Transmission device and drive unit having transmission device

A transmission device and drive unit technology, applied to transmission devices, gear transmission devices, transmission device parts, etc., can solve problems such as noise, wear, and ball bearings that are not suitable for large axial forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

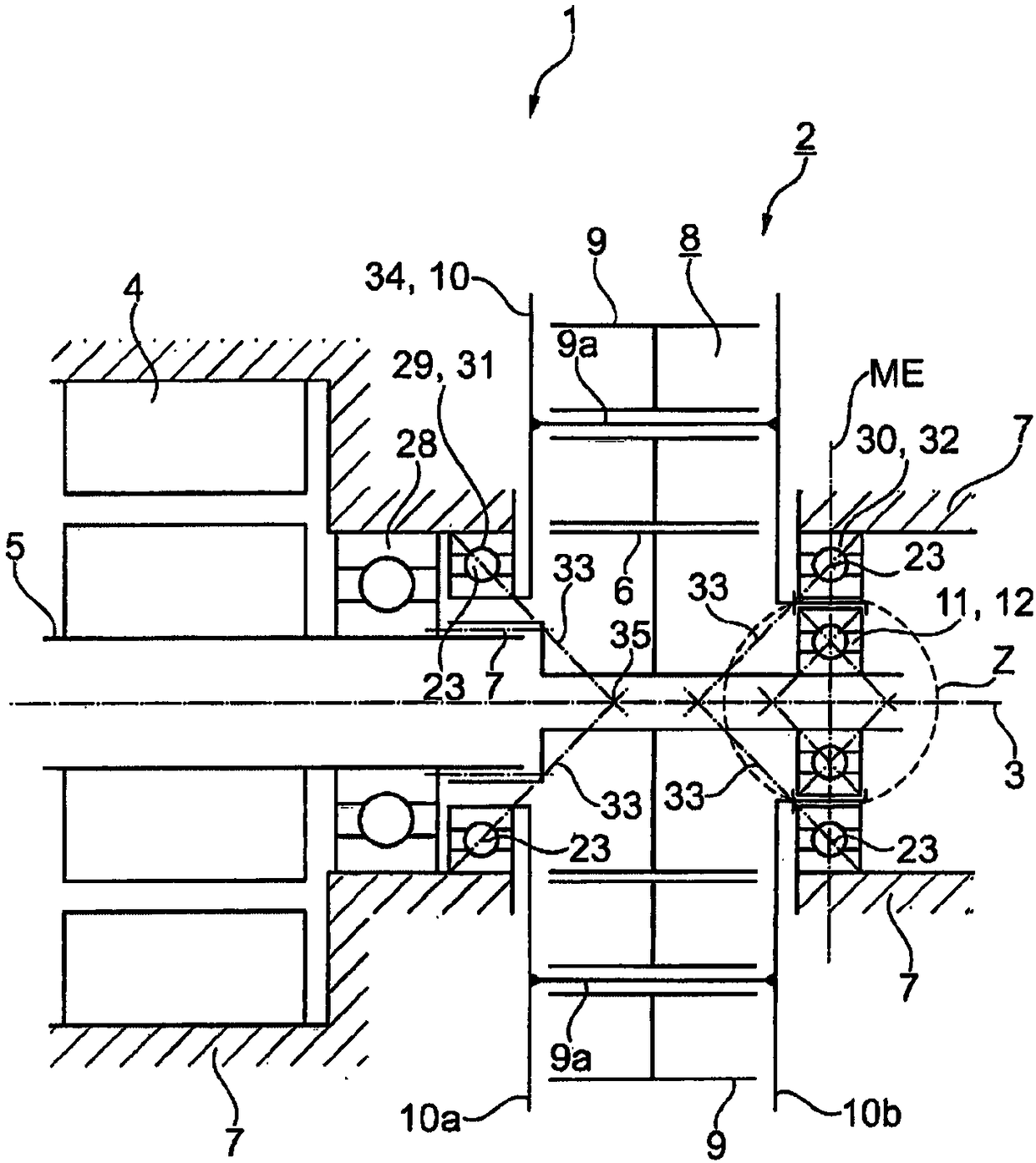

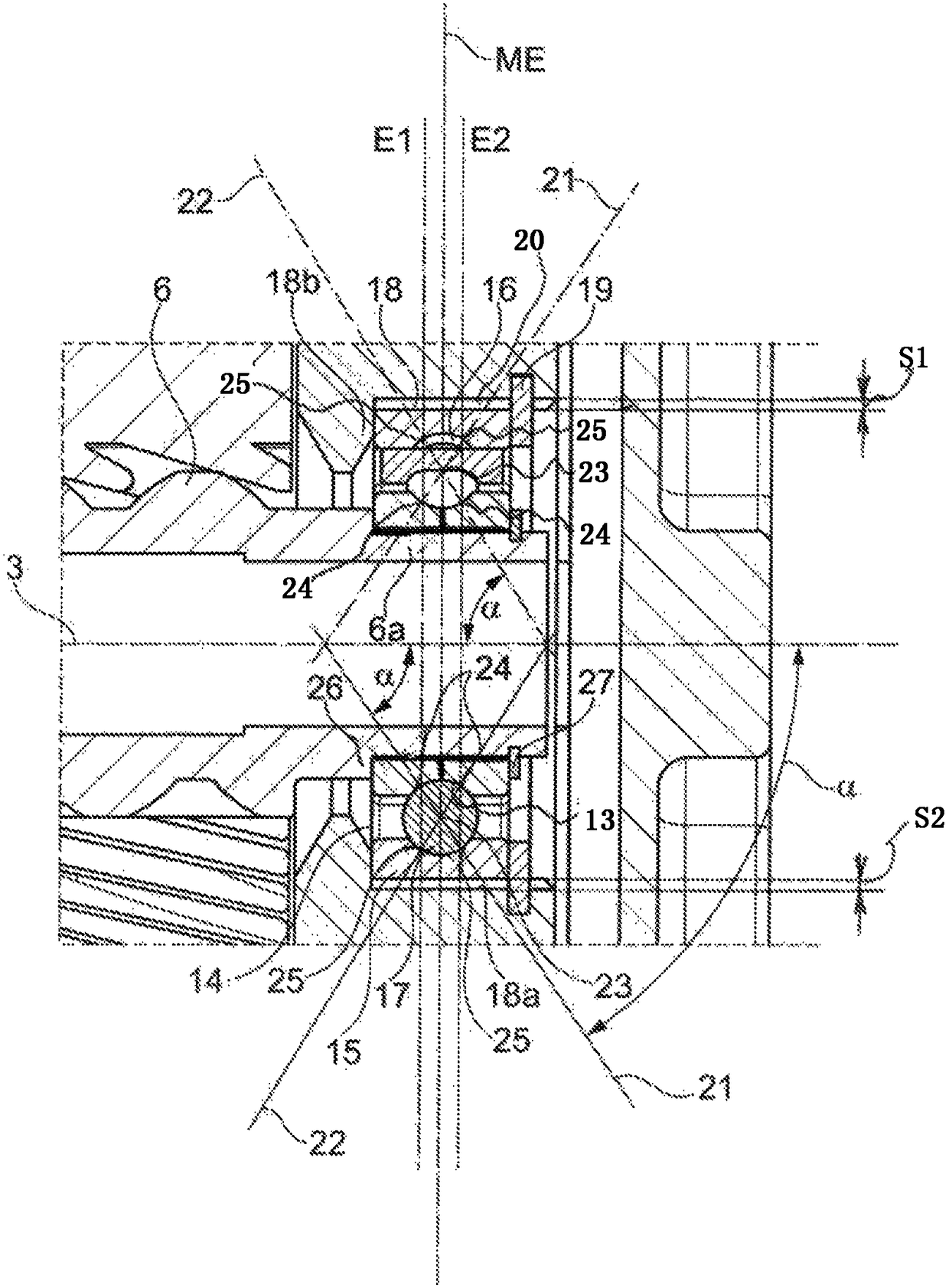

[0031] figure 1 : The drive unit 1 has an electric motor drive 4, the rotor shaft 5 of which is operatively connected to the sun gear 6 of the transmission 2 via a form-fit connection. The form-locking connection is produced, for example, by means of splines, so that the sun gear 6 can be displaced axially in a limited manner relative to the rotor shaft 5 . This ensures that no axial force of the sun gear 6 can be applied to the bearing 28 of the rotor shaft 5 . The transmission 2 is not shown completely. Parts of the housing 7 and the planetary gear 8 can be seen. The planetary transmission 8 is composed at least of a planet carrier 10 , a sun gear 6 and a set of planet gears 9 . The planet carrier 10 has two carrier plates 10 a and 10 b on which the planet pins 9 a are carried. The planet wheels 9 are seated on the planet pins 9a. The axes of rotation of the sun gear 6 and of the planet carrier 10 are each the central axis 3 . The sun gear 6 is axially supported or sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com