Resistance-capacitance composite touch sensor, electronic skin and smart robot

A touch sensor, electronic skin technology, applied in the fields of resistance-capacitance composite touch sensor, electronic skin and intelligent robots, can solve the problems of poor anti-interference ability, loss of classification recognition, low sensitivity, etc., to avoid crosstalk and improve anti-interference ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

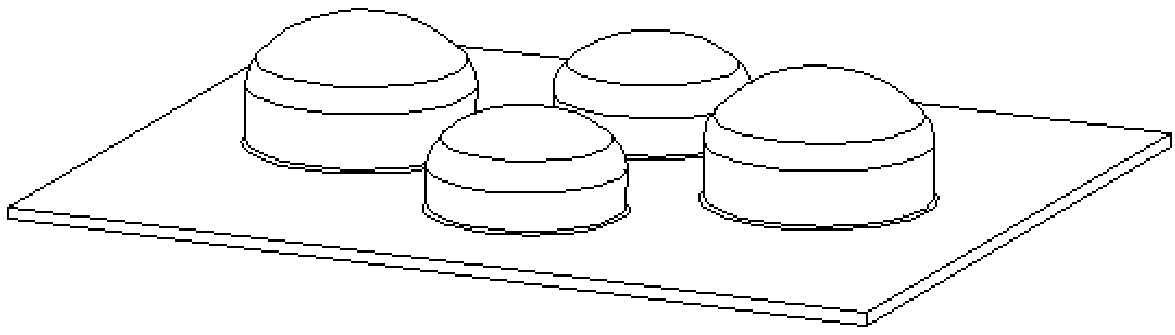

[0079] In this embodiment, the detection unit used to detect the three-dimensional force inside the multifunctional layer is a parallel plate capacitor.

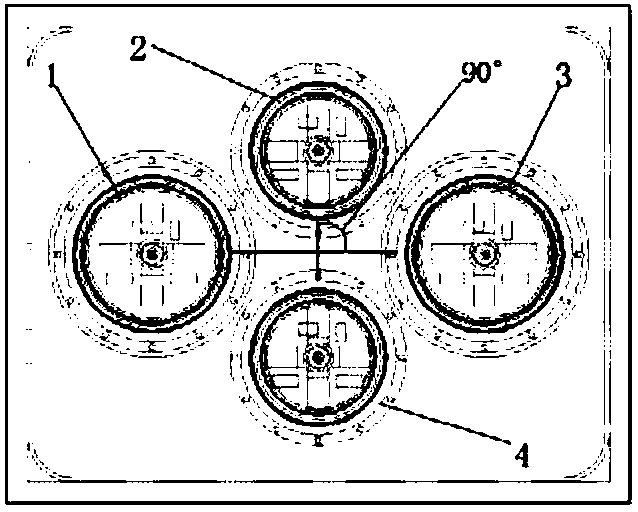

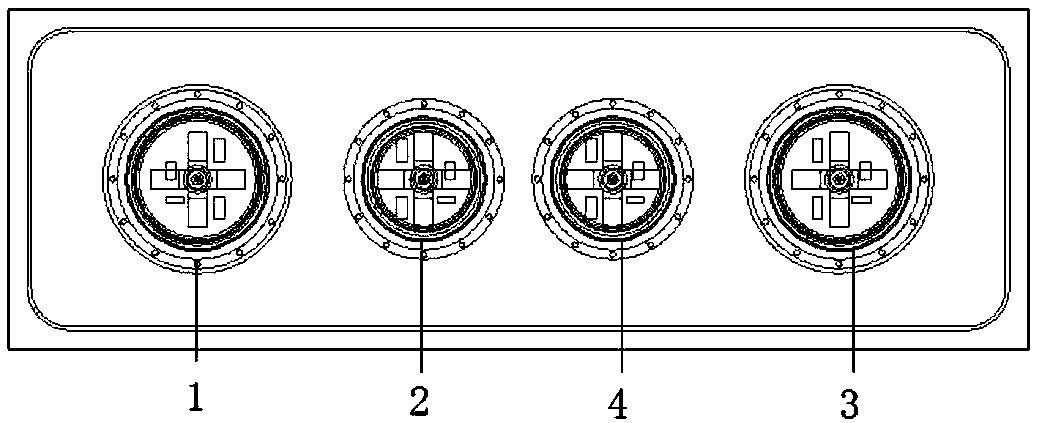

[0080] The parallel plate capacitor structures inside the four multifunctional layers on each sensor unit are the same. For simplicity of description, only the internal structure of the first multifunctional layer 1 is used as an example for illustration.

[0081] Such as Figure 15 , 16 , 21, and 22, the upper cross-shaped common electrode 6 of the first multifunctional layer 1 forms four parallel plate capacitors C3, C4, C5, and C6 with the four rectangular independent electrodes 7 corresponding to the lower layer, and the second multifunctional The upper cross-shaped common electrode 6 of layer 2 forms four parallel plate capacitors C7, C8, C9, and C10 with the four rectangular independent electrodes 7 corresponding to the lower layer respectively, and the upper cross-shaped common electrode 6 of the third multifunctiona...

Embodiment 2

[0101] In this embodiment, the detection unit used to detect the three-dimensional force inside the multifunctional layer is a piezoresistor.

[0102] Such as Figure 23-26 As shown, the structure and function of the multifunctional layer are the same as those of the multifunctional layer in Example 1. However, the structure used to measure the three-dimensional force inside the multifunctional layer is changed from a parallel plate capacitor to a piezoresistor, and the internal electrode structure of the multifunctional layer remains unchanged, but four are added between the upper cross-shaped common electrode 6 and the lower rectangular independent electrode 7 The rectangular flexible varistor 21, the upper cross-shaped common electrode 6 and the lower 4 rectangular independent electrodes are used as the two poles of the varistor 21. When subjected to a normal force, the four varistors 21 are subjected to the same deformation pressure. In the case of axial force and sliding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com