Aseptic rtd peanut milk and method of making thereof

An emulsifier and milk protein technology, applied in the field of plant protein dairy beverages, can solve problems such as not being able to match the growing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] Example 1 - Composition of RTD Peanut Milk Beverage

[0120] Table 1 shows two non-limiting examples of ingredient ranges for RTD peanut dairy beverages containing a thickening / stabilizing system, where the thickening / stabilizing system in beverage 1 is a gellan gum stabilizing system, and the gellan gum stabilization system in beverage 2. The thickening / stabilizing system is gellan gum / sodium caseinate stabilizing system. Ingredients are listed in amounts expressed as percent by weight of the beverage.

[0121] Table 1: Exemplary RTD Peanut Dairy Beverages

[0122]

[0123]

Embodiment 2

[0124] Components of embodiment 2-peanut milk product beverage and its preparation process

[0125] The formulations of peanut milk beverages with different stabilization systems are disclosed in Table 2. Ingredients are listed in amounts expressed as percent by weight of the composition.

[0126] Beverages may be prepared using any suitable method. As a non-limiting example, a method for preparing Formulation 1 is provided as follows:

[0127] Dissolve 8g of skimmed milk powder in a milk solution tank filled with 100g of 65°C hot water and shear at 4000rpm for 10min. 1.8g of sodium caseinate (emulsifier) was added to the milk solution tank and kept at a shear rate of 4000rpm for 10min. Dry gellan gum (Kelcogel HMBPC 0.39g) and 10g sugar were dissolved in 500g hot water at 70°C, and kept at a shear rate of 4000rpm for 10min to obtain a stabilizer solution. The stabilizer solution was added to the milk solution tank and kept at a shear rate of 4000 rpm for 10 min. The ...

