Patents

Literature

30results about How to "Shorten FPOT" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

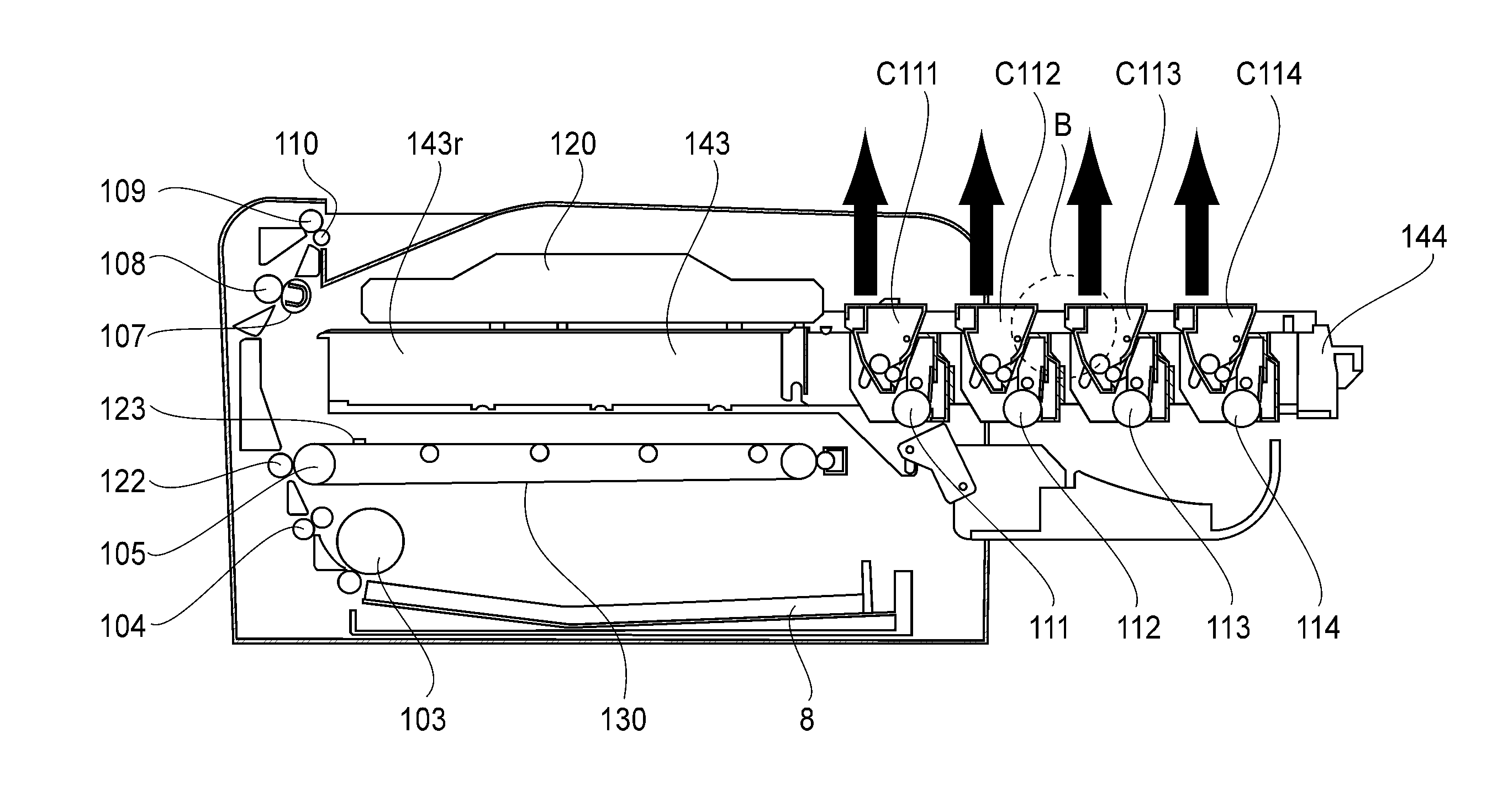

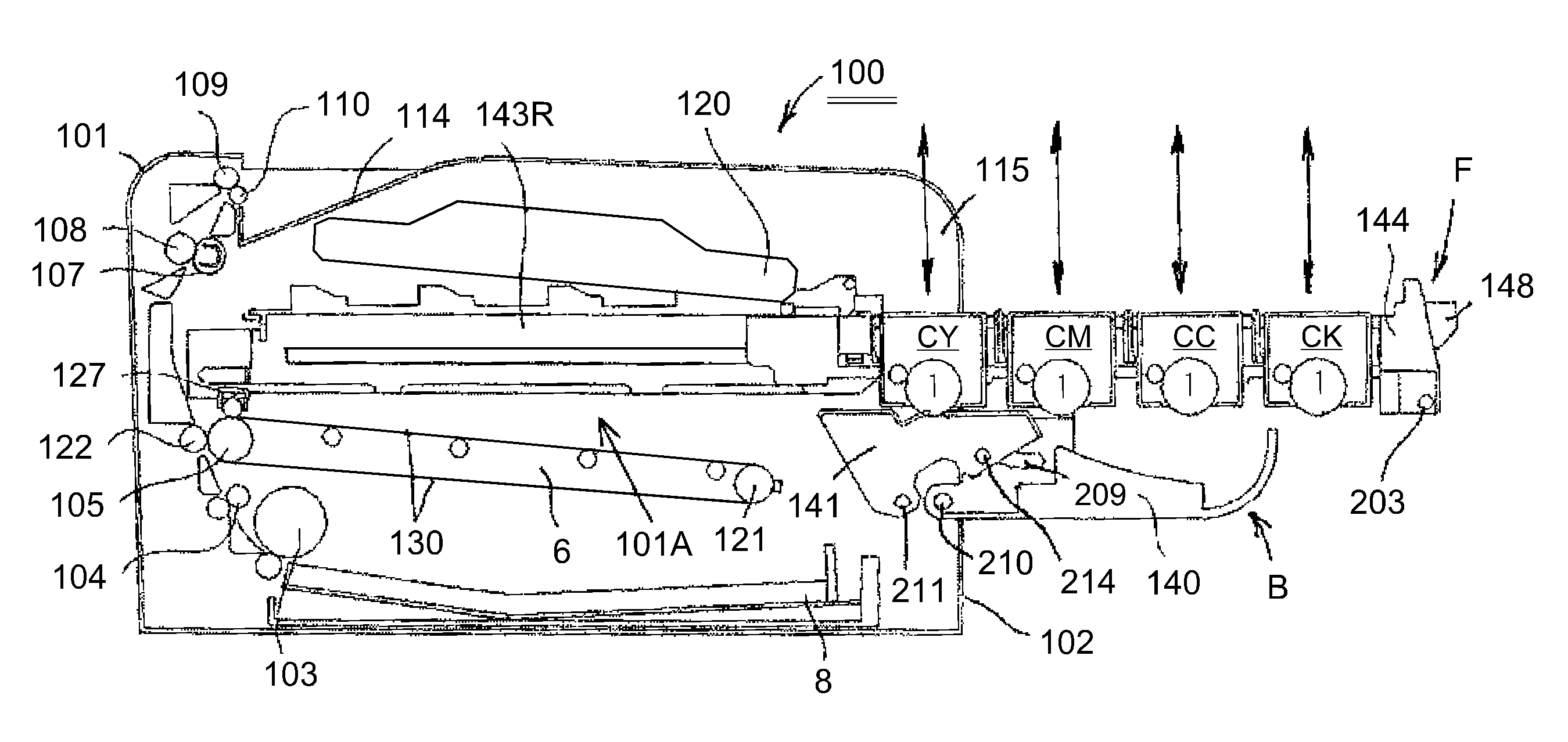

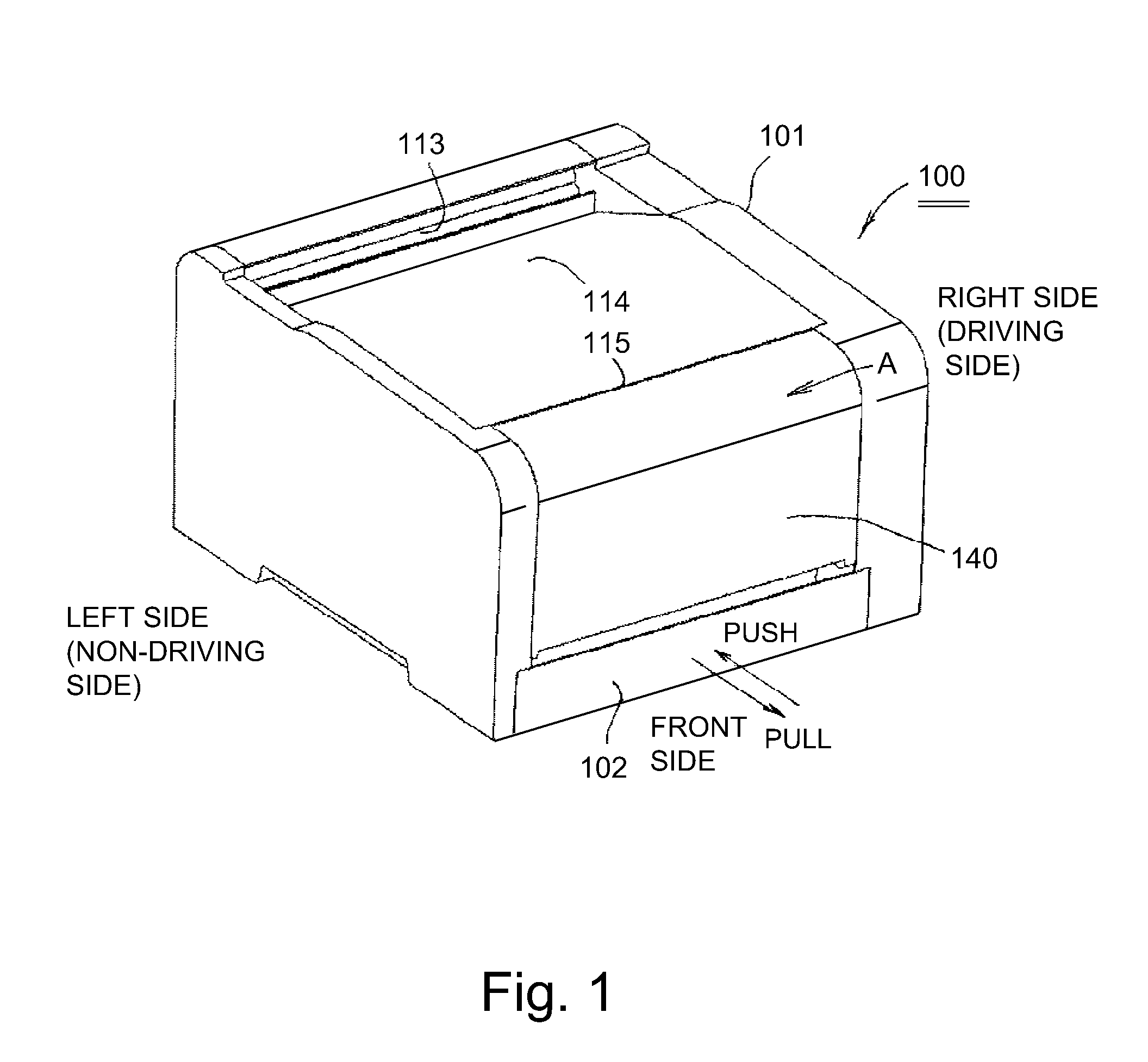

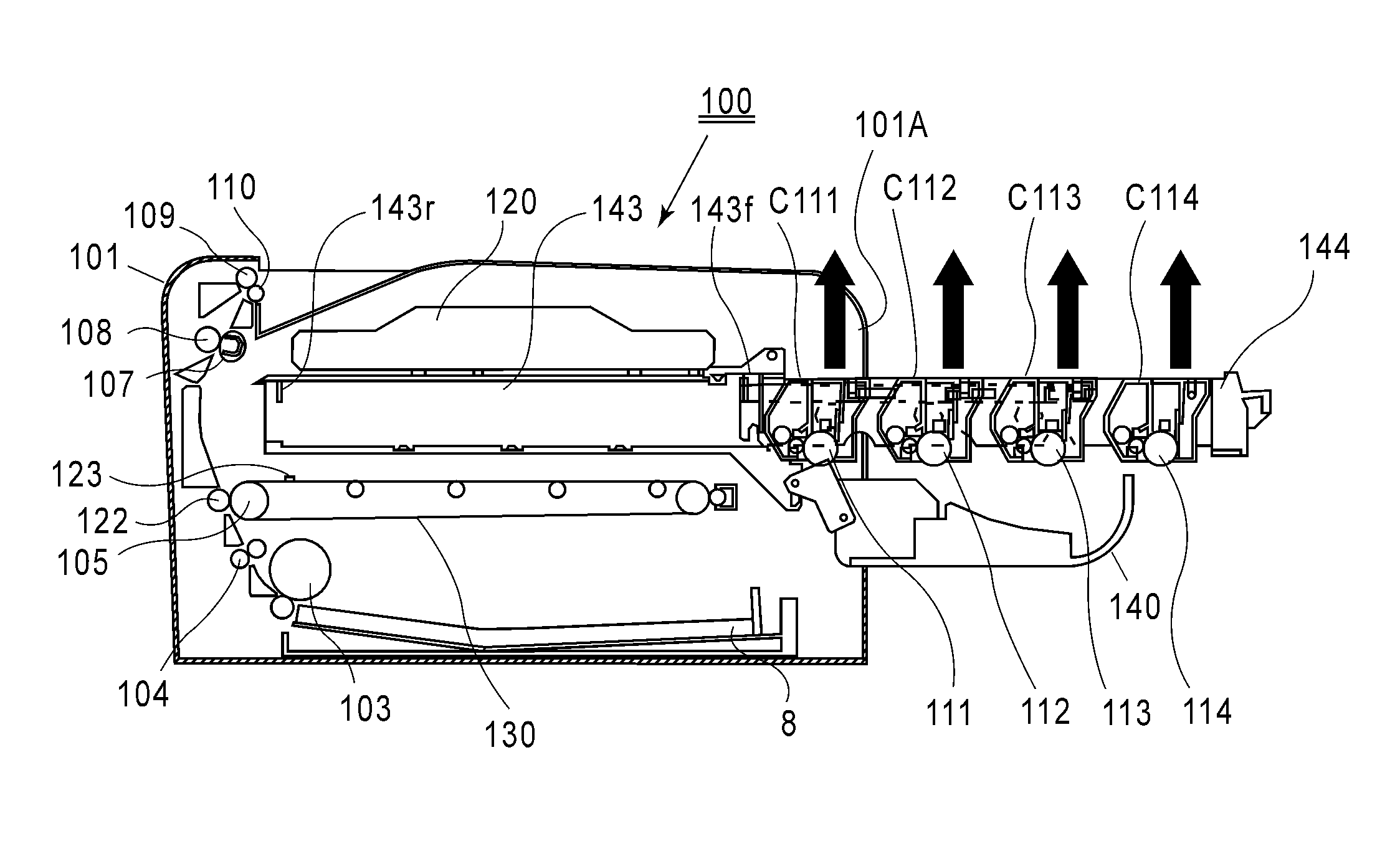

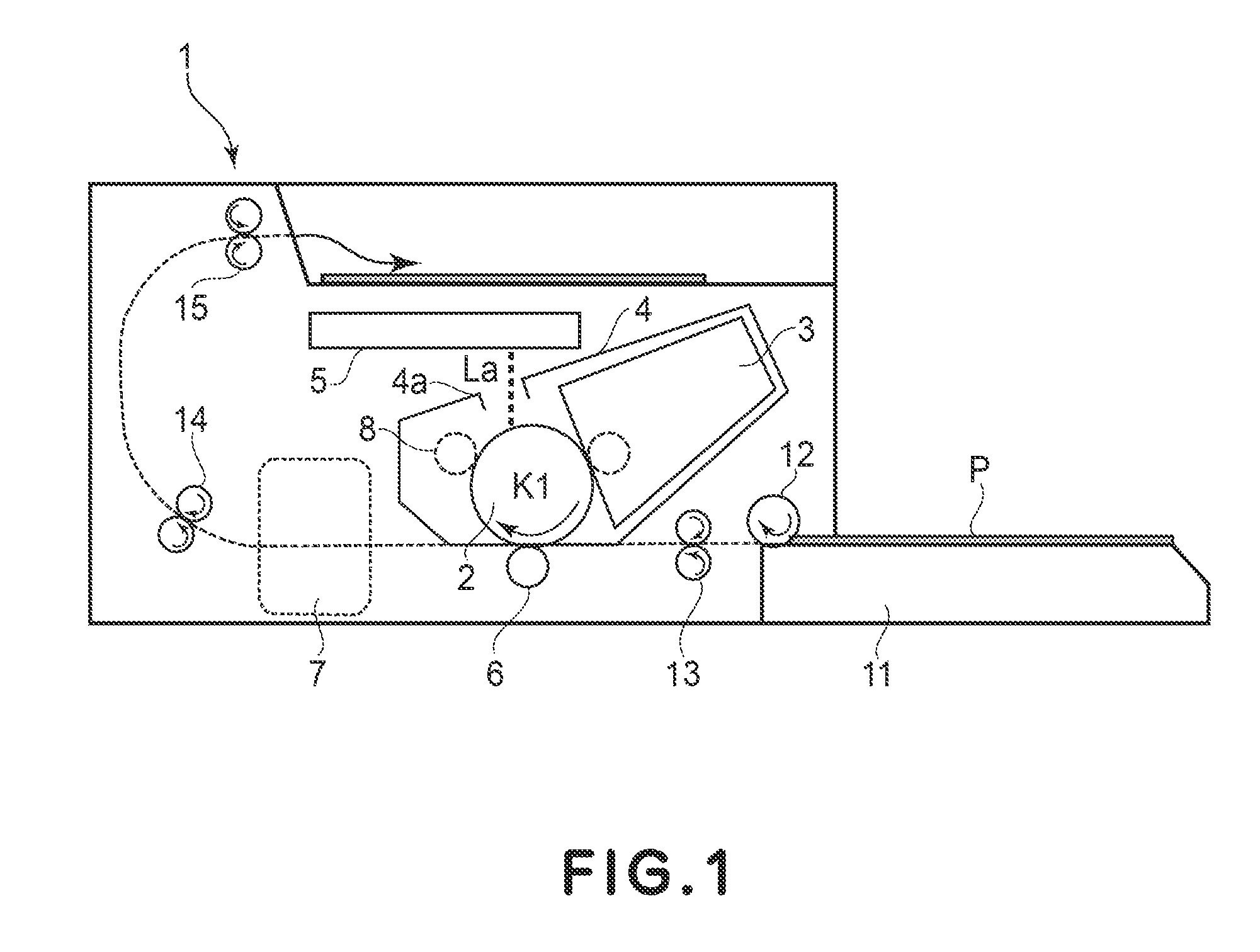

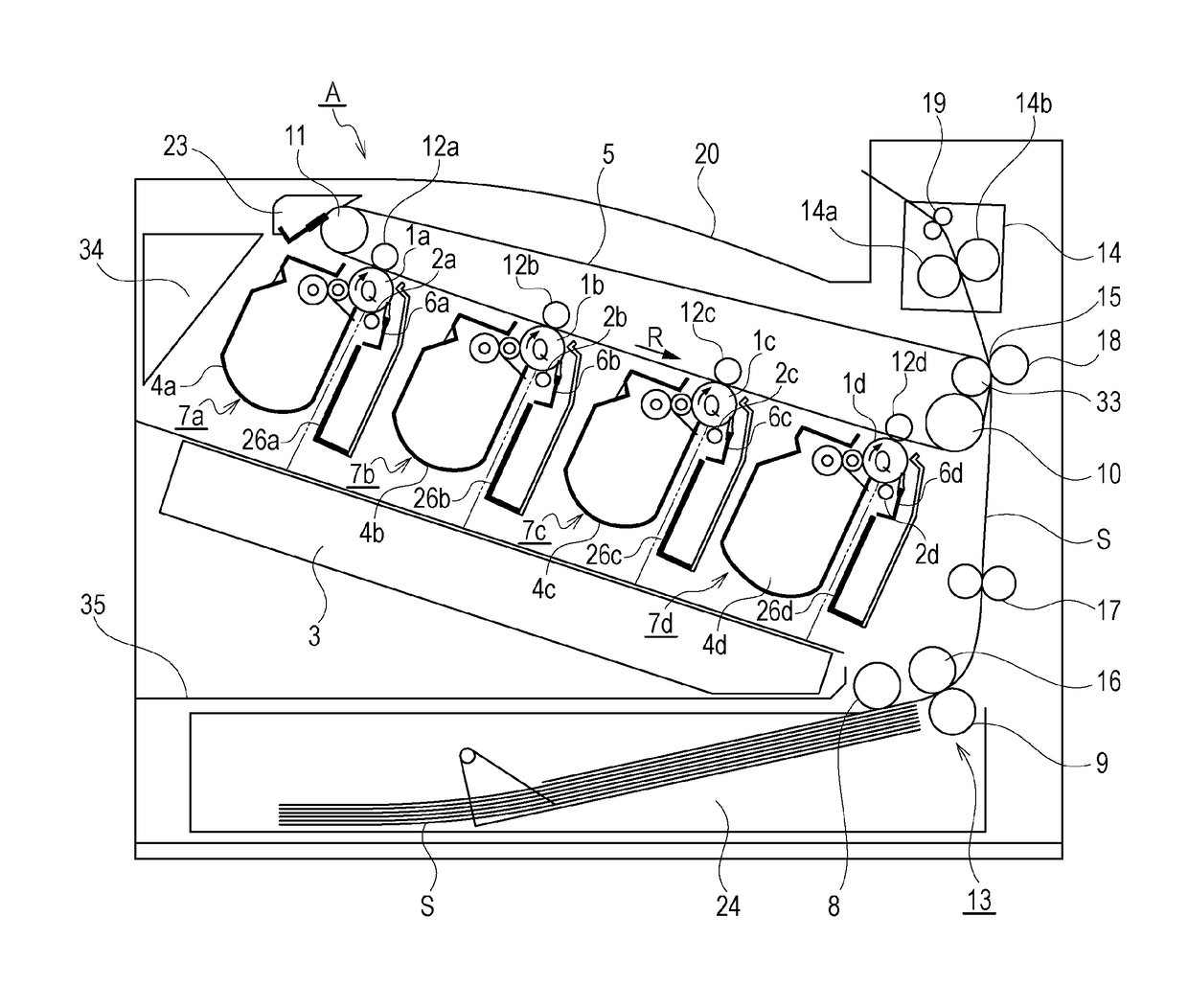

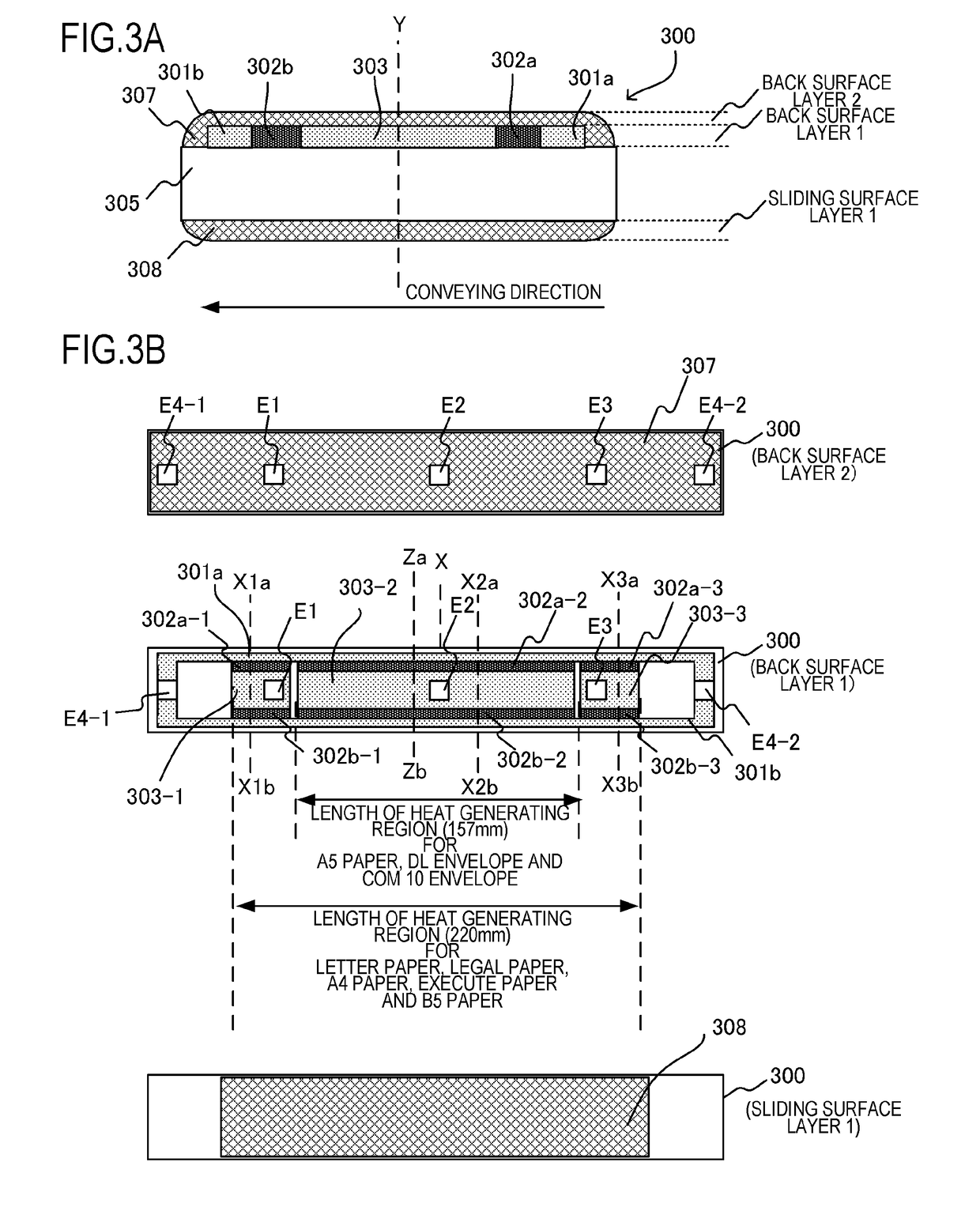

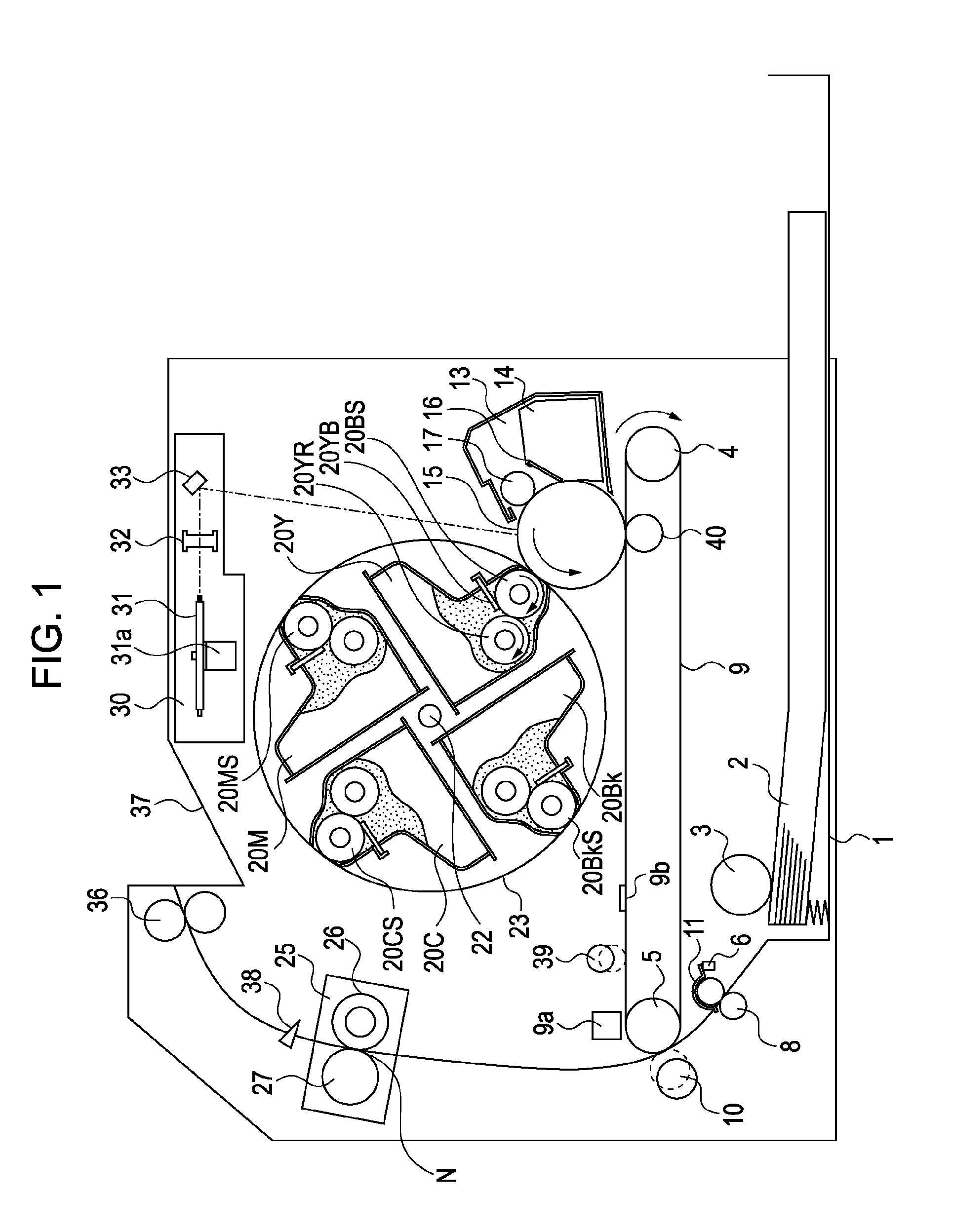

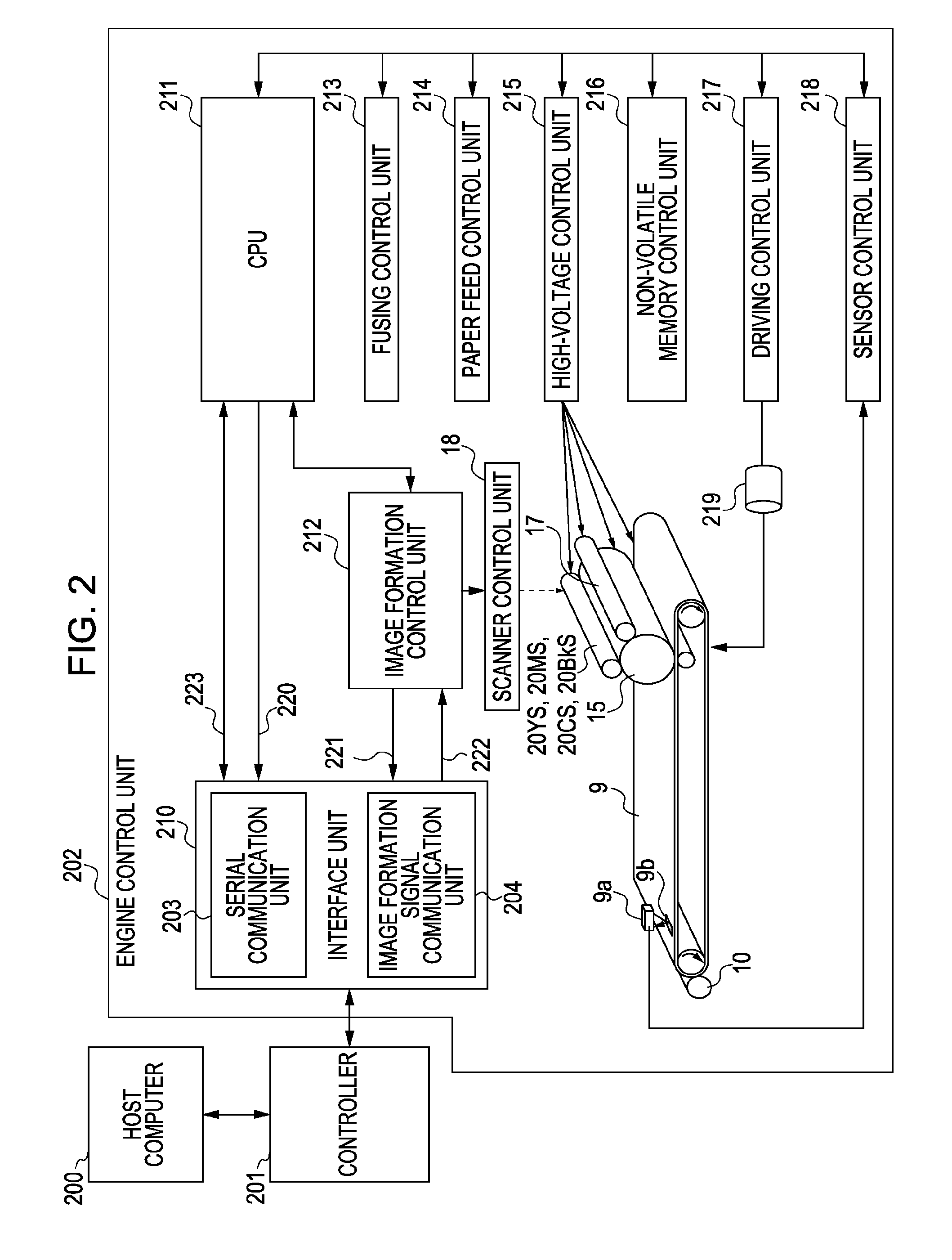

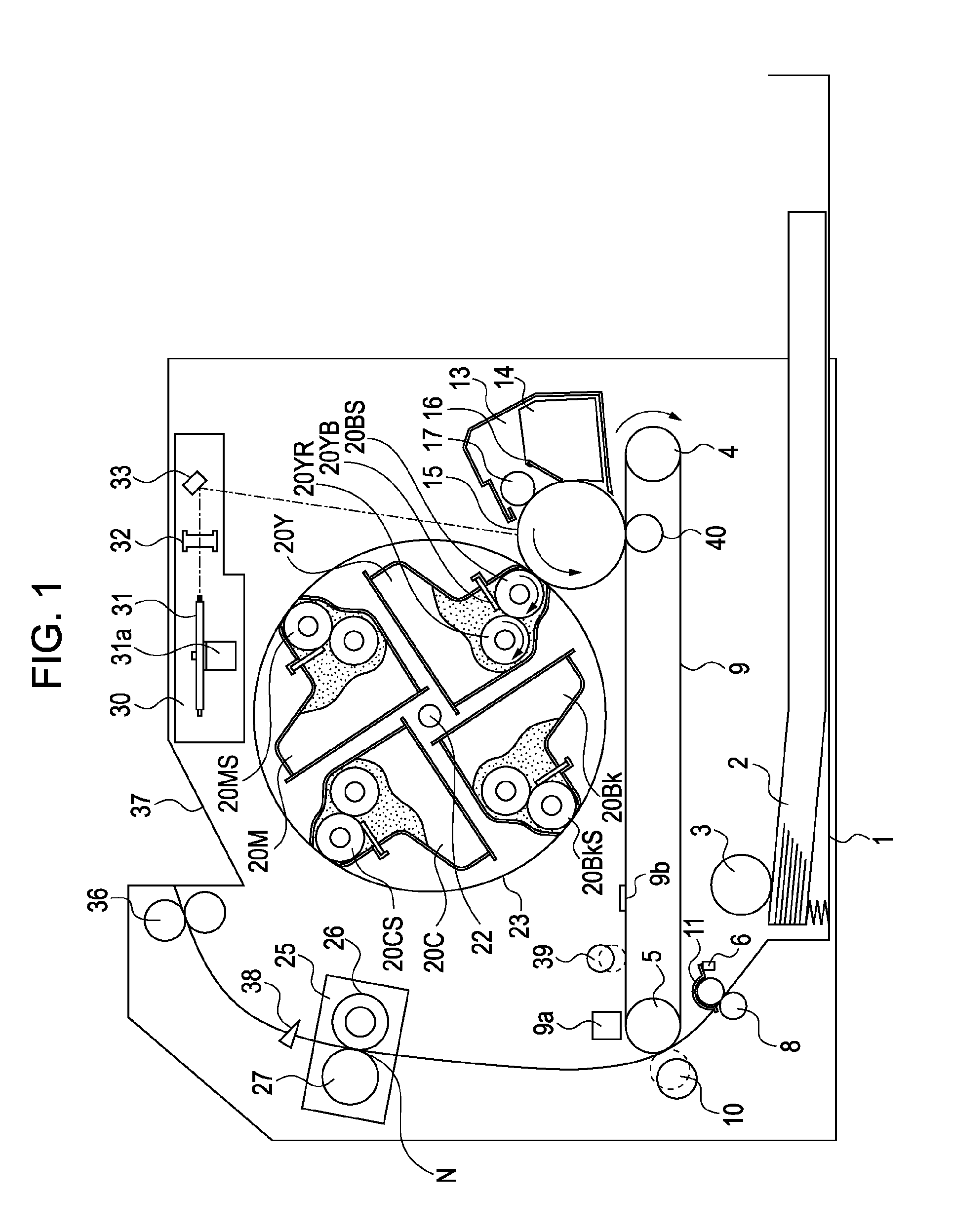

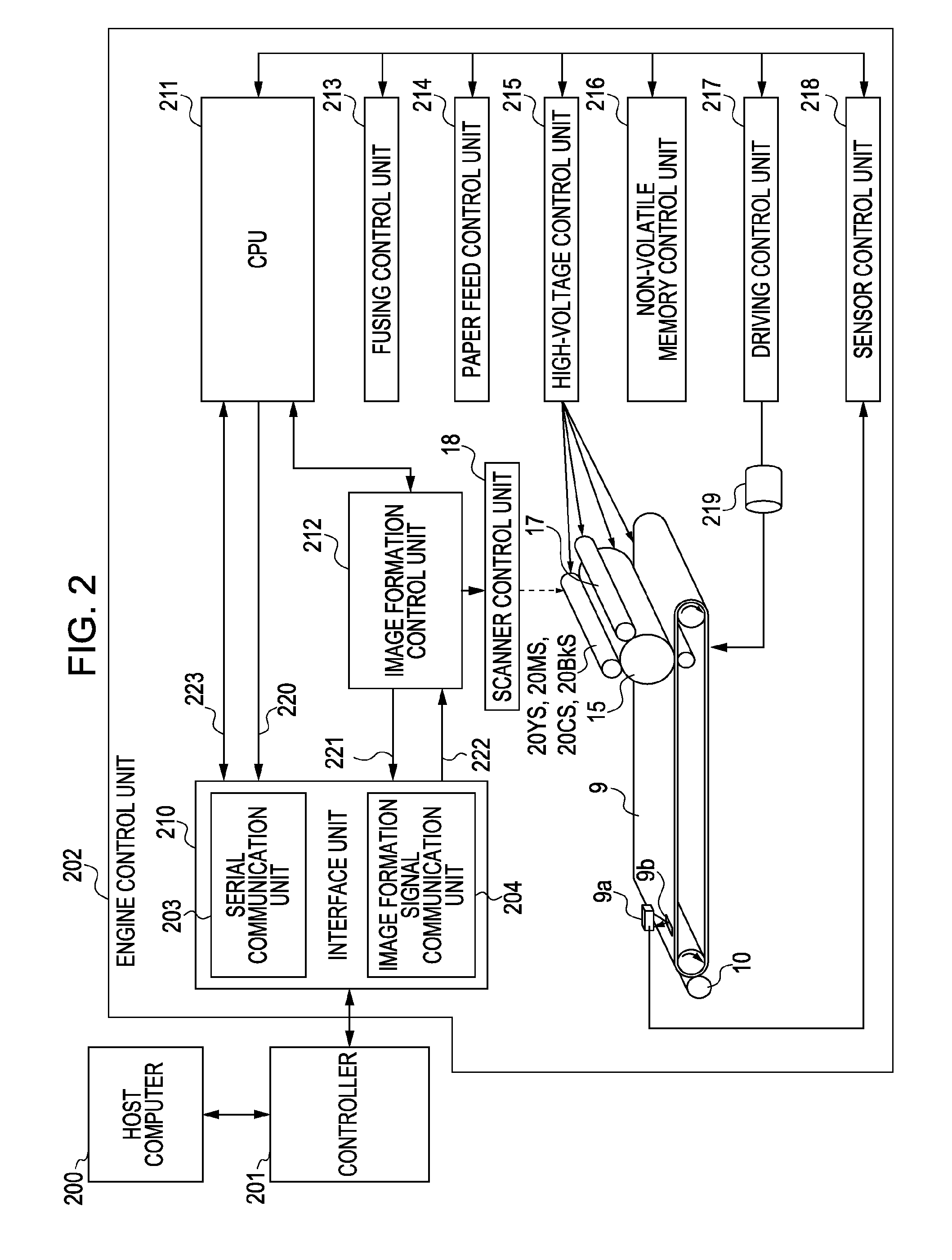

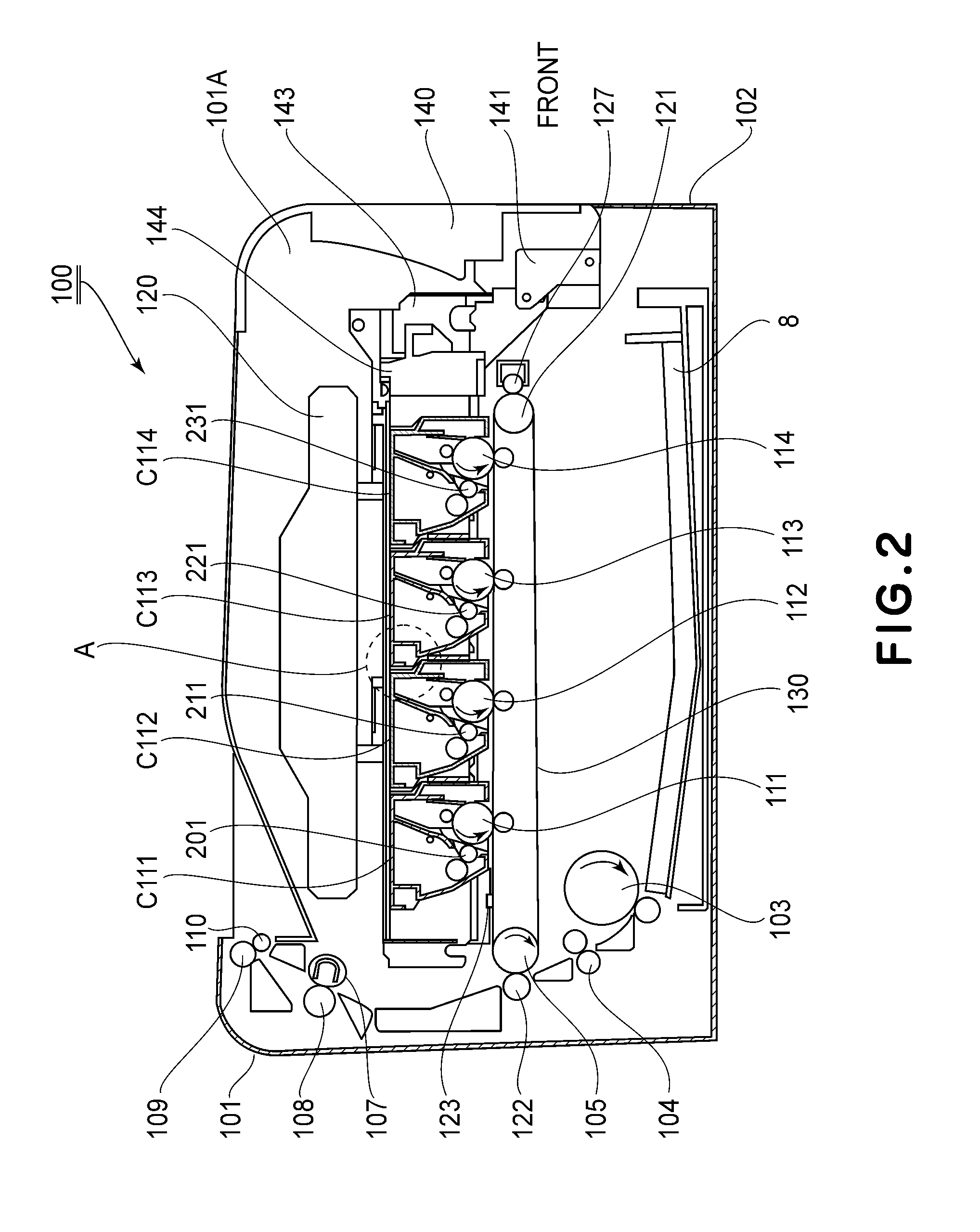

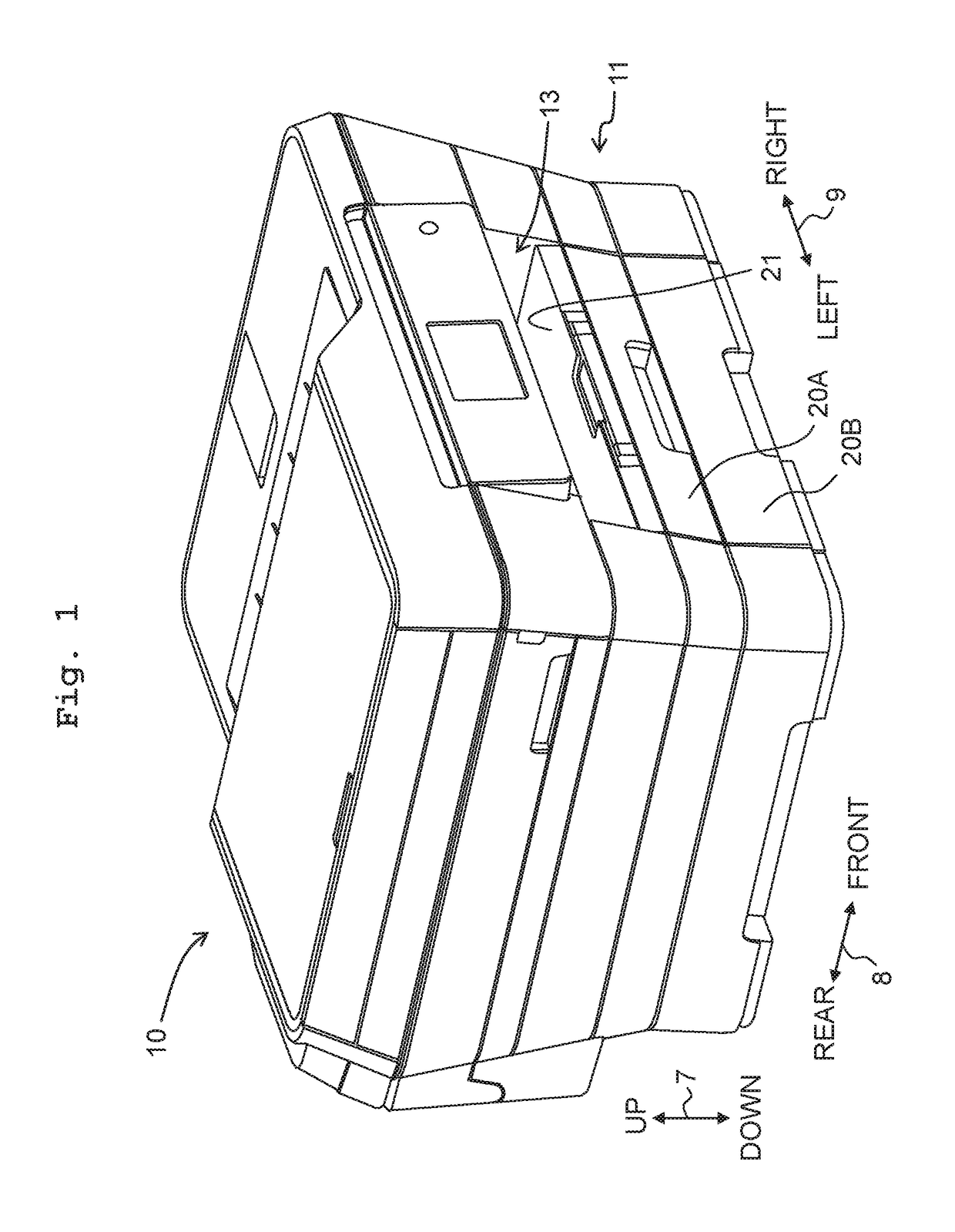

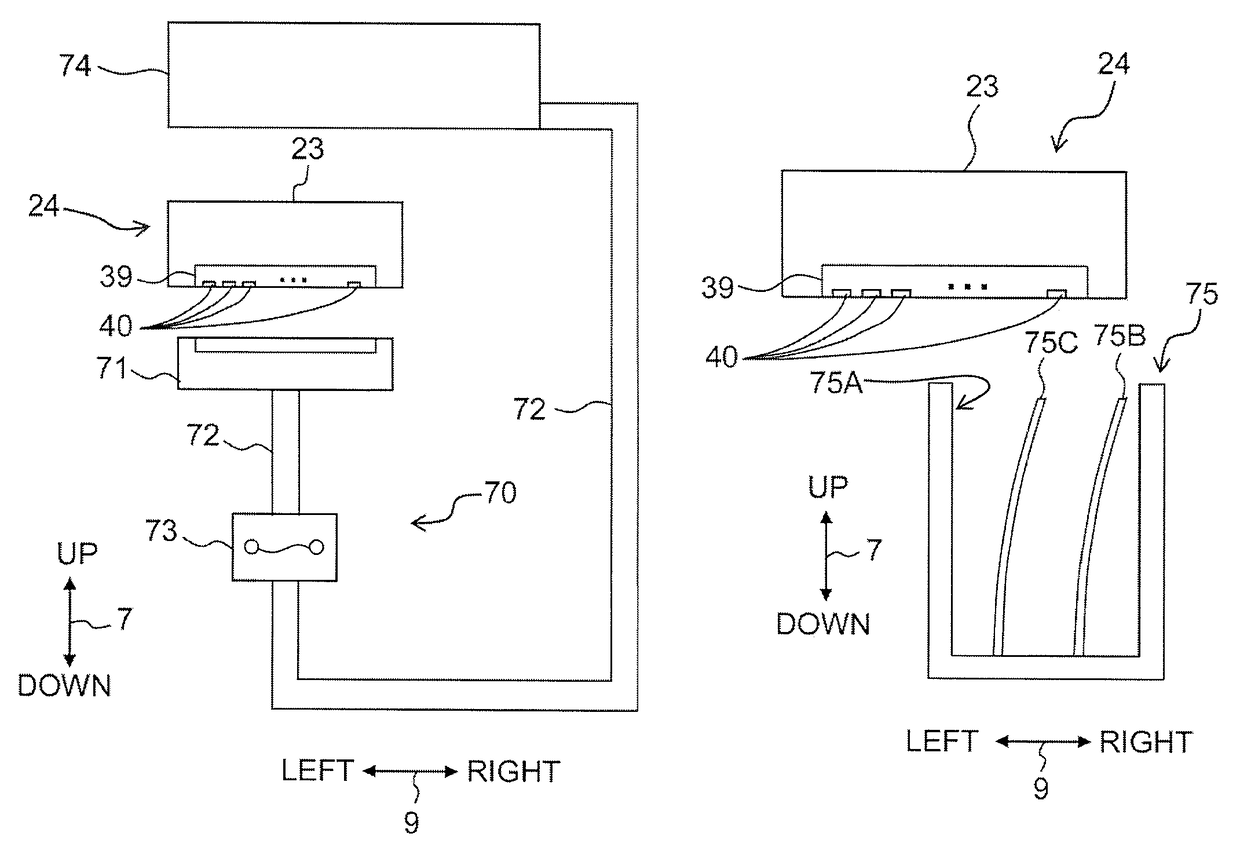

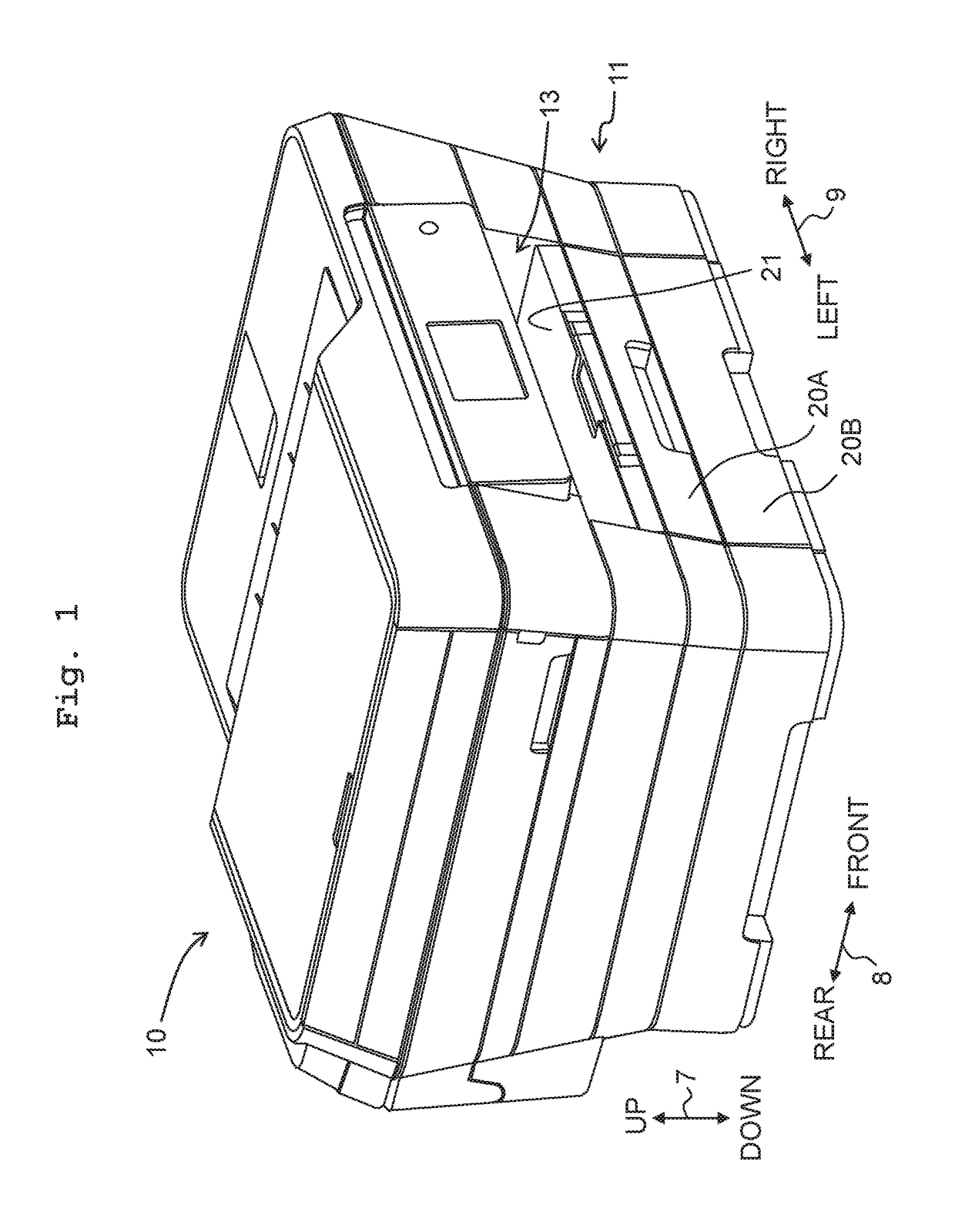

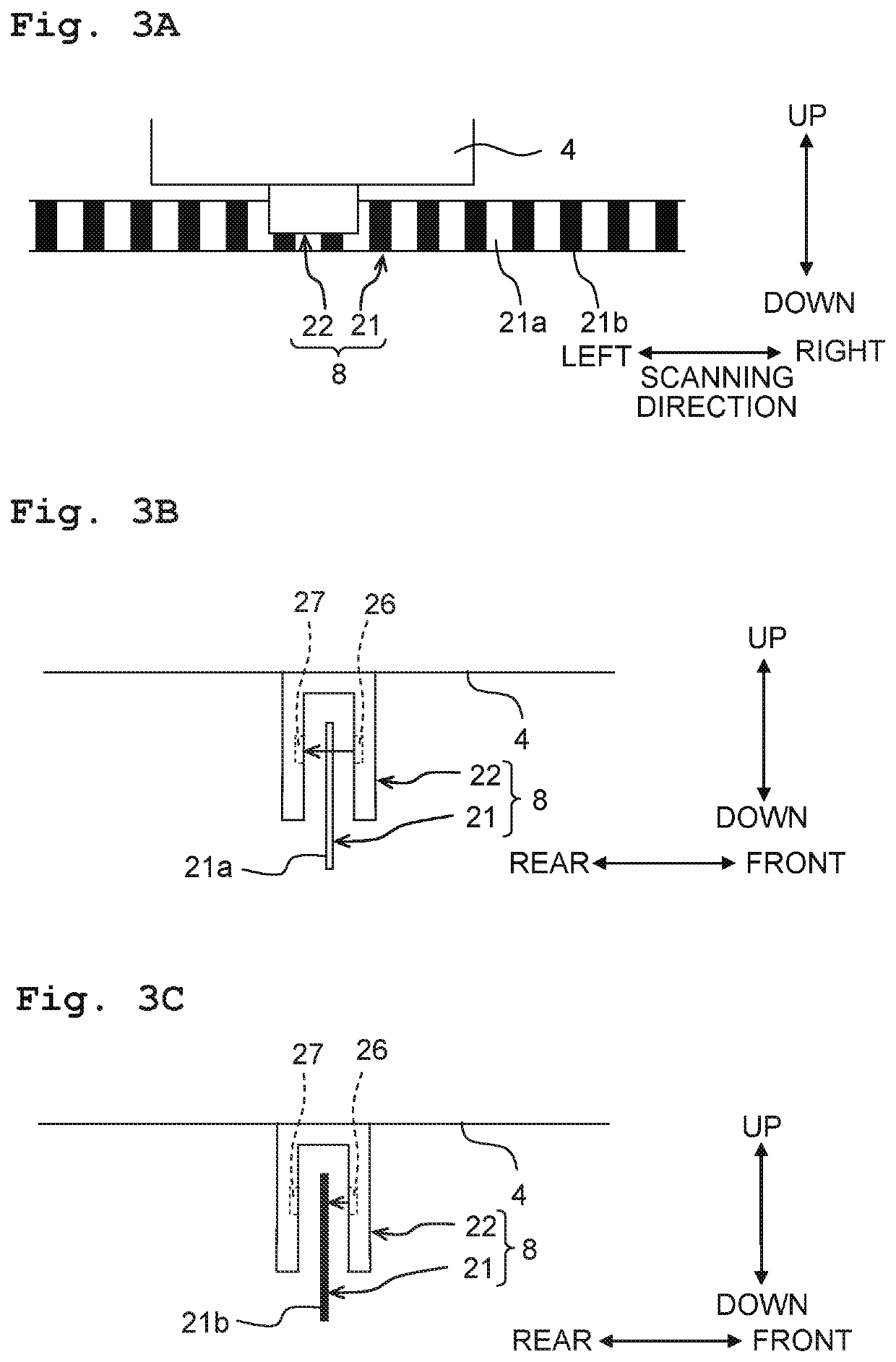

Image forming apparatus and process cartridge

InactiveUS20150055974A1Improve usabilityShorten FPOTElectrographic process apparatusImage formationEngineering

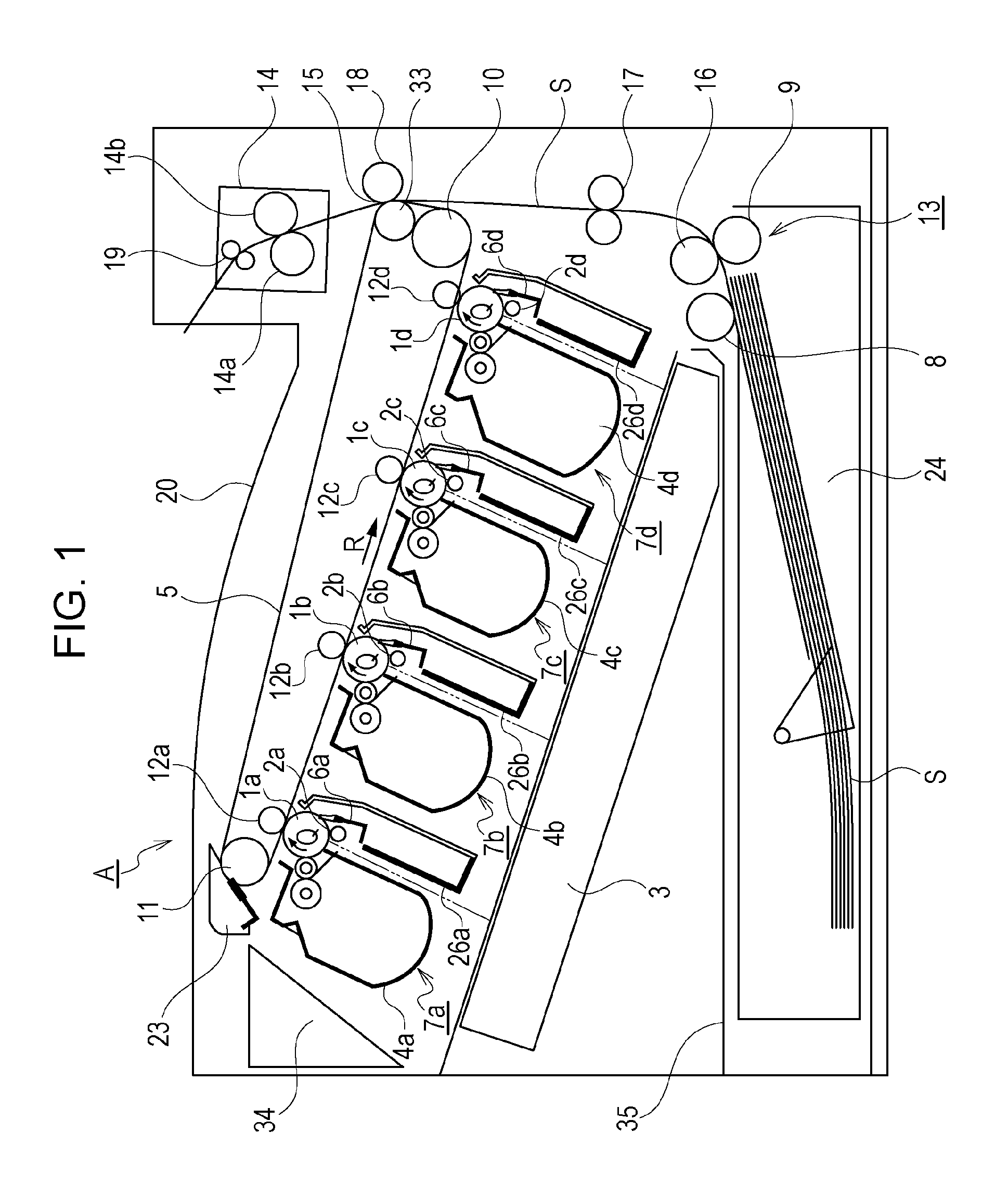

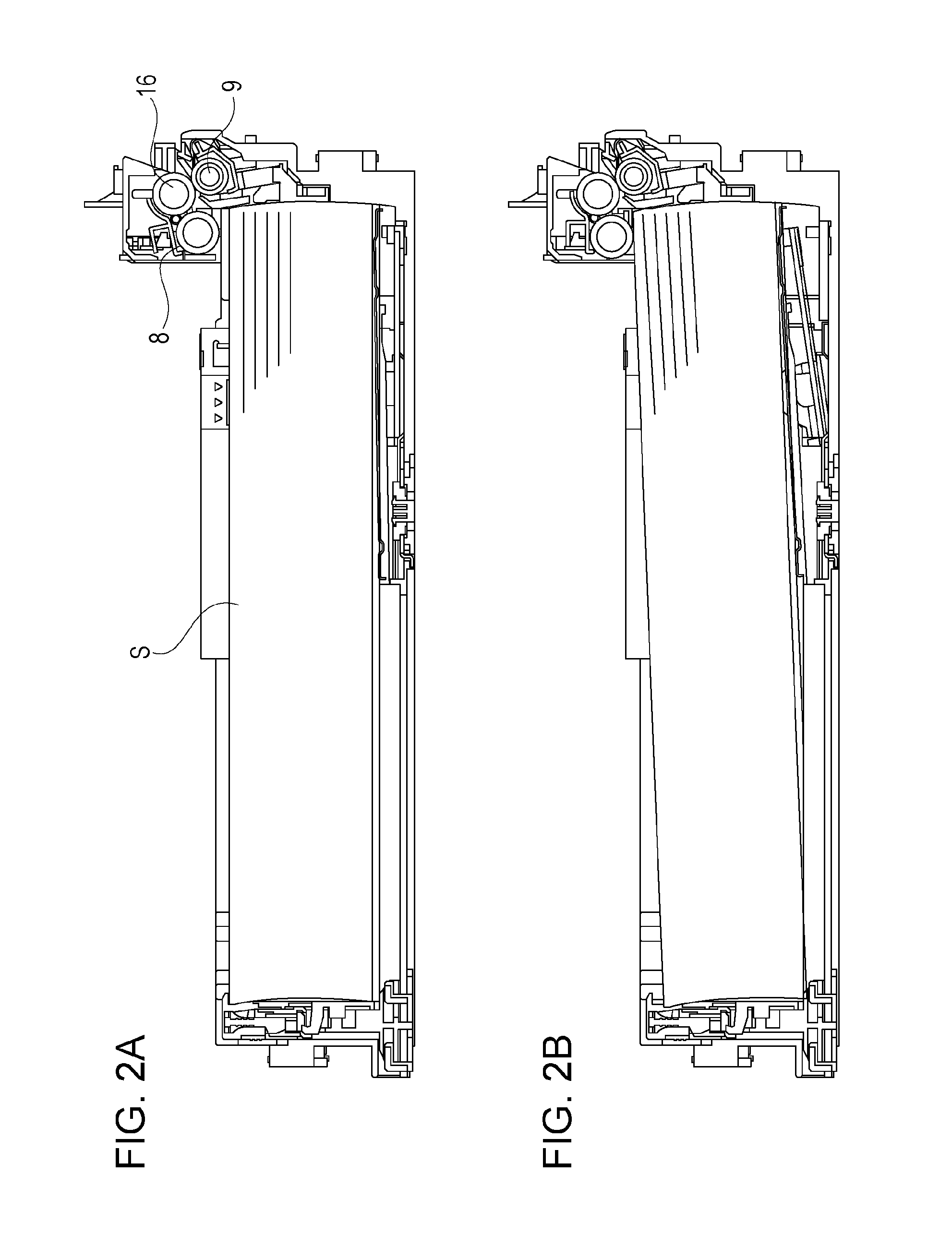

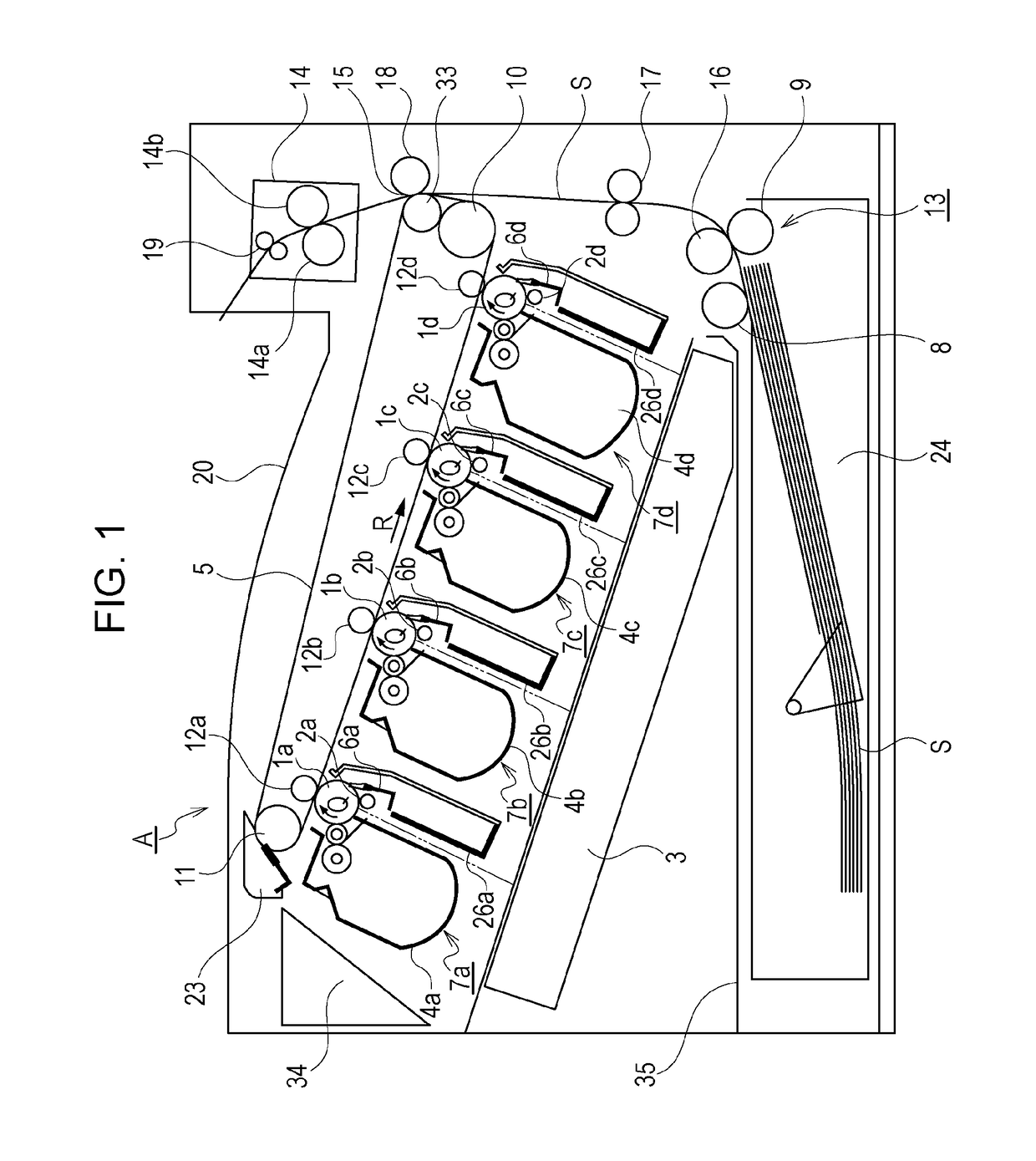

