An in-situ synthesized carbon nanotube/hafnium boride nanocomposite material and its preparation method

A technology of carbon nanotubes and composite materials, applied in the field of materials, can solve the problems of difficult dispersion, inability to completely eliminate, and easy agglomeration of carbon nanotubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

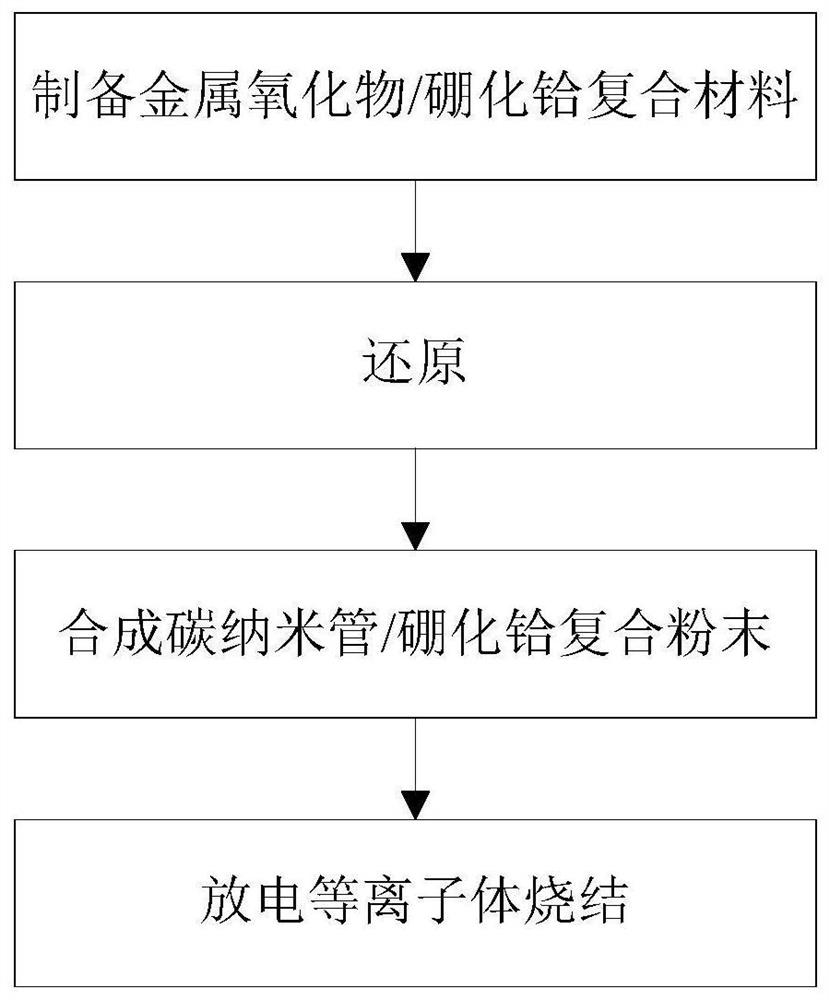

[0038] The invention provides a preparation method for in-situ synthesis of carbon nanotube / hafnium boride nanocomposite ceramic material, the preparation method comprising the following steps:

[0039] (1) Mix the nano-hafnium boride powder with the metal ion solution, adjust the pH of the mixed solution until the metal ions are completely precipitated, and then wash, dry, grind and calcinate the precipitate in sequence to obtain a metal oxide / hafnium boride composite material .

[0040] The particle size of the hafnium boride powder also has an influence on the mechanical properties of the carbon nanotube / hafnium boride nanocomposite powder. If the particle size of hafnium boride powder is too large, it may not be able to adsorb to the surface of the precipitate formed by metal ions, and if the particle size is too small, a large amount of agglomeration will occur, which will lead to uneven distribution of metal on the surface of hafnium boride, which will affect the carbon ...

Embodiment 1

[0056] Such as figure 1 As shown, the preparation method of the present embodiment comprises the following steps:

