Novel efficient tilt rotor unmanned aerial vehicle

A technology of unmanned aerial vehicles and tilt rotors, applied in the field of aviation products, can solve the problems of reduced aircraft aerodynamic efficiency, poor control performance, low efficiency of vertical rotors, etc., to achieve enhanced pitch control performance, enhanced heading control performance, and improved battery life the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

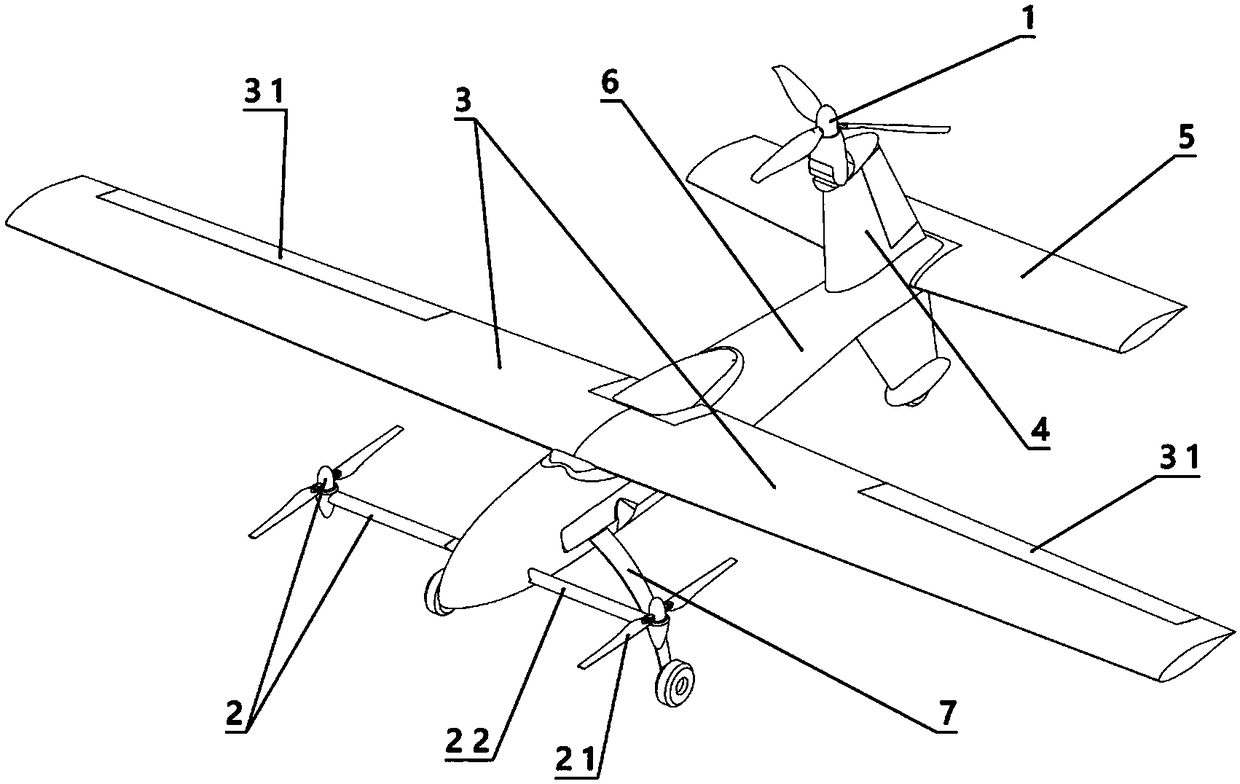

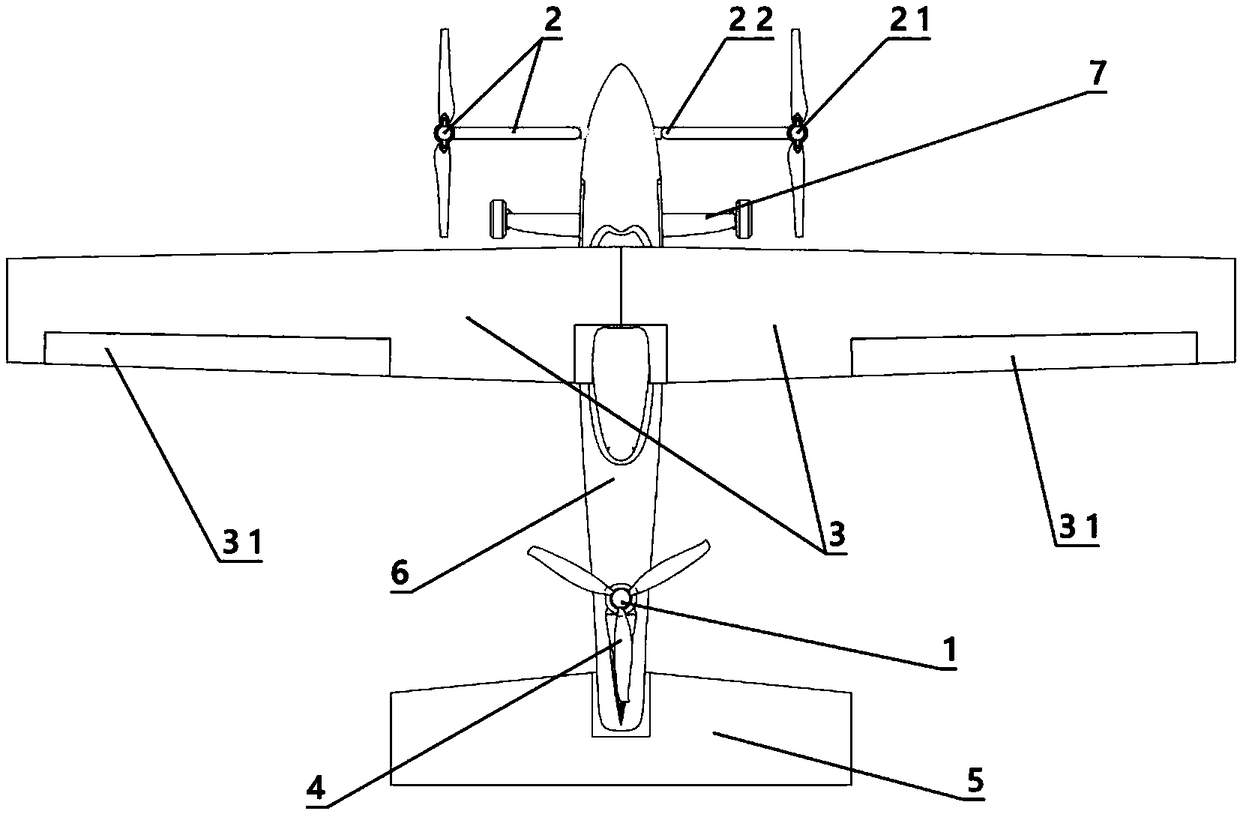

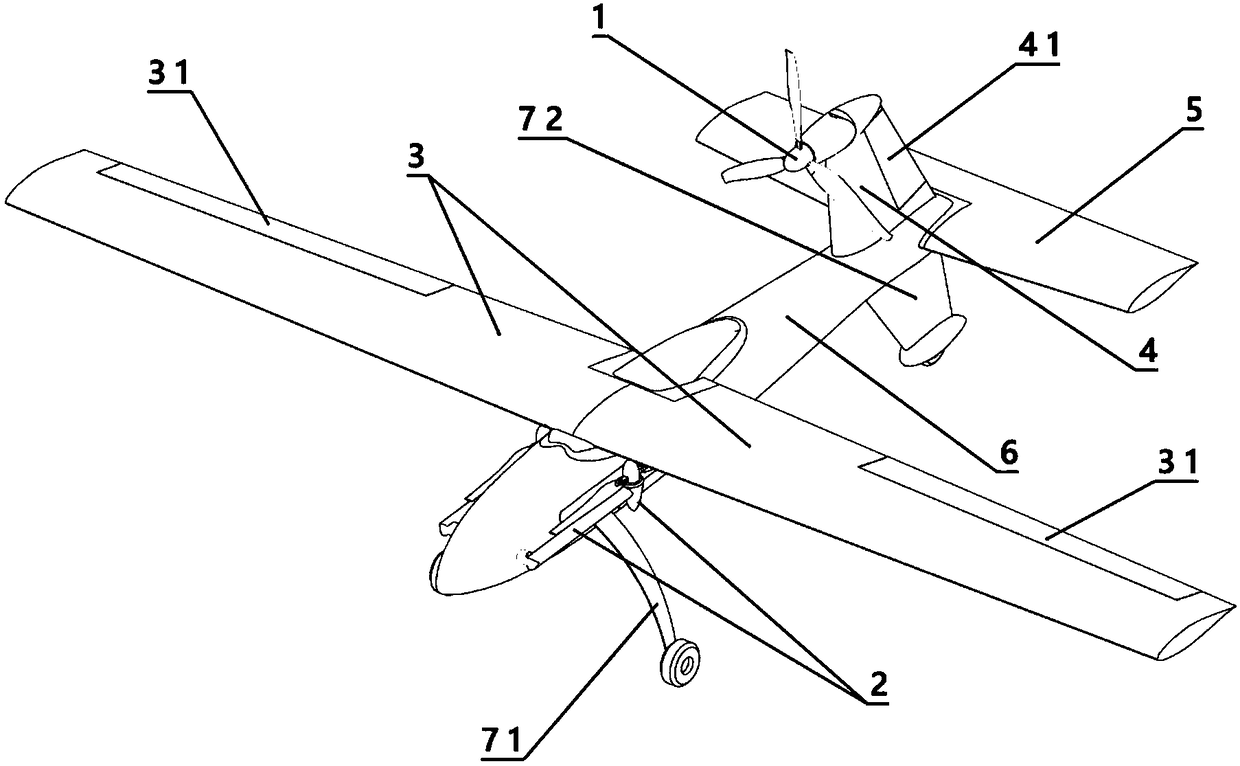

[0027] Figure 1-5 Shown is the basic structural layout and operation mode of a novel high-efficiency tilt-rotor unmanned aerial vehicle of the present invention. The aircraft includes: tilting rotor (1), vertical flying mechanism (2), fixed wing (3), fixed vertical tail (4), full-moving horizontal tail (5), fuselage structure (6) and landing gear (7) , which is characterized in that the tilt rotor is located at the top of the vertical tail and can be tilted in both horizontal and vertical directions; the vertical flight mechanism can be folded to both sides of the fuselage.

[0028] The aircraft can fly in three flight states, including: vertical flight state, transition state and flat flight state. figure 1 , figure 2 The relative positions of the tilt rotor (1) and the vertical flight mechanism (2) and the fuselage structure (6) in the vertical flight state of the present embodiment are shown; image 3 , Figure 4 When showing the level flight state of the present embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com