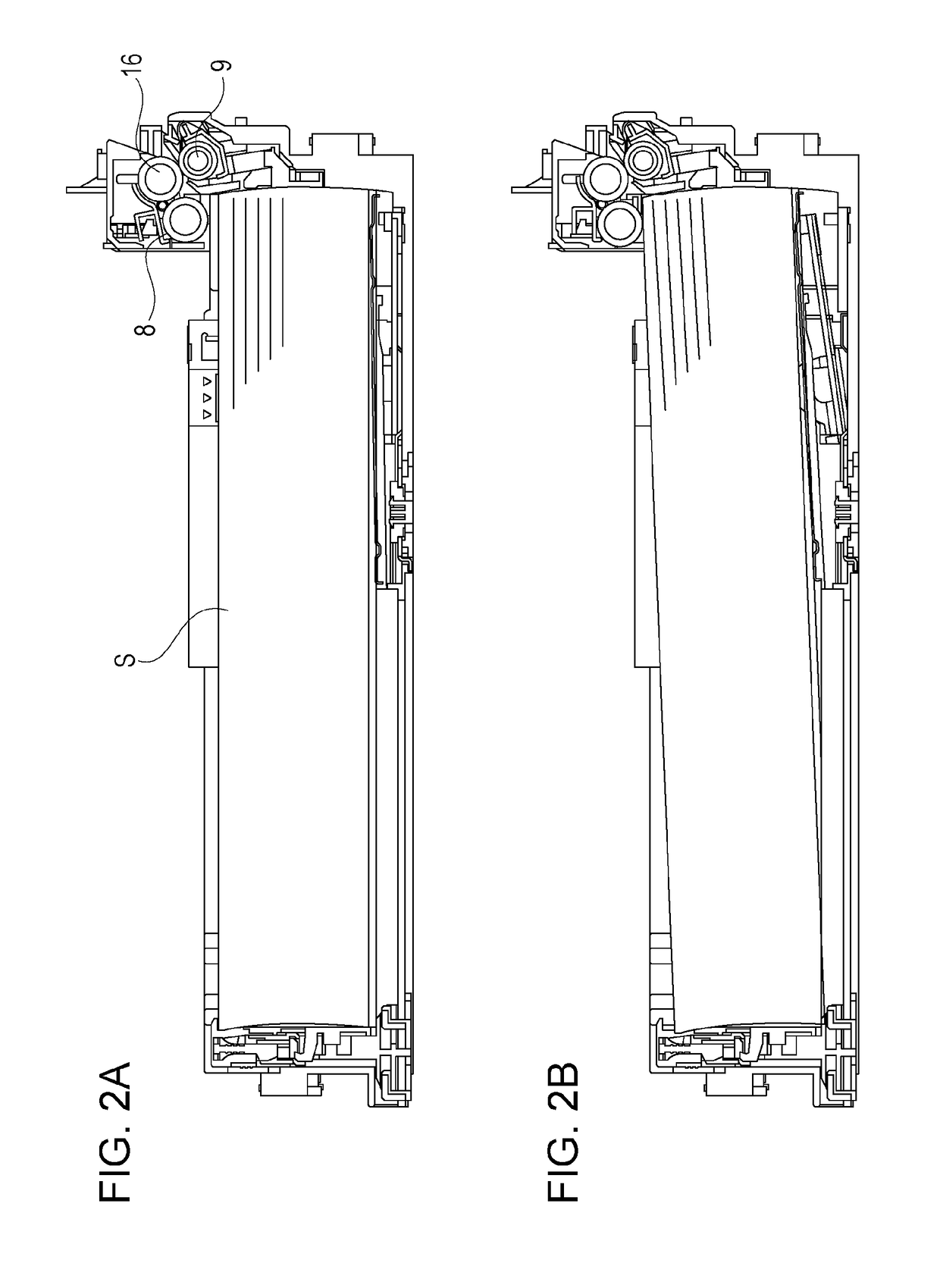

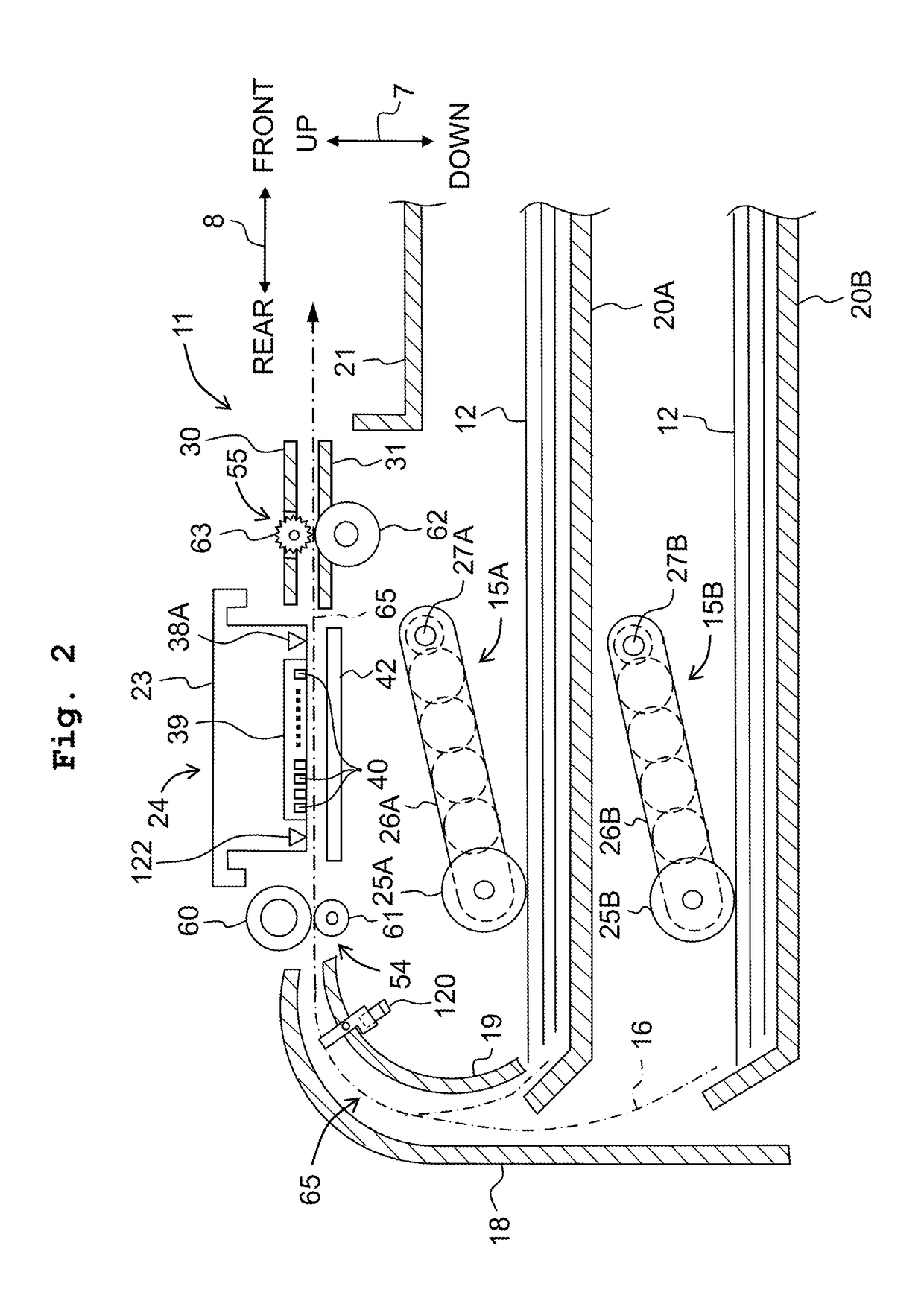

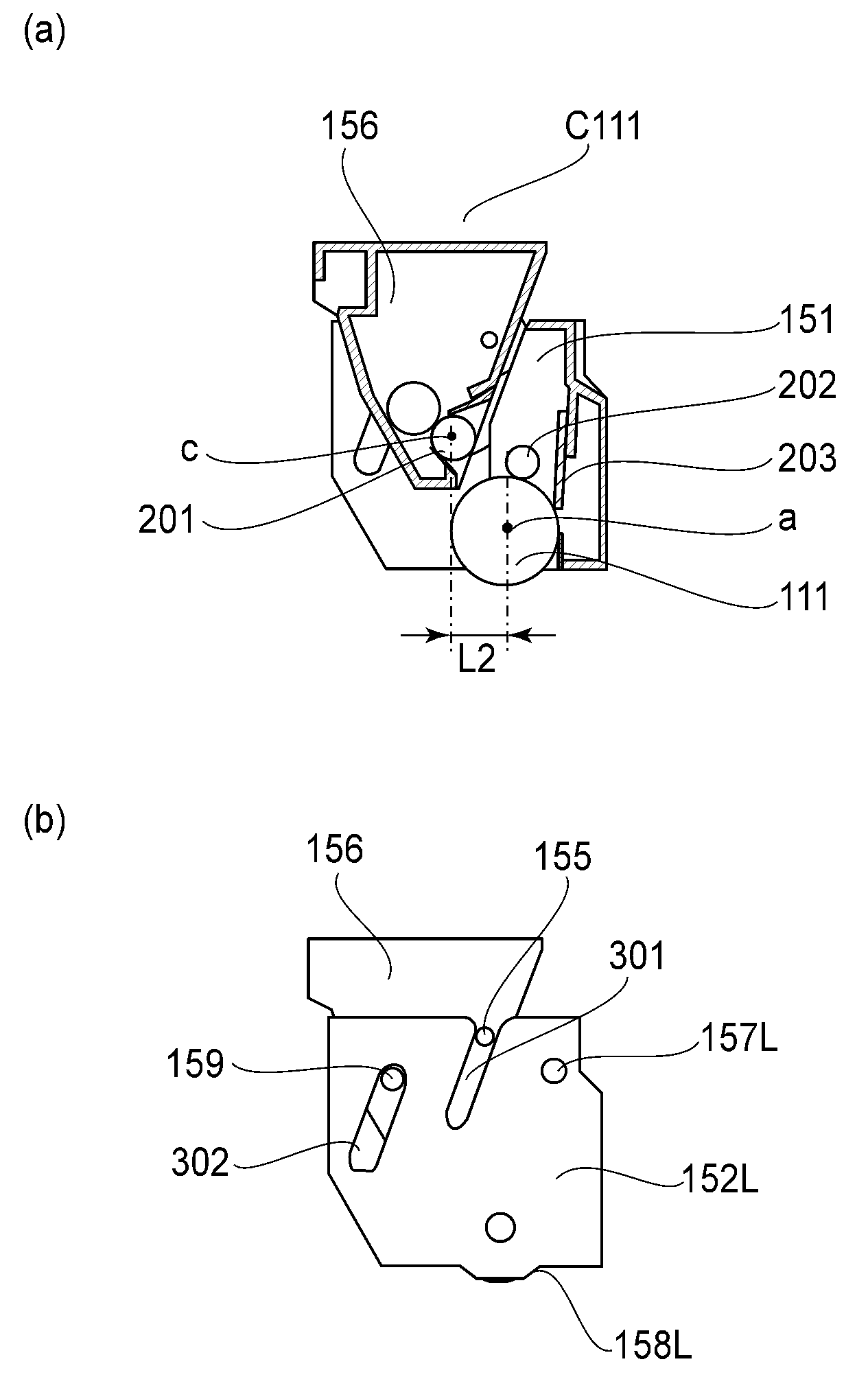

An image forming apparatus, to which process cartridges each including a photosensitive drum and a developing roller, includes: a movable member movable between an inside and an outside of a main assembly of the image forming apparatus in a movement direction crossing a longitudinal direction of the photosensitive drum; a mounting portion for supporting the process cartridges, wherein the process cartridges are detachably mountable to the mounting portion from a direction crossing the longitudinal direction and the movement direction; and an interrelating member, movable in interrelation with movement of the movable member, for moving the developing roller relative to the photosensitive drum so that a distance between a rotation center of the photosensitive drum and a rotation center of the developing roller is decreased with respect to the movement direction when the movable member is moved from the inside to the outside of the main assembly.

