II columns 3 by using the energy-dissipating connector 4 of the cap and the energy-dissipating connecting steel plate 5 to form a side-column composite column structure.

[0085] Such as Figure 15 and 16 As shown, one type I column 2 and two type II columns 3 are combined by using the energy-dissipating connector 4 of the cap and the energy-dissipating connecting steel plate 5 to form a corner column composite column structure.

Embodiment 3

[0087] The installation method of the prefabricated double-energy-dissipative recoverable square steel tube concrete composite column of the present invention comprises the following steps:

[0088] Step 1: insert the circular inner connecting cylinder 13 into the lower circular steel pipe 15, and the threaded hole should correspond to the position of the lower long hole slot;

[0089] Step 2: Set the lower square steel pipe 14 outside the lower round steel pipe 15, and the positions of the long holes in the front and rear should correspond to each other;

[0090] Step 3: Set the square outer sleeve connecting piece 6 outside the square steel pipe 14, the high-strength bolt hole 12 should correspond to the position of the long hole slot, and then pass through the square outer sleeve connecting piece 6 and the lower square steel pipe in turn through the long high-strength bolts 14. The circular steel pipe 15 in the lower section is fixedly connected to the threaded hole corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com