Method for determining geological state of rock mass in real time by monitoring drilling process of pneumatic bolt drilling machine

A technology for bolting rigs and drilling parameters, which is applied in the field of real-time determination of the geological state of surrounding rock and rock mass, can solve the problems of limited application scope, time-consuming and labor-intensive, etc., and achieves the effects of wide applicability, avoidance of limitations, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

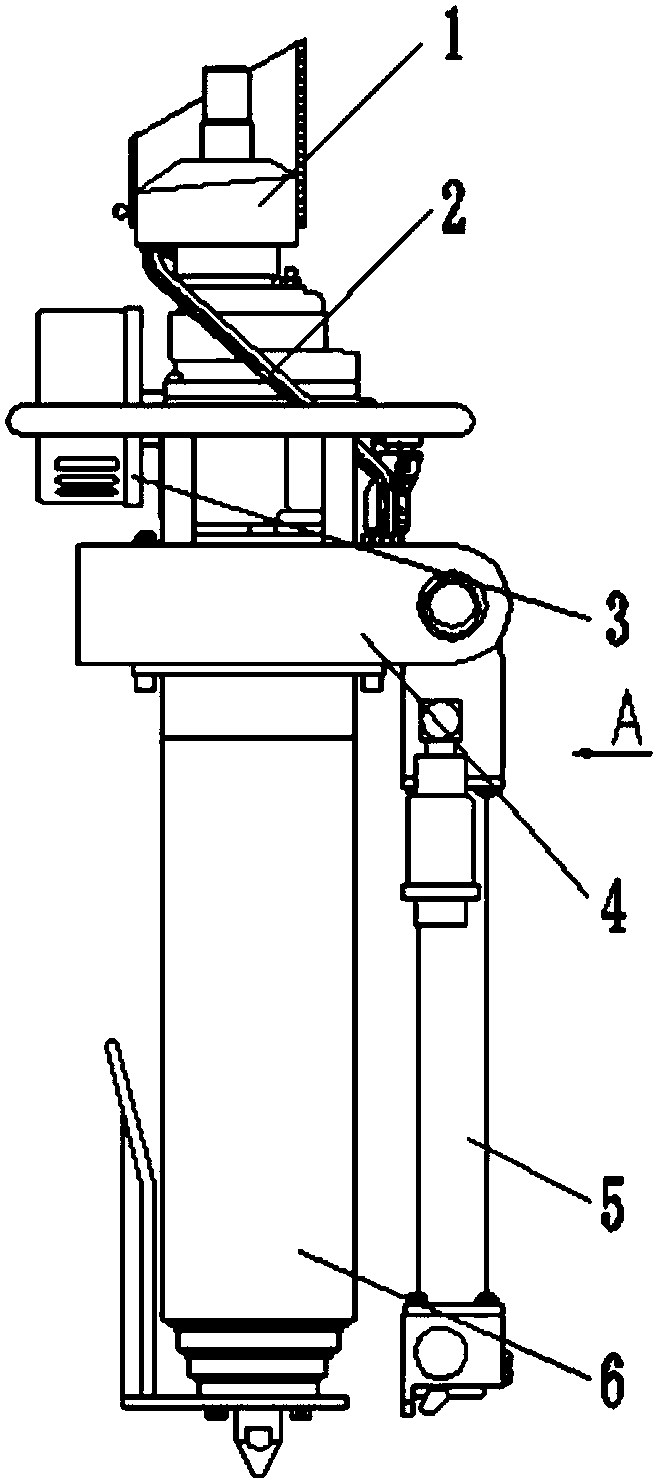

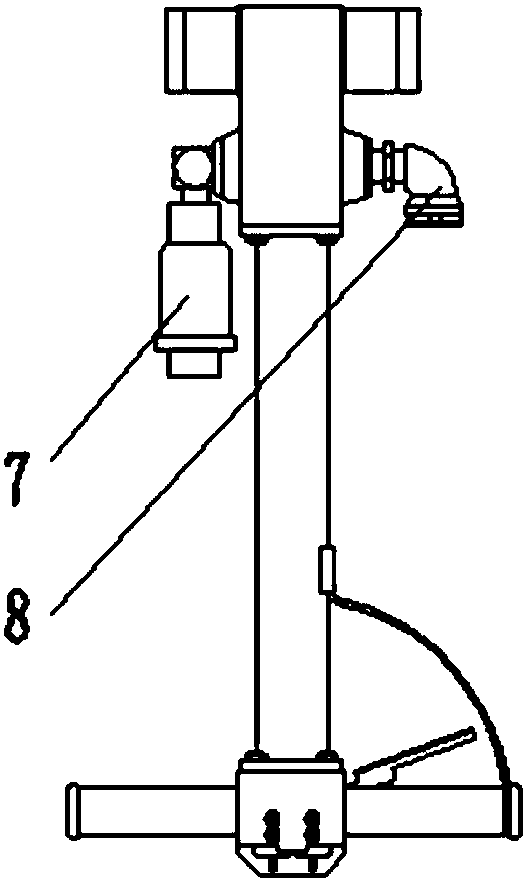

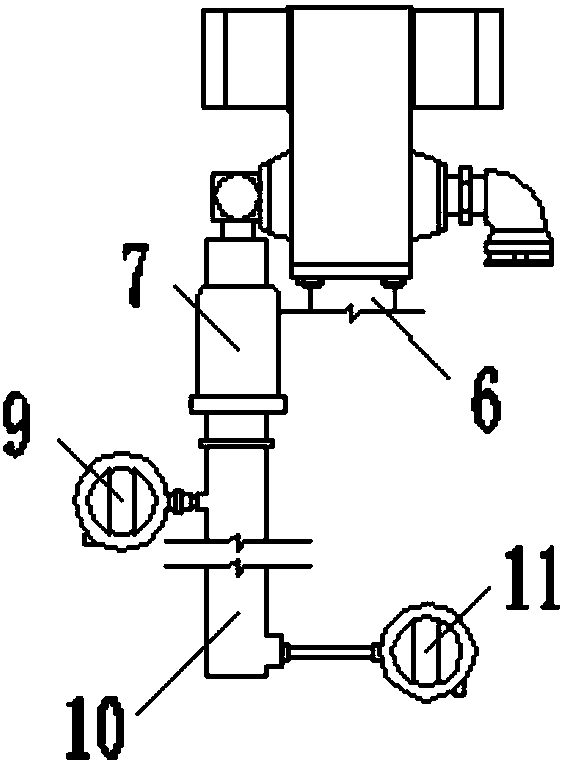

[0028] The present invention will be further explained below in conjunction with the accompanying drawings.

[0029] Such as Figure 5 As shown, the method for determining the geological state of the rock mass in real time during the drilling process of the pneumatic rock bolter includes the following steps:

[0030] Step 1: Connect the pressure gauge and flowmeter in series to the motor intake pipeline of the pneumatic rock drill, install the Hall speed sensor vertically on the drill pipe of the pneumatic rock drill, and obtain The operating parameters during the drilling process of the pneumatic rock bolter include the intake pressure P and air consumption Q of the motor, as well as the rotation rate ω and the penetration rate v of the drill pipe.

[0031] Step 2: For the air motor, calculate the output torque M of the air bolter according to the relationship between the output torque M of the air bolter, the air consumption Q, and the rotation rate ω under a certain intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com