Owner:CANON KK

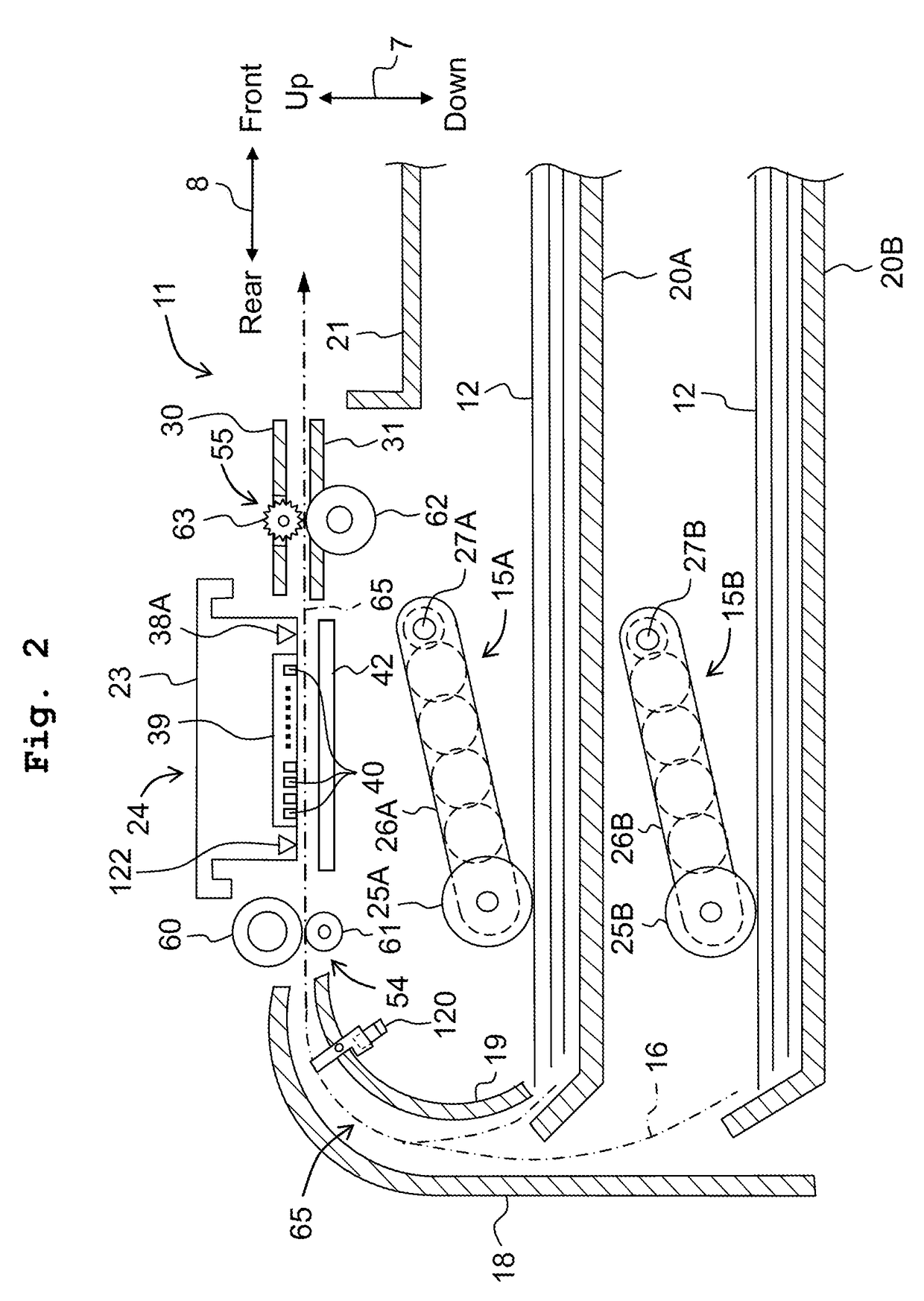

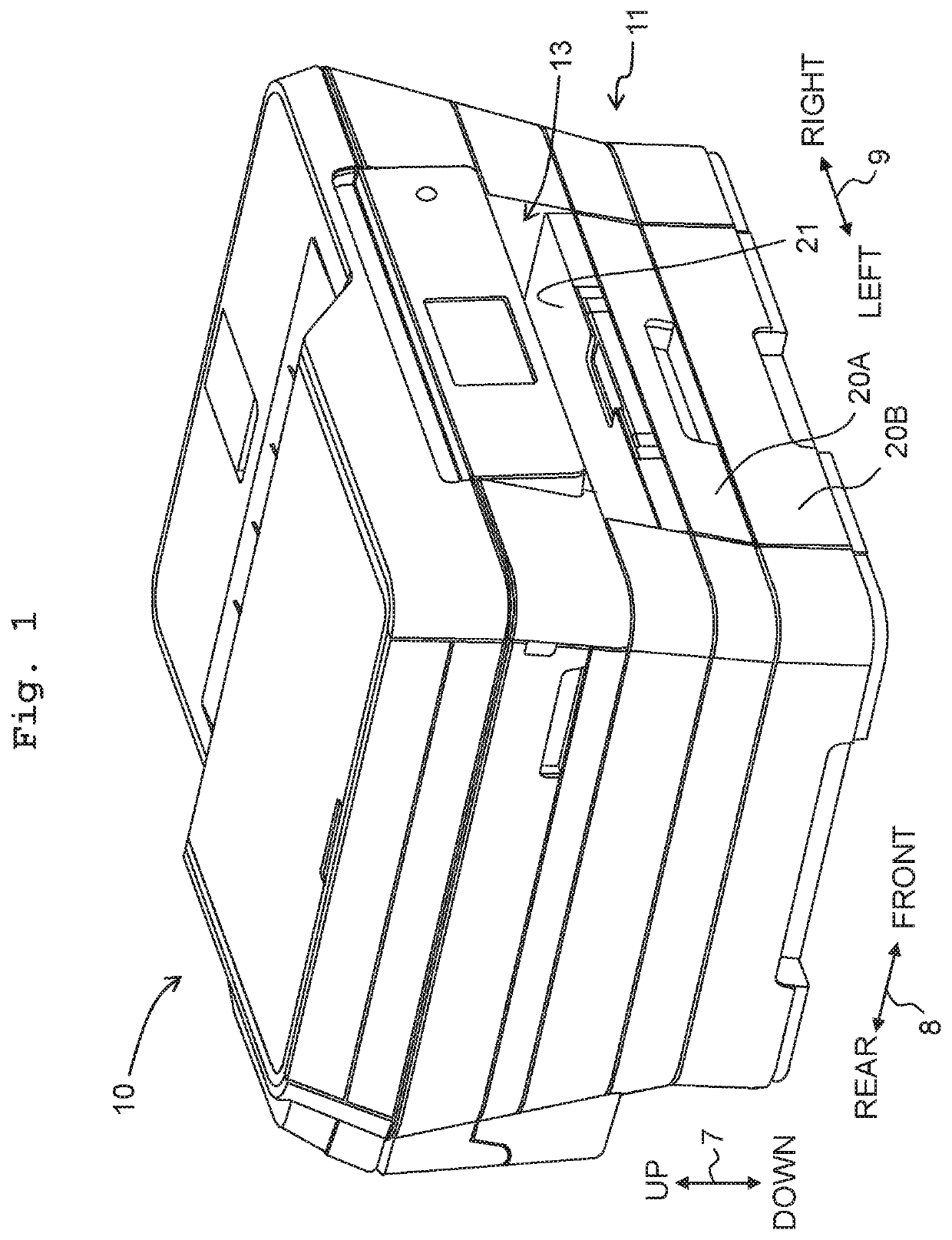

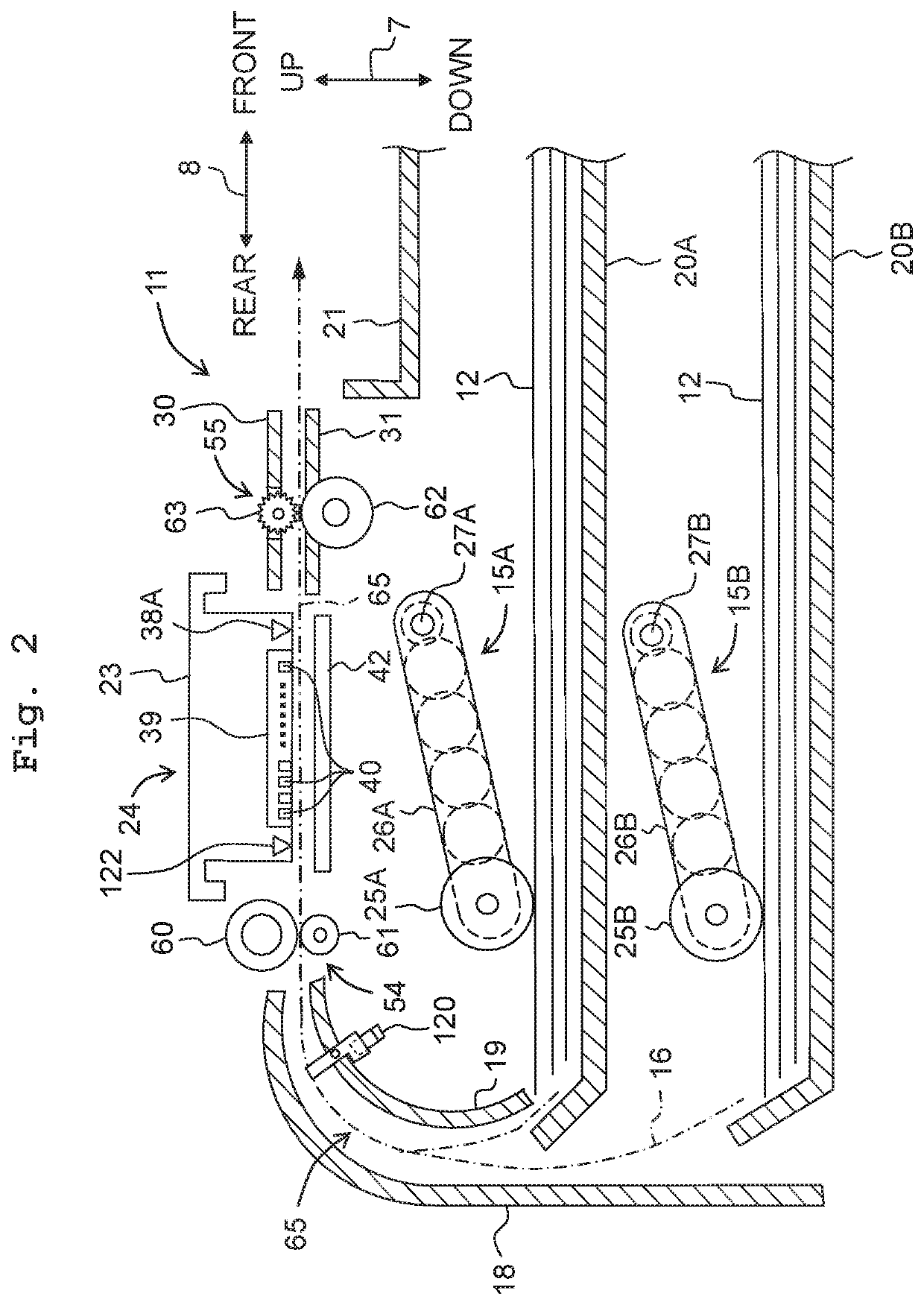

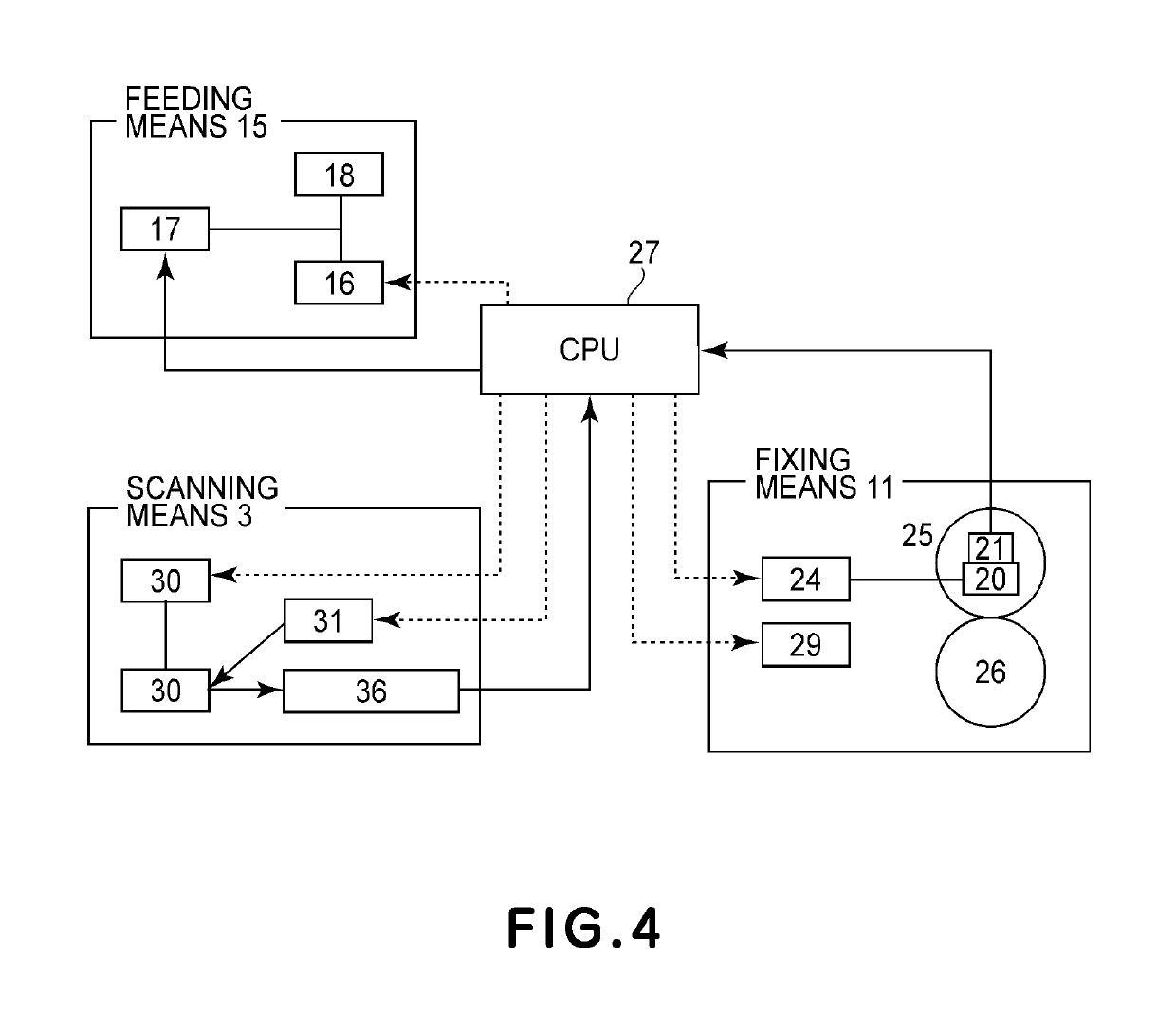

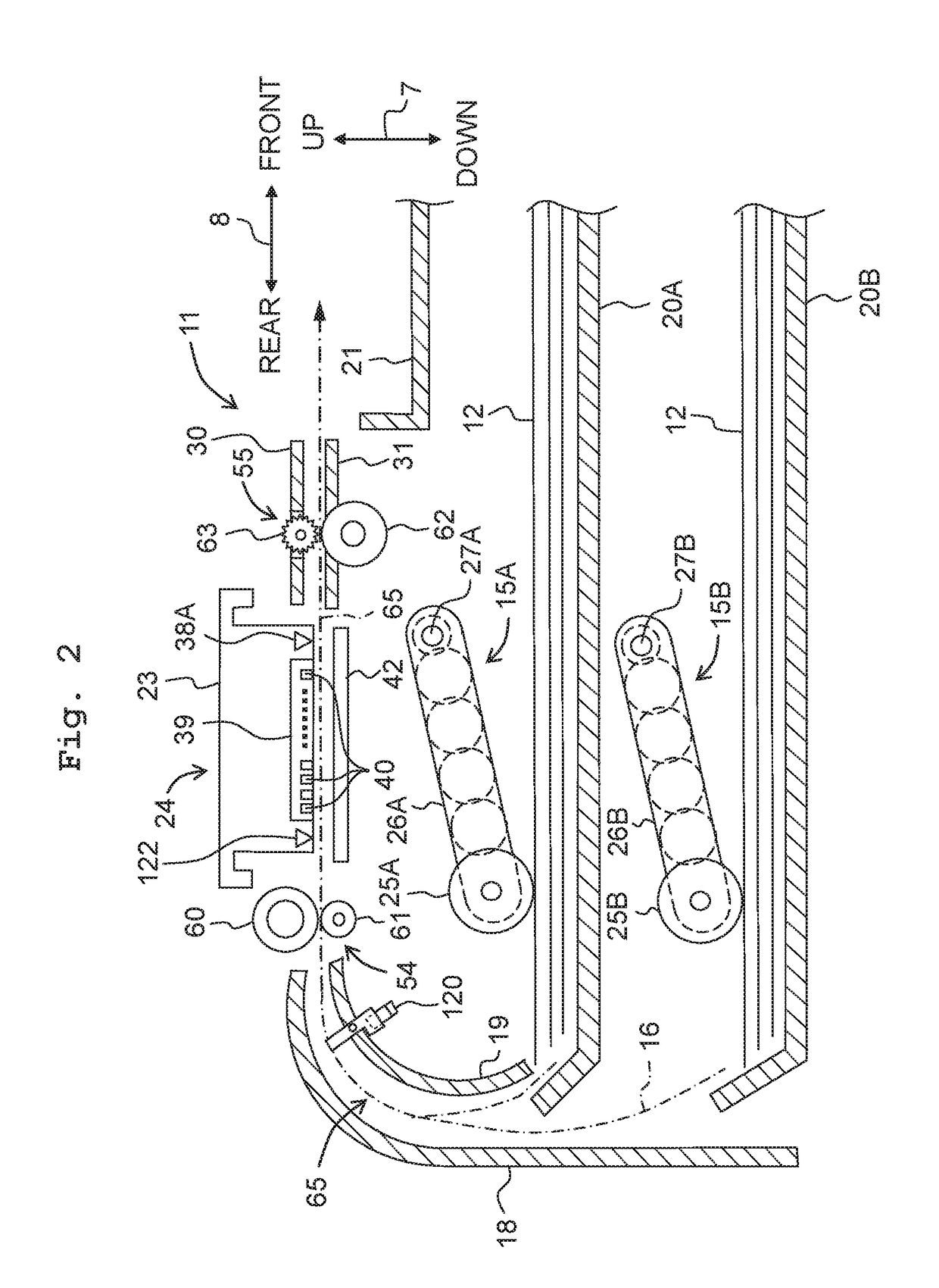

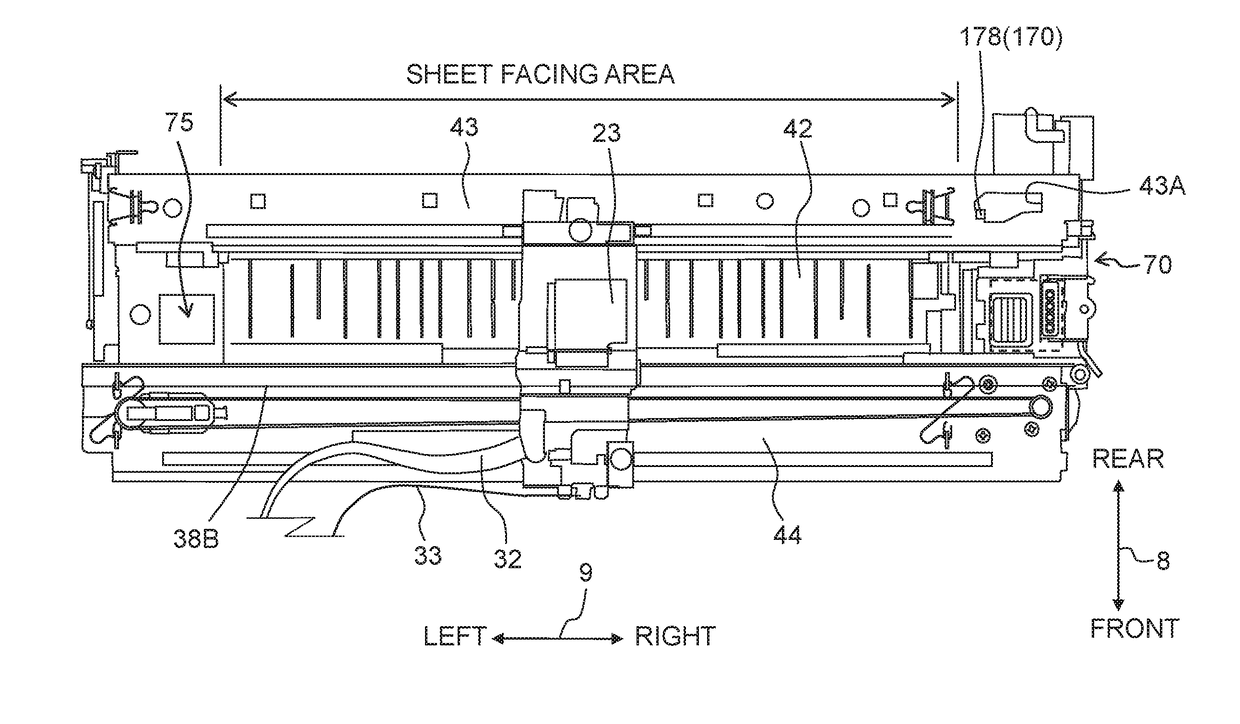

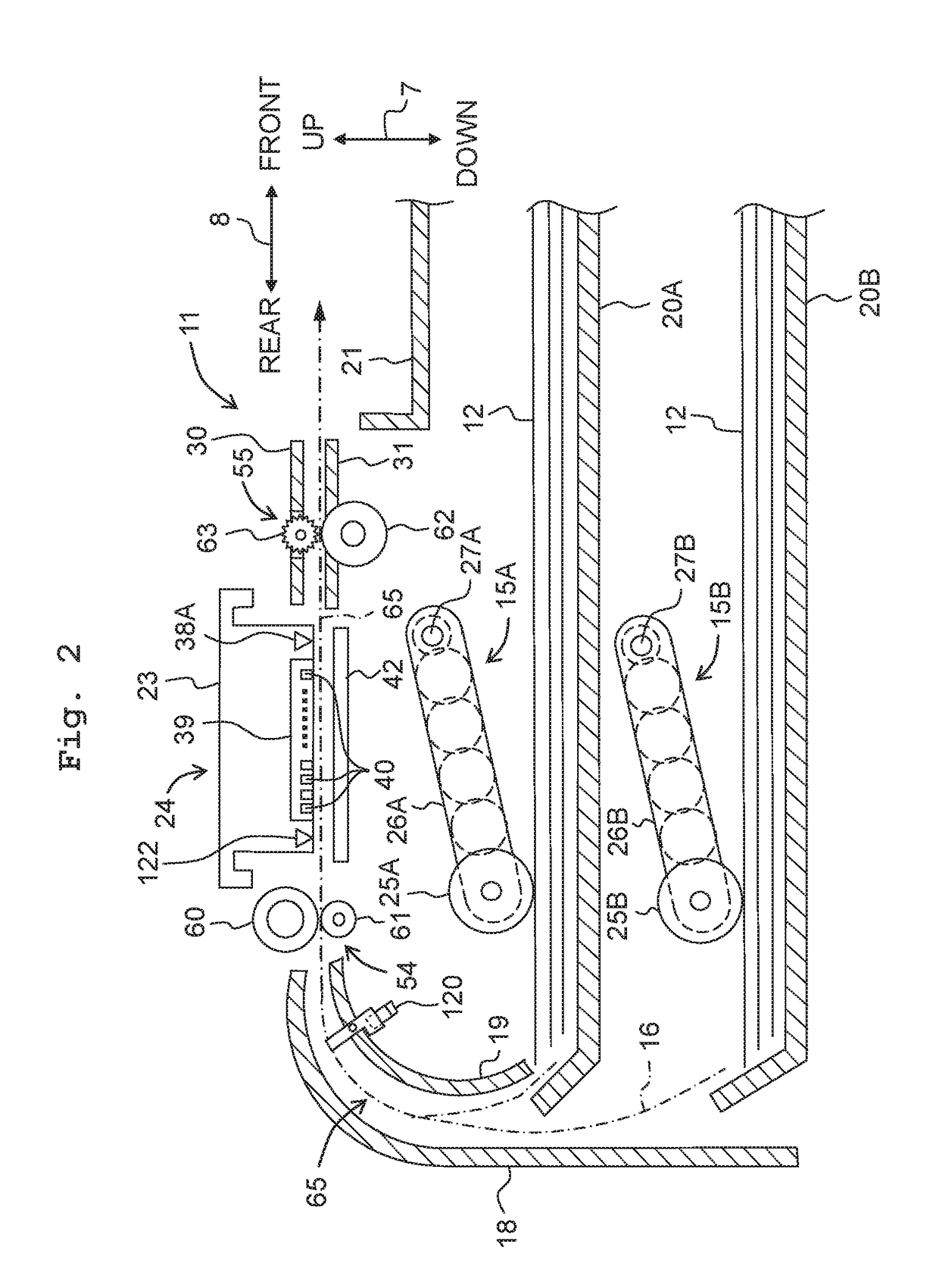

Feeding device and image forming apparatus

ActiveUS20150344246A1Reduce decreaseEnhance the imageFunction indicatorsArticle feedersEngineeringContact position

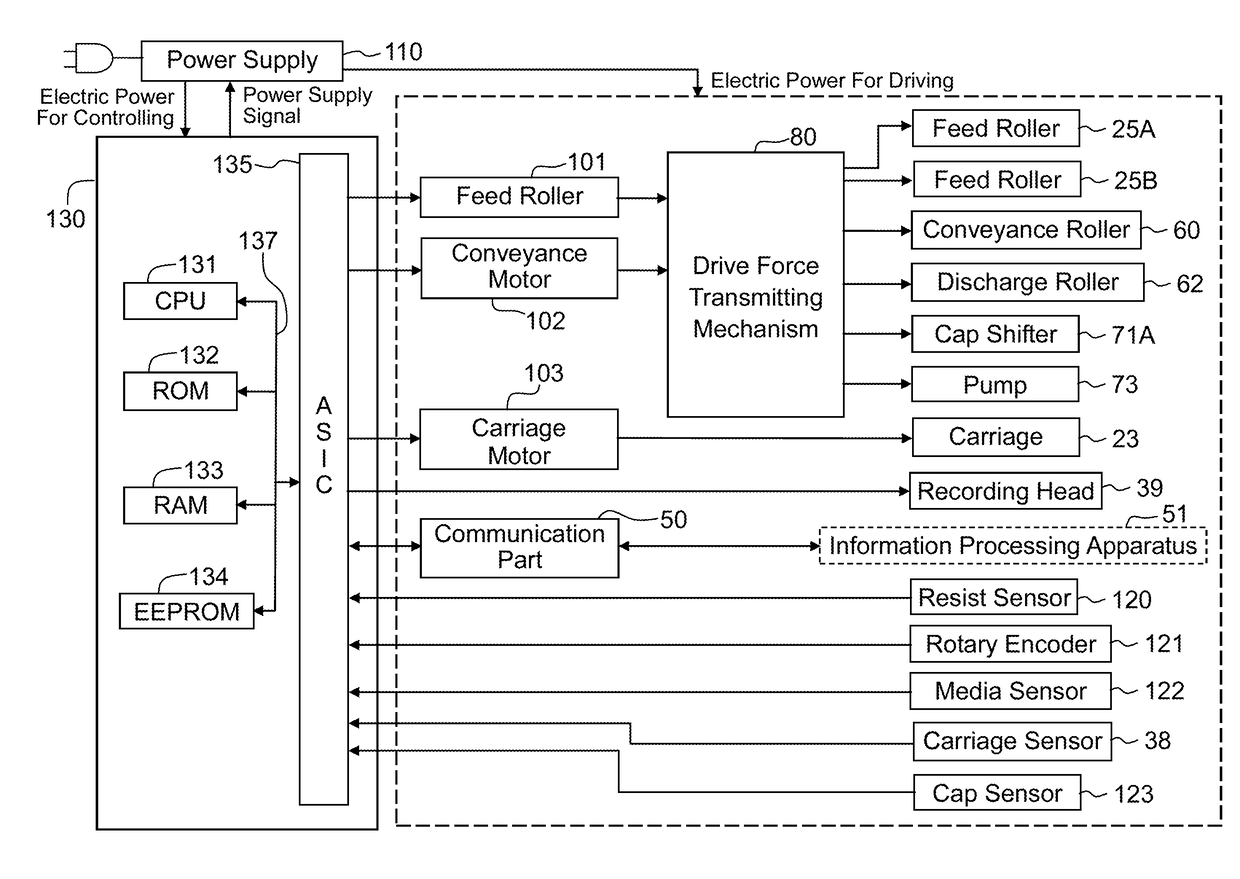

A pickup roller is moved to a retracted position by rotating a feeding motor in reverse by a first predetermined amount and is moved to a contact position by rotating the feeding motor forward by a second predetermined amount.

