Novel high-damping rigidity-variable extruding type earthquake isolation device

A technology with variable stiffness and high damping, which is applied in the field of new high-damping variable stiffness extrusion-type seismic isolation devices, can solve the problems of low damping energy consumption performance and weak energy consumption capacity of shear-type seismic isolation, so as to improve the isolation energy consumption. The effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

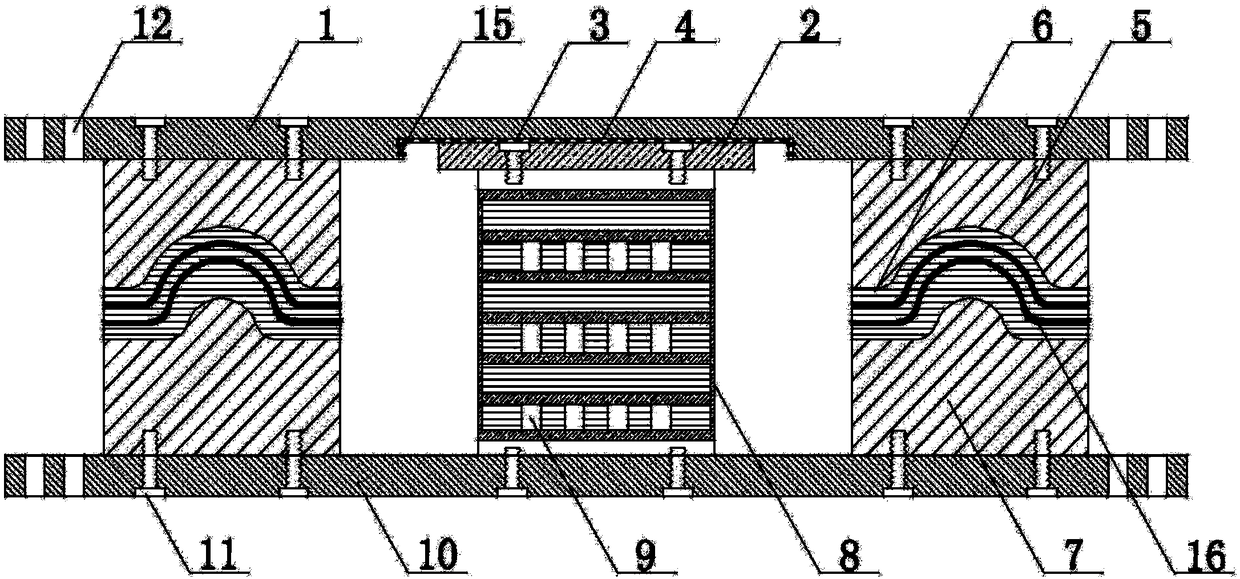

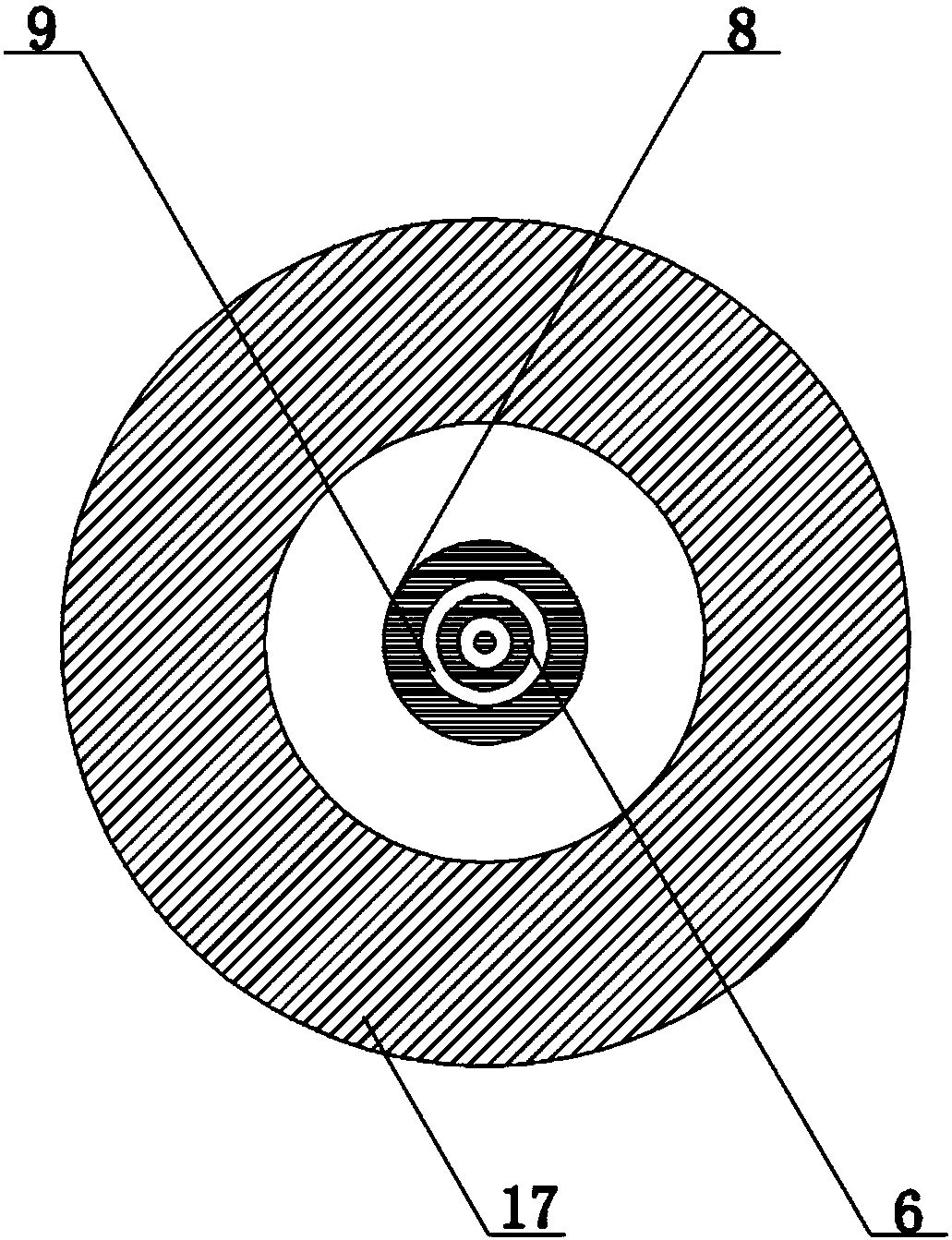

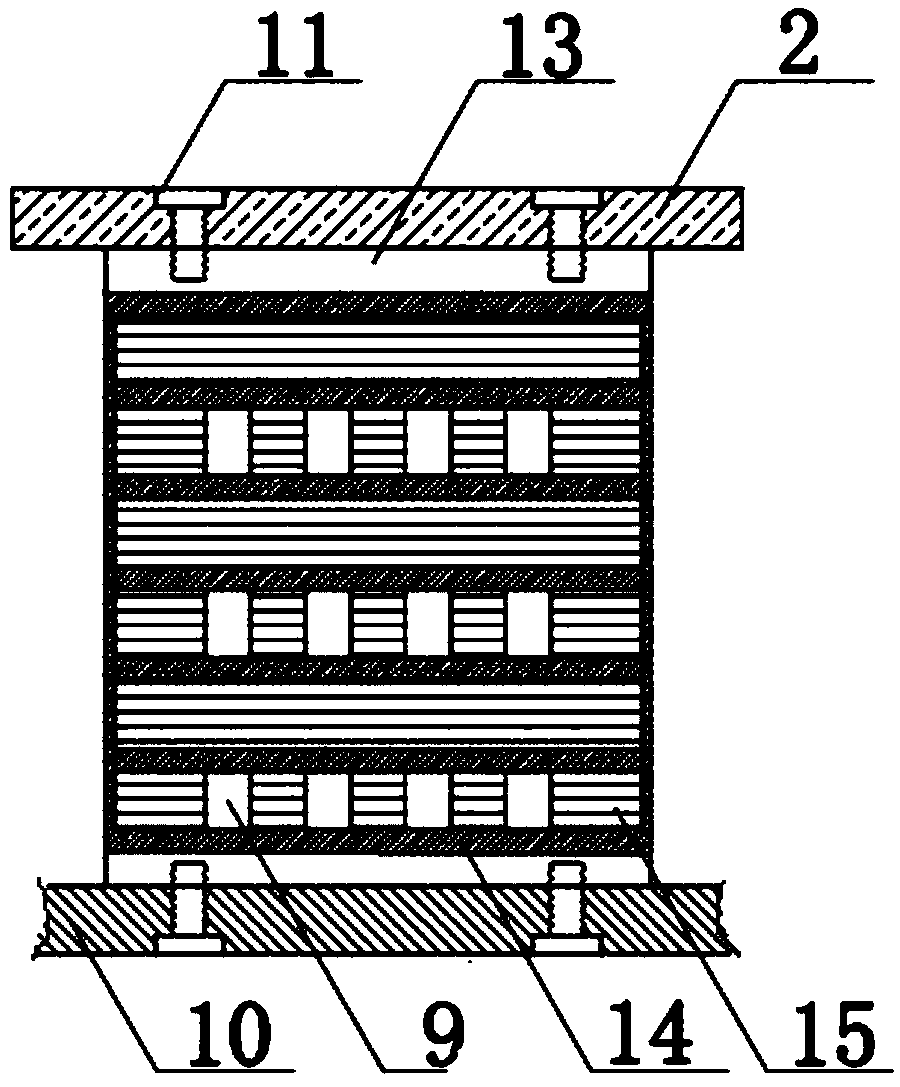

[0036] combined with figure 1It is a novel high-damping and variable-stiffness extruded shock-isolating device of the present invention. Press block 5, annular chlorinated butyl rubber-phenolic resin composite high damping material layer 6, downward convex extrusion block 7, variable stiffness cylinder 8, cavity 9, lower bottom plate 10, bolt holes 12; characterized in that: The groove 3 is opened at the bottom of the upper cover plate 1, the graphene-polyvinyl chloride composite material layer 4 is glued in the groove 3 after surface treatment, and the rubber pad 15 is bonded to the end of the groove 3 through vulcanization; the steel plate 13, The steel sheet 14 and the chlorinated butyl rubber-phenolic resin composite high damping material layer 6 are stacked alternately from top to bottom and connected with adhesives, every two layers of chlorinated butyl rubber-phenolic resin composite high damping material A STG cavity 9 is set in the middle of the layer to form a varia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com