Embodiment 3

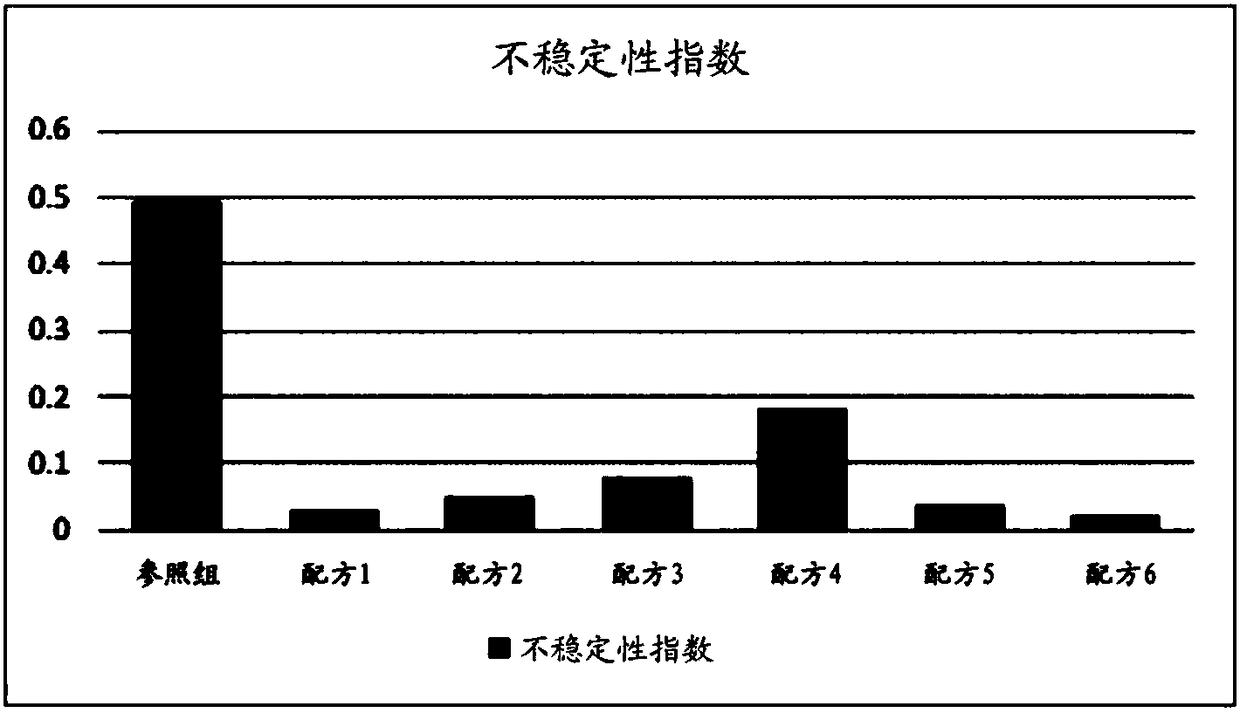

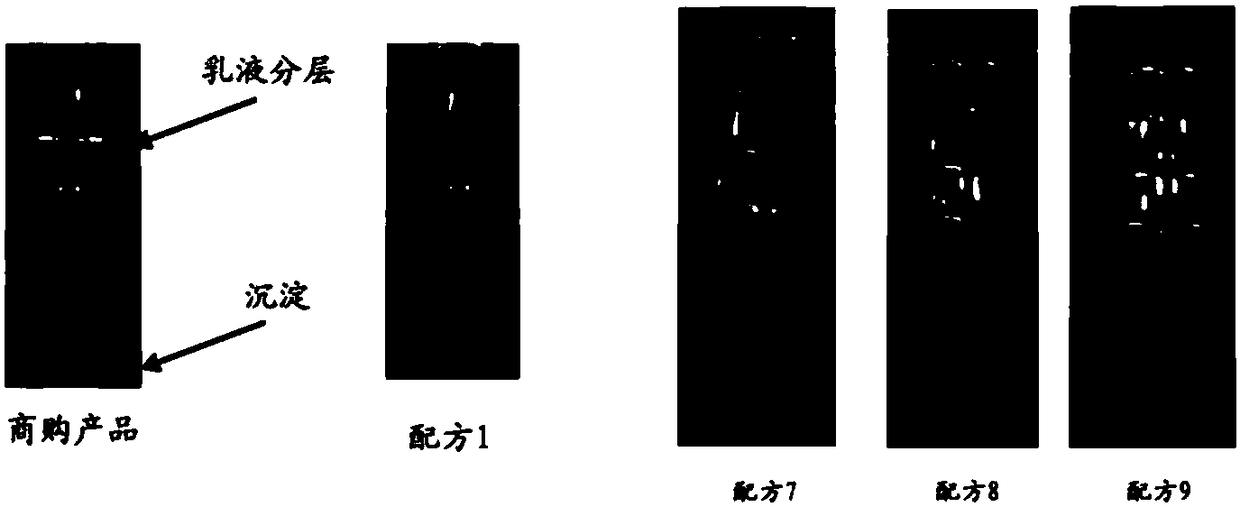

[0134] Example 3 - Physical Stability Evaluation of Prepared Beverages

[0135] The physical stability of all tested beverages listed in Table 2 was evaluated by using the following assays, where the reference beverage in Table 2 was used as a control.

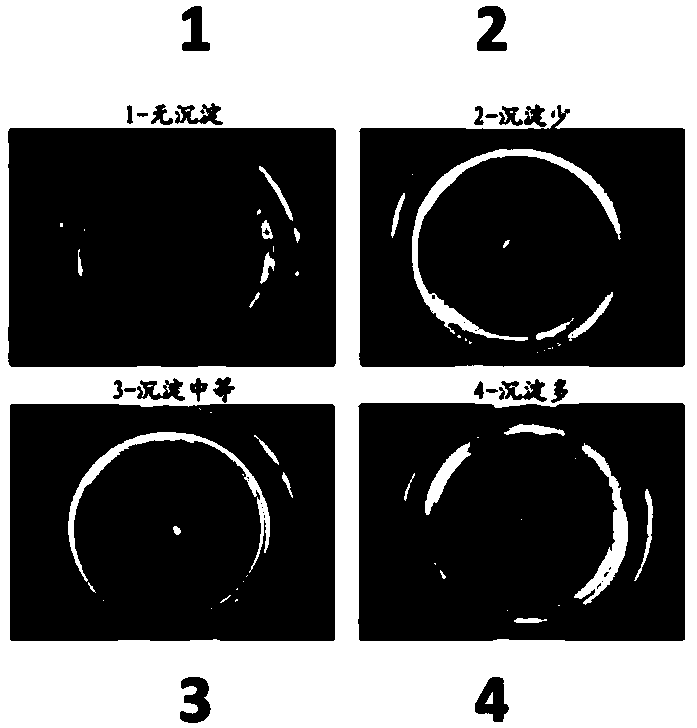

[0136] Physical stability was assessed by combining LUMISizer analysis and visual observation.

[0137] 1. LUMISizer analysis

[0138] Suspension stability was assessed by analysis using LUMISizer. The LUMISizer is a temperature-controlled benchtop dispersion / stability analyzer for the comprehensive characterization of emulsions and suspensions. Various rectangular sample chambers and the analysis software SEPView make the device ideal for analyzing low or highly concentrated dispersions and analyzing sedimentation or emulsion separation during centrifugation.

[0139] The Lumisizer operates using the principle of centrifugation of the sample at different g forces for a given time. A transmission profile is generated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com