Owner:CANON KK

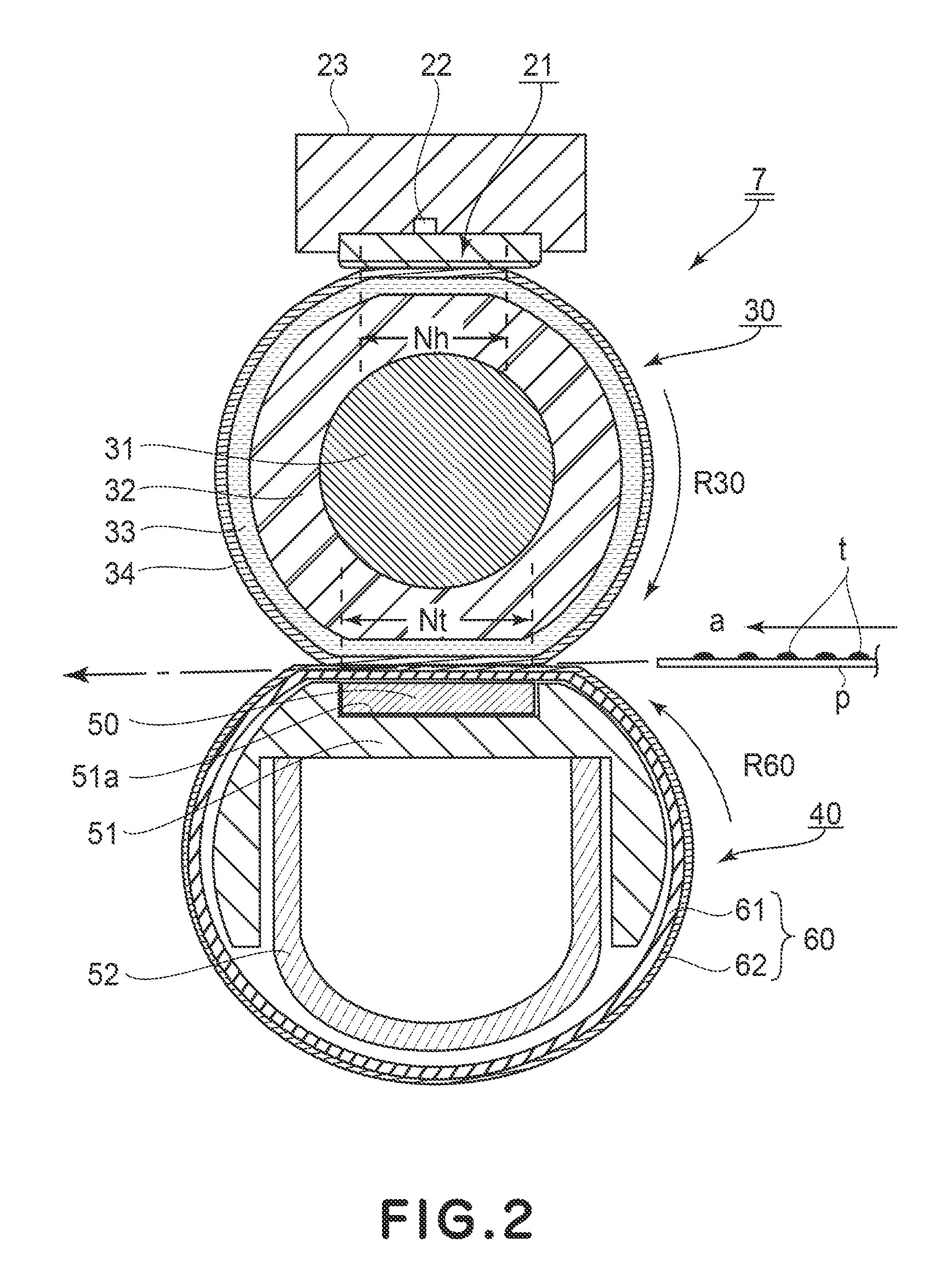

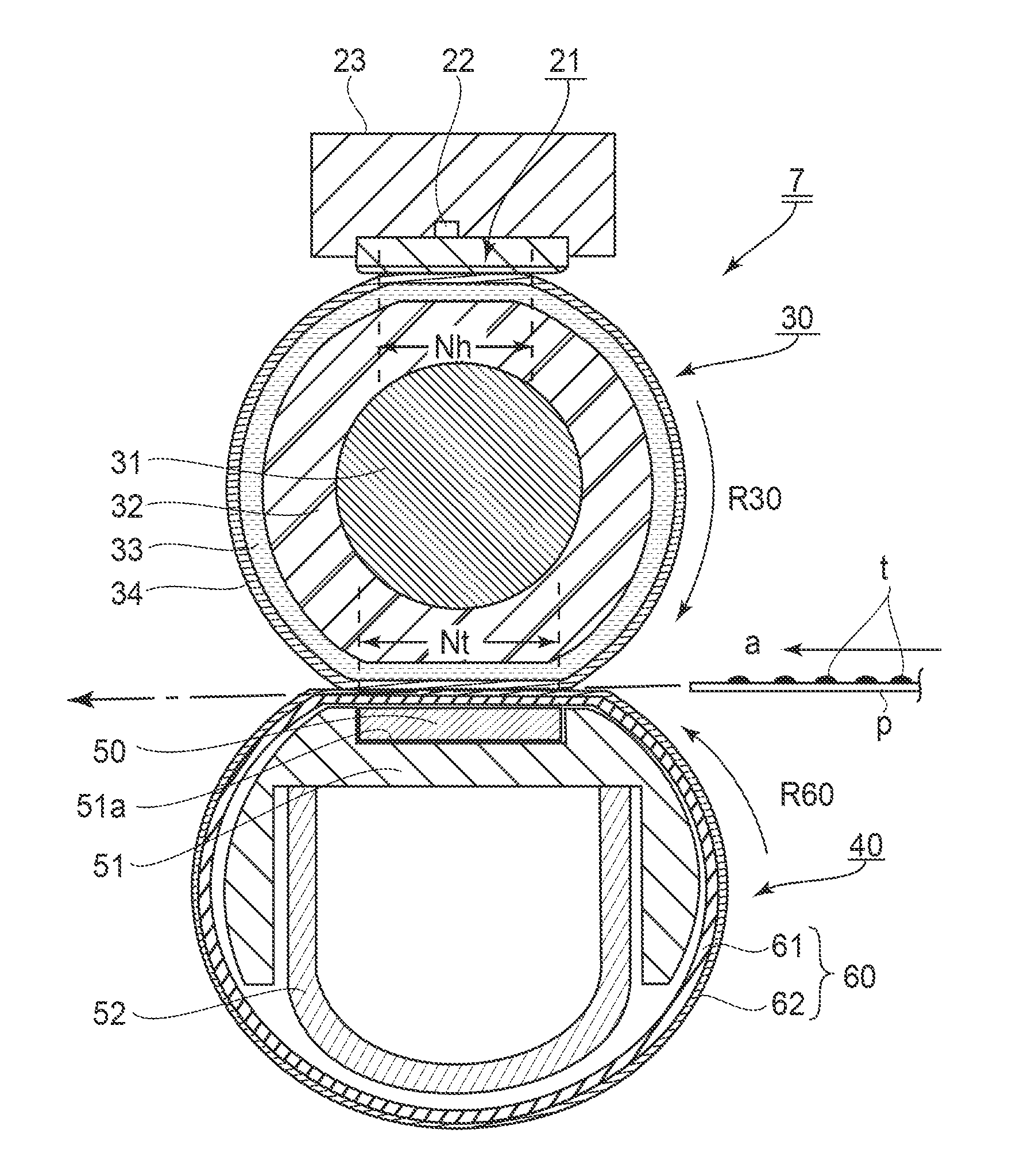

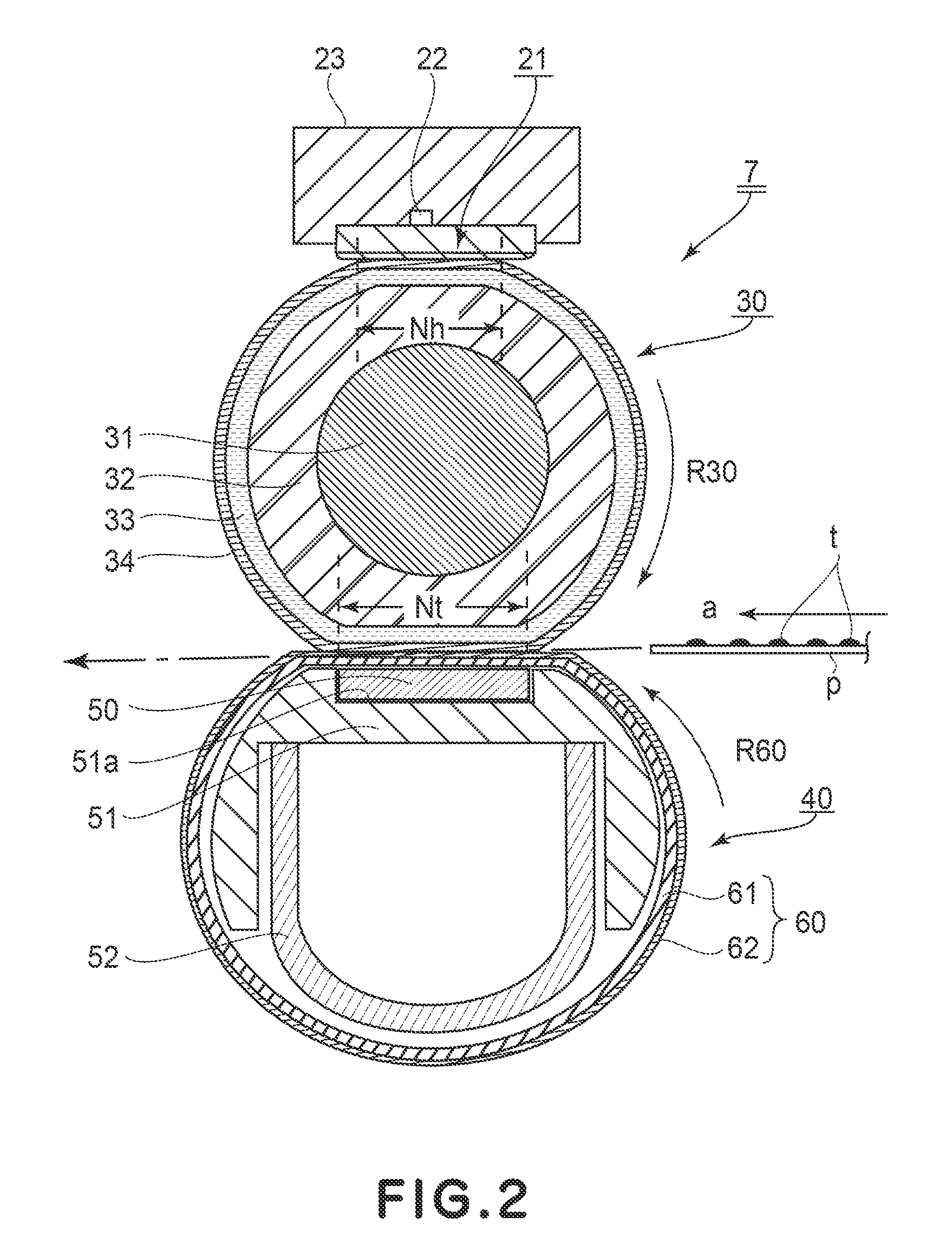

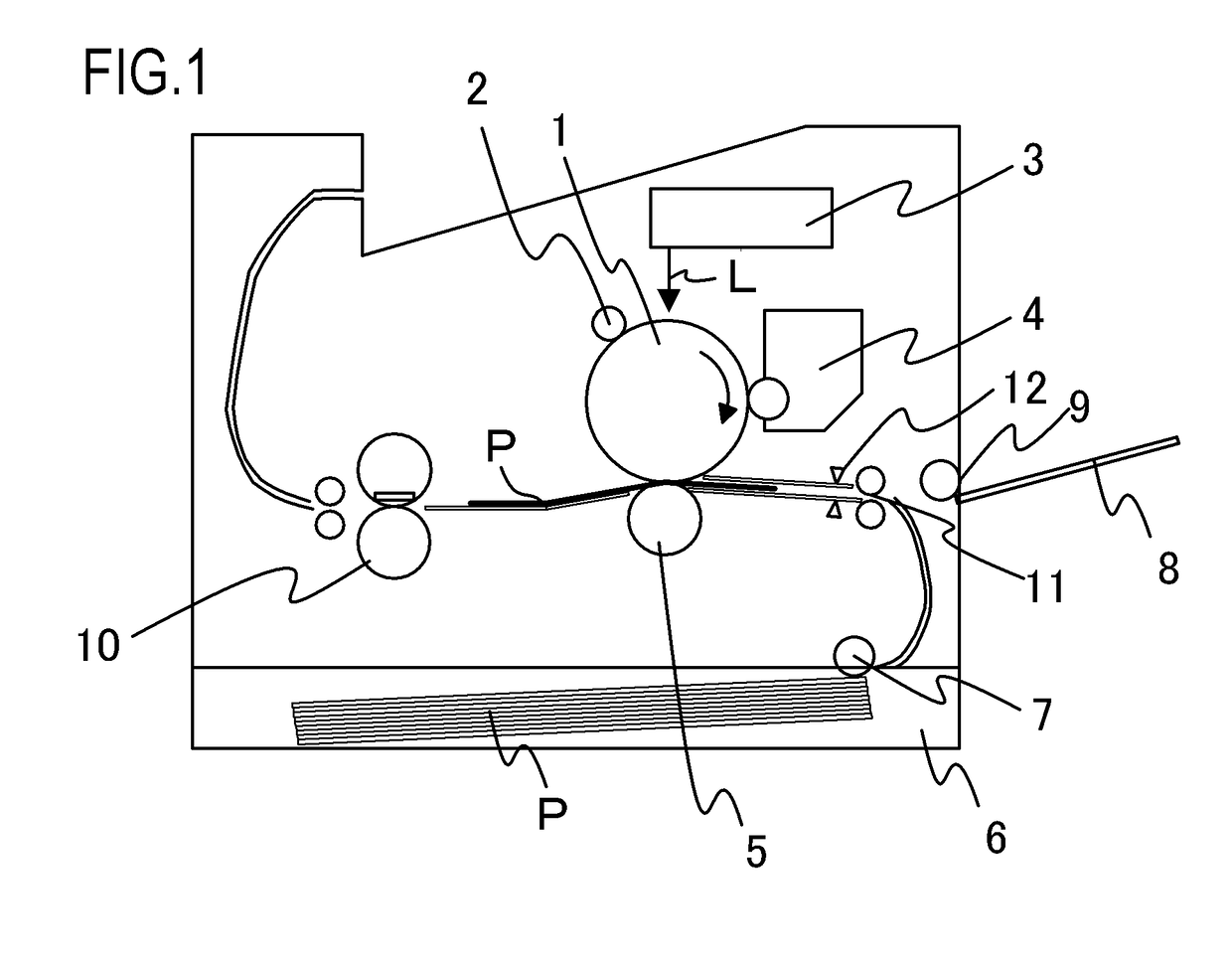

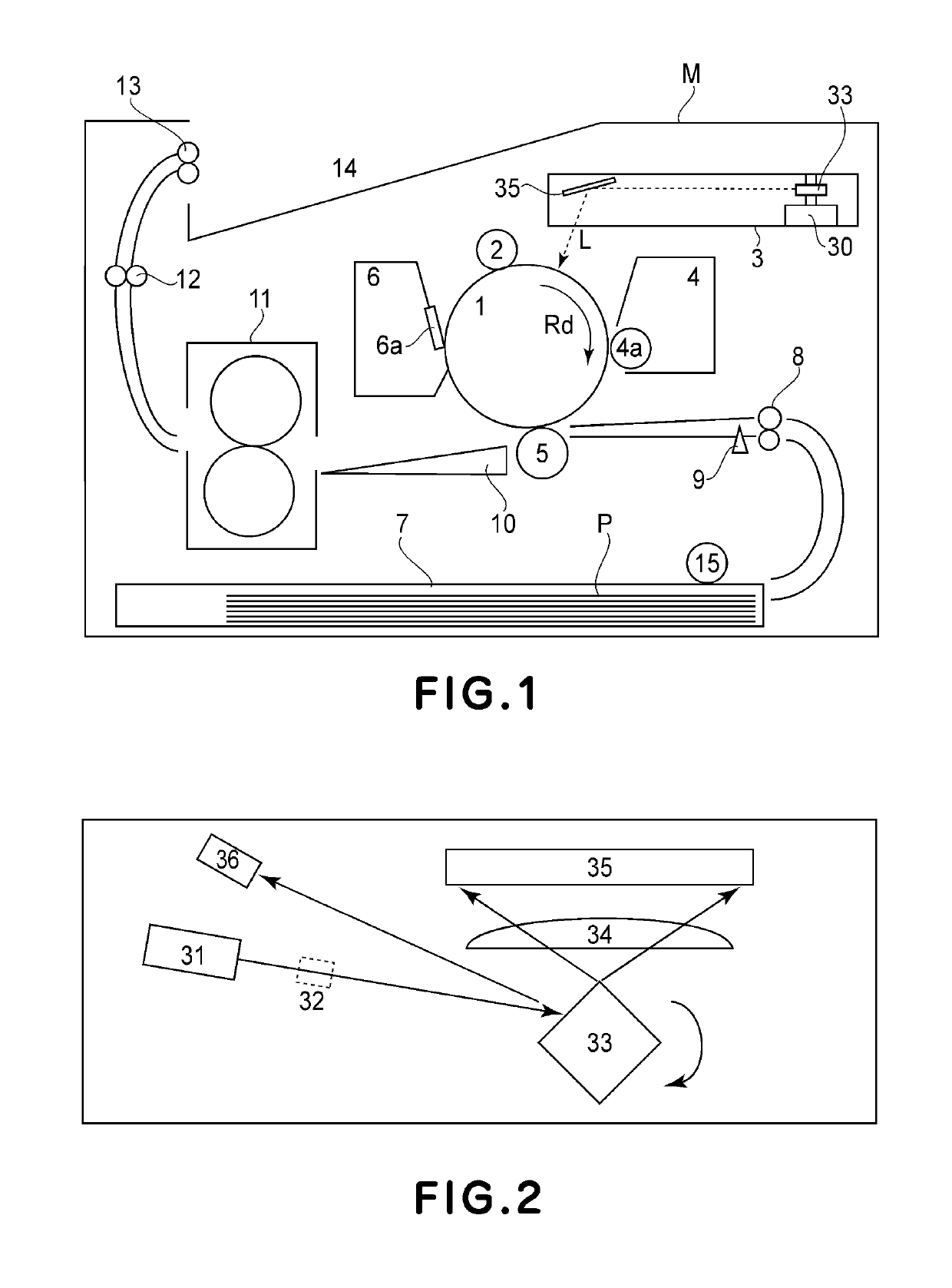

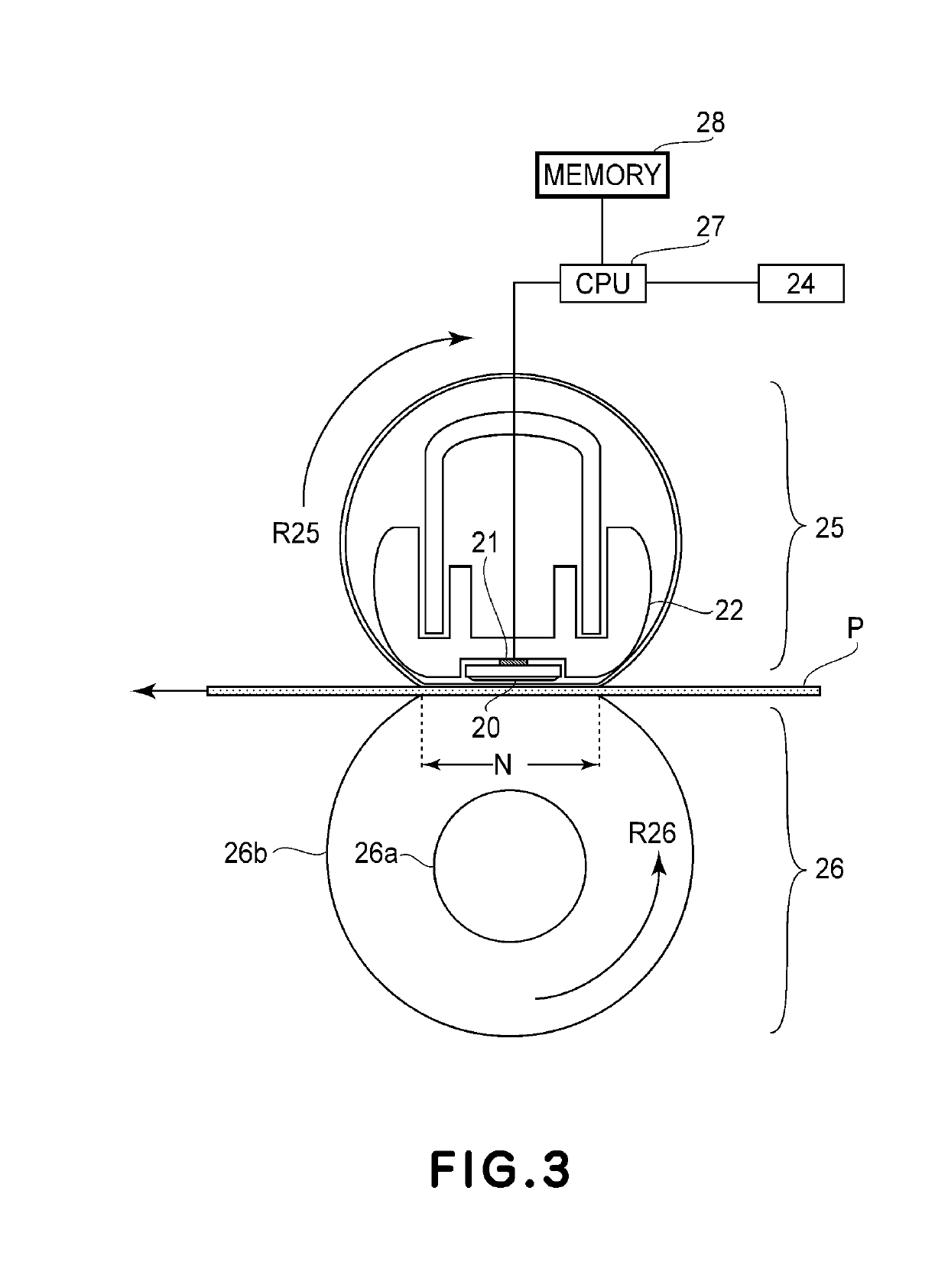

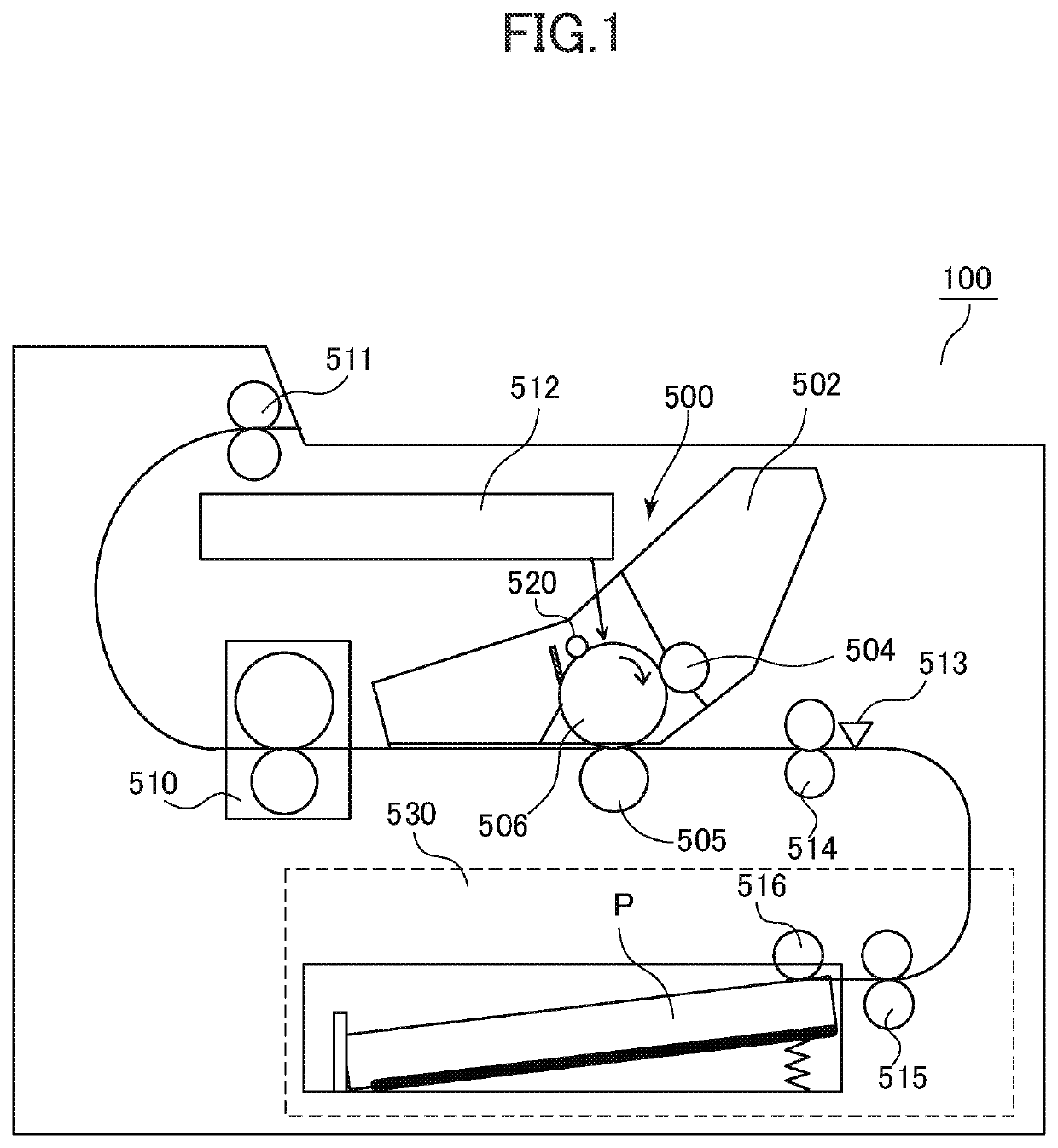

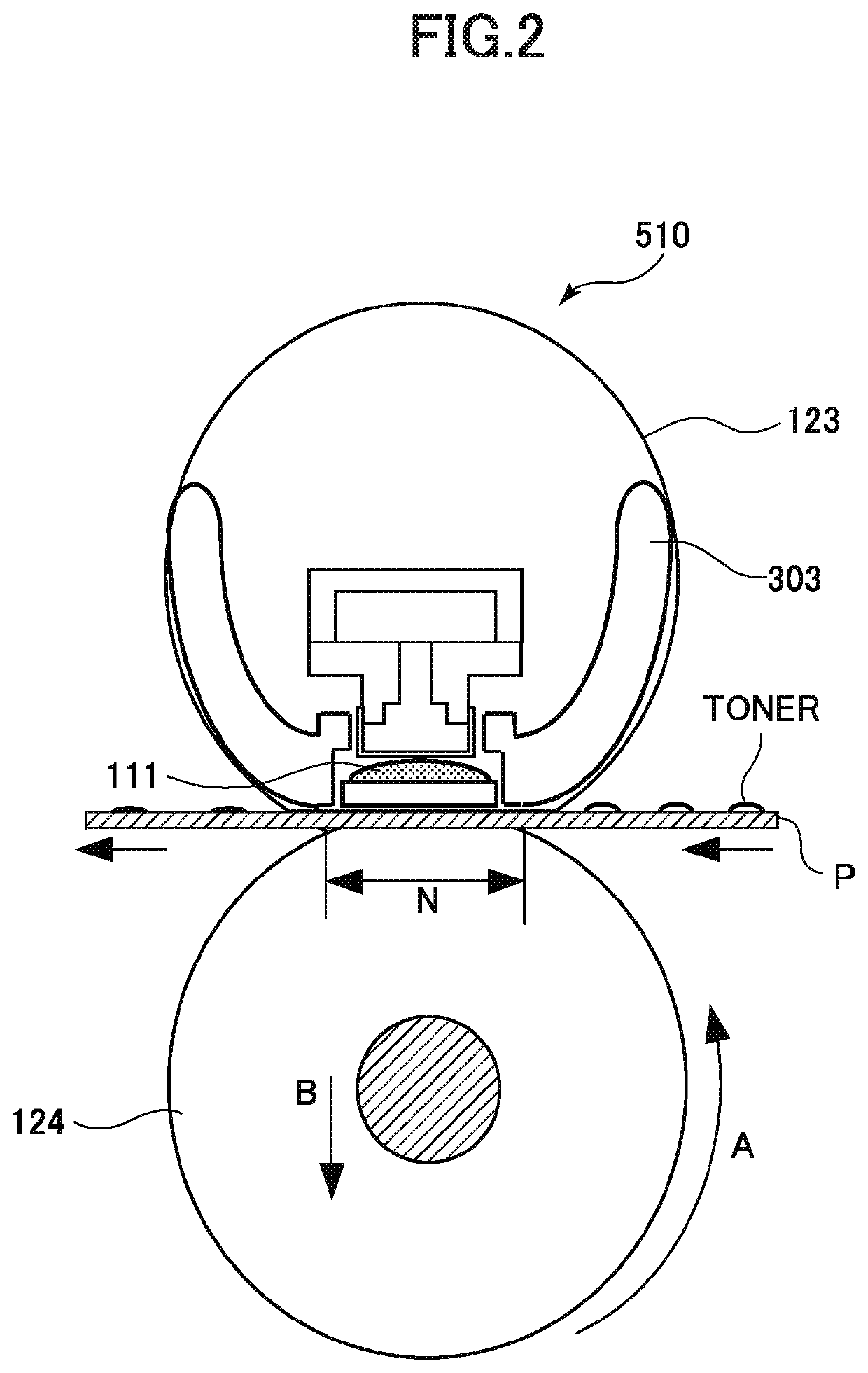

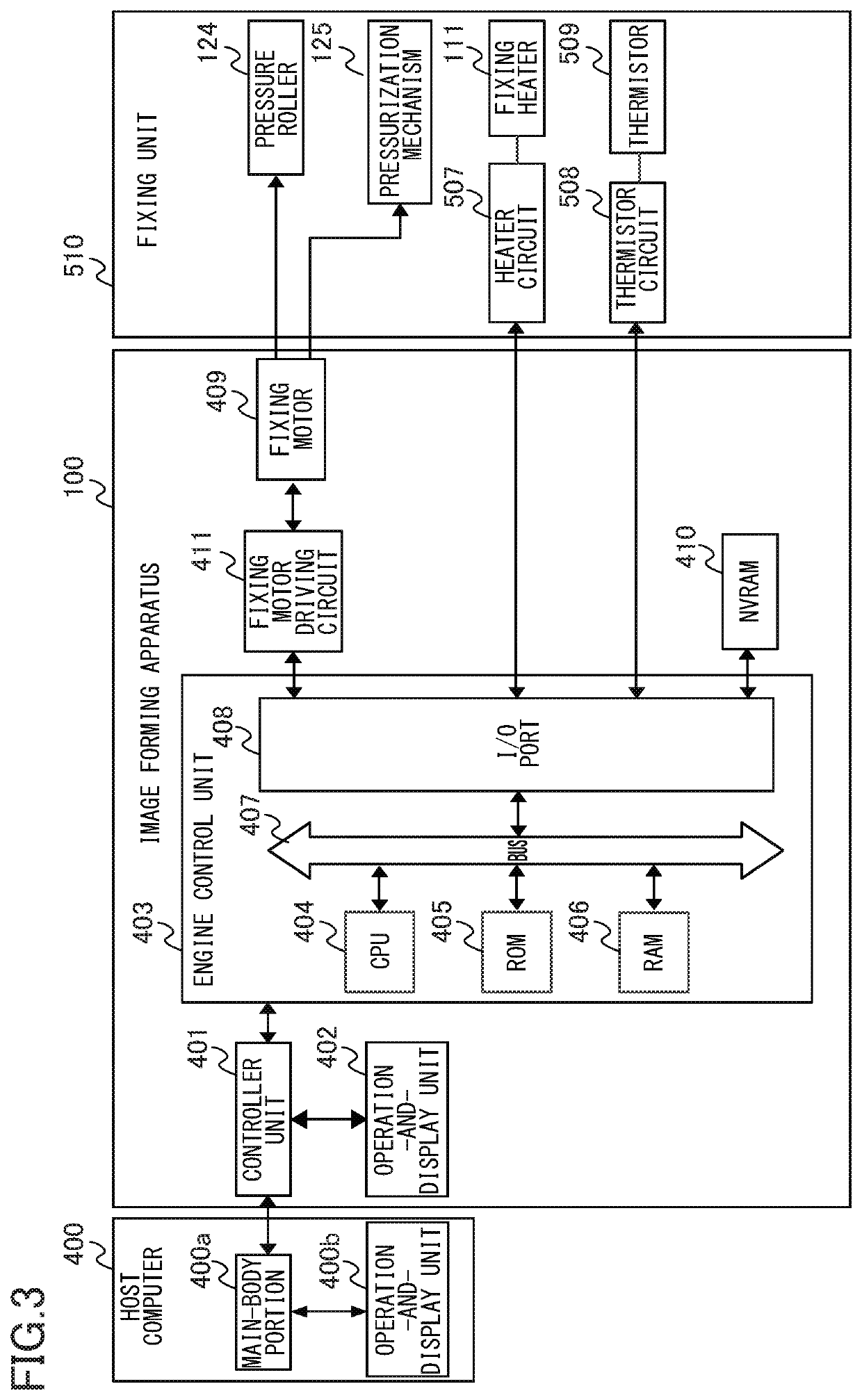

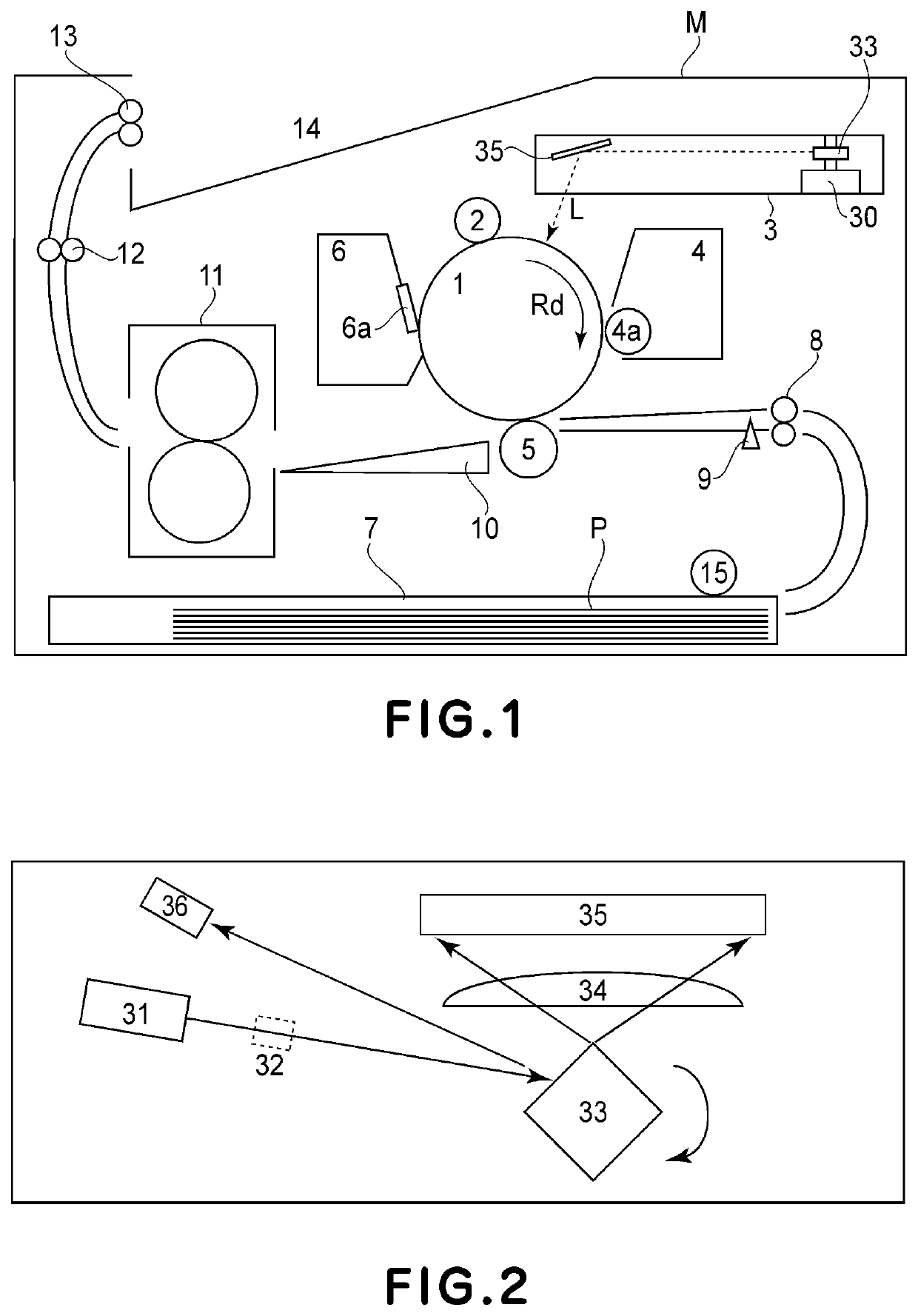

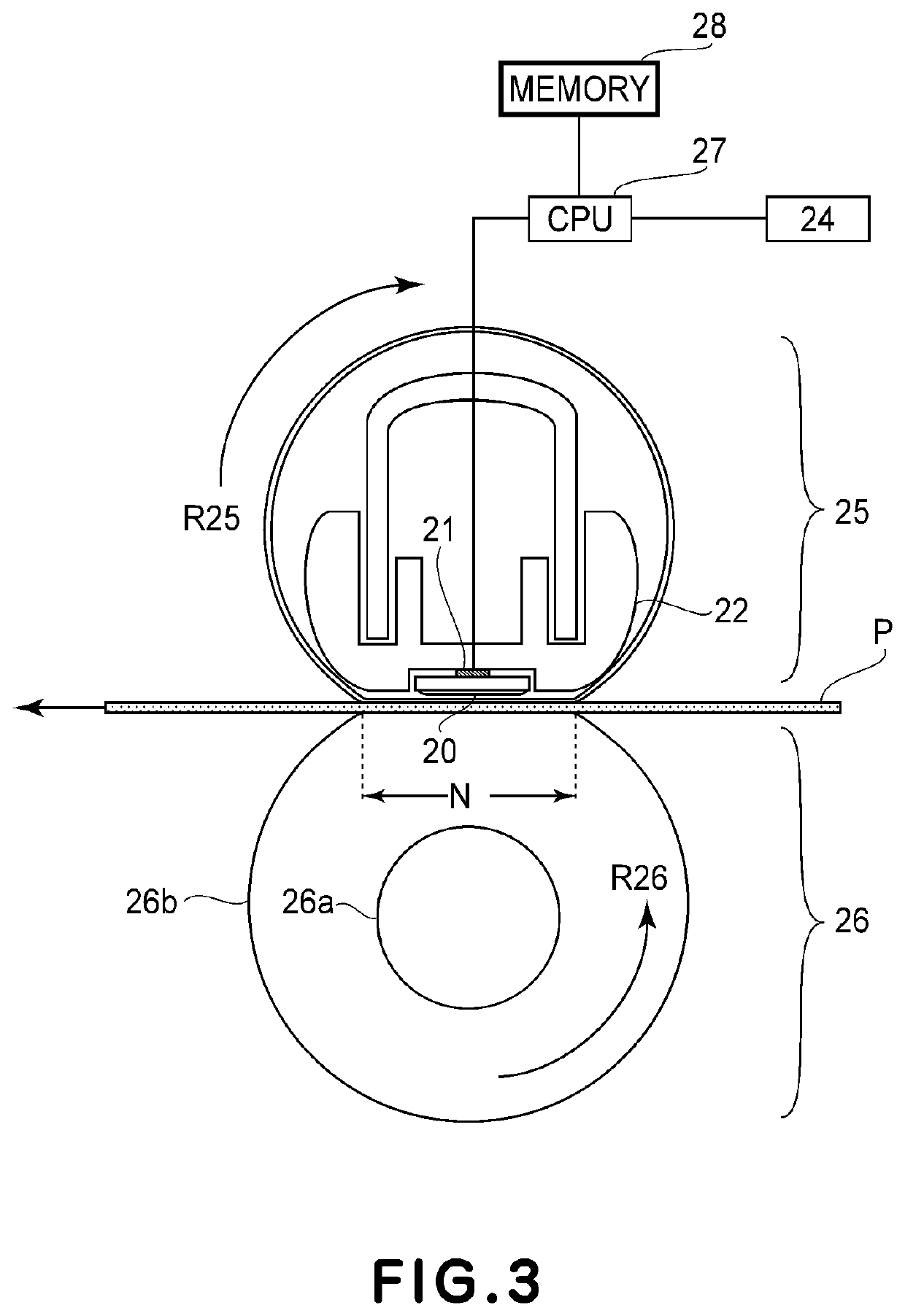

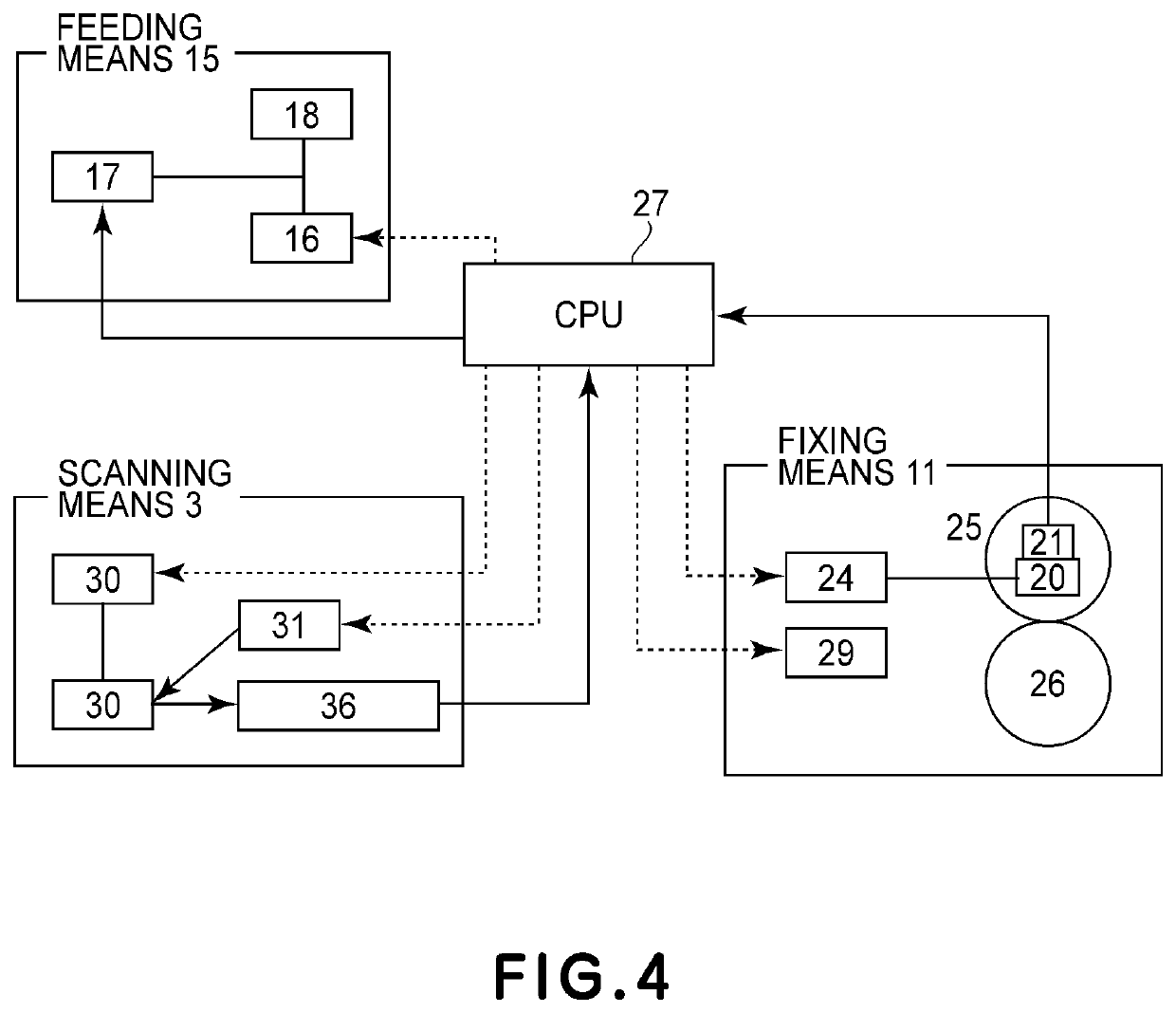

Image heating apparatus

ActiveUS20120328341A1Reduce capacityShorten FPOTElectrographic process apparatusEngineeringThermal transmittance

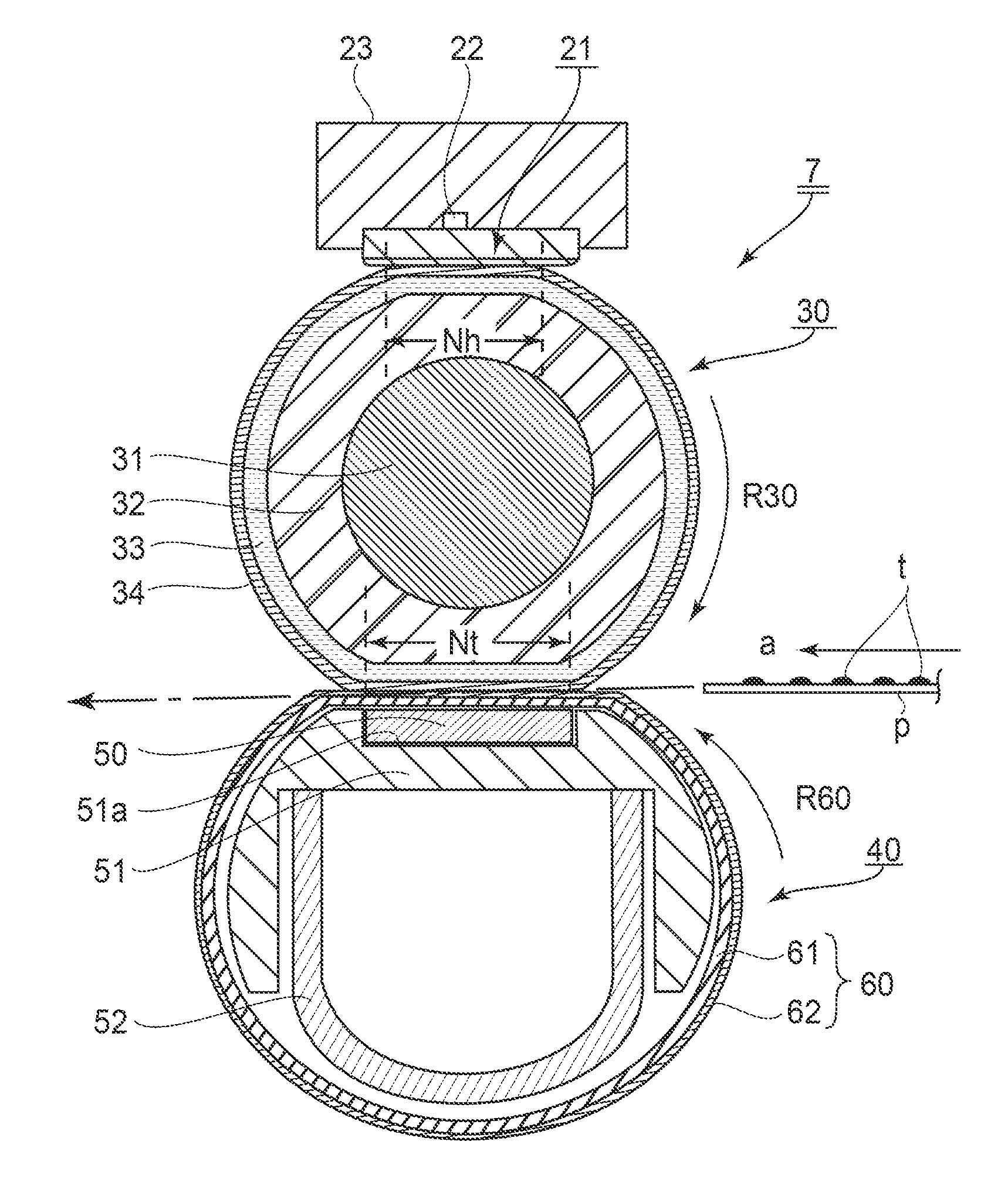

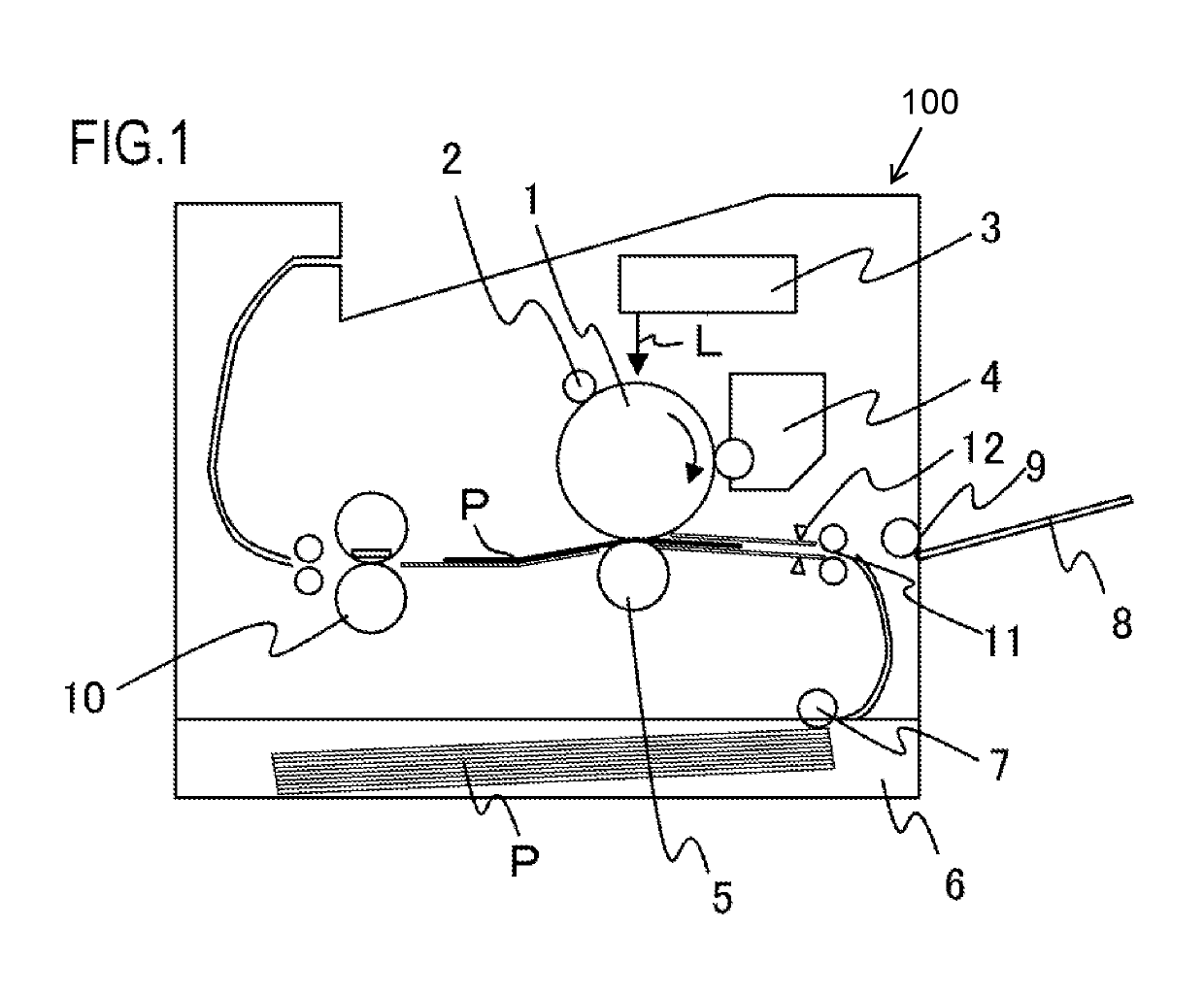

An image heating apparatus for heating a recording material, on which a toner image is carried, while conveying the recording material in a nip includes: a fixing roller including a core metal, a heat insulating layer formed on a surface of the core metal, and a high heat transfer layer which is formed on an outer peripheral surface of the heat insulating layer and has a higher thermal conductivity than the heat insulating layer; a heating member for heating the fixing roller from an outside; and a back-up member for forming the nip together with the fixing roller. When the fixing roller and the back-up member opposing the fixing roller are supplied with the same heat quantity, a temperature rise rate in a neighborhood of the surface of the back-up member supplied with the heat quantity is higher than that of the fixing roller.

