Fresh tea leaf winnowing machine

A technology of air separator and fresh tea leaves, which is applied in the direction of solid separation, sieve, grille, etc., can solve the problem that the quality of air separation is not as good as that of open type models, etc., and achieve the effect of accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

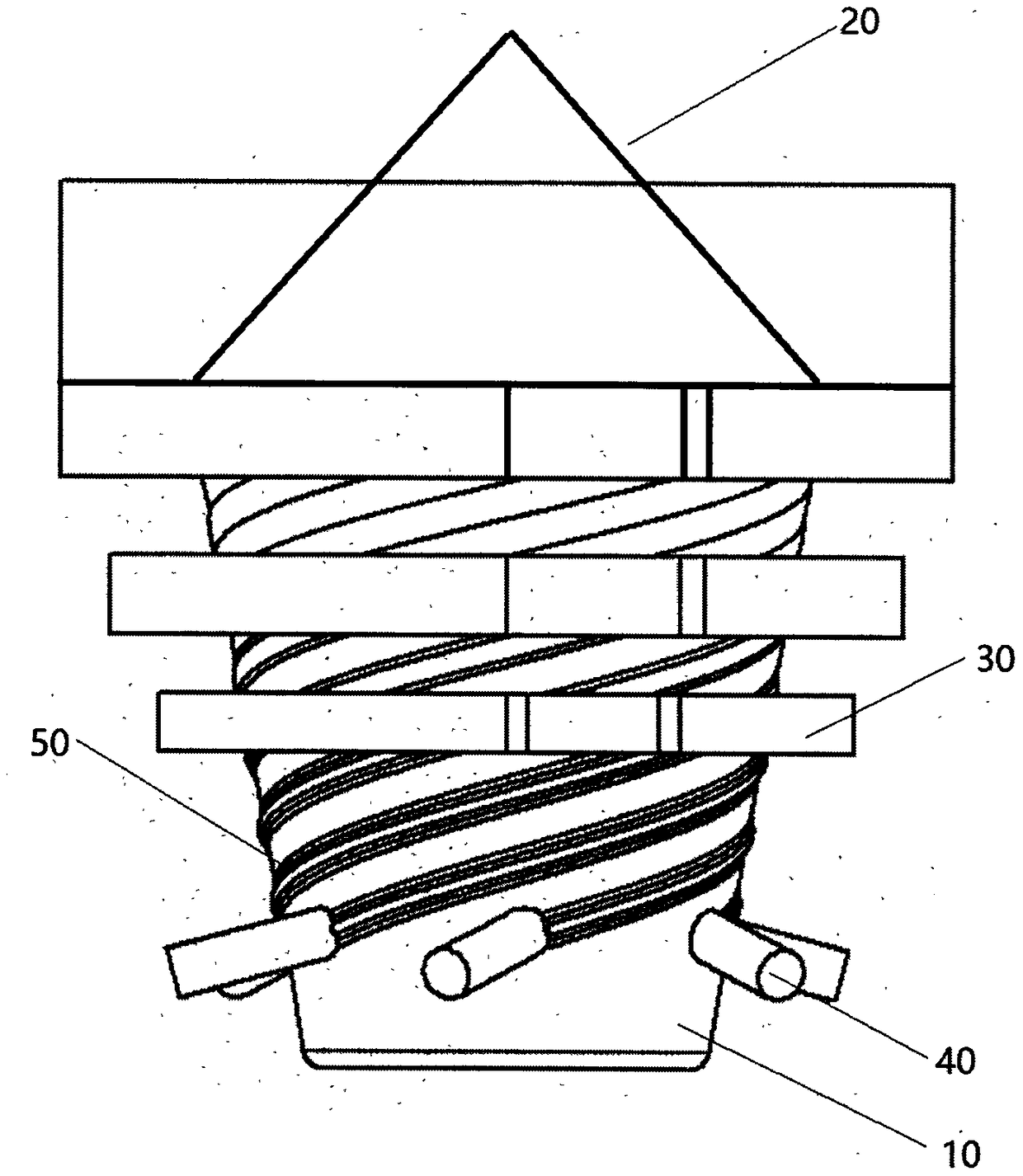

[0026] Such as figure 1 and Figure 4 As shown, it is a schematic diagram of the planar structure of a kind of air separator for fresh tea leaves of the present invention and a schematic diagram of the structure of its micro-fan, including a rounded truncated housing 10, the upper surface of which is a feed inlet, The feeding port is connected with a conical sieve 20. The conical sieve 20 is a conical shape placed upright. The sides of the conical sieve 20 are all screens 201, and the mesh sizes of the screens 201 are set from small to large from top to bottom. The outer surface of 20 also has a left spiral descending ramp to slow down the descending process of fresh tea leaves on the cone sieve 20, so that the screening process of the cone sieve 20 is finer; Dust removal device: several outlets are evenly arranged at three different levels on the inner wall of the rounded frustum-shaped housing 10, and the number of outlets arranged at the same level is six, and the sizes of...

