SCR (selective catalytic reduction) denitration system control method for preventing urea from being excessively sprayed

A control method, urea injection technology, applied in SCR denitrification, SCR denitrification system control field to prevent excessive injection of urea, can solve problems such as large input deviation, and achieve the effect of avoiding continuous abnormal increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

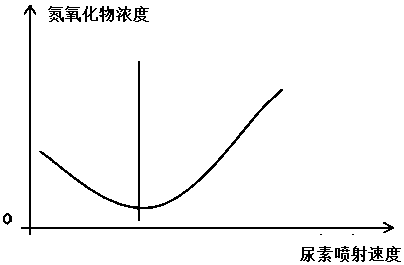

[0019] Such as figure 1 As shown, after the urea injection speed is greater than the turning point, the continuous increase of urea injection will not only fail to reduce the emission of nitrogen oxides due to the state of excessive injection of urea, but will increase the emission of nitrogen oxides significantly, which cannot be effectively controlled by the traditional PID mode ,definition figure 1 The left side of the straight line passing through the turning point is the linear work area, and the right side is the nonlinear work area. In order to overcome the defects of traditional control methods, the present invention discloses a control method of SCR denitrification system to prevent excessive injection of urea, including the following steps:

[0020] Step 1. Turn on the machine and enter the PID mode. In the PID mode, set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com