Owner:CANON KK

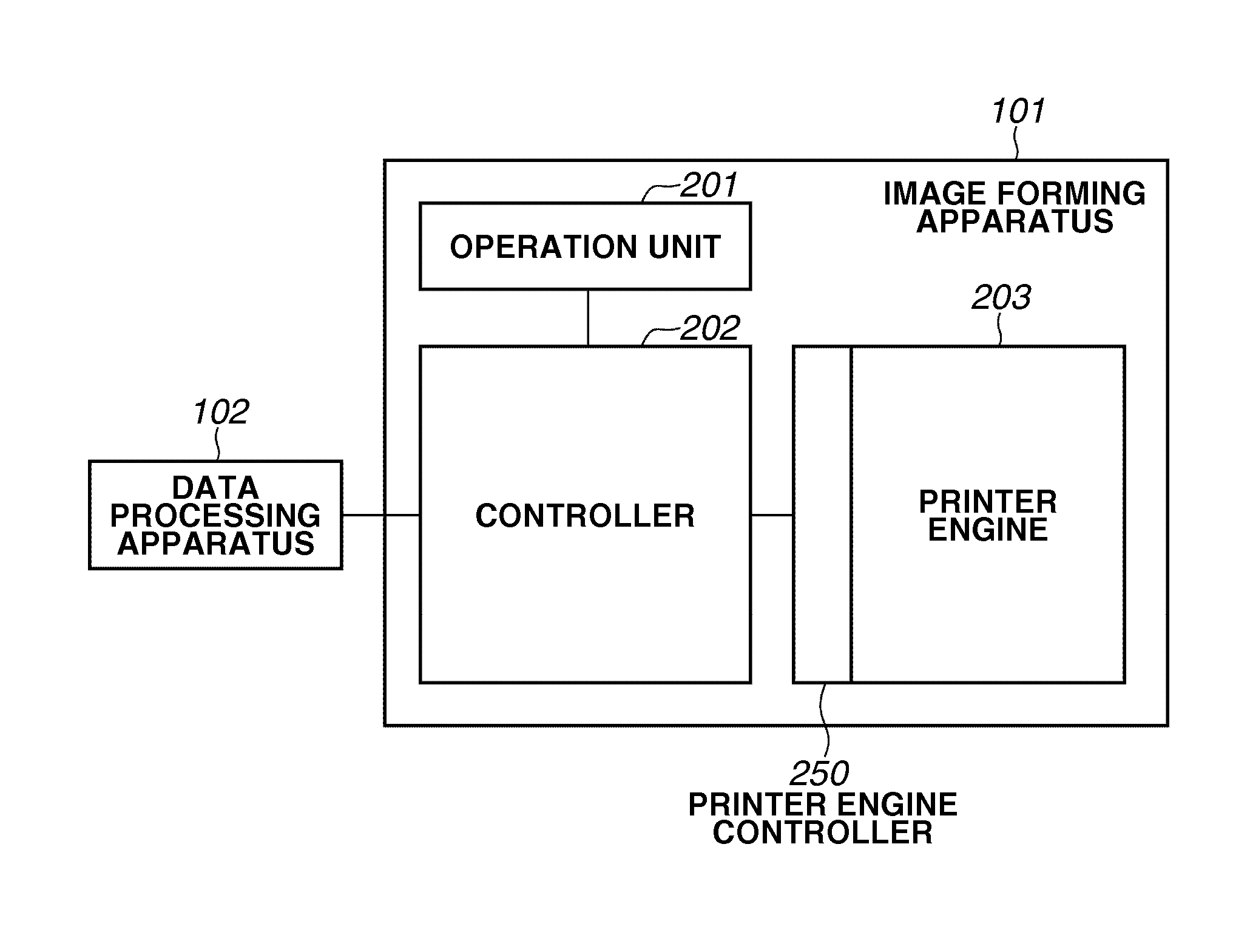

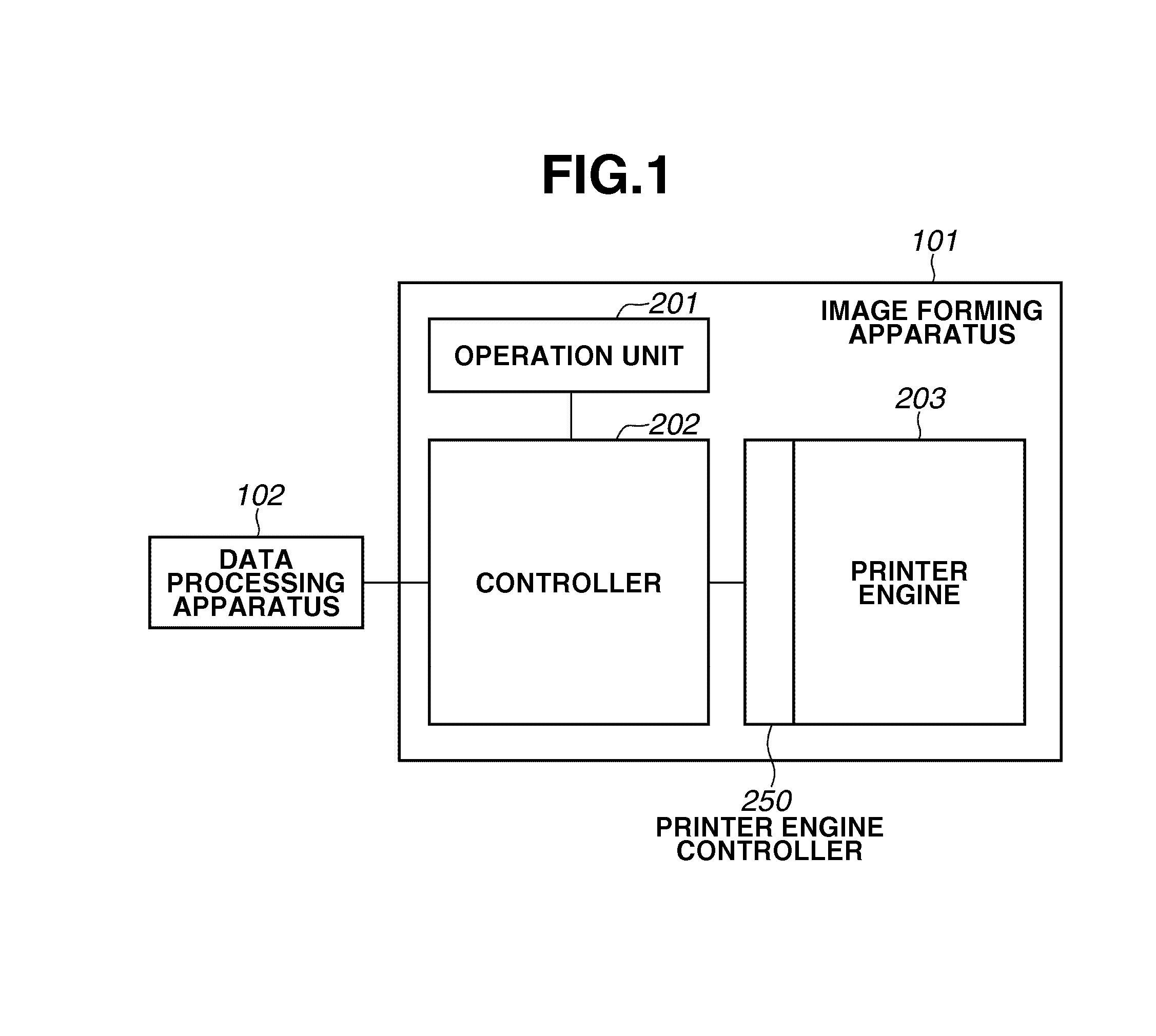

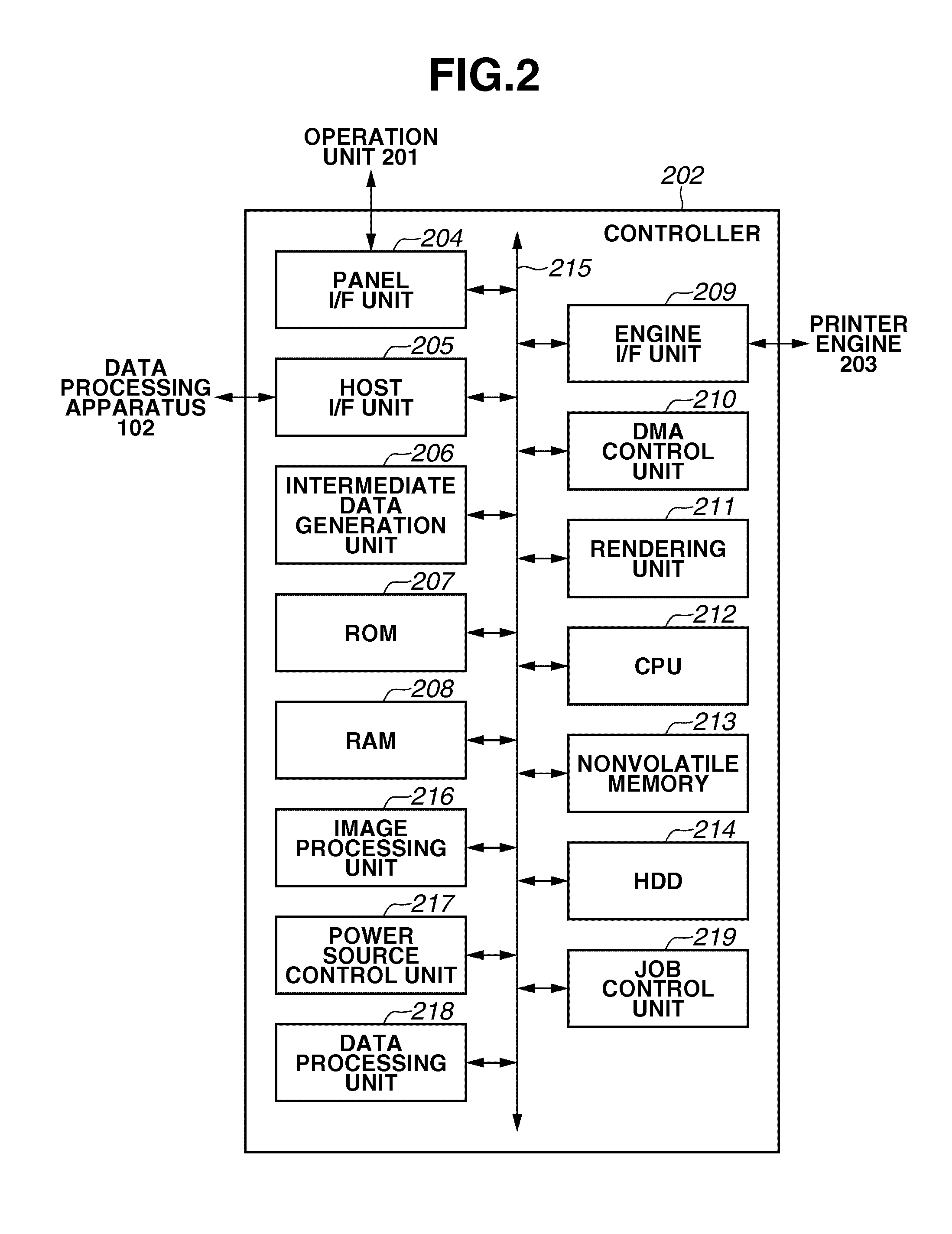

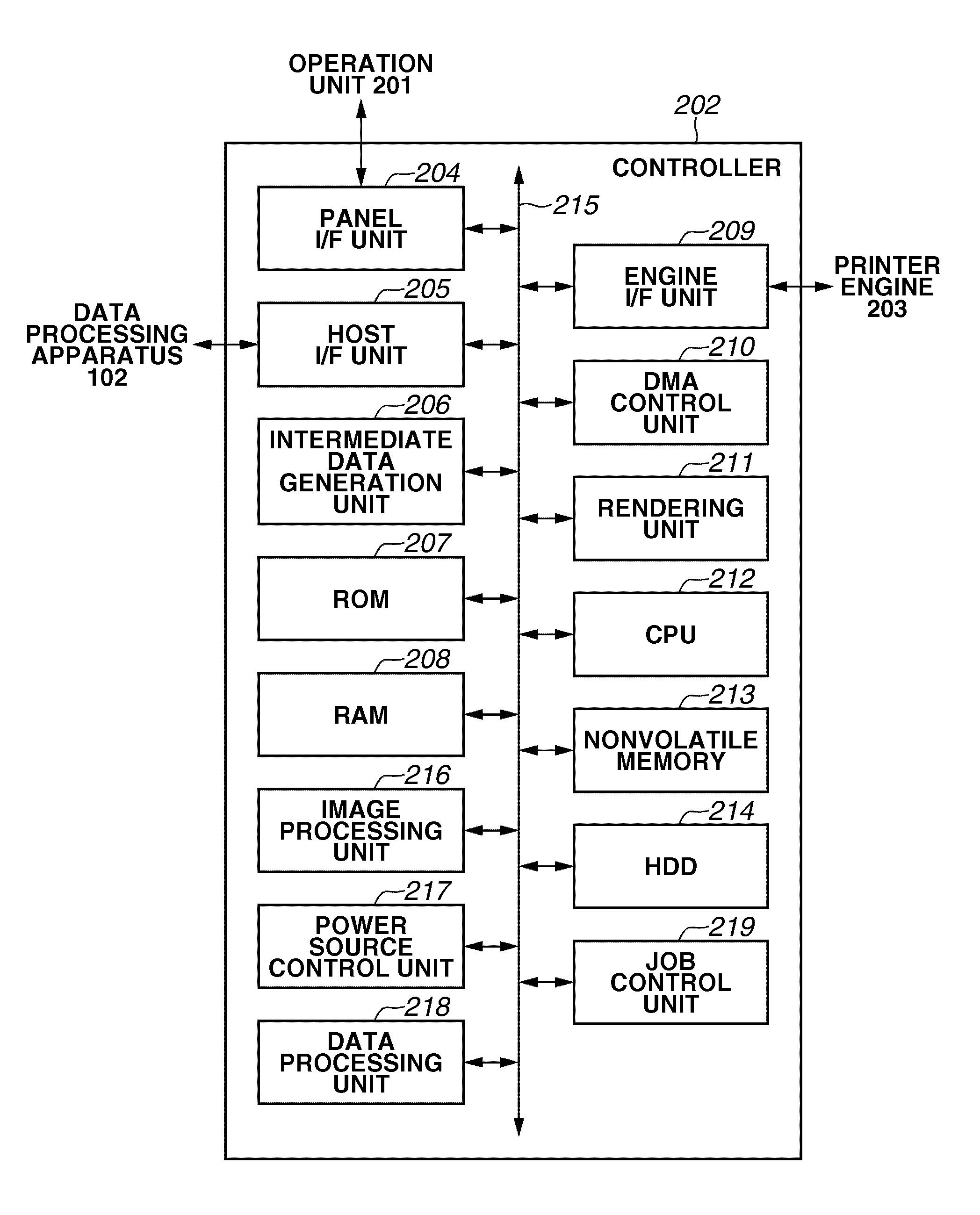

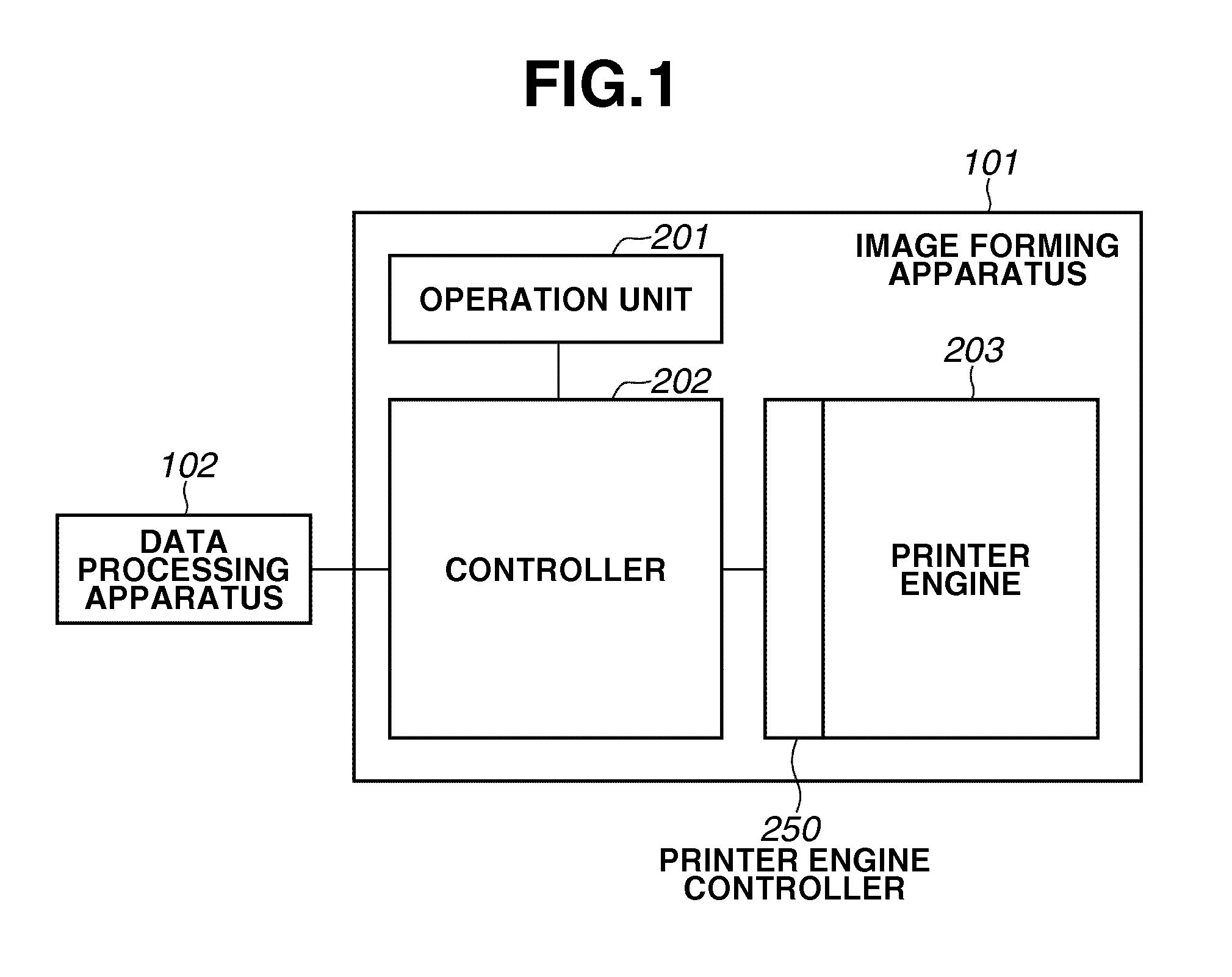

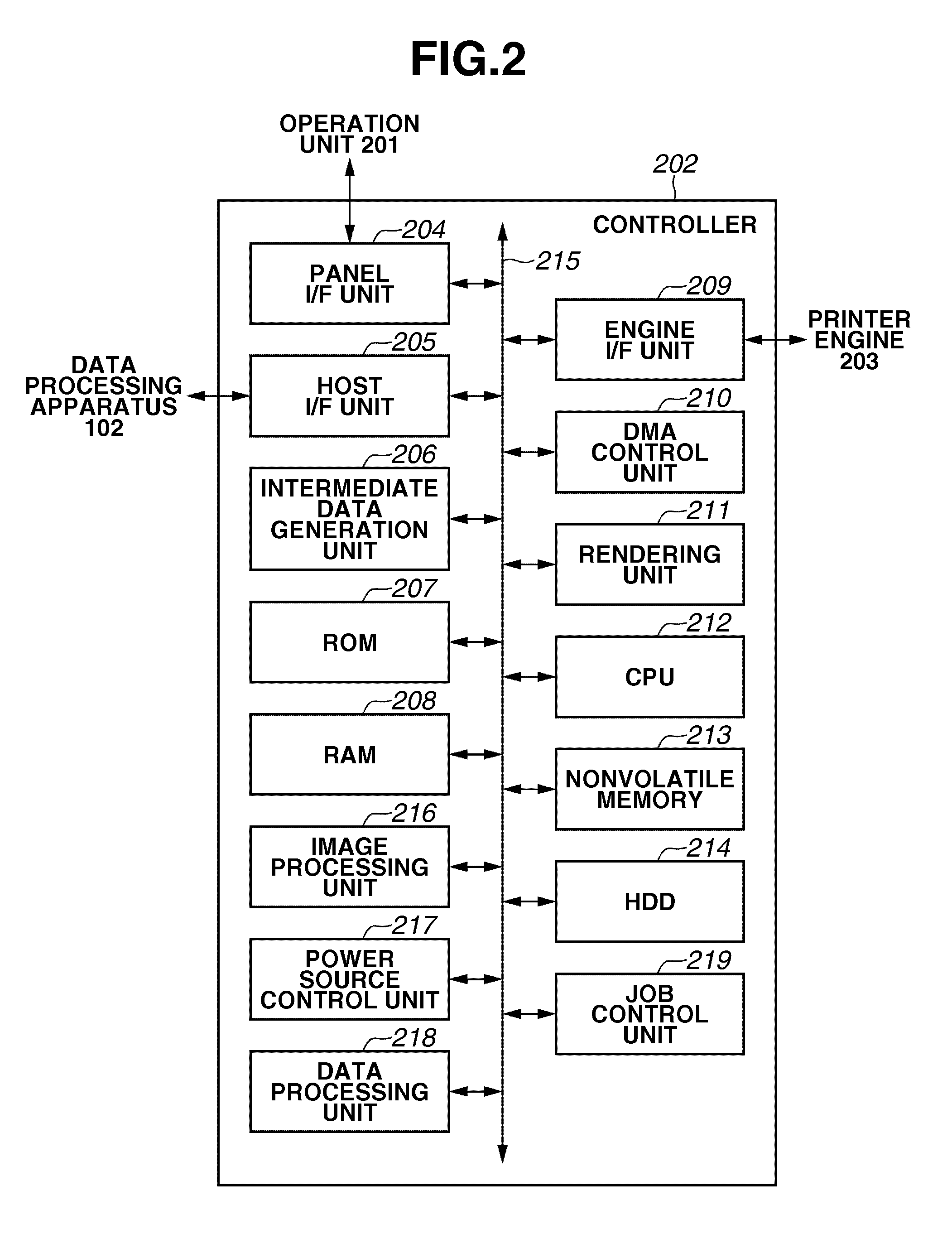

Printing apparatus, control method of the printing apparatus, and storage medium

ActiveUS20140160526A1Shorten FPOTOptimizing temperature adjustment controlElectrographic process apparatusDigital output to print unitsEngineering

A printing apparatus sets, as time for performing pre-processing before performing print processing, first time if the printing rate calculated by the calculation unit is smaller than a predetermined value, and second time that is longer than the first time if the printing rate calculated by the calculation unit is larger than the predetermined value.

