A pressure-relieving device for accurate construction and monitoring of the pre-tightening force of roadway bolts and its application method

A technology of pretightening force and anchor rod, which is applied in the direction of measuring device, installation of anchor rod, force/torque/work measuring instrument, etc., and can solve the problem of large gap in pretightening force, relationship between pretightening force of anchor rod and pretightening torque of nut Complicated, large errors in the conversion process, etc., to achieve better deformation of surrounding rock, avoid instability accidents, and improve safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An implementation example of the present invention will be further described below in conjunction with accompanying drawing:

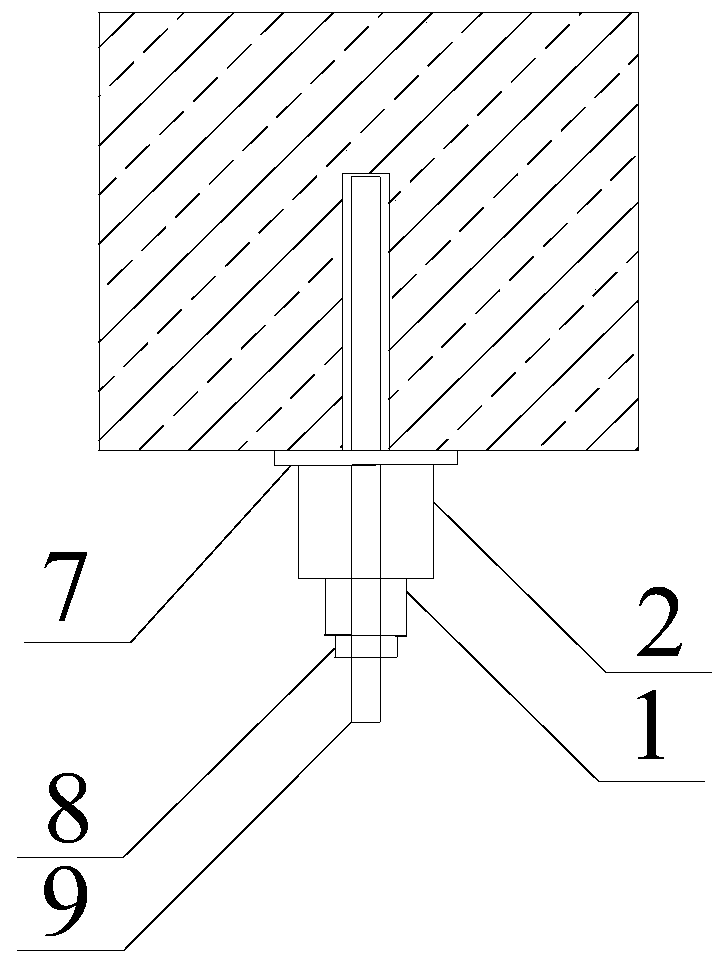

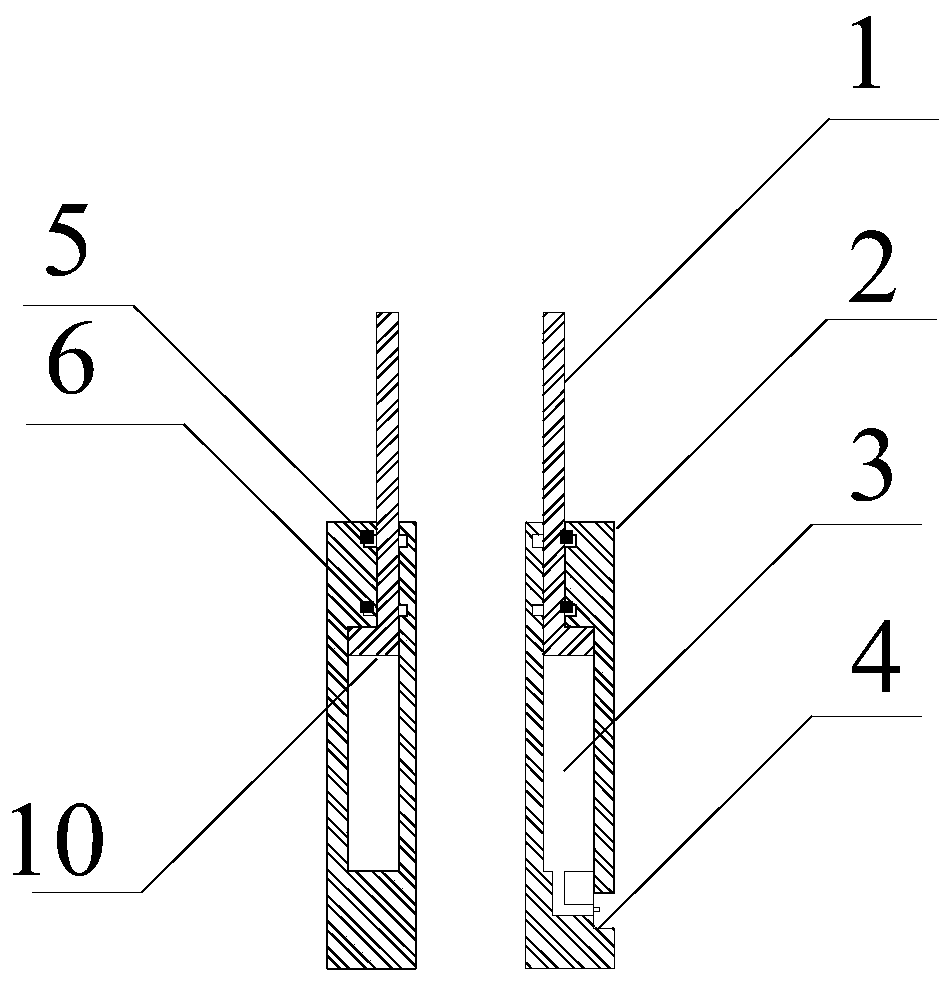

[0023] Such as figure 1 , figure 2 with image 3 As shown, the pressure-relieving device for accurate construction and monitoring of the pre-tightening force of the roadway anchor rod of the present invention is arranged between the tray 7 and the nut 8 at the end of the anchor rod 9, and is characterized in that it includes a piston rod 1 and a Cylinder 2, the inner diameter of the cylinder 2 and the diameter of the anchor rod are matched in engineering with a difference of 2mm, and the corresponding anchor rod diameter is 16-25mm; the middle of the piston rod 1 and the cylinder 2 is provided with a through hole matching the tail of the anchor rod 9, Piston rod 1 and cylinder 2 have a ring-shaped cylindrical structure in cross-section. Cylinder cavity 3 is provided inside cylinder 2. Cylinder cavity 3 is filled with nitrogen. , the inner di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com