Control apparatus for internal combustion engine

A technology for controlling equipment and internal combustion engines, which is applied in the direction of mechanical equipment, engine control, fuel injection control, etc., and can solve problems such as the increase in the degree of change and the increase in the amount of exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

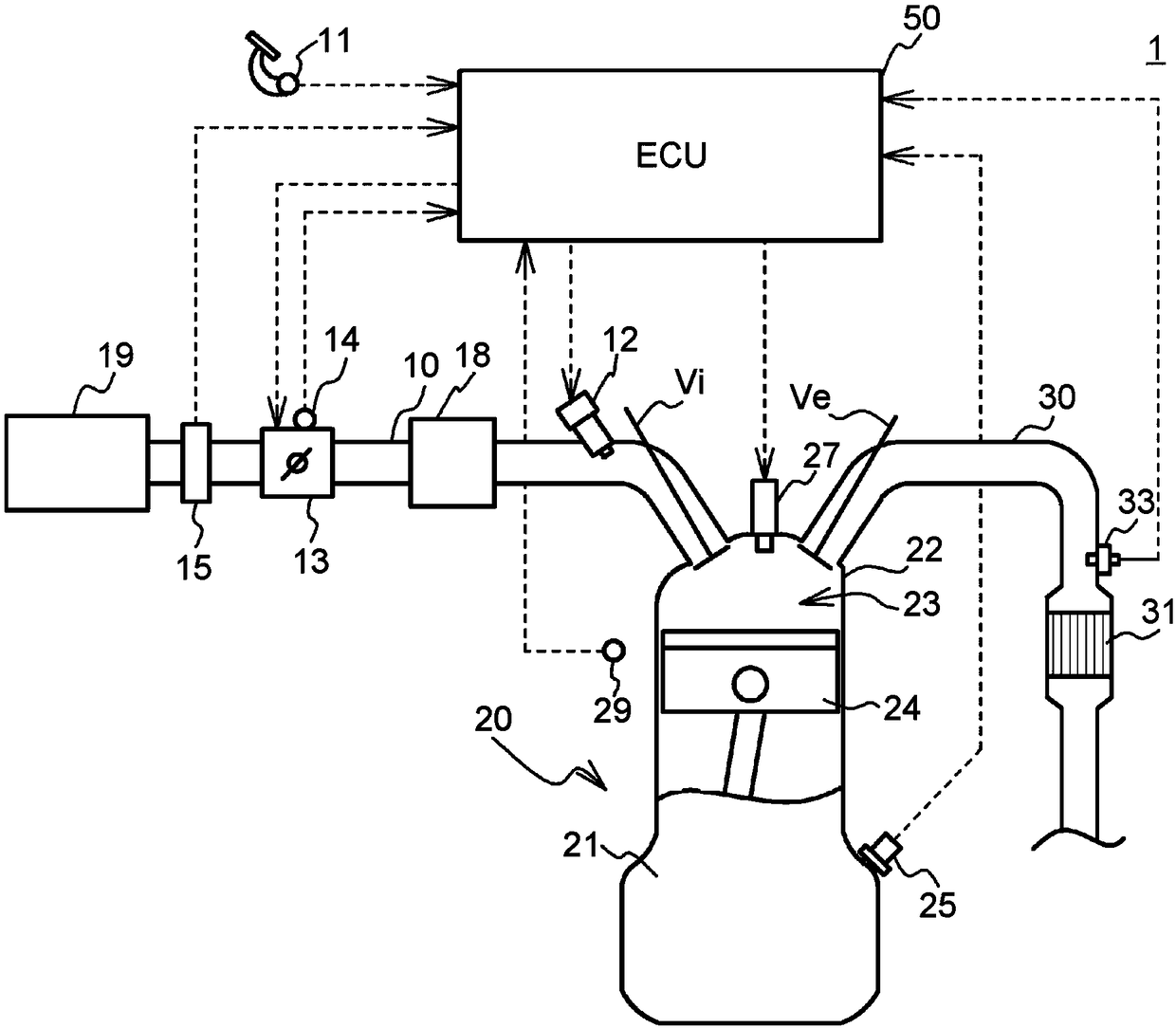

[0022] figure 1 is a schematic configuration diagram of the engine system 1 . as in figure 1 As shown schematically in , the engine system 1 includes a three-way catalyst 31 configured to purify exhaust gas exhausted from the engine 20 , and the like. The engine 20 is constructed such that an air-fuel mixture is combusted in a combustion chamber 23 in a cylinder head 22 placed on a cylinder block 21 to cause a piston 24 to reciprocate. In the present embodiment, the engine 20 is an inline four-cylinder engine. However, the engine 20 is not limited to an inline four-cylinder engine as long as the engine 20 includes a plurality of cylinders.

[0023] Each cylinder is provided with an intake valve Vi and an exhaust valve Ve placed in a cylinder head 22 of the engine 20 . The intake valve Vi is configured to open and close an intake port, and the exhaust valve Ve is configured to open and close an exhaust port. Furthermore, each cylinder is provided with an ignition plug 27 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com