Owner:CANON KK

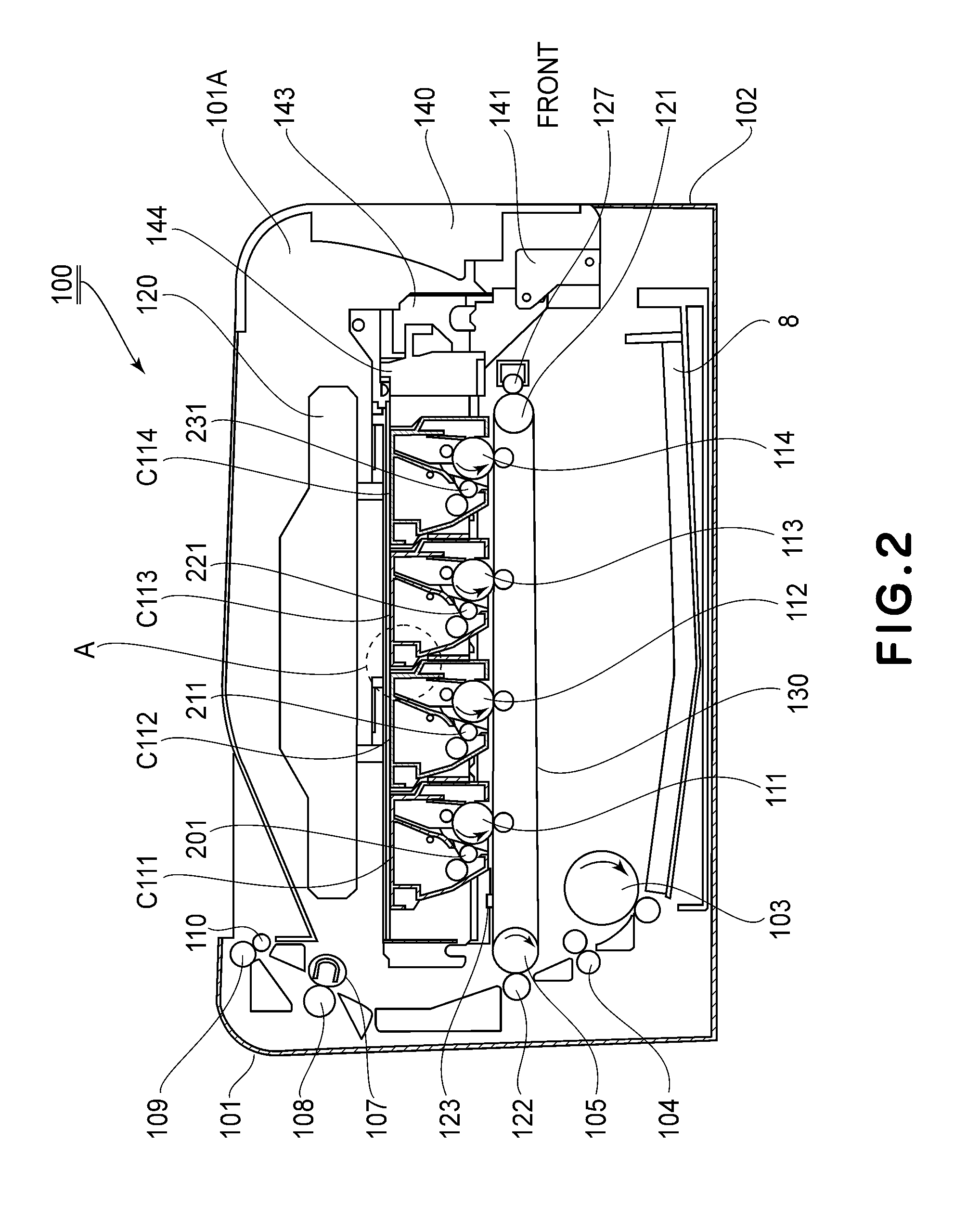

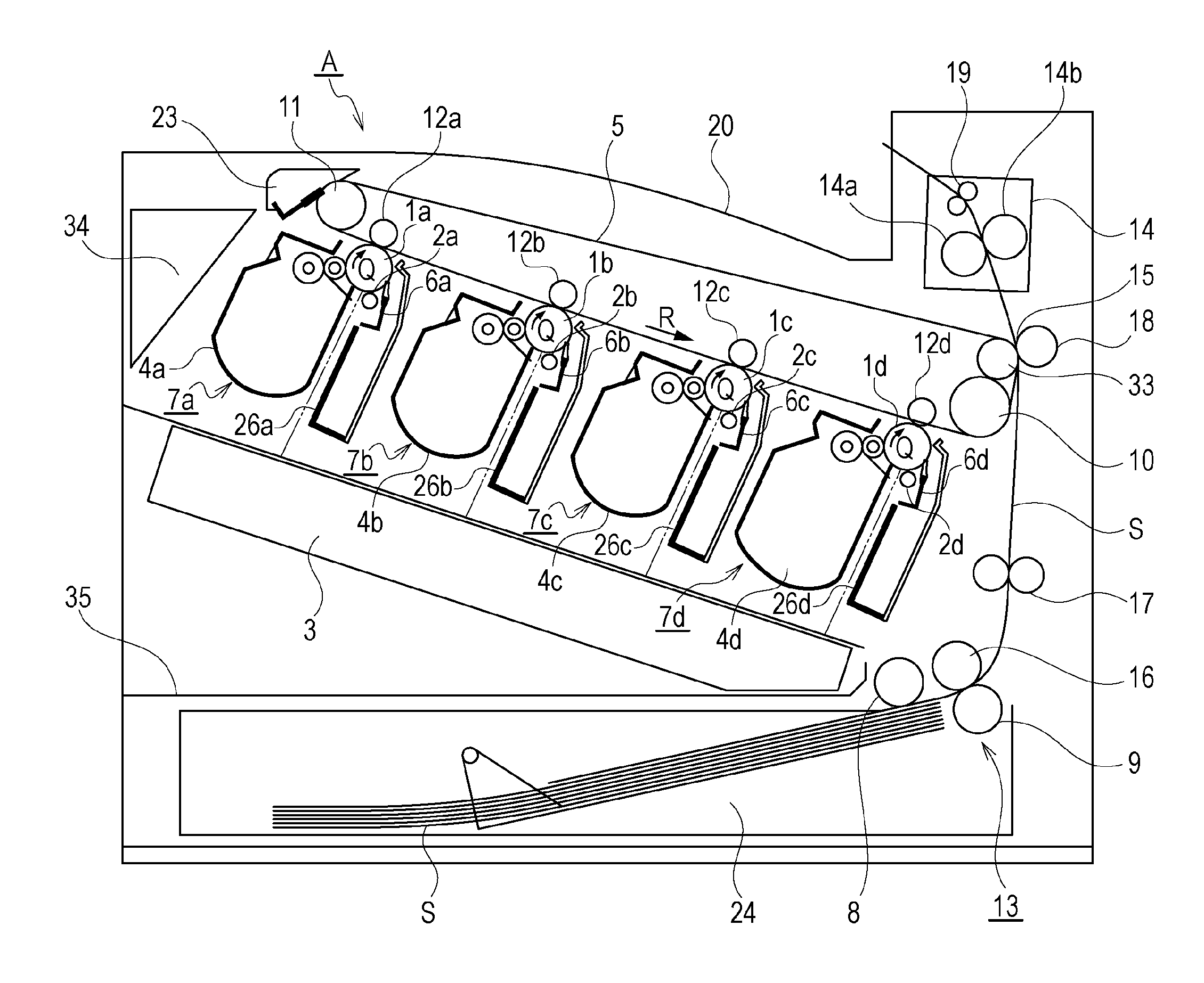

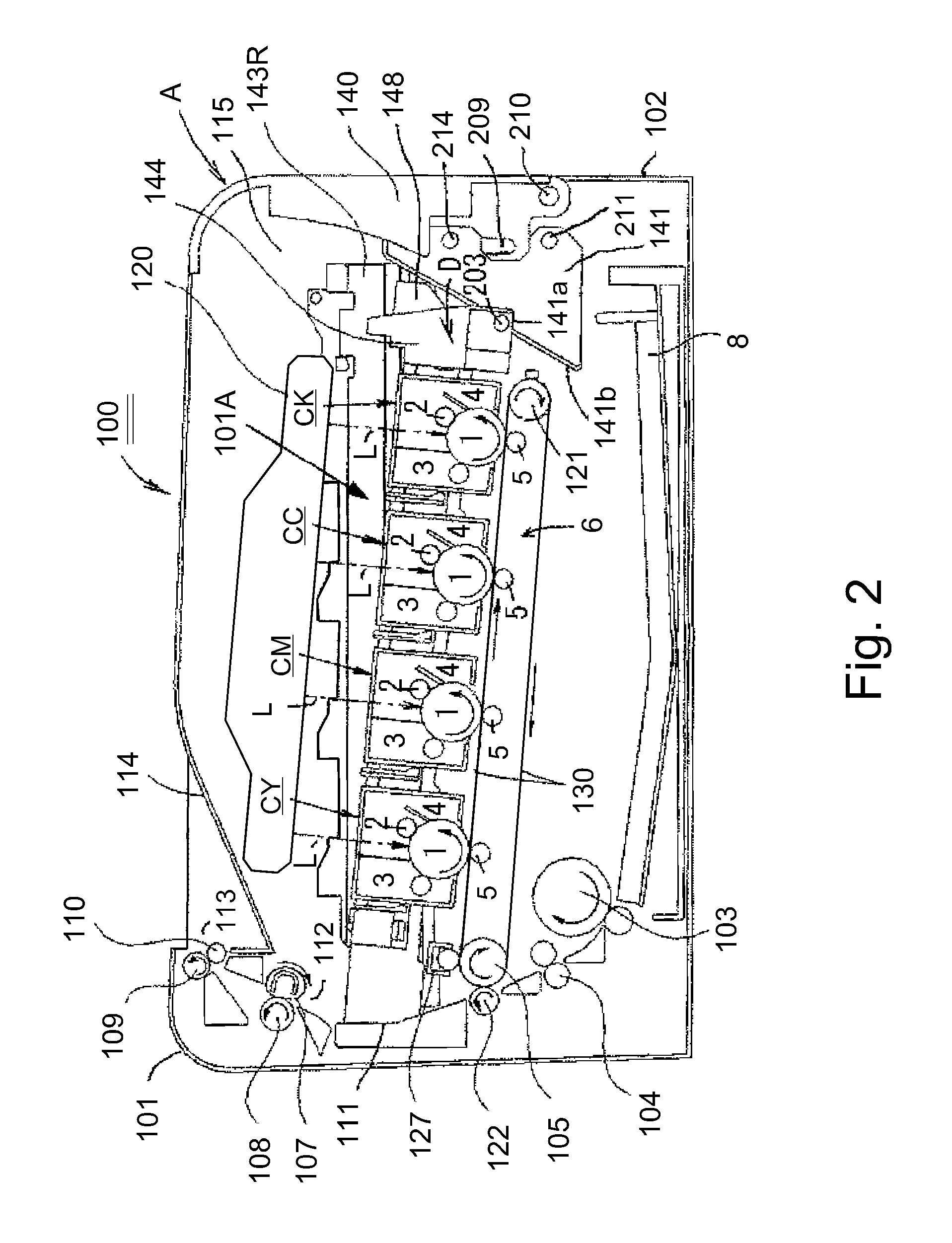

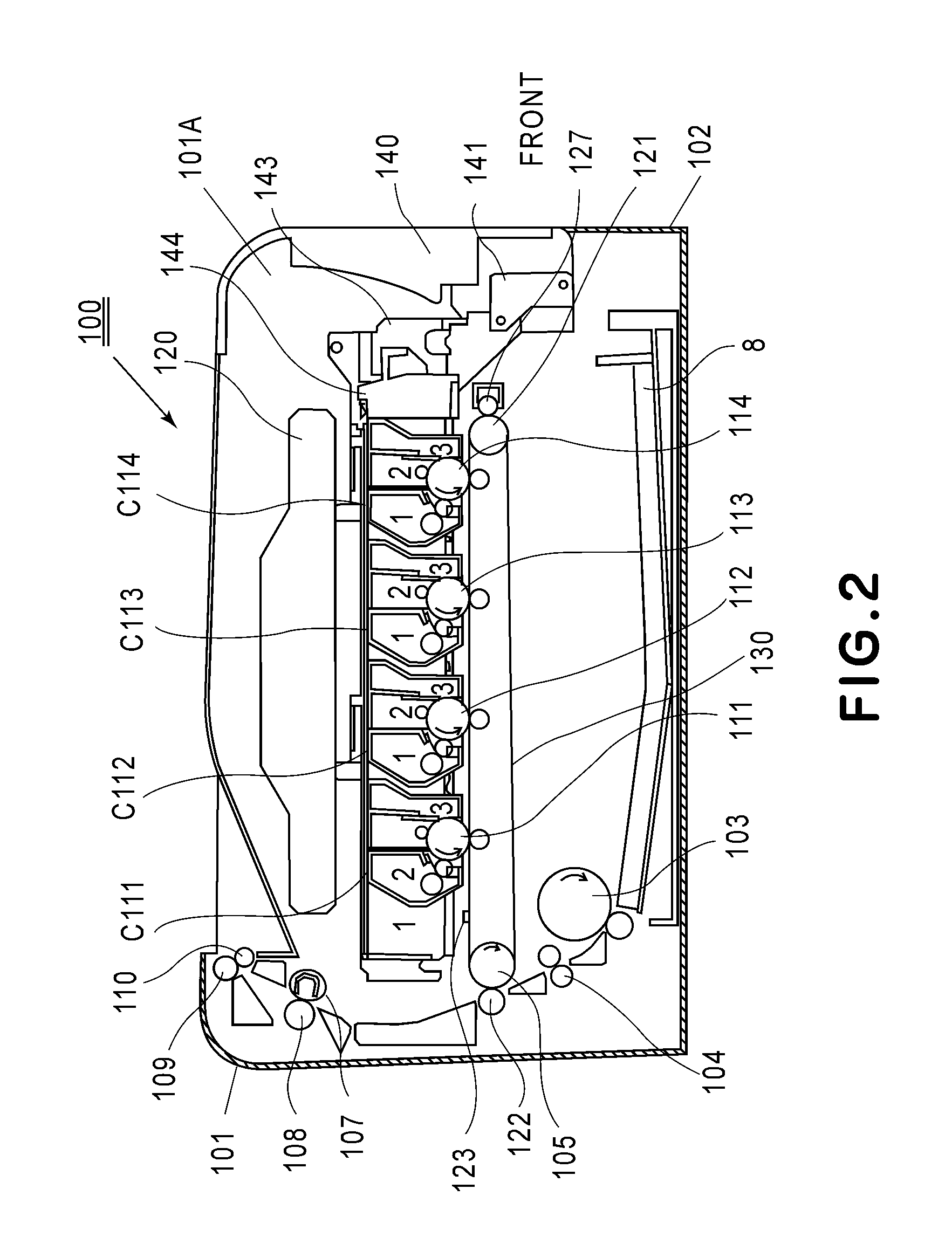

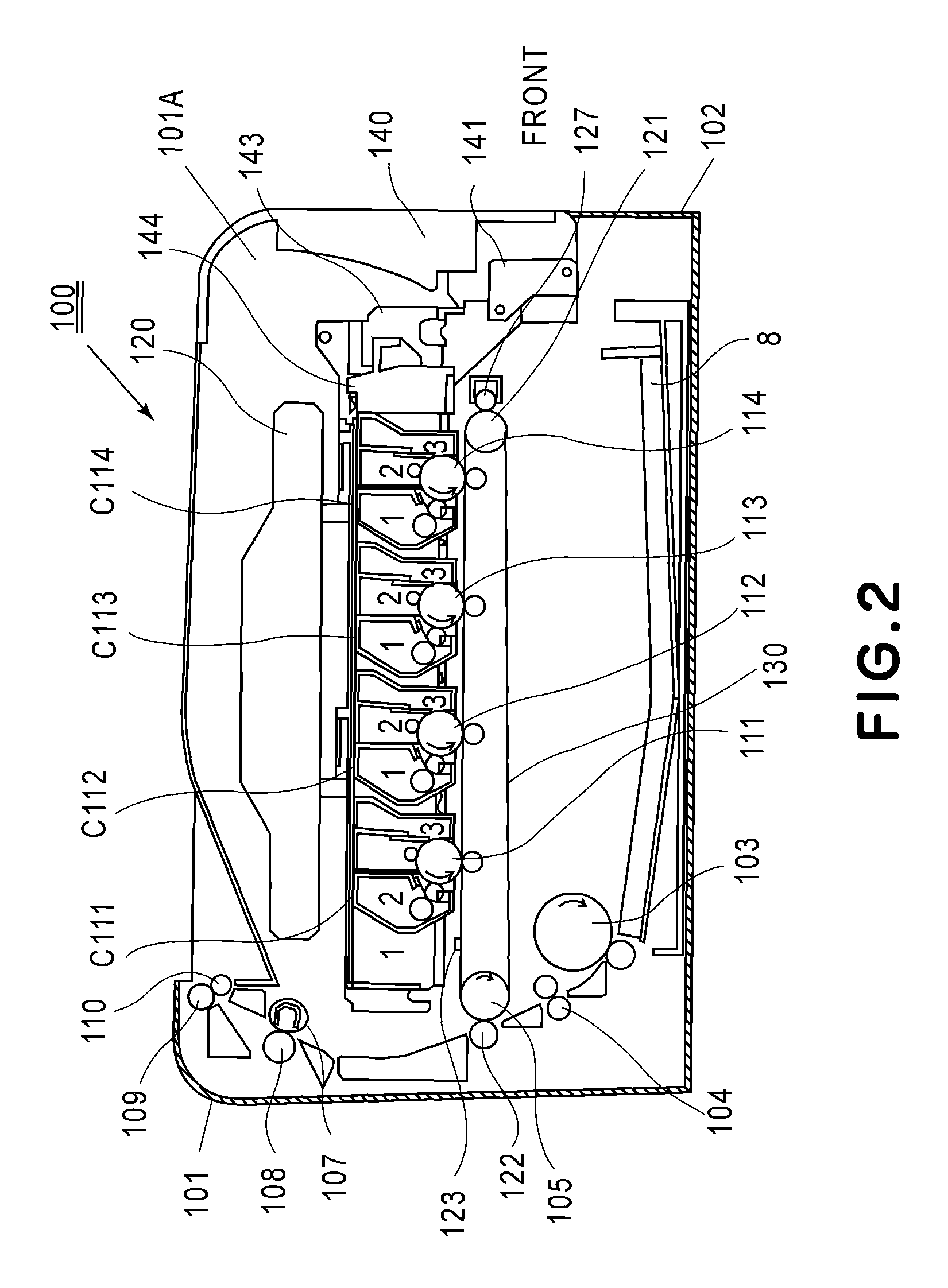

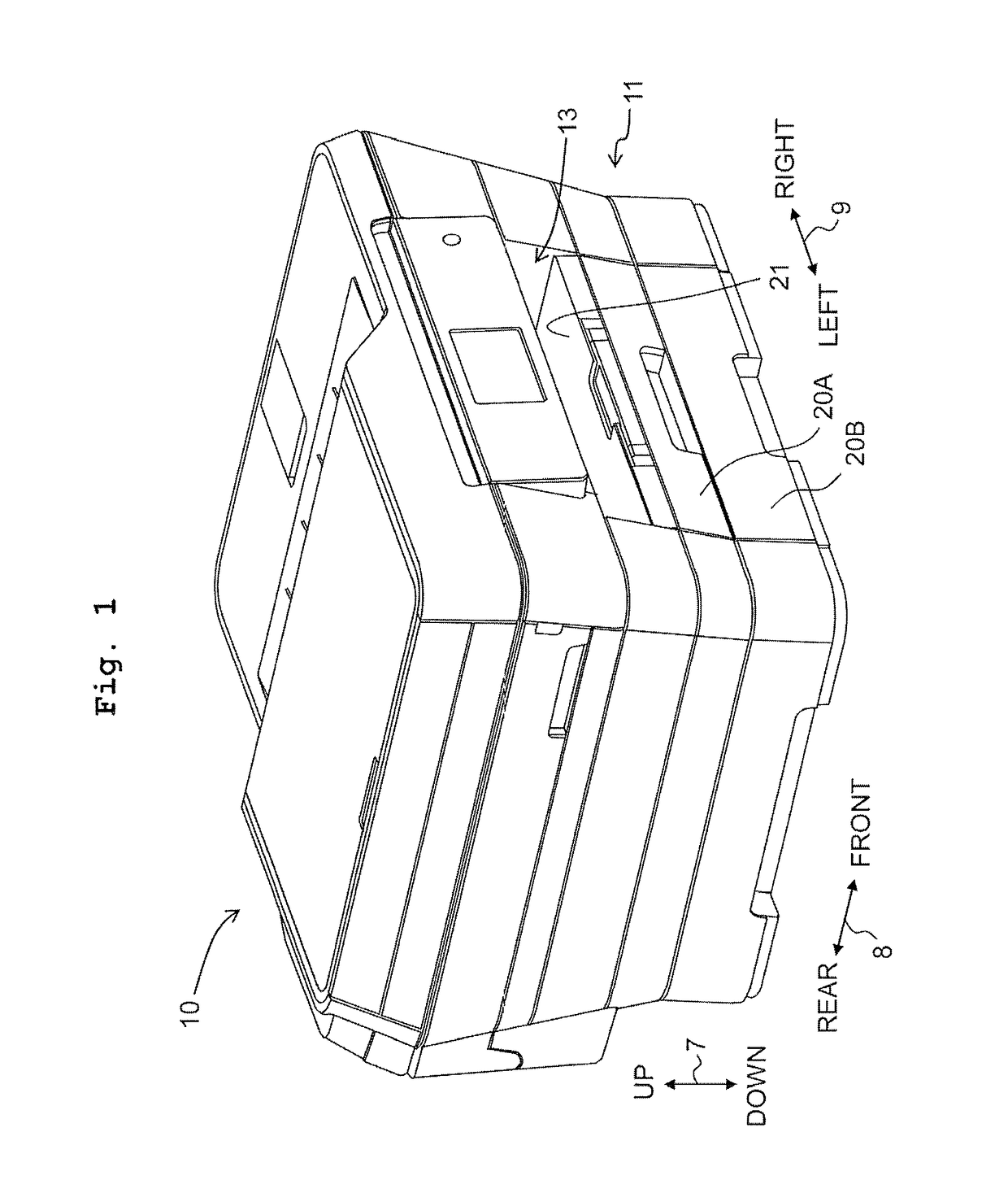

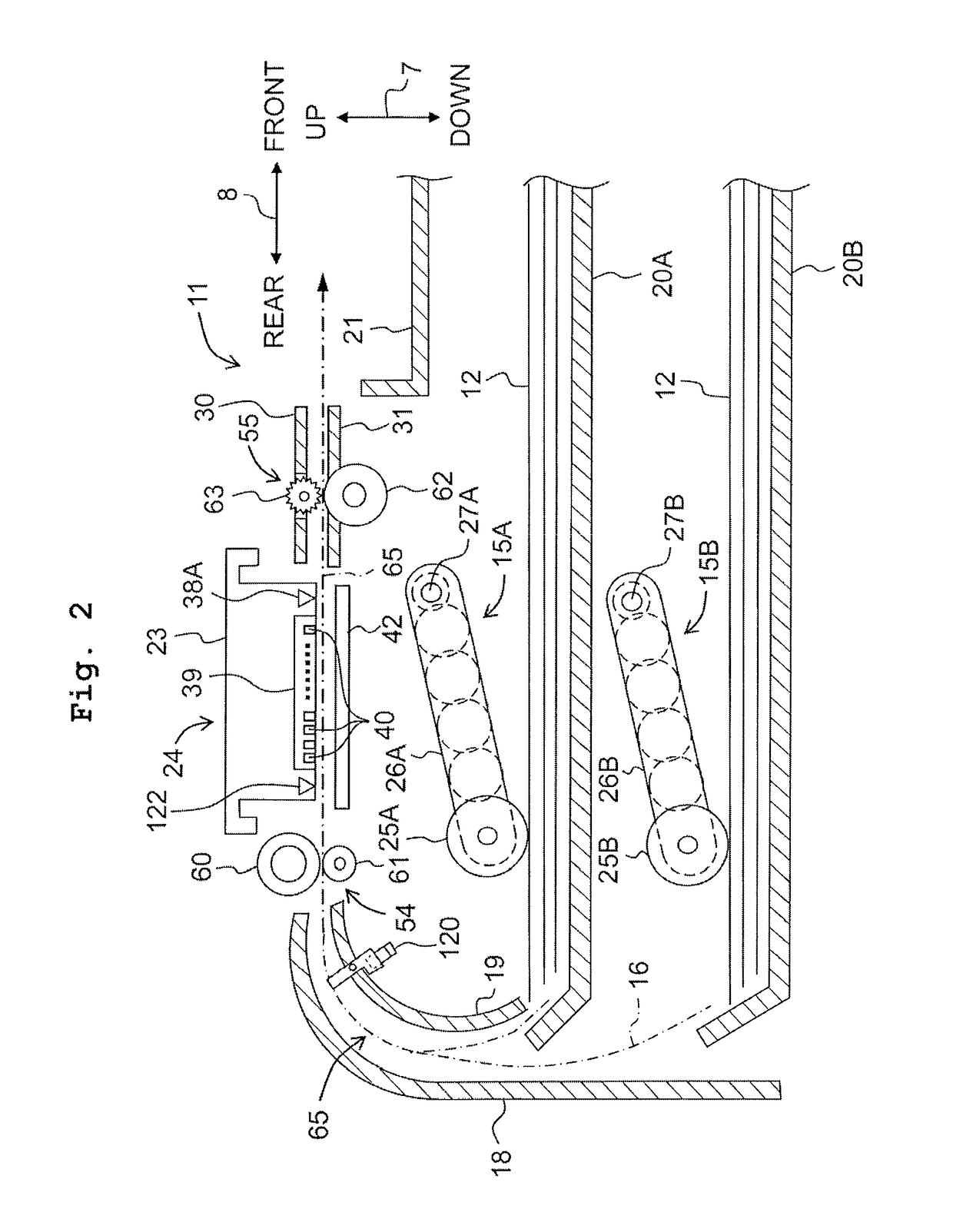

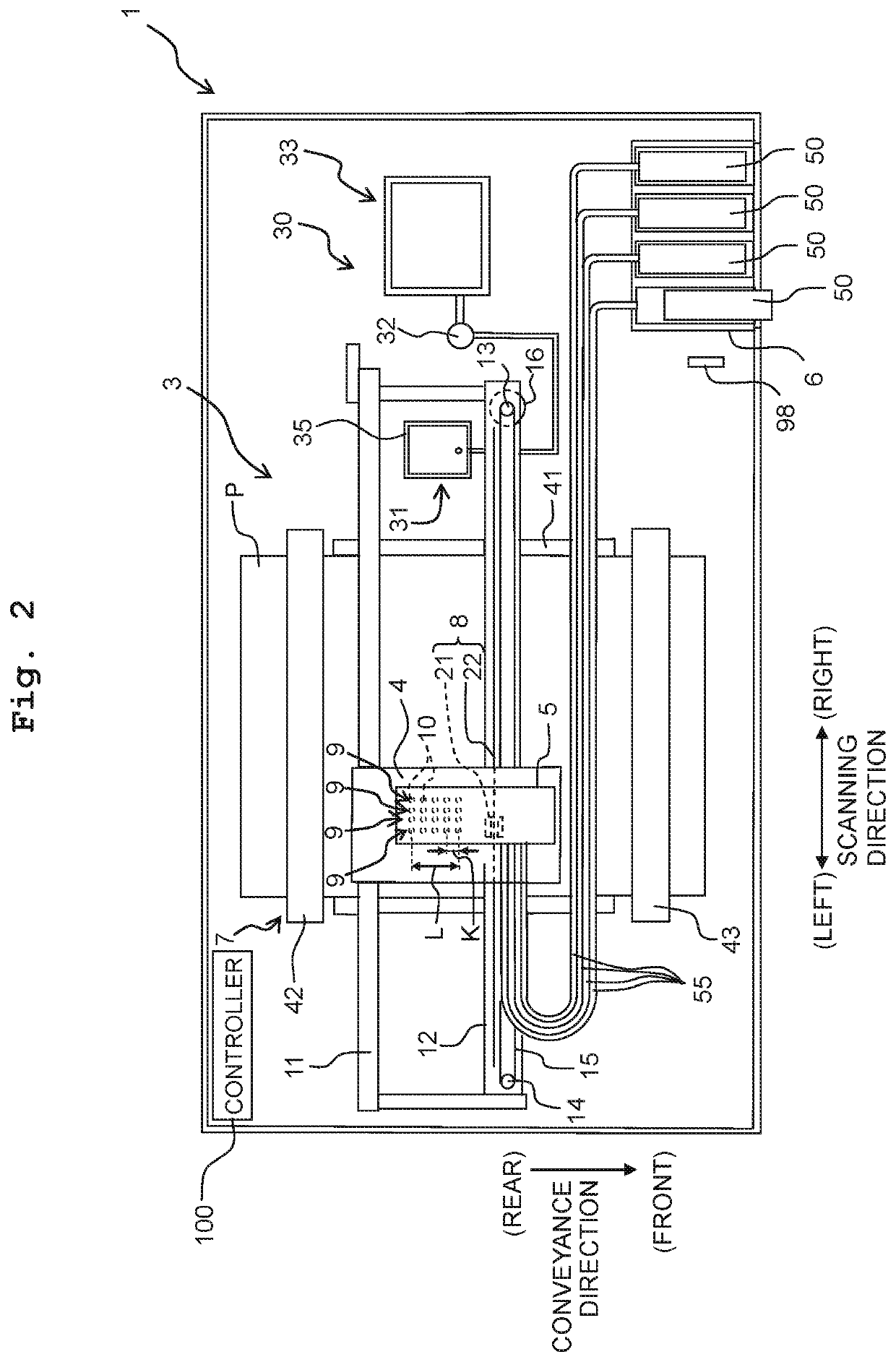

Image forming apparatus

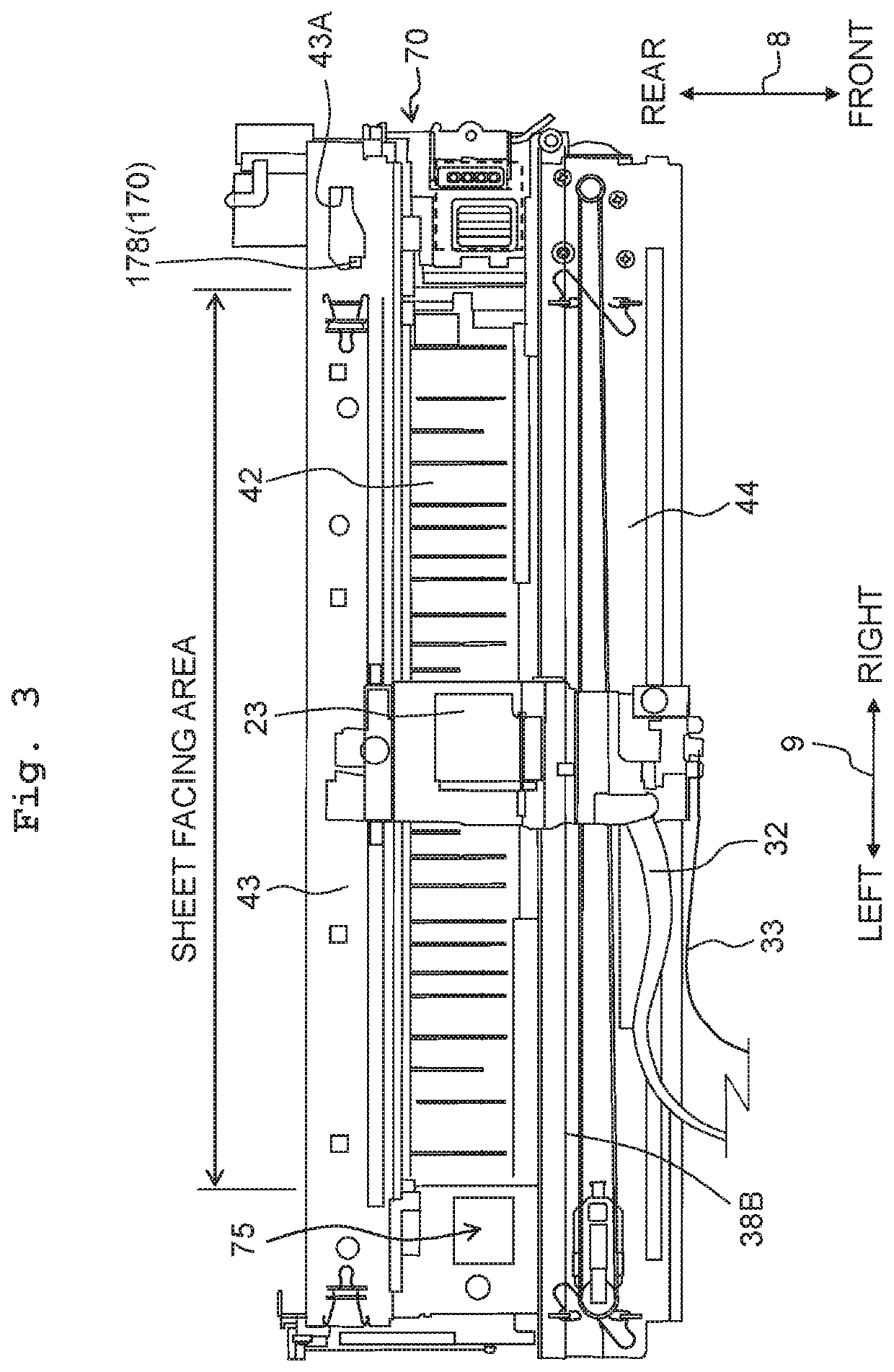

InactiveUS20150055976A1Improve usabilityShorten FPOTElectrographic process apparatusImage formationMechanical engineering

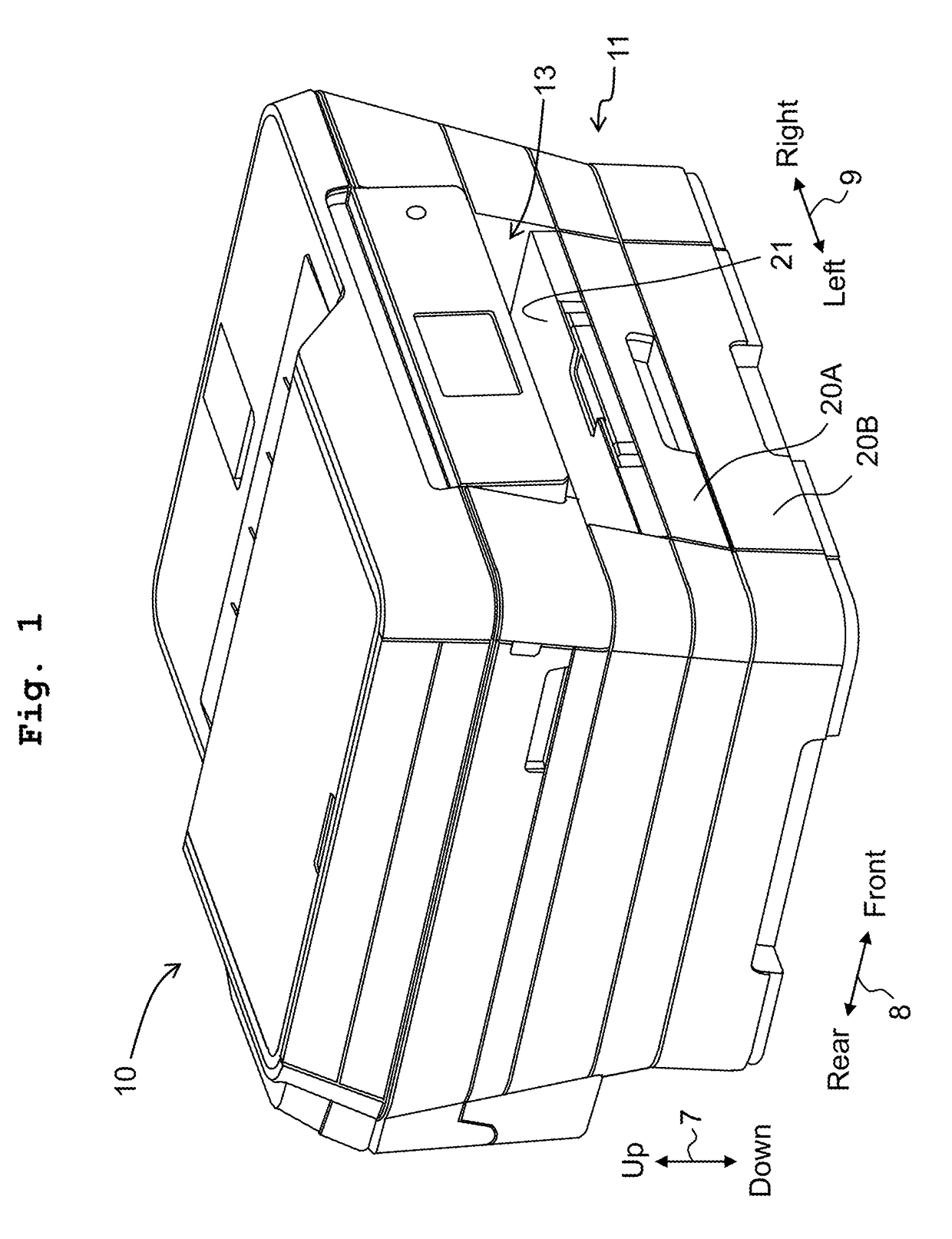

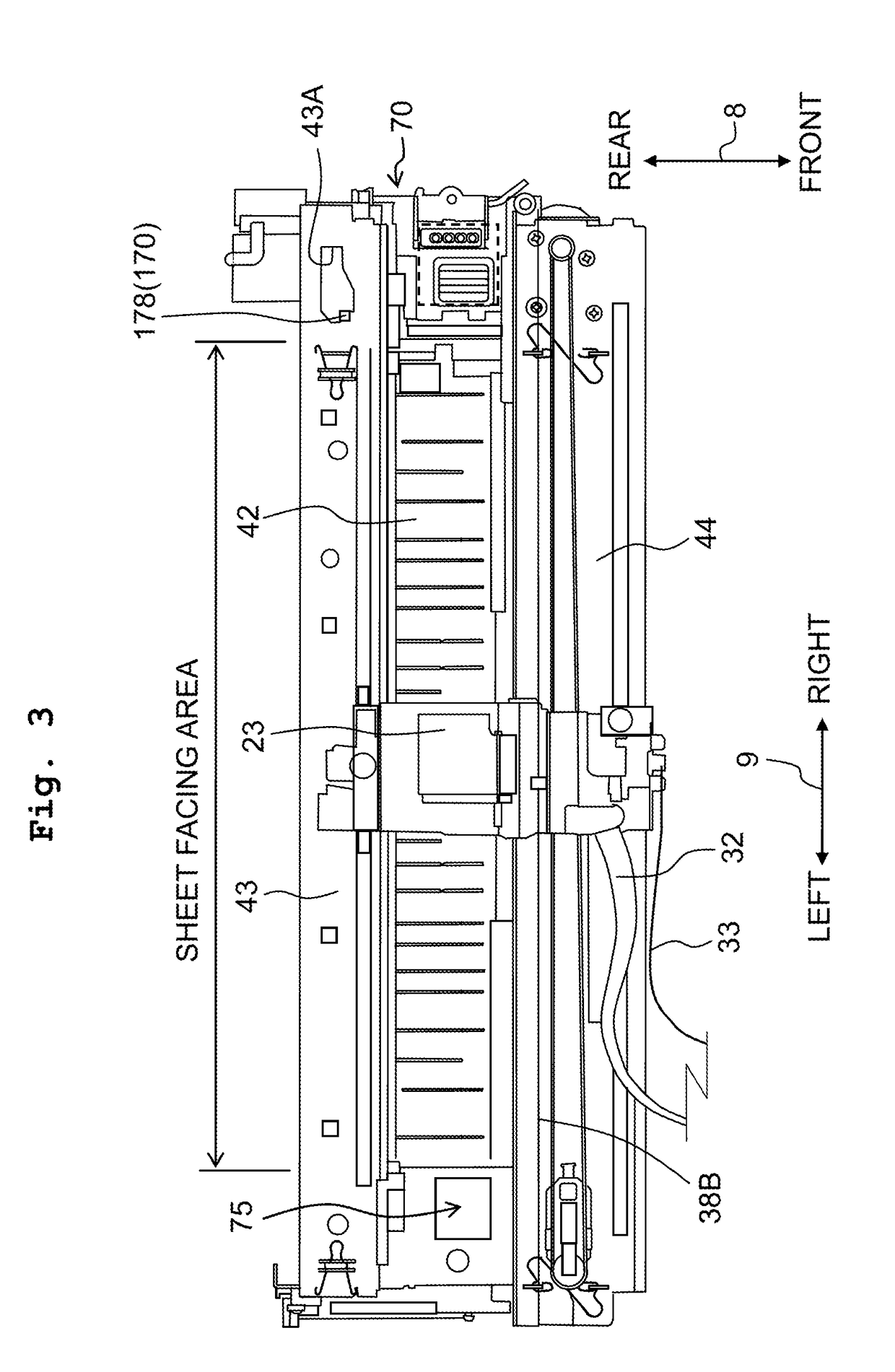

An image forming apparatus includes a movable member movable between first and second inside position and between the second inside position and an outside position, supporting cartridges arranged in an arranging direction. At the outside position, the cartridges are detachably mountable outside a main assembly of the image forming apparatus in a direction crossing with the arranging direction and with a longitudinal direction of each cartridge. At the first inside position, the cartridges are positioned inside the main assembly. The second inside position is inside the main assembly partway of a movement path between the outside position and the first inside position. The movable member supports the cartridges so that a distance between adjacent two cartridges of the cartridges is increased with respect to the arranging direction in interrelation with movement of the movable member from the first inside position to the second inside position.