Embodiment 2

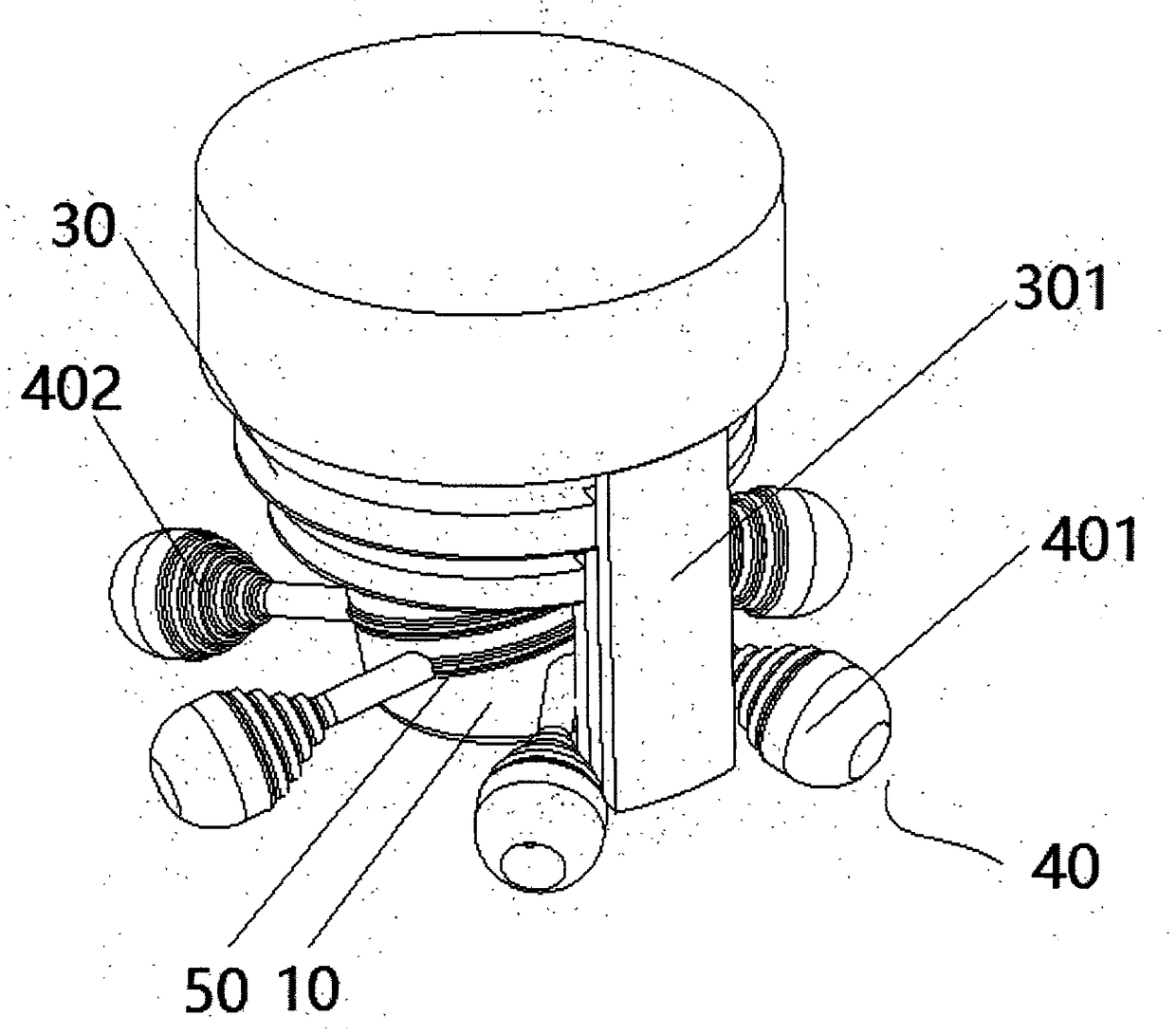

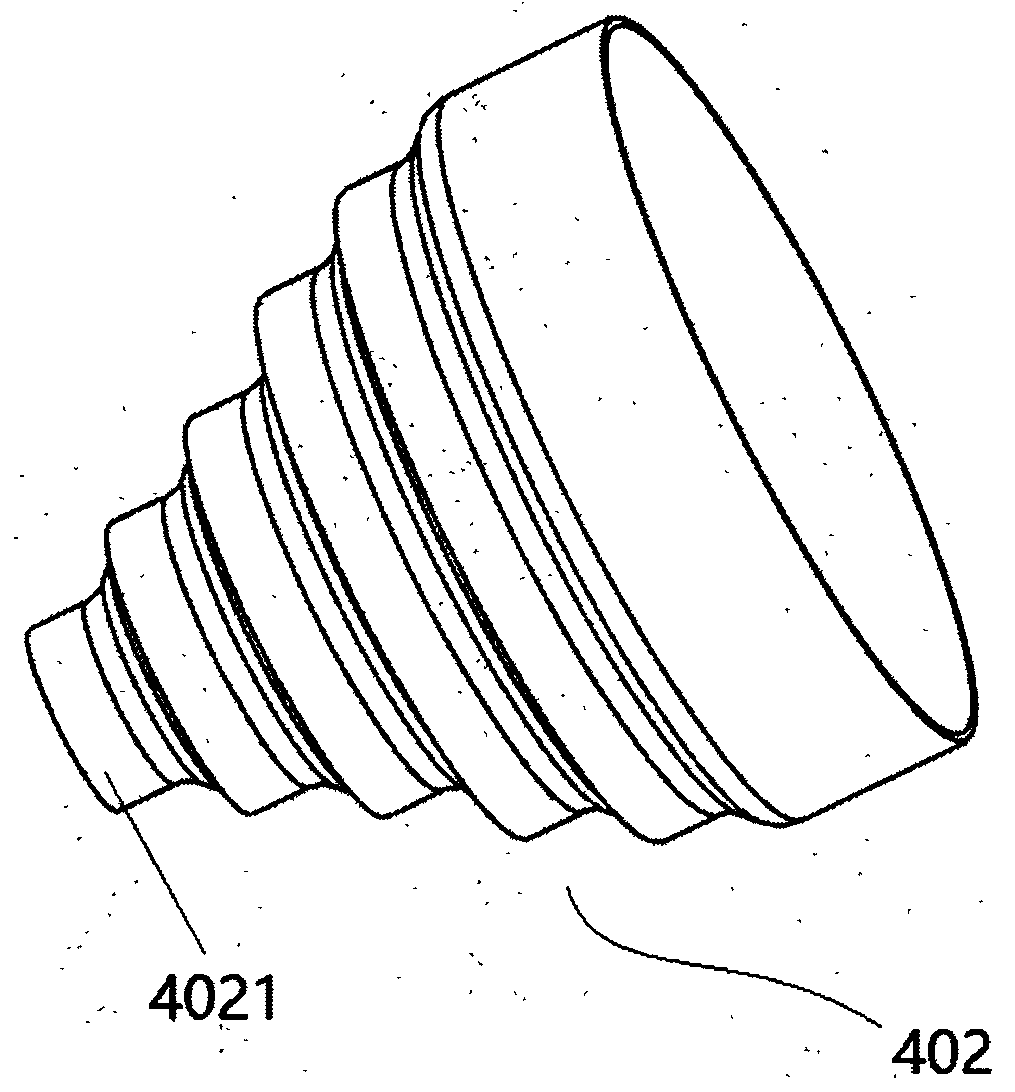

[0037] Such as Figure 2-3 As shown, it is a schematic diagram of the three-dimensional structure of Embodiment 2 of the present invention and a schematic diagram of the structure of the retractable corrugated shell 402. On the basis of Embodiment 1, the blowing device 40 can be configured to include a hard hemispherical shell 401 and a retractable corrugated shell 402. , the hard hemispherical shell 401 and the retractable corrugated shell 402 are connected to form a hollow cavity, and a fan is arranged in the hollow cavity, and the fan shown is electrically connected to the controller. It is airtightly connected with the air inlet of the shell. The fan injects wind into the shell through the air inlet on the rounded table-shaped shell 10, and the wind forms a stable wind field along the air guide rail. Through the retractable corrugated shell 402, the relative relative to the shell when the wind enters the rounded table shell can be adjusted. The angle of the side wall meet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com