A storage device for construction materials

A technology for construction engineering and storage devices, applied in packaging, transportation and packaging, external frames, etc., can solve the problems of lack of good wind and rain protection measures, rusting of steel bars and metal pipes, affecting the overall efficiency of the project, etc. The effect of green safety management, reducing rust and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

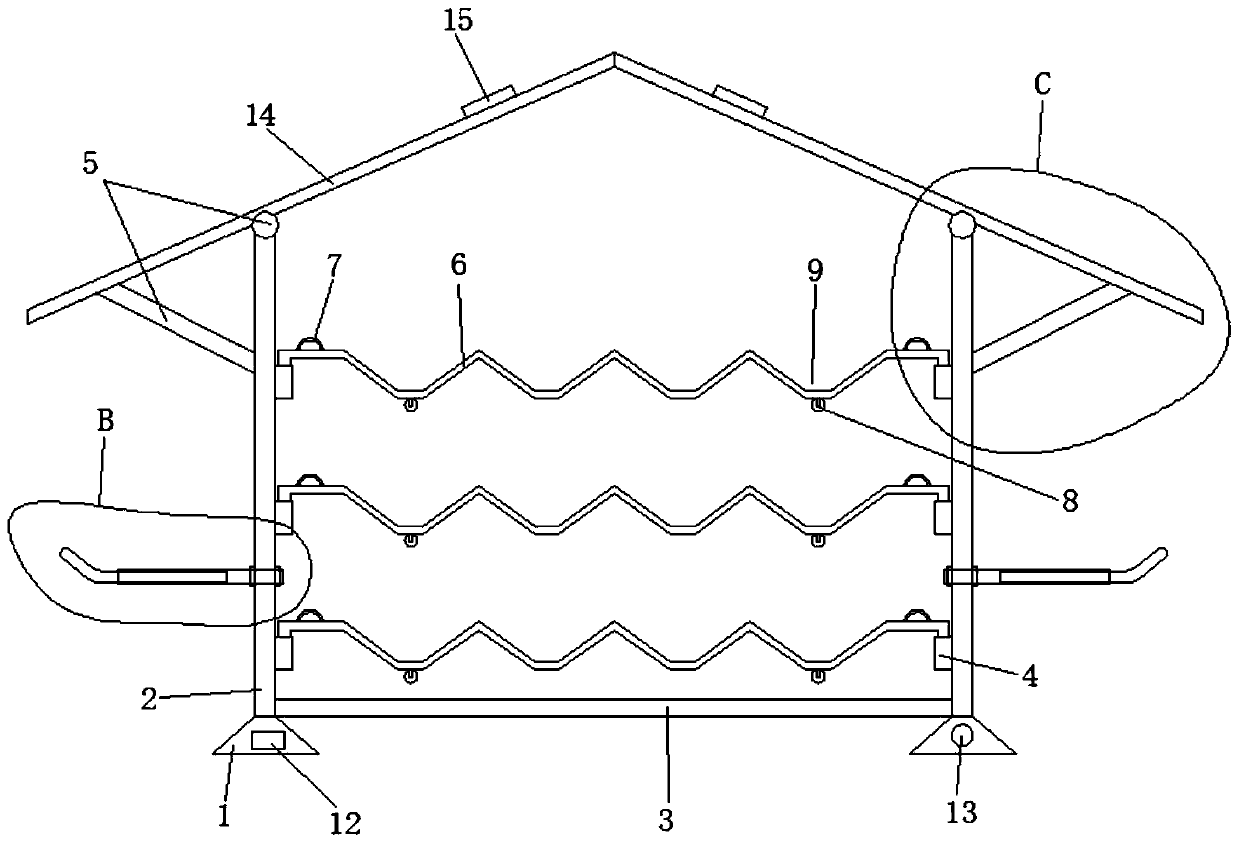

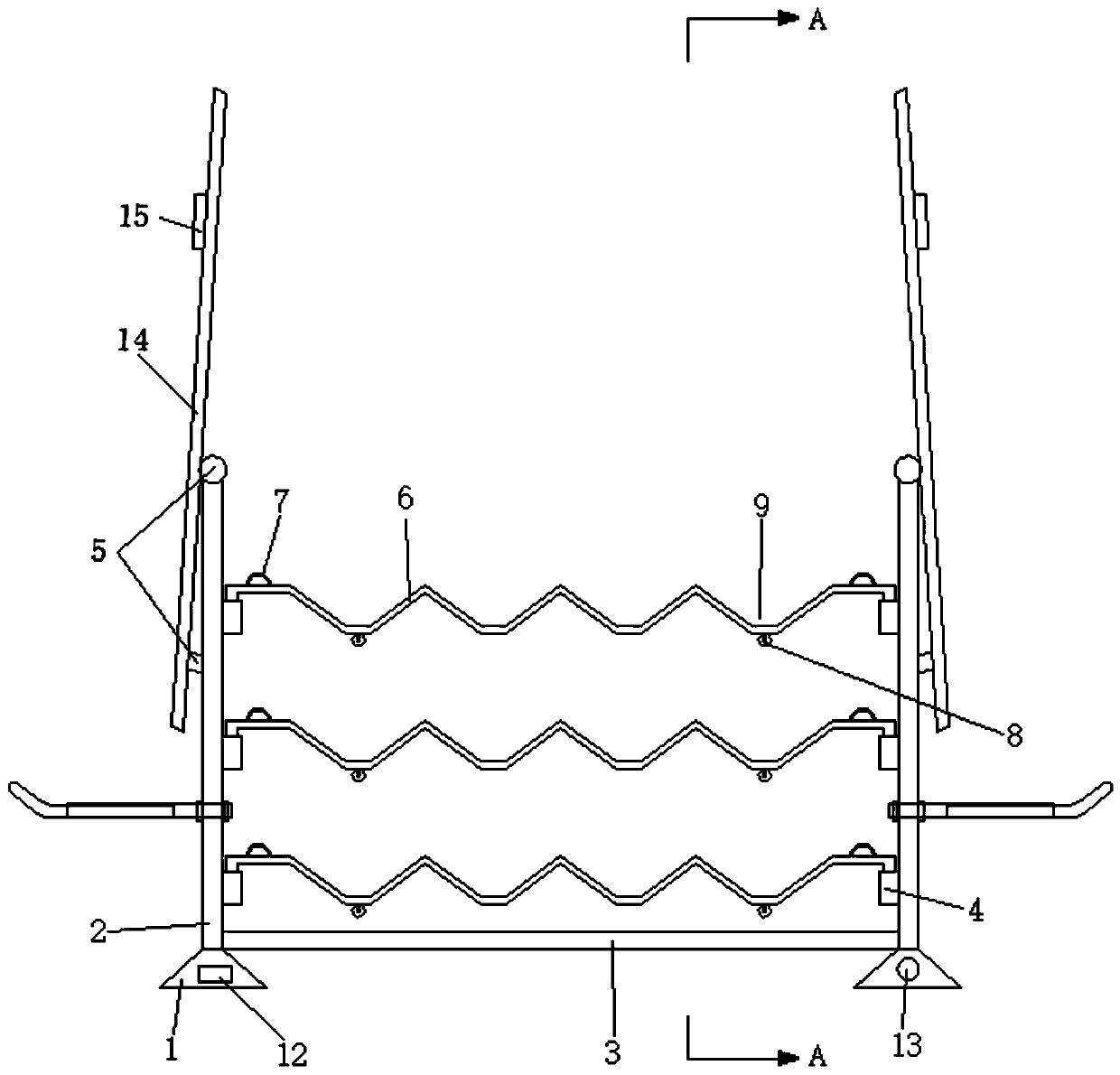