Owner:CANON KK

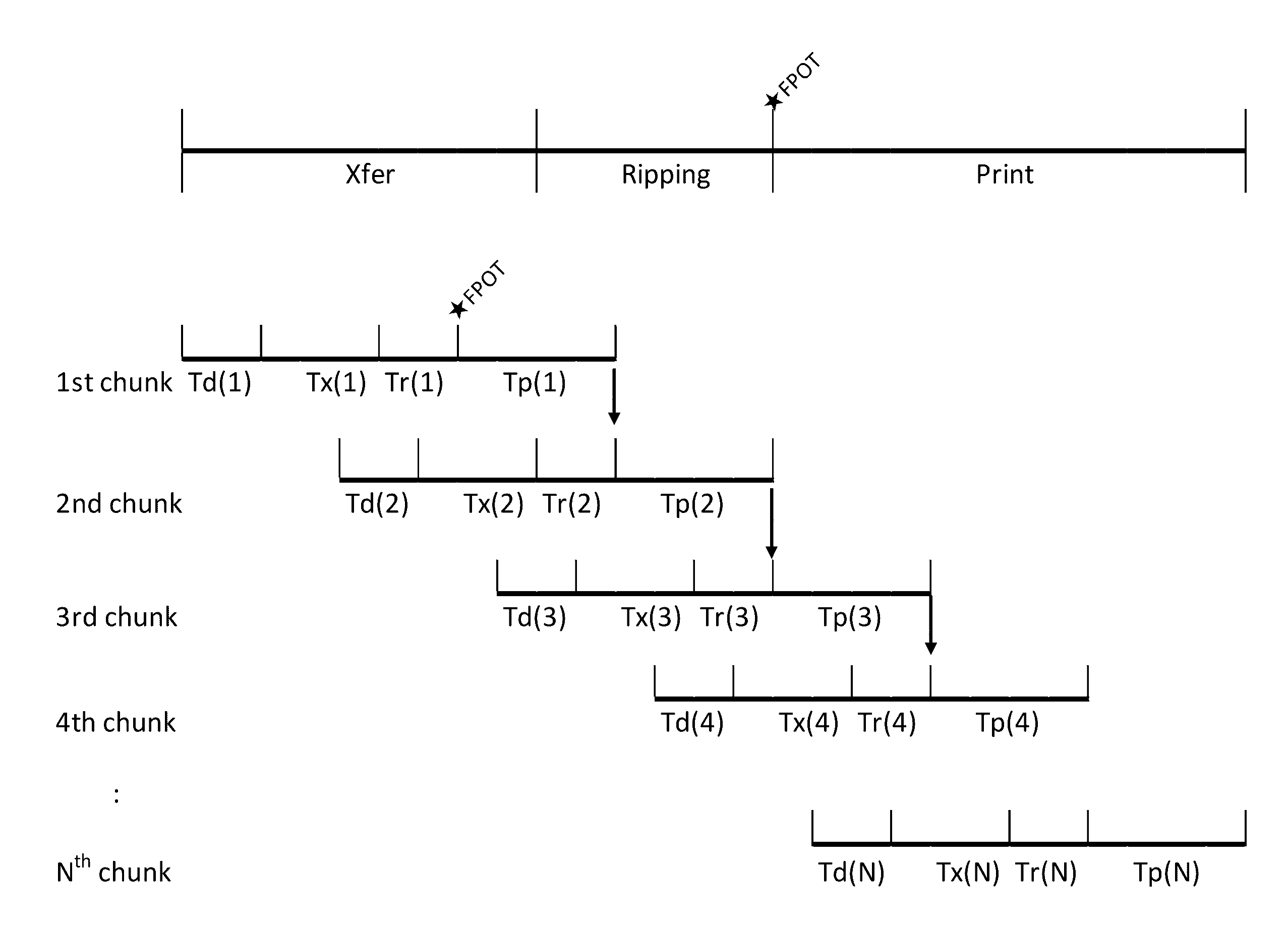

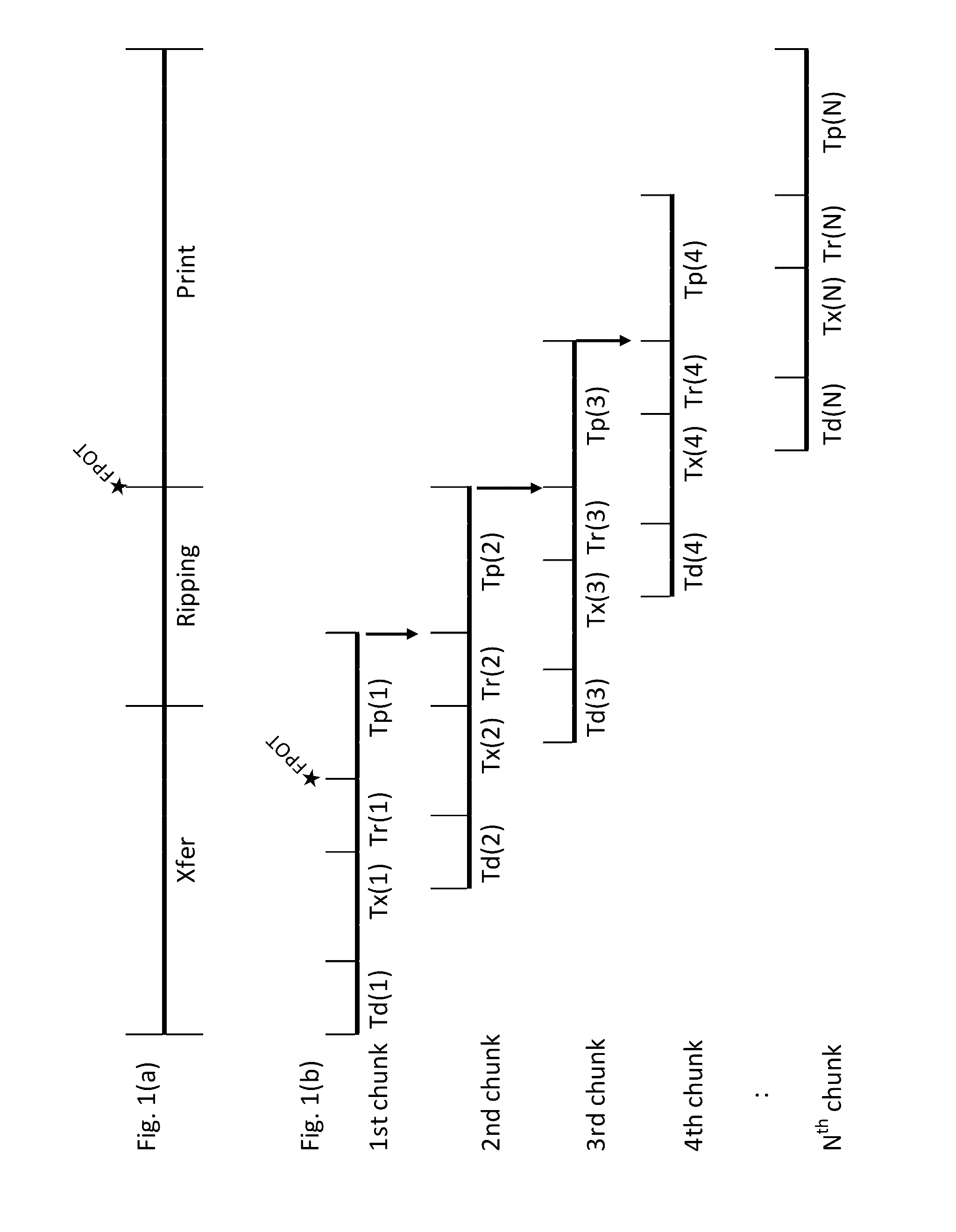

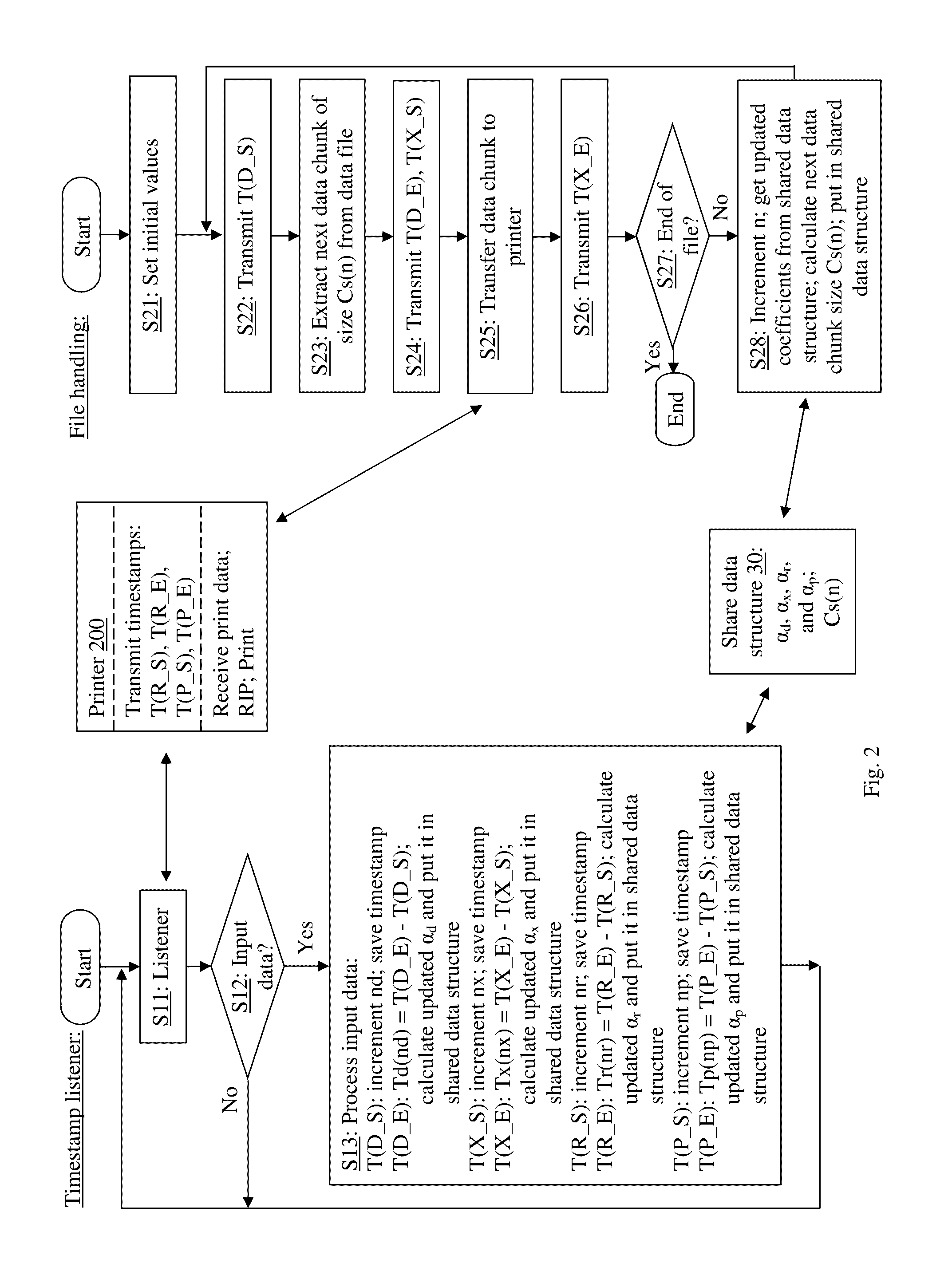

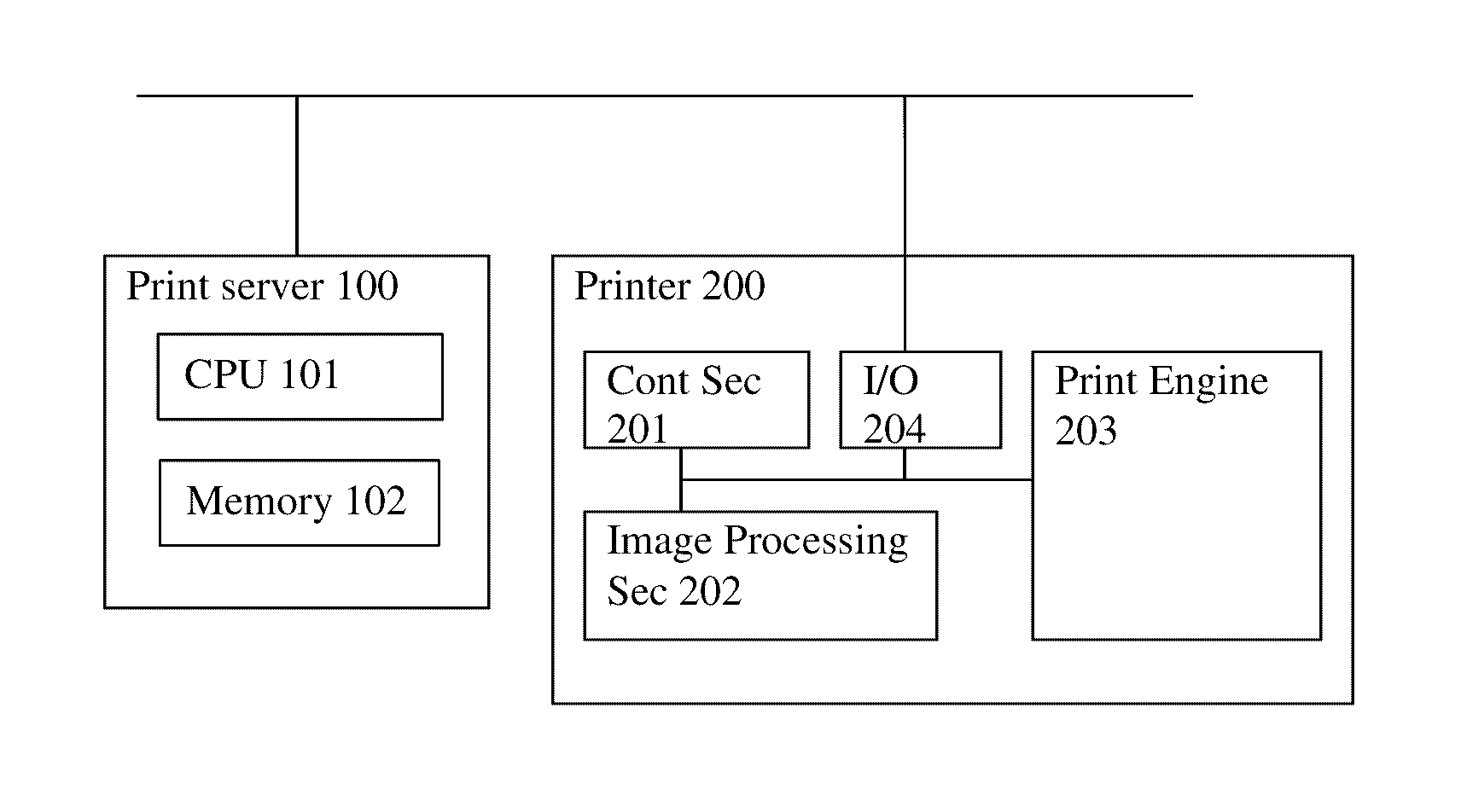

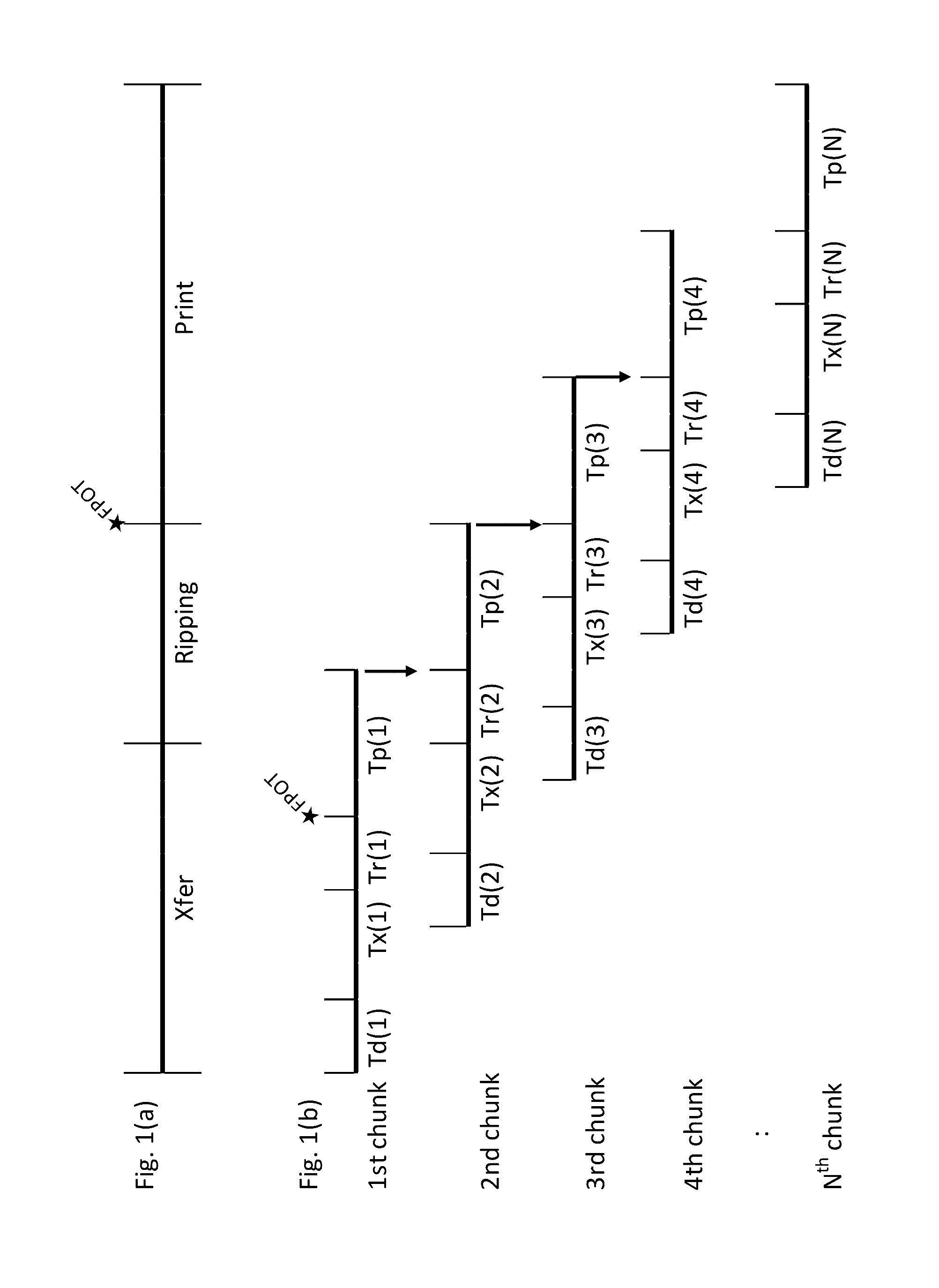

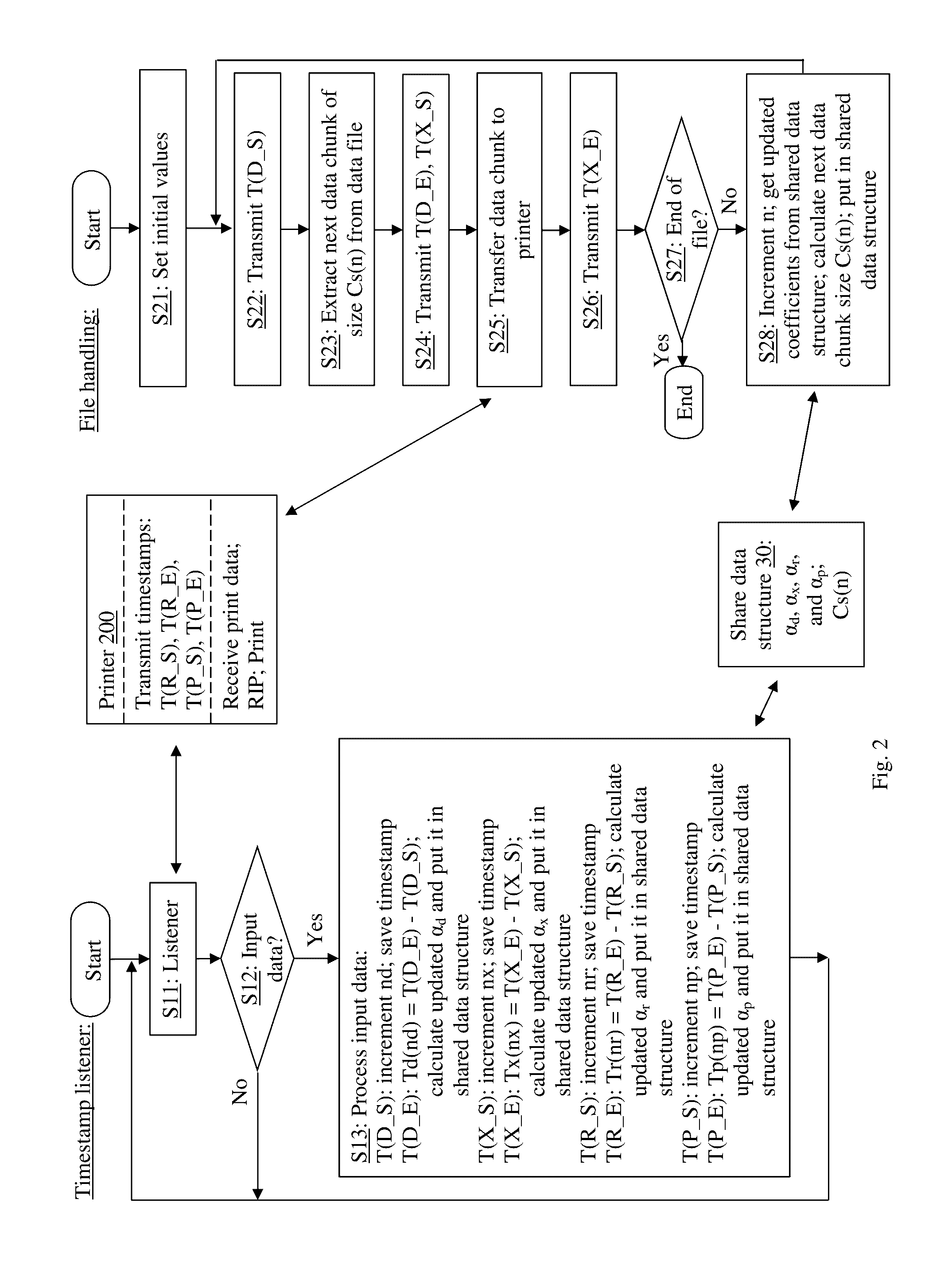

Stream printing method for handling large print jobs to achieve reduced first-page-out time

ActiveUS20160321017A1Shorten FPOTImprove printing efficiencyVisual presentation using printersDigital output to print unitsHome pageComputer printing

A stream printing method implemented in a print server and a printer for handling printing of large files. The print server divides the input data file into a plurality of data chunks, and transfers them sequentially to the printer. The printer sequentially rips the data chunks and prints them. The print server dynamically monitors the system performance factors to measure, for each data chunk, the time required to extract the data chunk from the data file, the time required to transfer the data chunk to the printer, the time required to rip the data chunk, and the time required to print the data chunk. The sizes of the data chunks are calculated using these performance factors and the chunk size of a previous data chunk.

Owner:KONICA MINOLTA LAB U S A INC

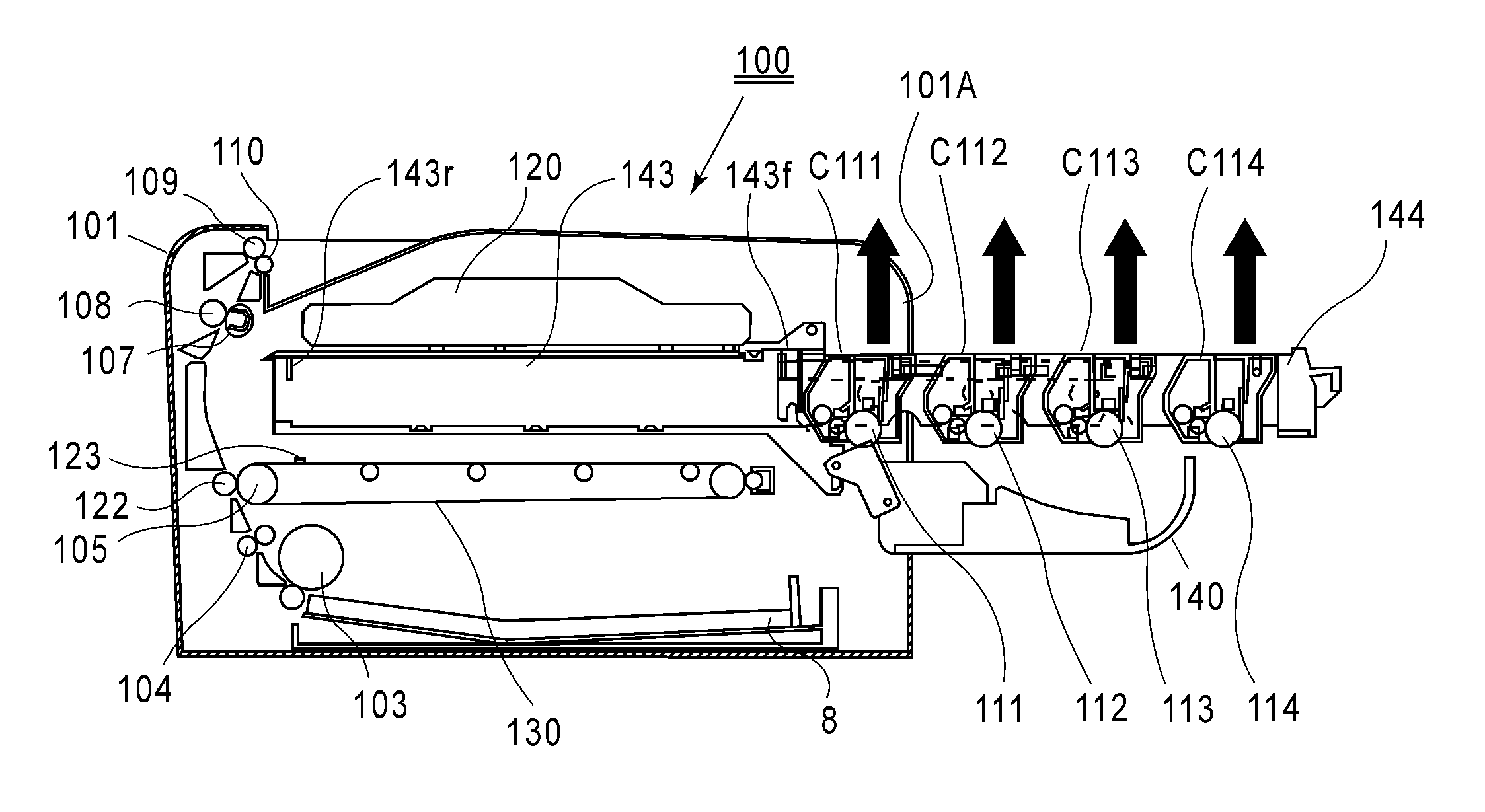

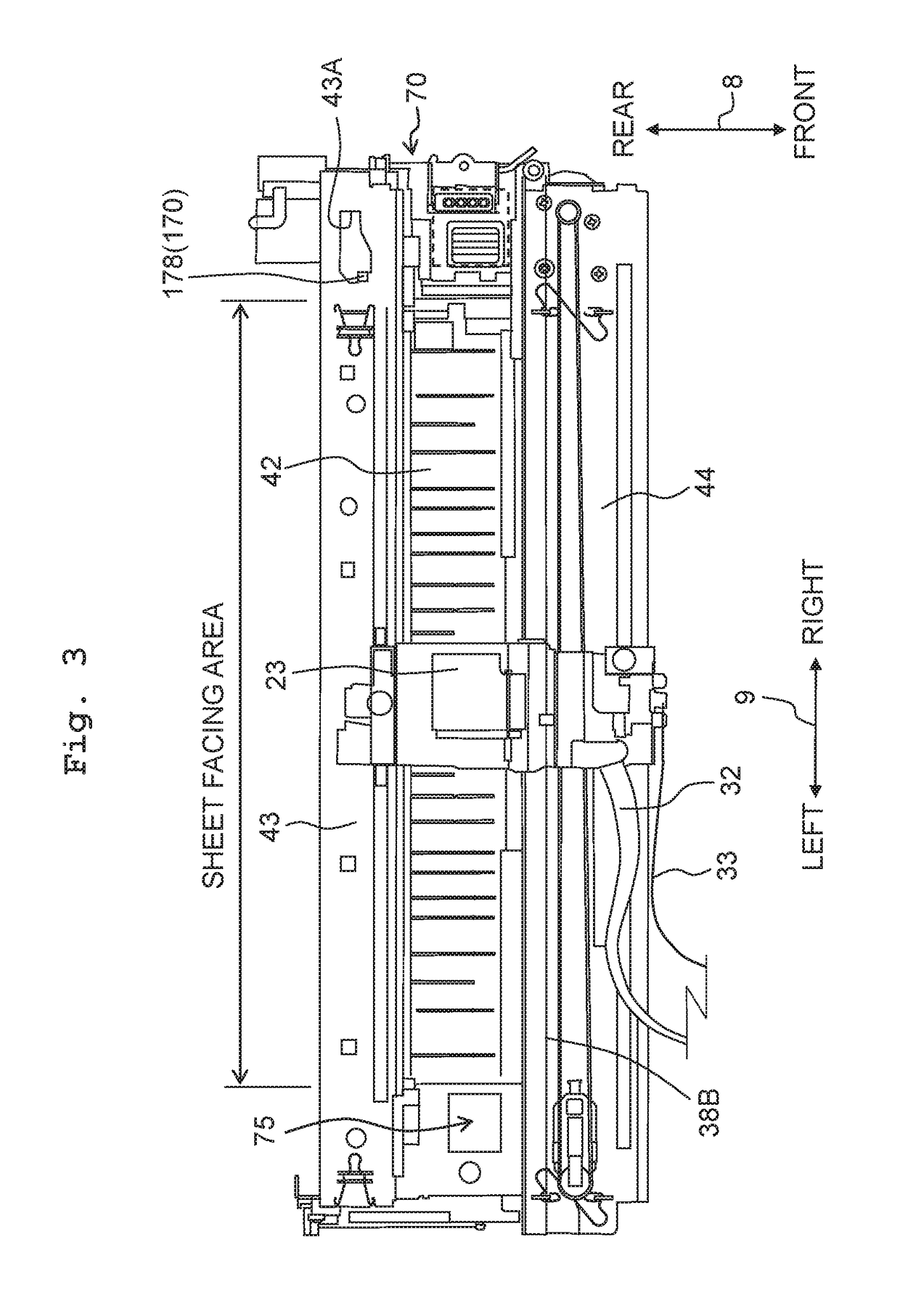

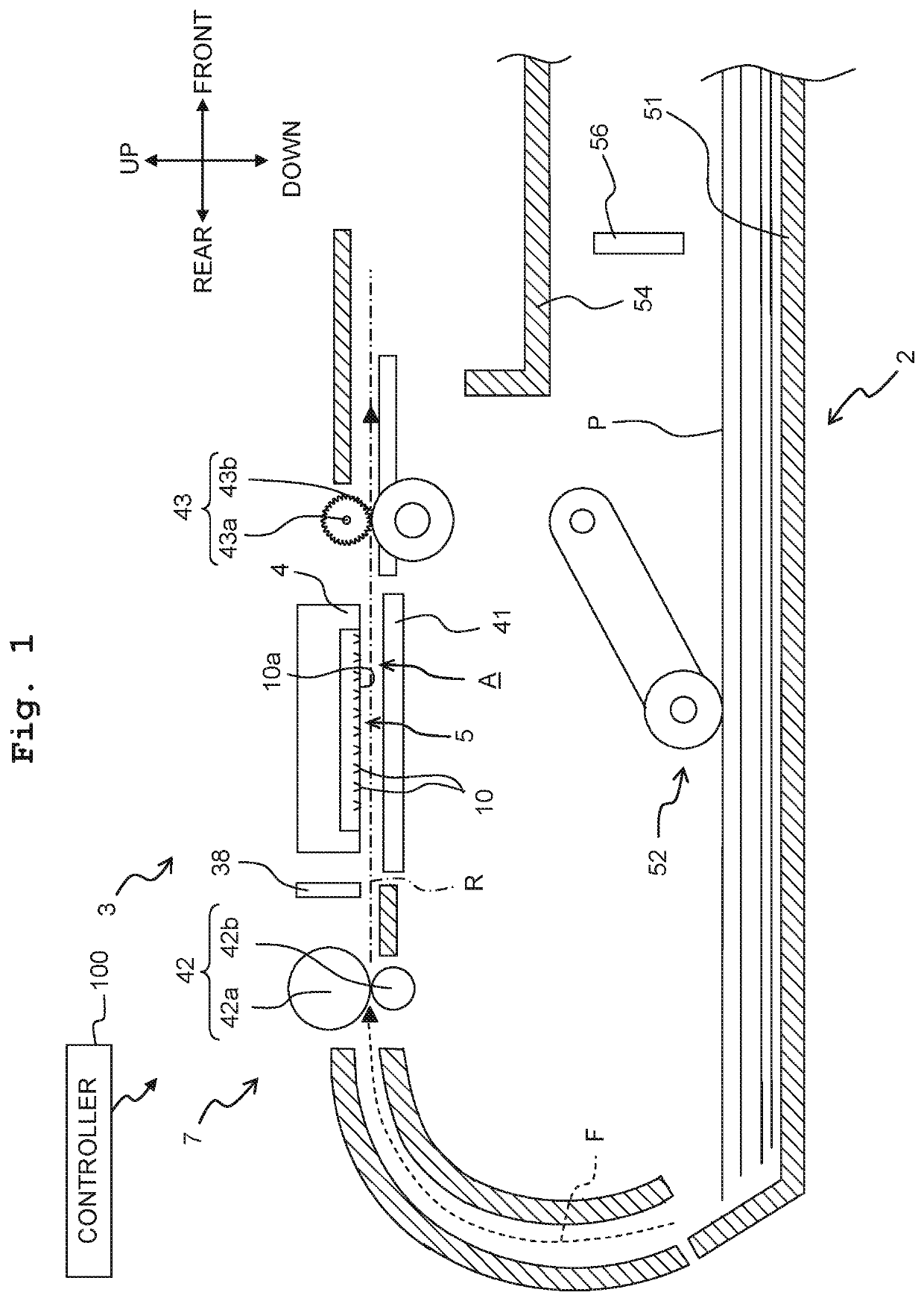

Image forming apparatus

ActiveUS20150055975A1Improve usabilityShorten FPOTElectrographic process apparatusImage formationEngineering

An image forming apparatus includes: an opening; an openable member; and a movable member, supporting cartridges in a state in which the cartridges are arranged in an arranging direction, movable in the arranging direction while passing through the opening between an inside position and an outside position in a direction crossing the arranging direction and a longitudinal direction. When the movable member is positioned at the inside position, adjacent two cartridges of the cartridges are in an overlapping state as seen in a direction perpendicular to the arranging direction and the longitudinal direction. When the movable member is moved from the inside position to the outside position and then one of the adjacent two cartridges is dismounted from the movable member, the one of the adjacent two cartridges is moved relative to the movable member so as to be prevented from interfering with the other cartridge.

Owner:CANON KK

Image heating apparatus

ActiveUS9014608B2Reduce capacityShorten FPOTElectrographic process apparatusEngineeringThermal transmittance

An image heating apparatus for heating a recording material, on which a toner image is carried, while conveying the recording material in a nip includes: a fixing roller including a metal core, a heat insulating layer formed on a surface of the core metal, and a high heat transfer layer which is formed on an outer peripheral surface of the heat insulating layer and has a higher thermal conductivity than the heat insulating layer; a heating member for heating the fixing roller from an outside; and a back-up member for forming the nip together with the fixing roller. When the fixing roller and the back-up member opposing the fixing roller are supplied with the same heat quantity, the temperature rise rate in a neighborhood of the surface of the back-up member supplied with the heat quantity is higher than that of the fixing roller.

Owner:CANON KK

Printing apparatus, control method of the printing apparatus, and storage medium

ActiveUS9430176B2Shorten FPOTEasy to controlElectrographic process apparatusDigital output to print unitsEngineering

Owner:CANON KK

Feeding device and image forming apparatus

ActiveUS10093497B2Shorten FPOTEnhance the imageFunction indicatorsArticle feedersEngineeringContact position

A pickup roller is moved to a retracted position by rotating a feeding motor in reverse by a first predetermined amount and is moved to a contact position by rotating the feeding motor forward by a second predetermined amount.

Owner:CANON KK

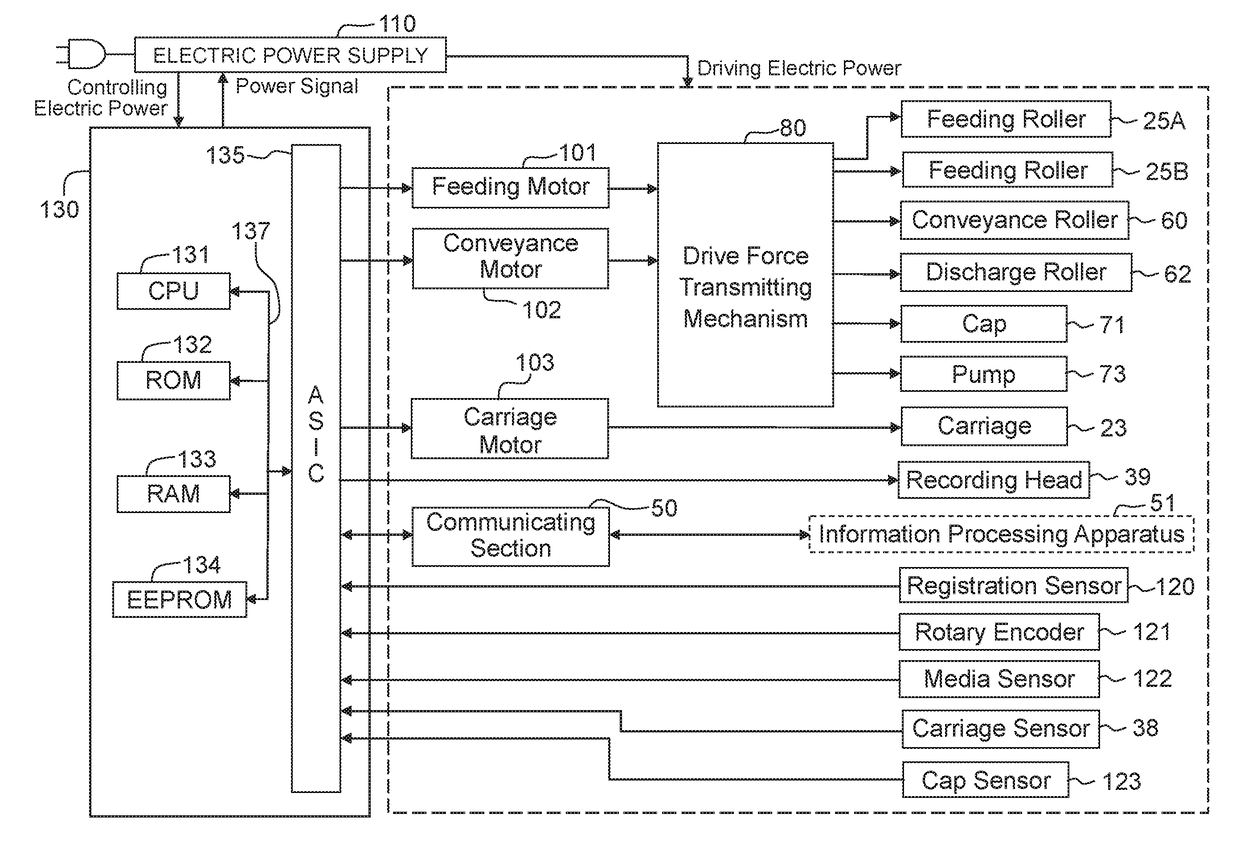

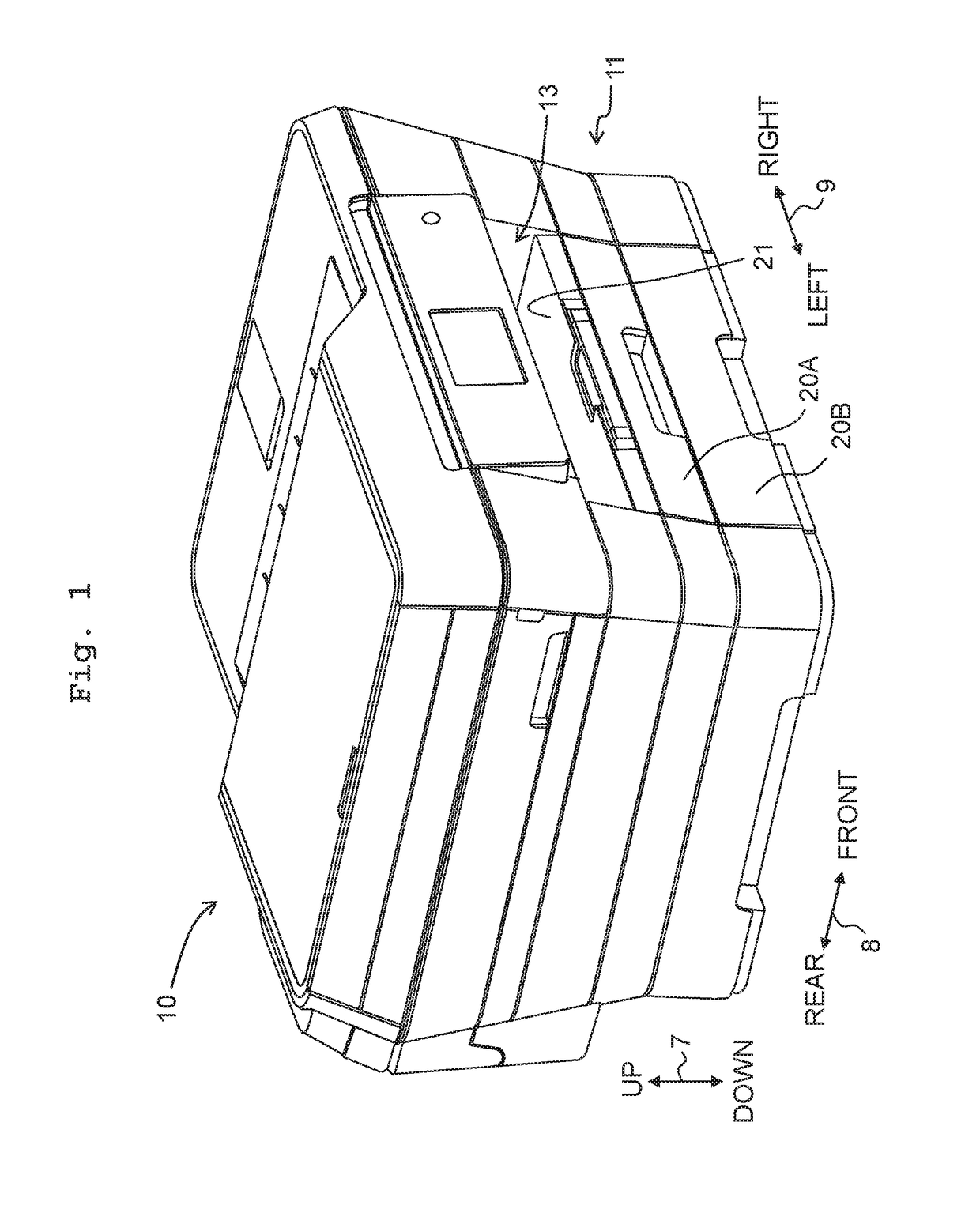

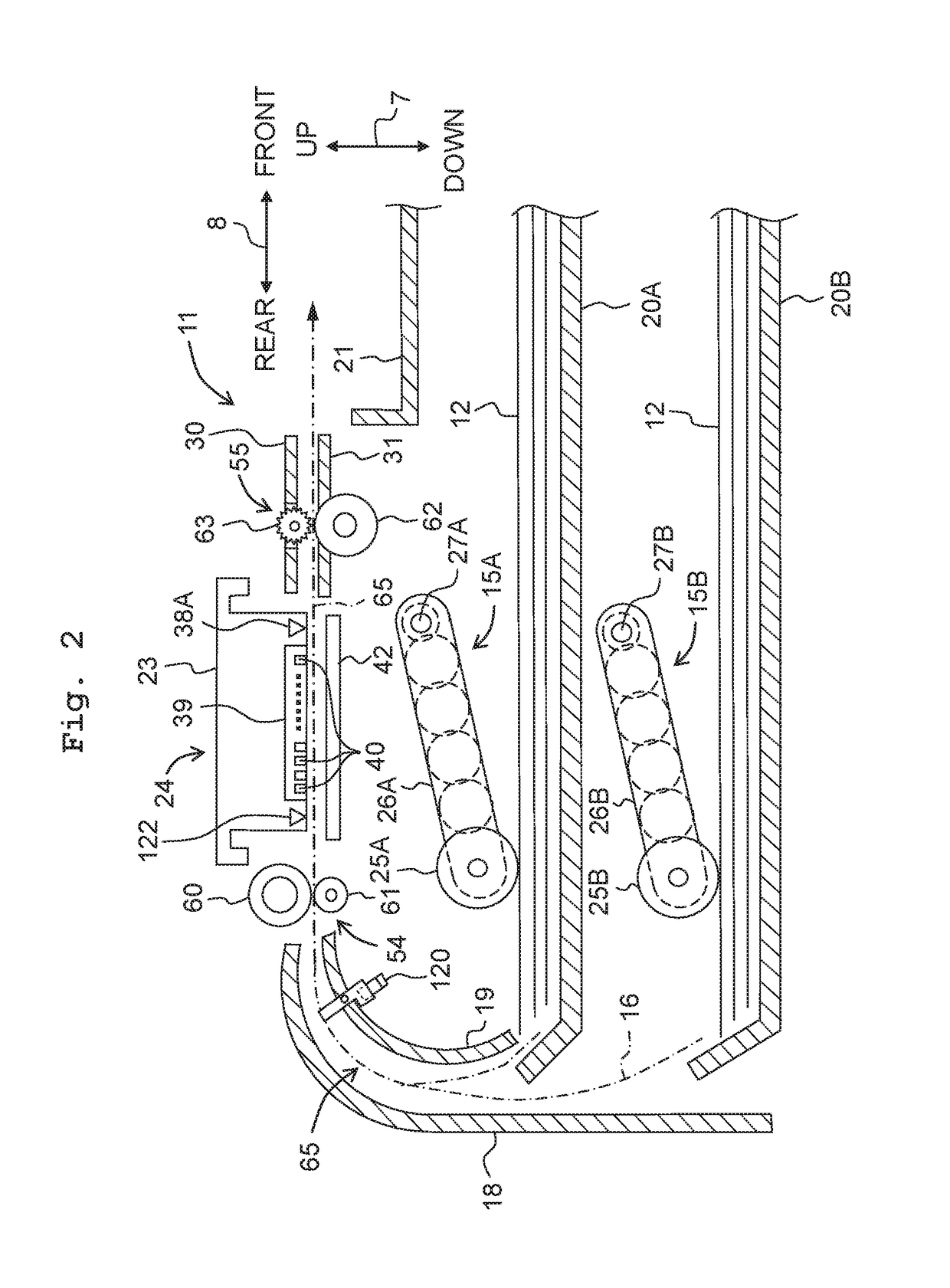

Ink-jet printer

An ink-jet printer including a conveyor, a carriage, a recording head, a power supply, an ink receiver, a command receiver, and a controller, is provided. The controller executes the steps of: determining a discharge ink amount that should be discharged to the ink receiver; raising a drive voltage to a first voltage when the discharge ink amount is less than a first threshold value, and raising the drive voltage to a second voltage when the discharge ink amount is the first threshold value or more; performing a flushing process; based on the flushing process after having raised the drive voltage to the second voltage having finished in the case of having raised the drive voltage to the second voltage, stepping down the drive voltage from the second voltage to the first voltage; and based on the flushing process having finished and on the drive voltage being the first voltage, performing a printing process.

Owner:BROTHER KOGYO KK

Image heating apparatus and image forming apparatus

ActiveUS20190041780A1Good output imageShorten FPOTElectrographic process apparatusEngineeringStart up

Owner:CANON KK

Ink-jet printer

ActiveUS20180281389A1Suppress increaseEasy to processOther printing apparatusEngineeringVoltage boosting

There is provided an ink-jet printer comprising: a recording head, an electric power supply, and a controller which is configured: to determine an ink amount in which an ink is jetted by the recording head in a flushing processing; in a case that the determined ink amount is less than a first ink amount, to boost a driving voltage of the electric power supply to a target voltage value, in accordance with a predetermined first voltage boosting pattern; and in a case that the determined ink amount is not less than the first ink amount, to boost the driving voltage to the target voltage value, in accordance with a predetermined second voltage boosting pattern in which a voltage boosting time is shorter than that in the first voltage boosting pattern. Accordingly, it is possible to shorten FPOT while reducing the load on the constitutive elements of the ink-jet printer.

Owner:BROTHER KOGYO KK

Ink-jet printer

ActiveUS10150298B2Suppress any loweringRecording quality can be securedPrintingEngineeringInkjet printing

There is provided an ink-jet printer including: a conveyer, a recording head, an ink receiver, a communicating interface and a controller. Under a condition that the controller receives a preceding command, the controller is configured to execute a first flushing processing; and under a condition that an elapsed time, elapsed after completion of the first flushing processing and until receipt of a recording command is not less than a threshold time in a case that the controller receives the recording command, the controller is configured to execute a second flushing processing and a recording processing, whereas under a condition that the elapsed time is less than the threshold time, the controller is configured to execute the recording processing without executing the second flushing processing.

