Large-depression-angle long-distance coal seam gas pressure testing drill hole cement mortar hole-sealing method

A technology of coal seam gas pressure and cement mortar, which is applied in the direction of gas discharge, measurement, earthwork drilling and mining, etc., to achieve good slurry blocking effect, prevent leakage, and widely popularize and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

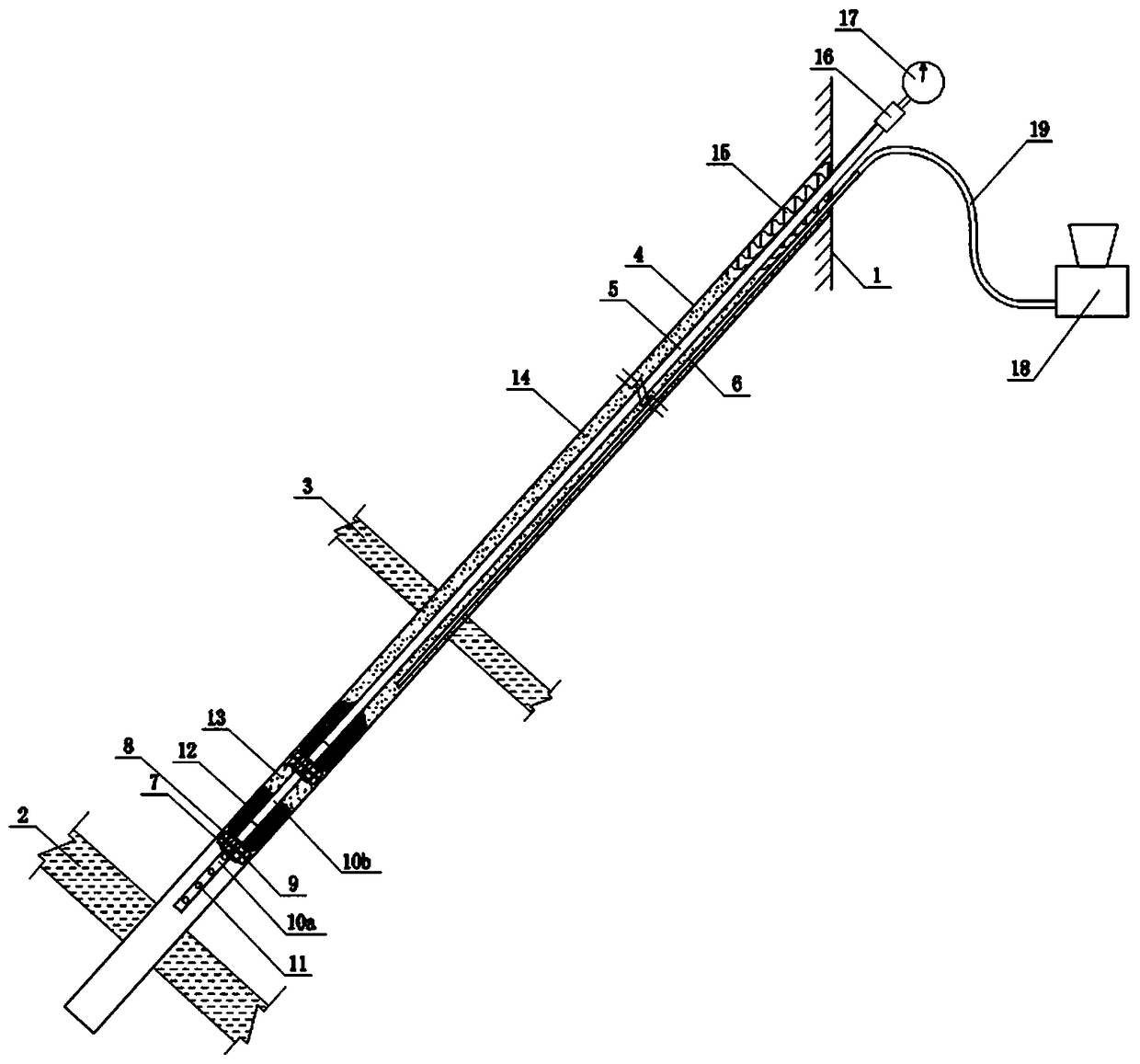

[0031] Below in conjunction with the accompanying drawings, a method for sealing holes with cement mortar for large-depression angle and long-distance coal seam gas pressure testing drilling holes of the present invention will be further described in detail.