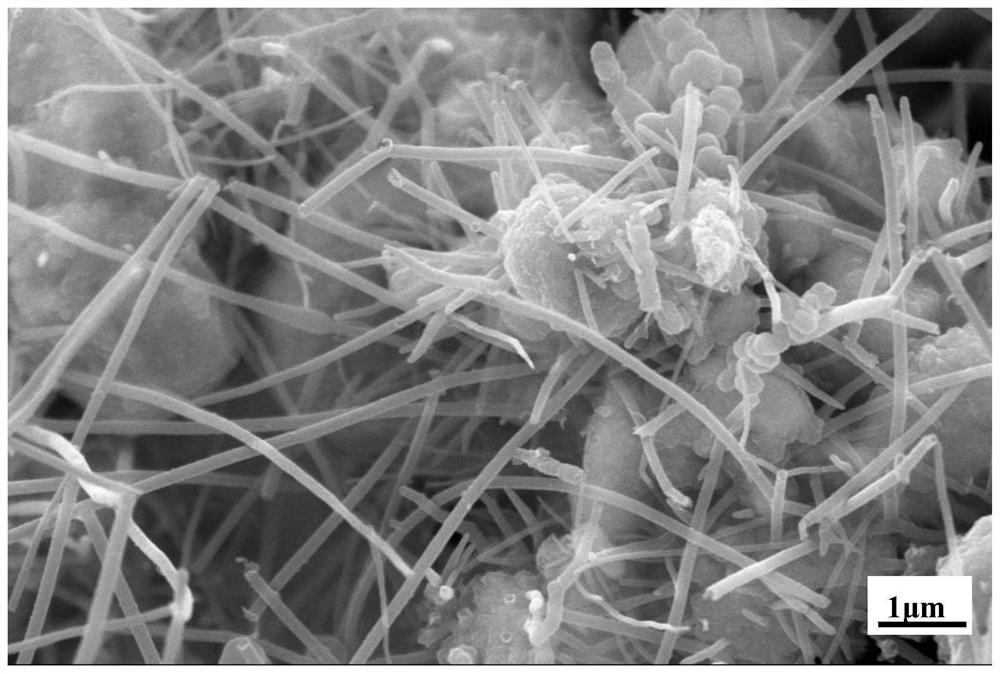

[0057] S1, adding nano-hafnium boride powder containing Ni 2+ In the deionized aqueous solution (prepared by dissolving nickel nitrate in deionized water), use a magnetic stirrer to continuously stir, and at the same time add NaOH aqueous solution to Ni 2+ Completely settled. After the above solution was left to stand for 24 hours, it was filtered and washed until the pH value was 7, and the solid precipitate was placed in an 80°C drying oven for drying treatment, and then ground to obtain Ni(OH) 2 Powder, Ni(OH) 2 The powder is placed in an atmosphere protection furnace, under N 2 Calcining at 600° C. for 2 hours under protection to obtain a NiO / hafnium boride composite material.

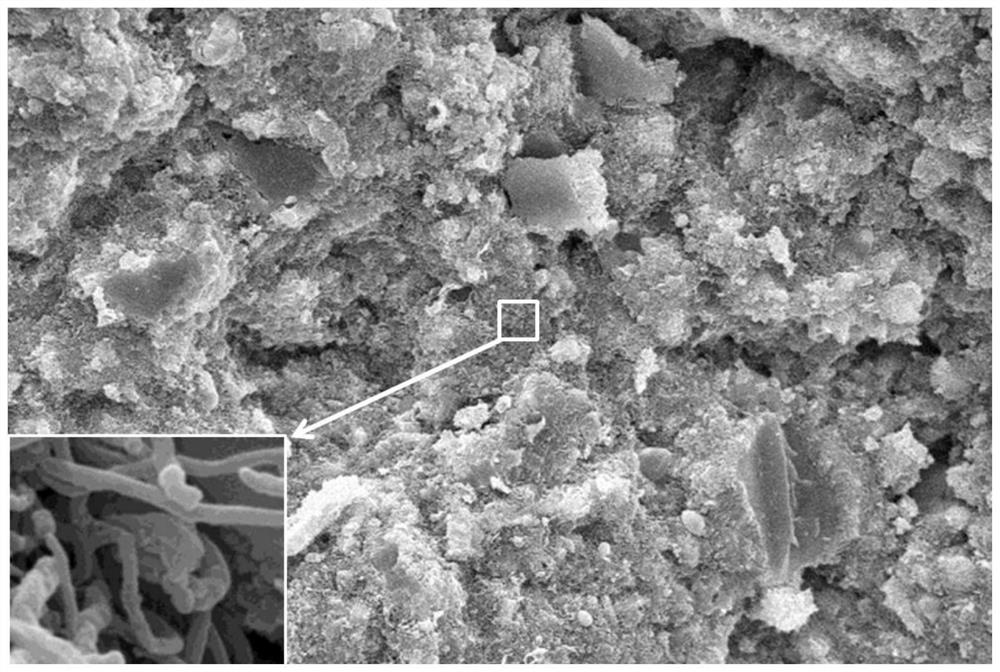

[0058] Put the NiO / HfB composite material into the constant temperature zone of the tube furnace and 2 Warm up to the reduction temperature of 600°C under protection, and then t...

Embodiment 2

[0064] Embodiment 2, Embodiment 3, and Embodiment 4 are carried out in the same manner as Embodiment 1, and the differences are shown in Table 3.

[0065] The preparation process conditions of each embodiment of table 3

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com