Paint brushing system for back of T-shaped elevator guide rail

A technology for elevator guide rails and guide rails, which is applied in the direction of pretreatment of surfaces, devices for applying liquid to surfaces, coatings, etc., can solve problems such as uneven paint thickness, high maintenance costs, and large workload, and reduce damage. risk, motor drive is smooth, rollover is gentle and gentle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

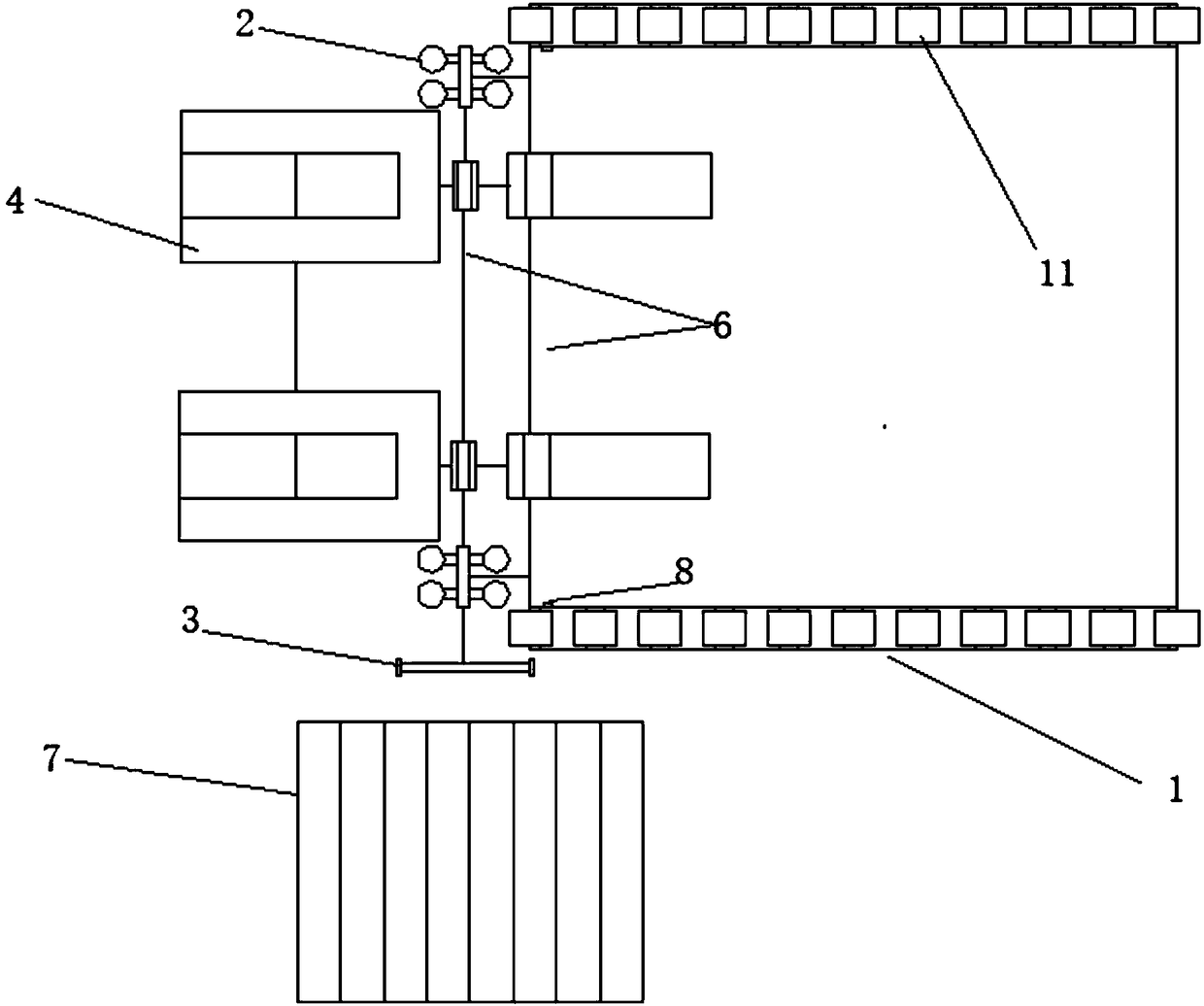

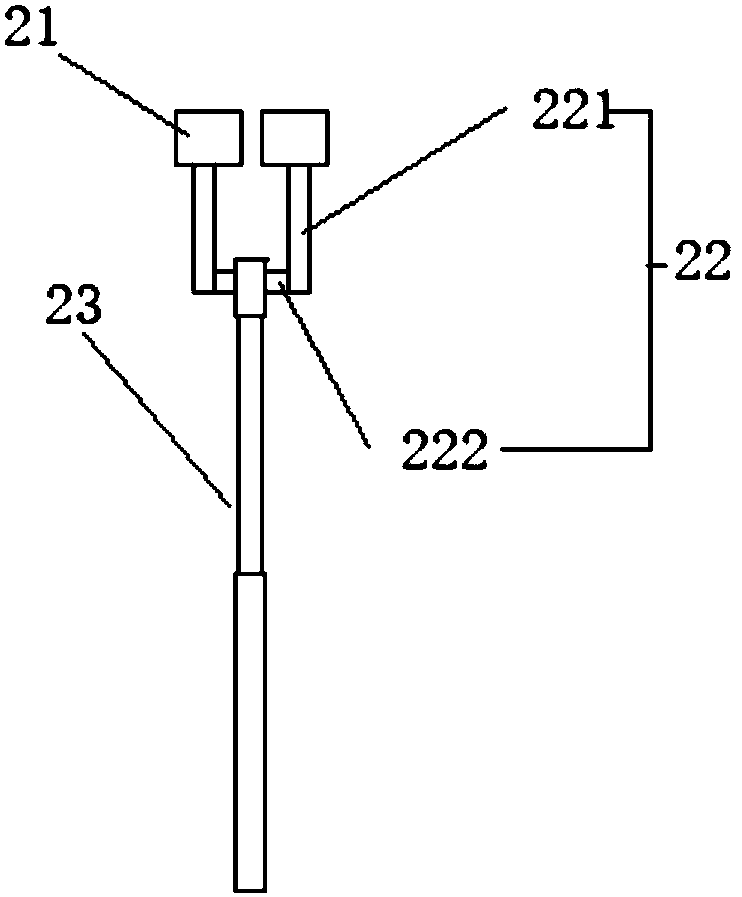

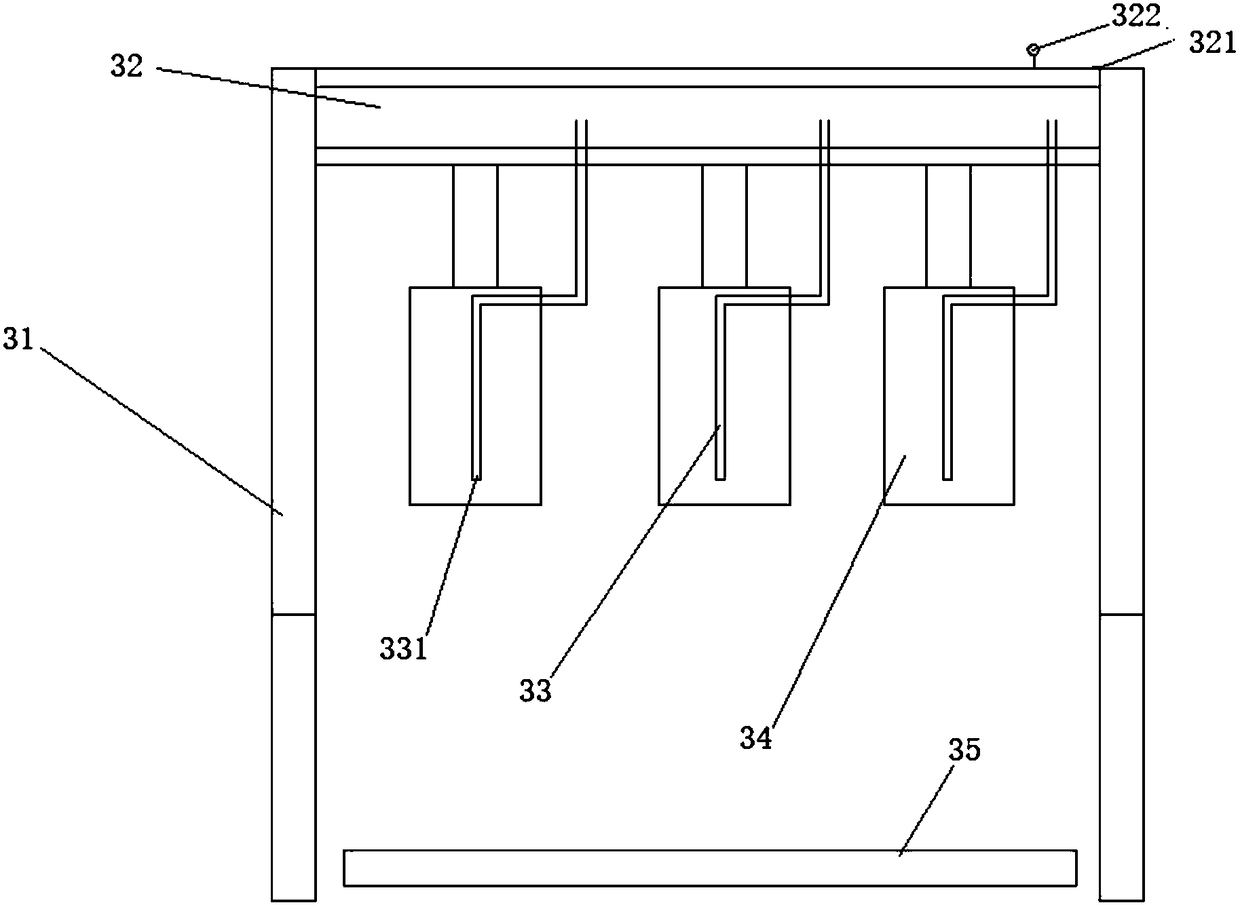

[0035] Such as Figure 1-4 As shown, a T-shaped elevator guide rail backside painting system includes: a support 6 and a horizontal conveying device 1 arranged on the support 6, a longitudinal conveying device 2, an automatic guide rail painting device 3, and a guide rail turning device 4.

[0036] Wherein the lateral conveying device 1 comprises two conveying tracks 11 arranged side by side, and the distance between the two conveying tracks 11 is not greater than the length of the elevator guide rail 5 . Two conveying tracks 11 are respectively placed at two ends of the elevator guide rail 5 during conveying, the guide rail rail body 51 faces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com