[0032] 1) According to the designed drilling inclination angle, azimuth, length and other parameters, from the drilling site 1 to the target coal seam 2, the construction diameter is φφ65 ~ φ95mm drilling 4 passes through the middle coal seam or coal line 3, considering the sediment factor, drilling 4 through Pass the target coal seam floor 2-3m for the final drilling, connect the compressed air to the drill pipe, and preliminarily clean the accumulated water and hole slag in the borehole 4;

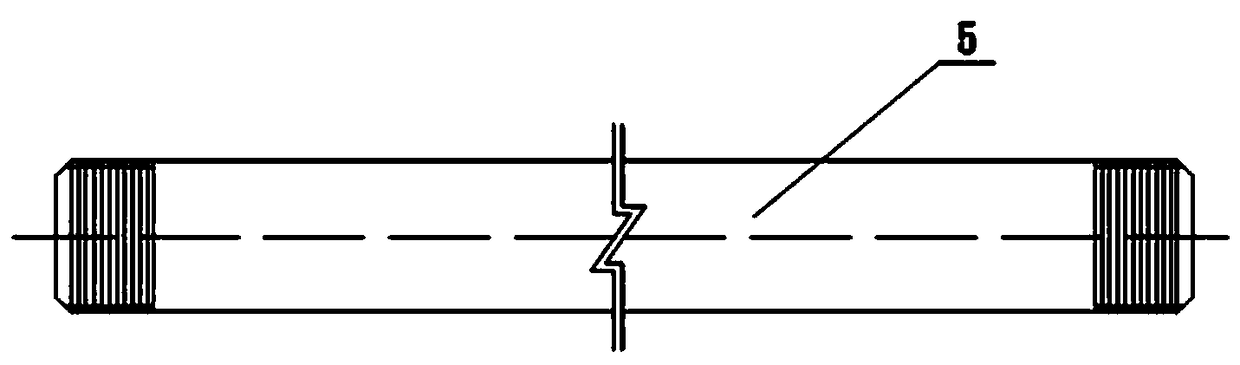

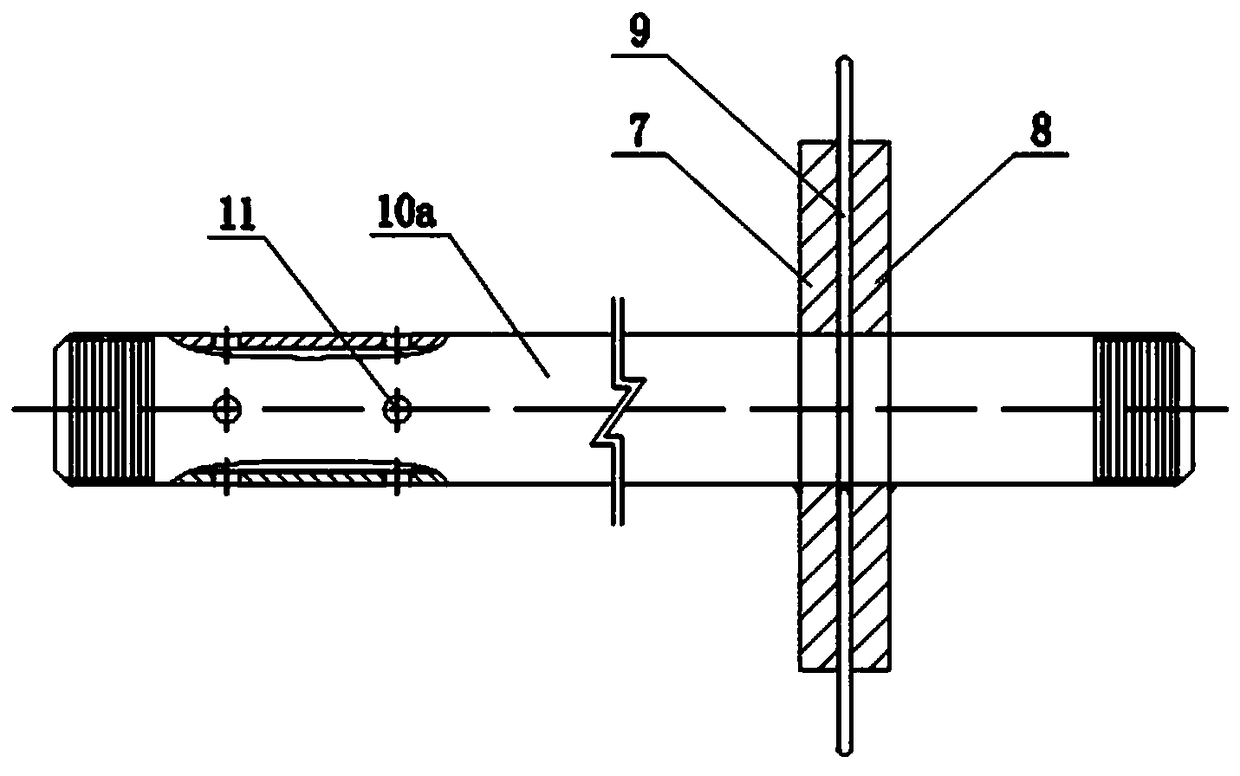

[0033] 2) Due to the large inclination angle of the depression angle and the long drilling distance, in order to prevent the grout from leaking and breaking through the baffle, two sets of baffles are designed, and each set consists...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com