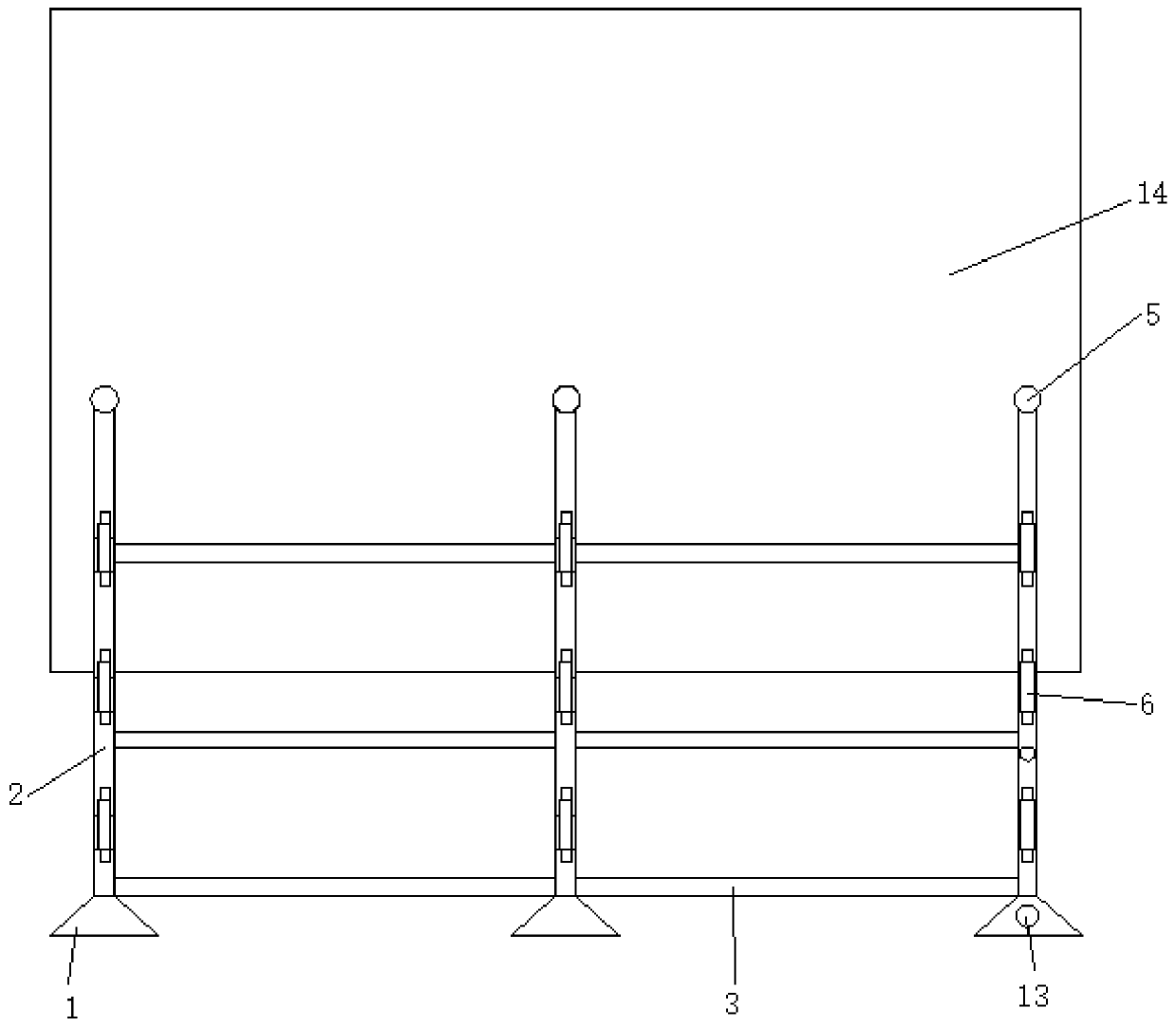

[0029] The invention provides a material storage device for construction engineering, specifically as Figure 1 to Figure 6 As shown, it includes a shielding device, a support frame and multiple sets of storage units; the device is mainly used to store wooden formwork, steel bars and metal pipes.

[0030] The supporting frame includes at least four supporting bodies. The four supporting bodies are arranged front and back in pairs. Each supporting body includes a base 1 and a column 2 arranged on the base 1. The lower ends of two adjacent columns 2 pass through connecting rods 3. In connection, a plurality of sleeves 4 are uniformly arranged on the column 2 along the height direction, the sleeves 4 on each group of the columns 2 are arranged oppositely, and an angle adjusting device 5 is arranged on the upper part of the column 2;

[0031] Each storage unit includes a cross brace 6, two lifting rings 7 and at least two universal wheels 8 with self-locking function. The cross brace 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com