Owner:BROTHER KOGYO KK

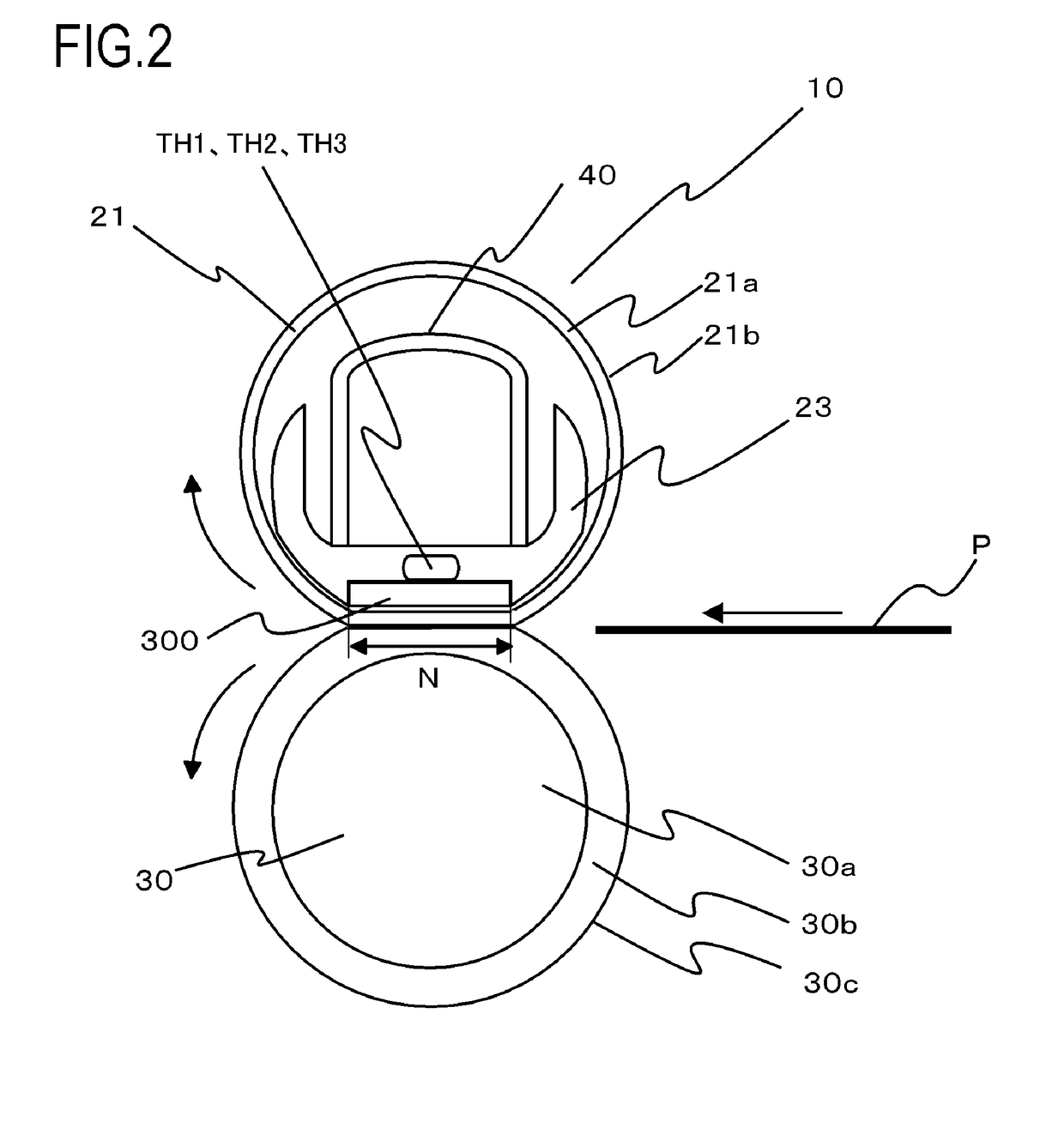

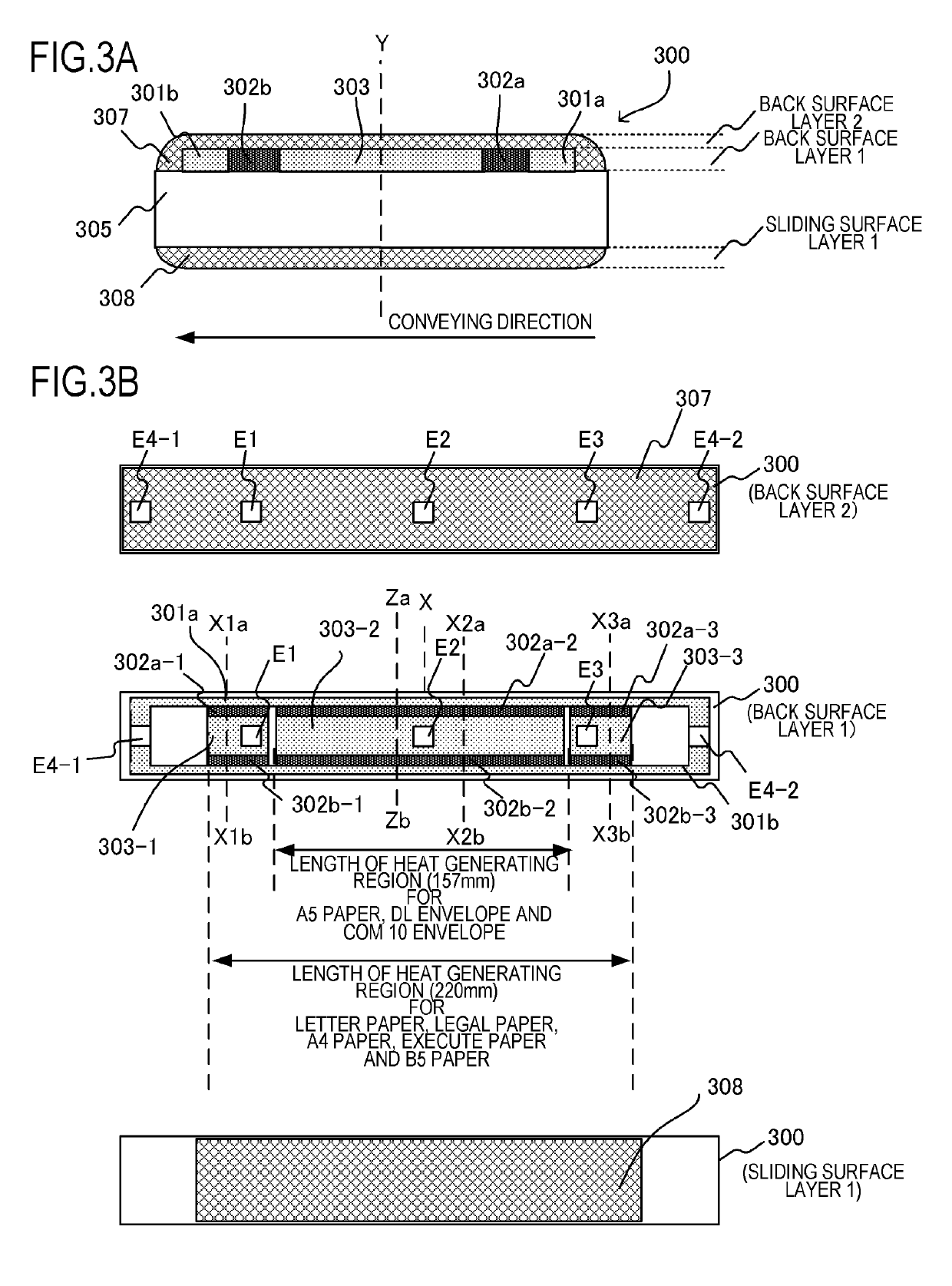

Image heating apparatus and image forming apparatus that correct an amount of current supplied to a plurality of heat generating resistors using detected temperatures

ActiveUS10514636B2Shorten FPOTEnhance the imageElectrographic process apparatusElectrical resistance and conductanceElectricity

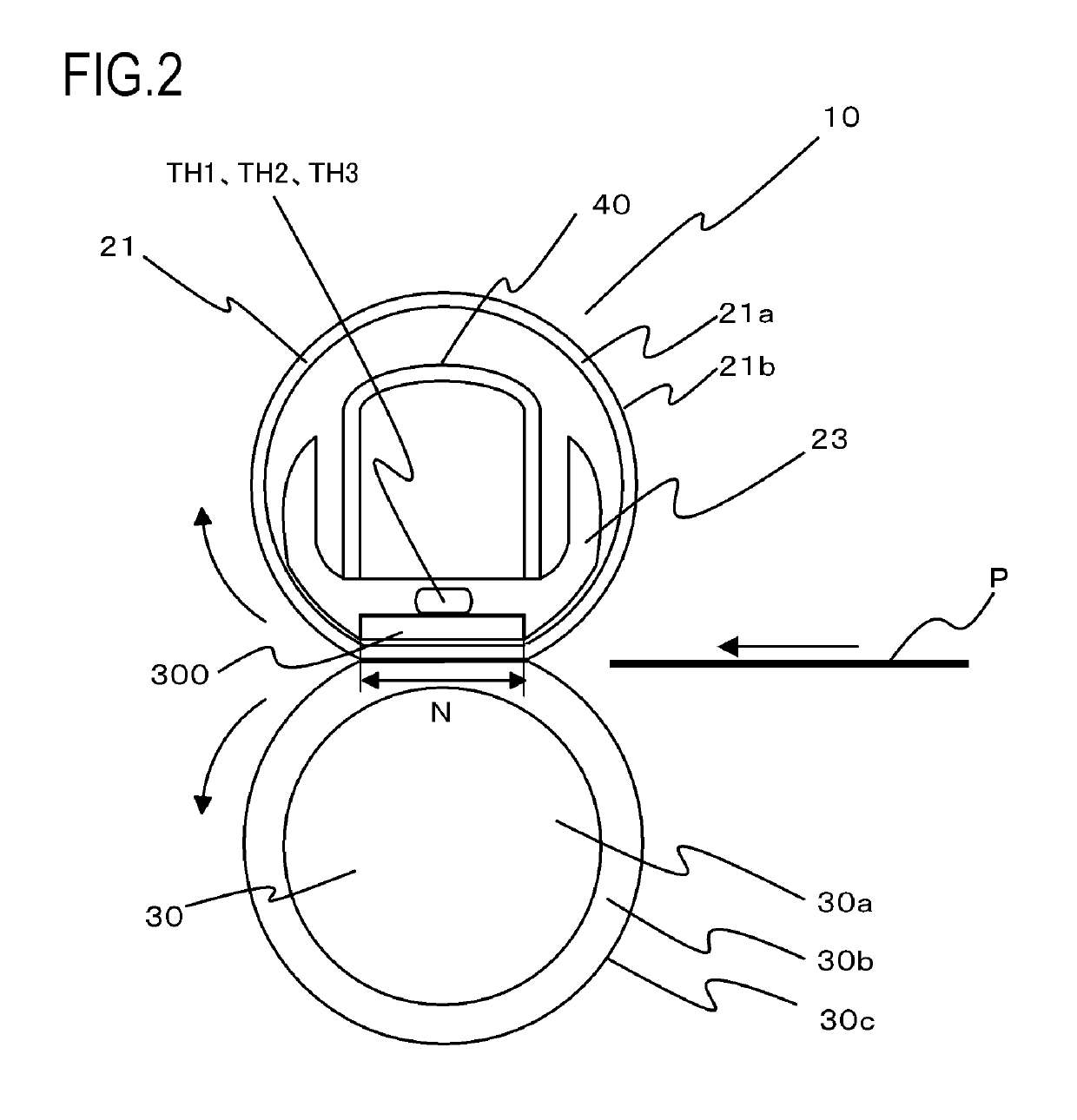

An image heating apparatus includes a heater having a plurality of resistors, and a power supply control circuit that controls power supplied to the plurality of resistors so as to selectively heat a plurality of heating regions. A plurality of thermistors detect a temperature of each of a plurality of regions of the image heater, and a processor functions as a current amount correcting portion that corrects an amount of current supplied to the plurality of resistors. The current amount is corrected based on the temperature detected by each of the plurality of thermistors, so that a difference of a temperature rising amount per unit time among the plurality of heating regions at the start of an image heating operation becomes small and a total amount of power supplied to the plurality of heat generating elements is kept to within a predetermined limited power amount.

Owner:CANON KK

Image forming apparatus with cartridge supporting movable member

ActiveUS9529318B2Improve usabilityShorten FPOTElectrographic process apparatusEngineeringMoving parts

Owner:CANON KK

Image forming apparatus

InactiveUS9069329B2Improve usabilityShorten FPOTElectrographic process apparatusImage formationMechanical engineering

An image forming apparatus includes a movable member movable between first and second inside positions and between the second inside position and an outside position, supporting cartridges arranged in an arranging direction. At the outside position, the cartridges are detachably mountable outside a main assembly of the image forming apparatus in a direction crossing with the arranging direction and with a longitudinal direction of each cartridge. At the first inside position, the cartridges are positioned inside the main assembly. The second inside position is inside the main assembly partway of a movement path between the outside position and the first inside position. The movable member supports the cartridges so that a distance between adjacent two cartridges of the cartridges is increased with respect to the arranging direction in interrelation with movement of the movable member from the first inside position to the second inside position.

Owner:CANON KK

Image forming apparatus

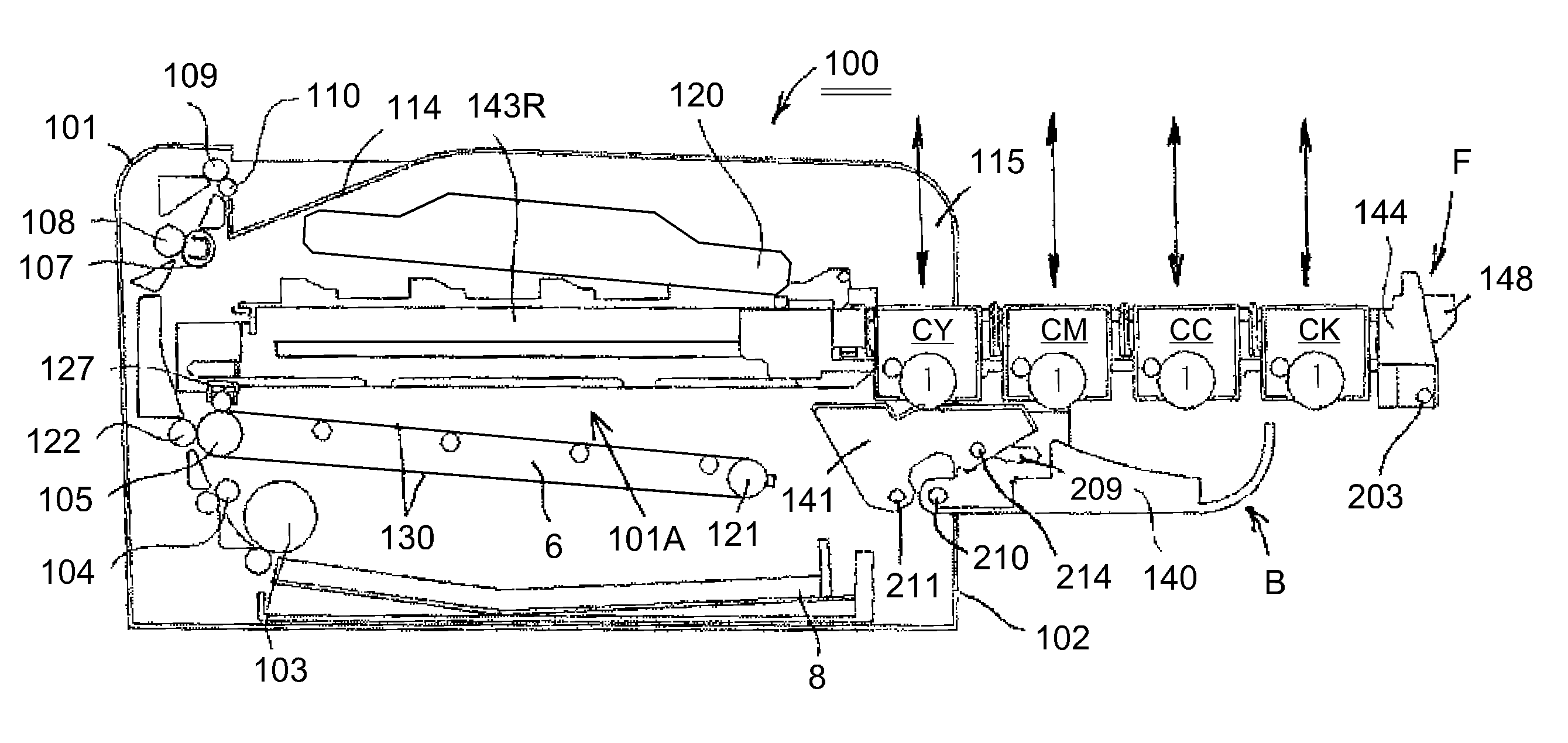

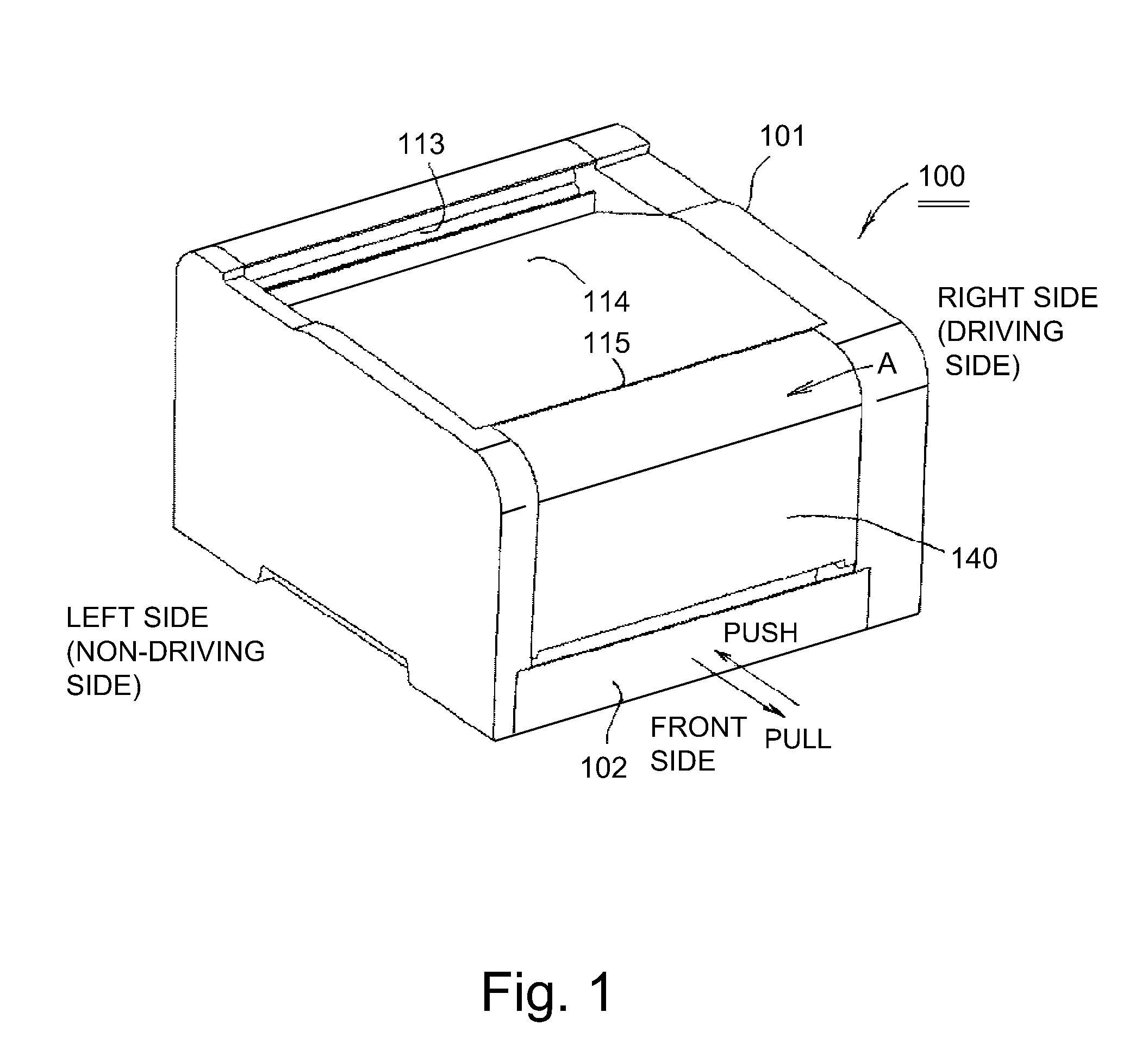

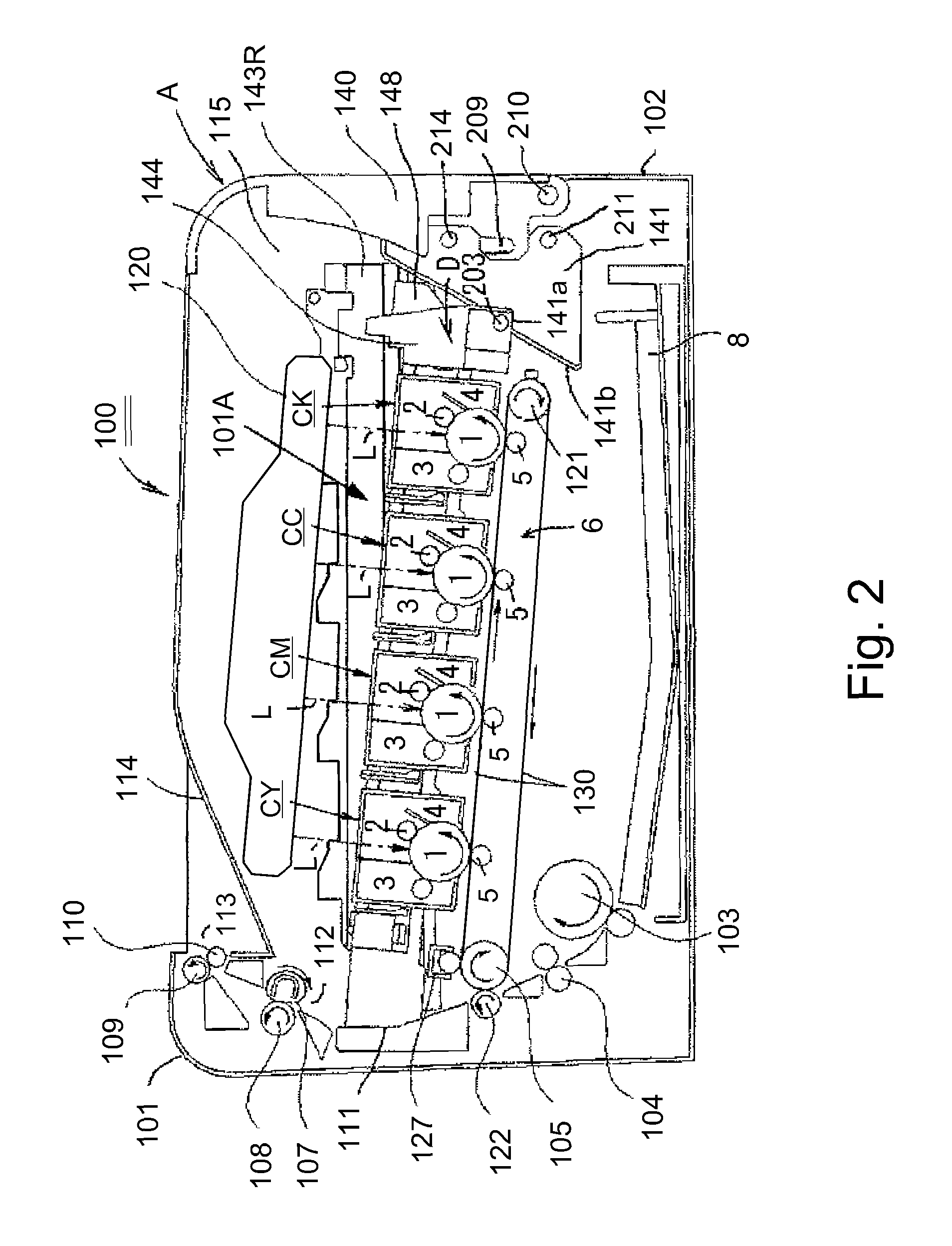

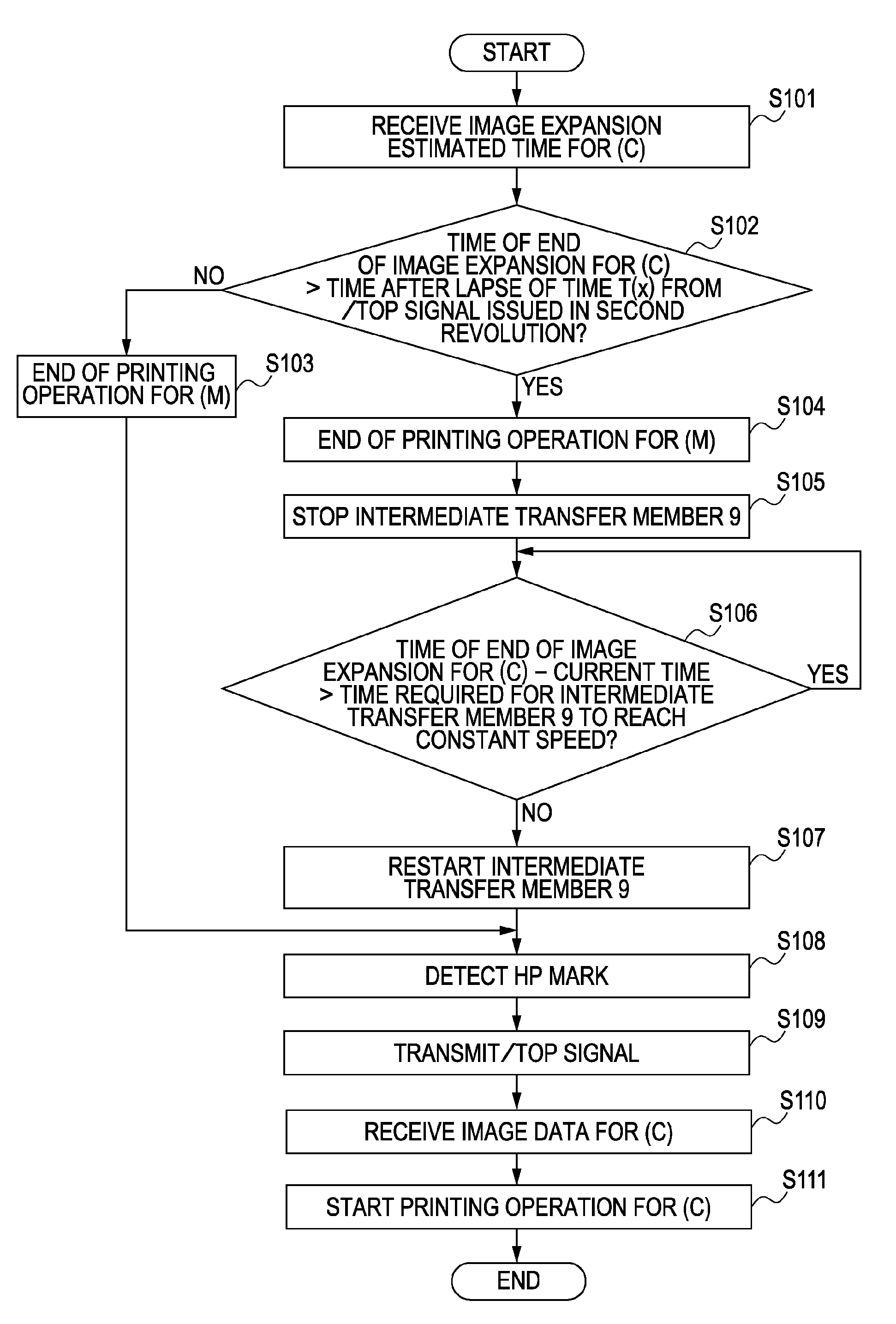

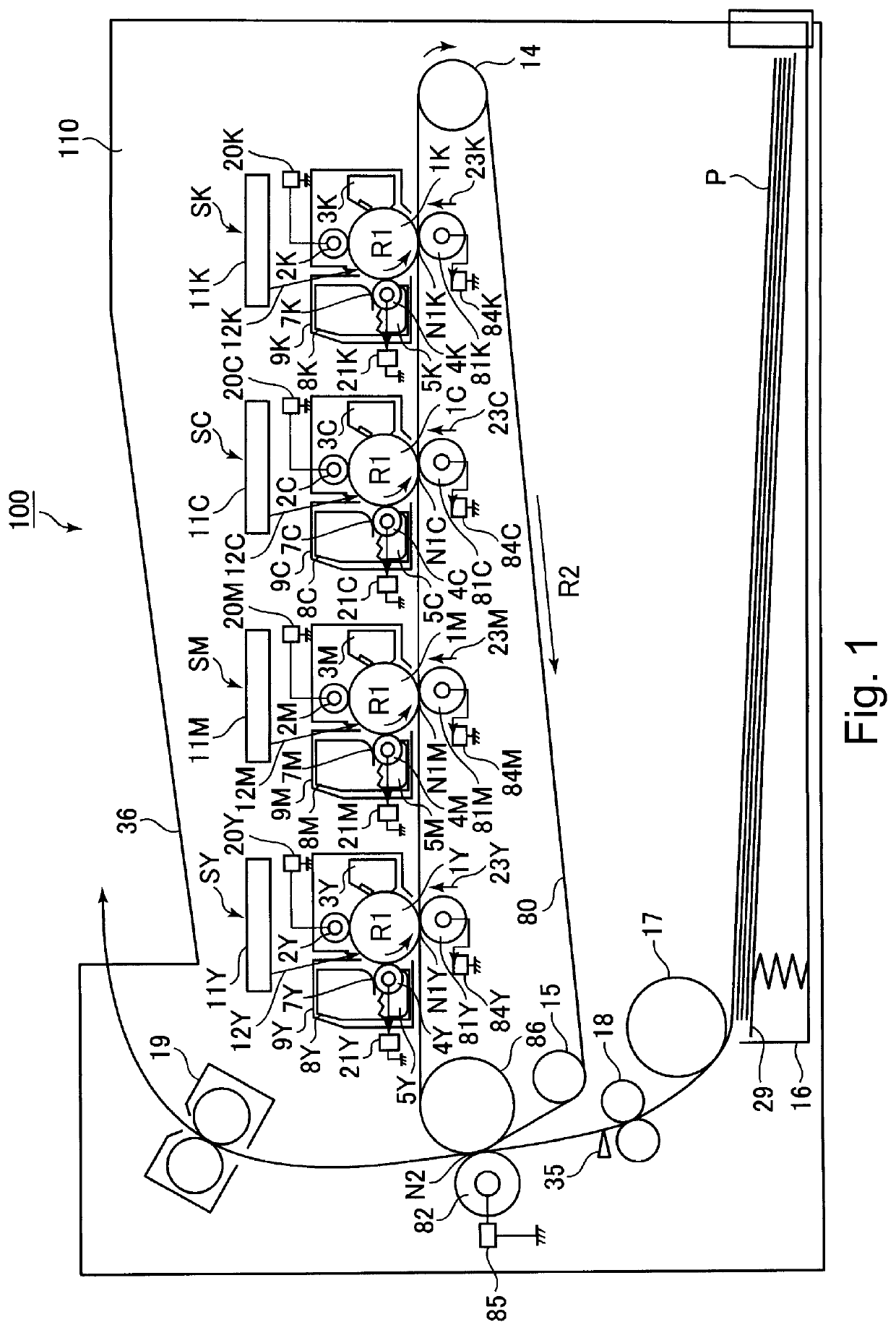

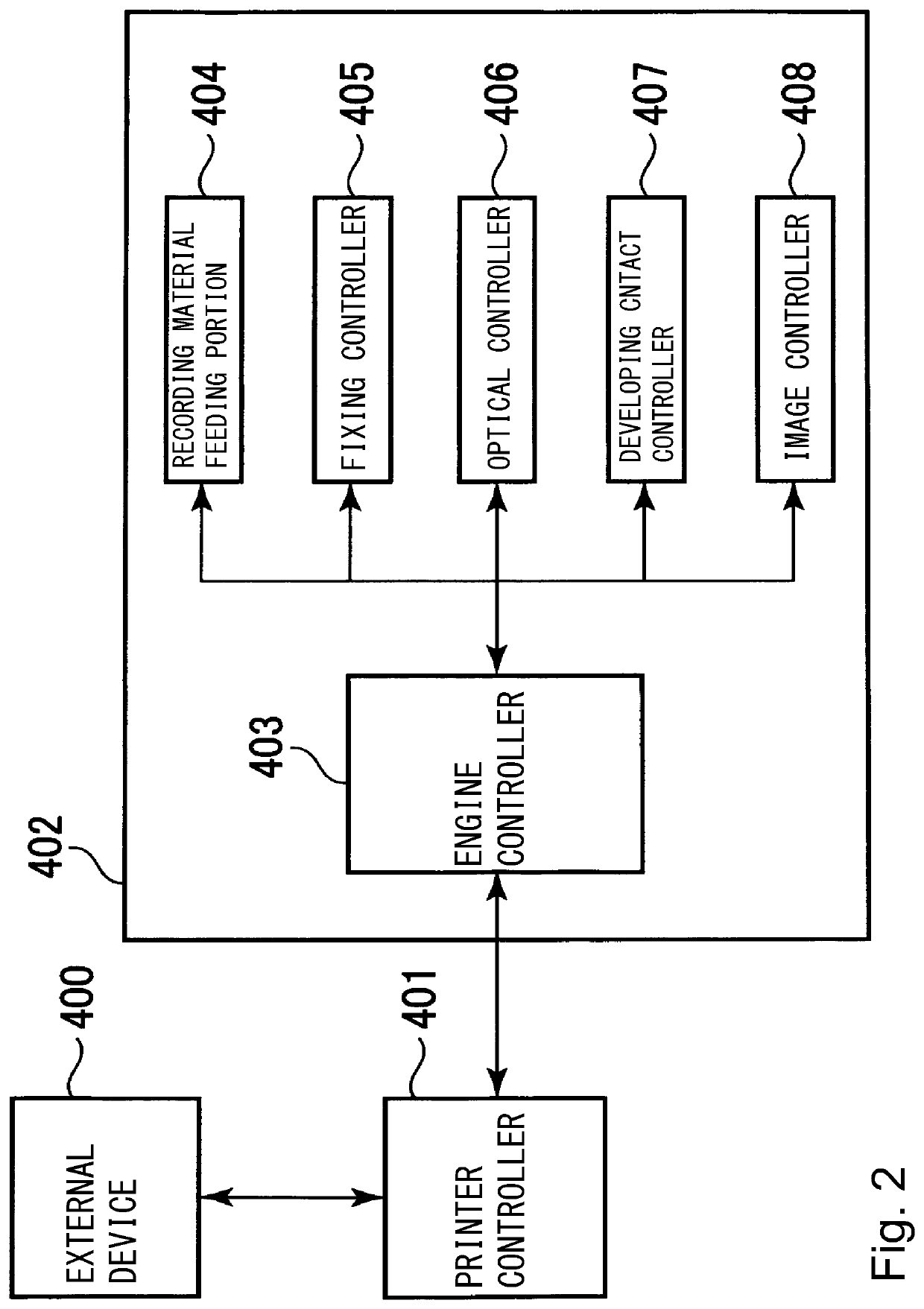

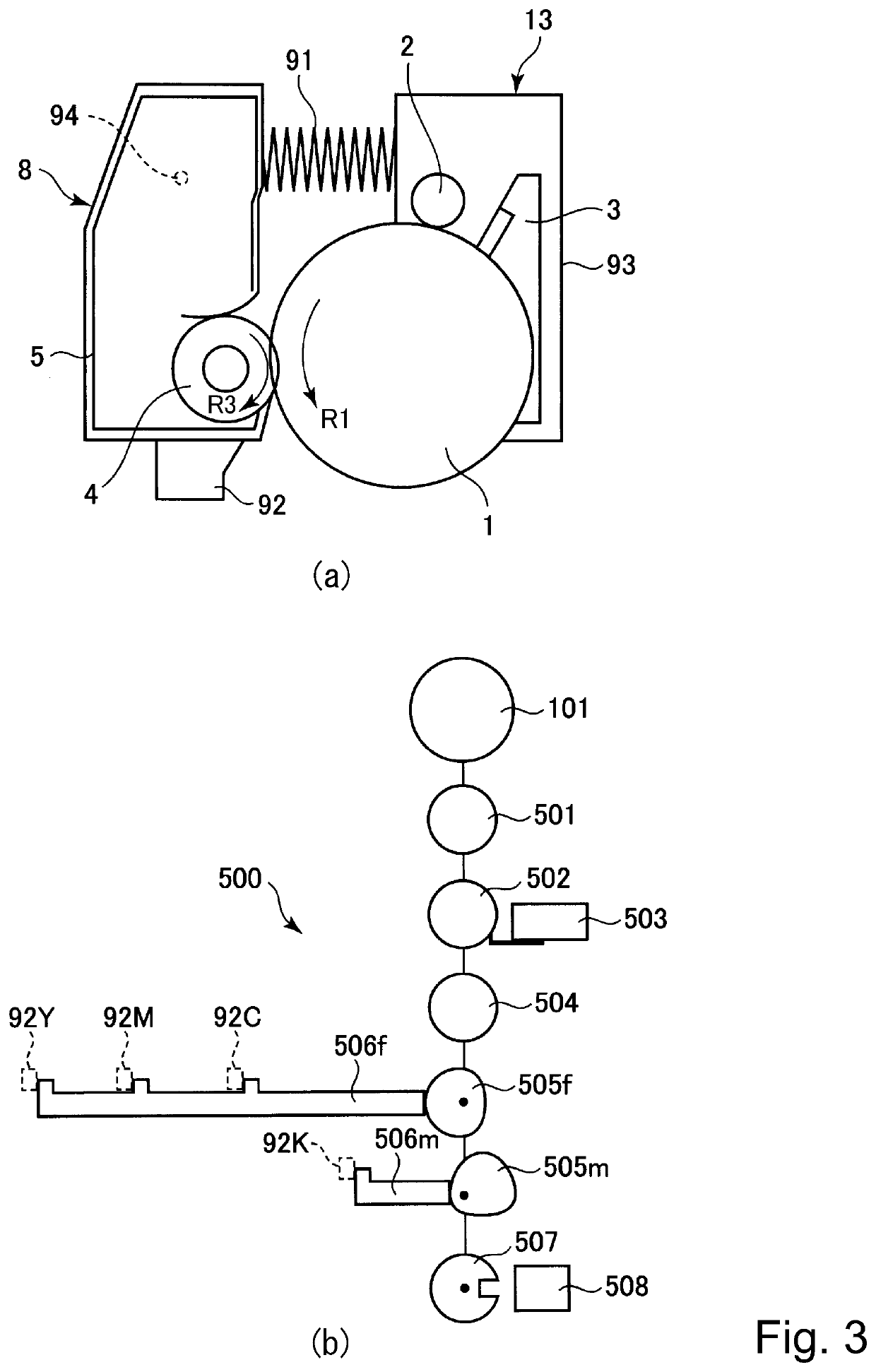

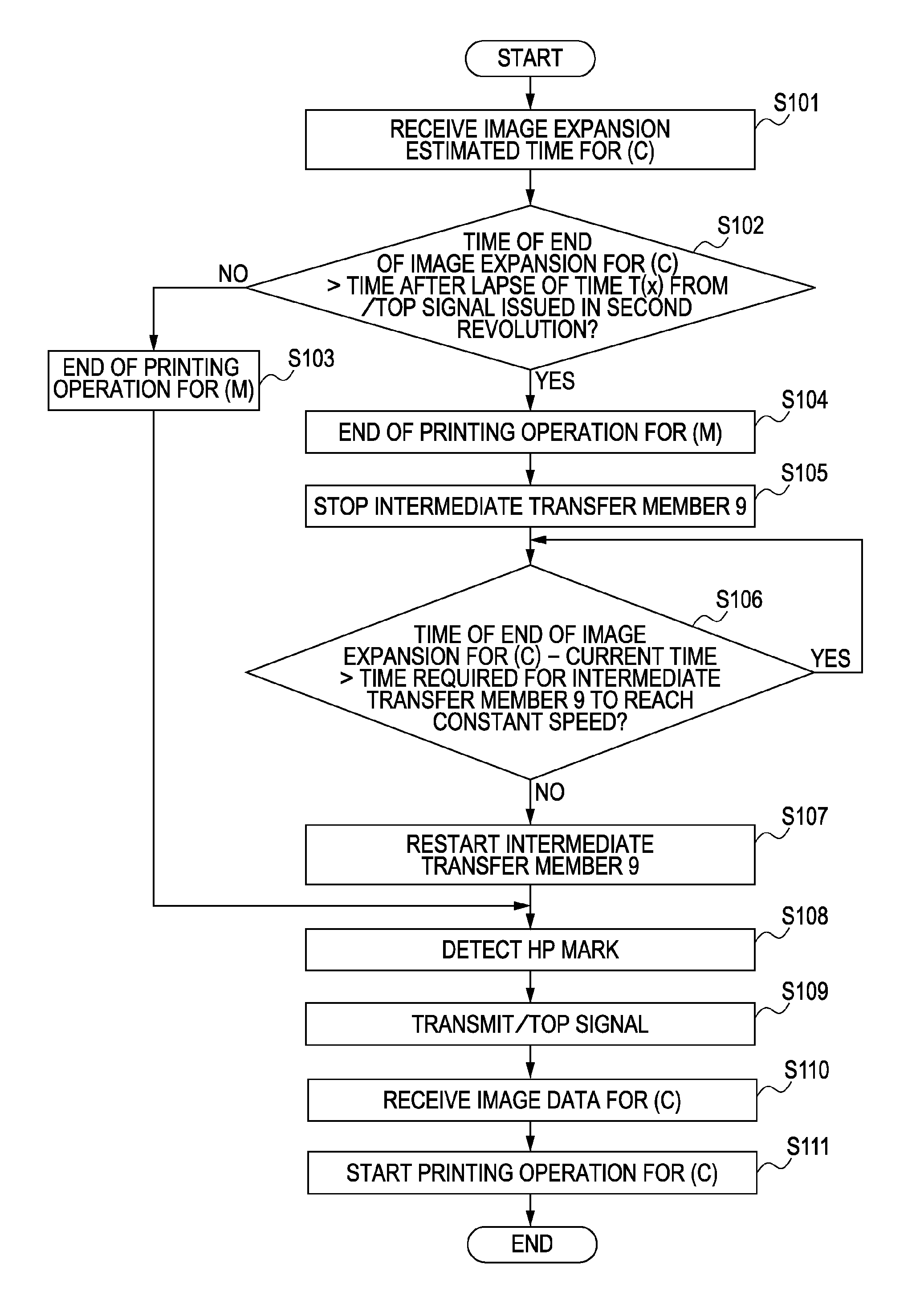

InactiveUS20100054783A1Shorten FPOTReduce lost timeElectrographic process apparatusExecution controlComputer graphics (images)

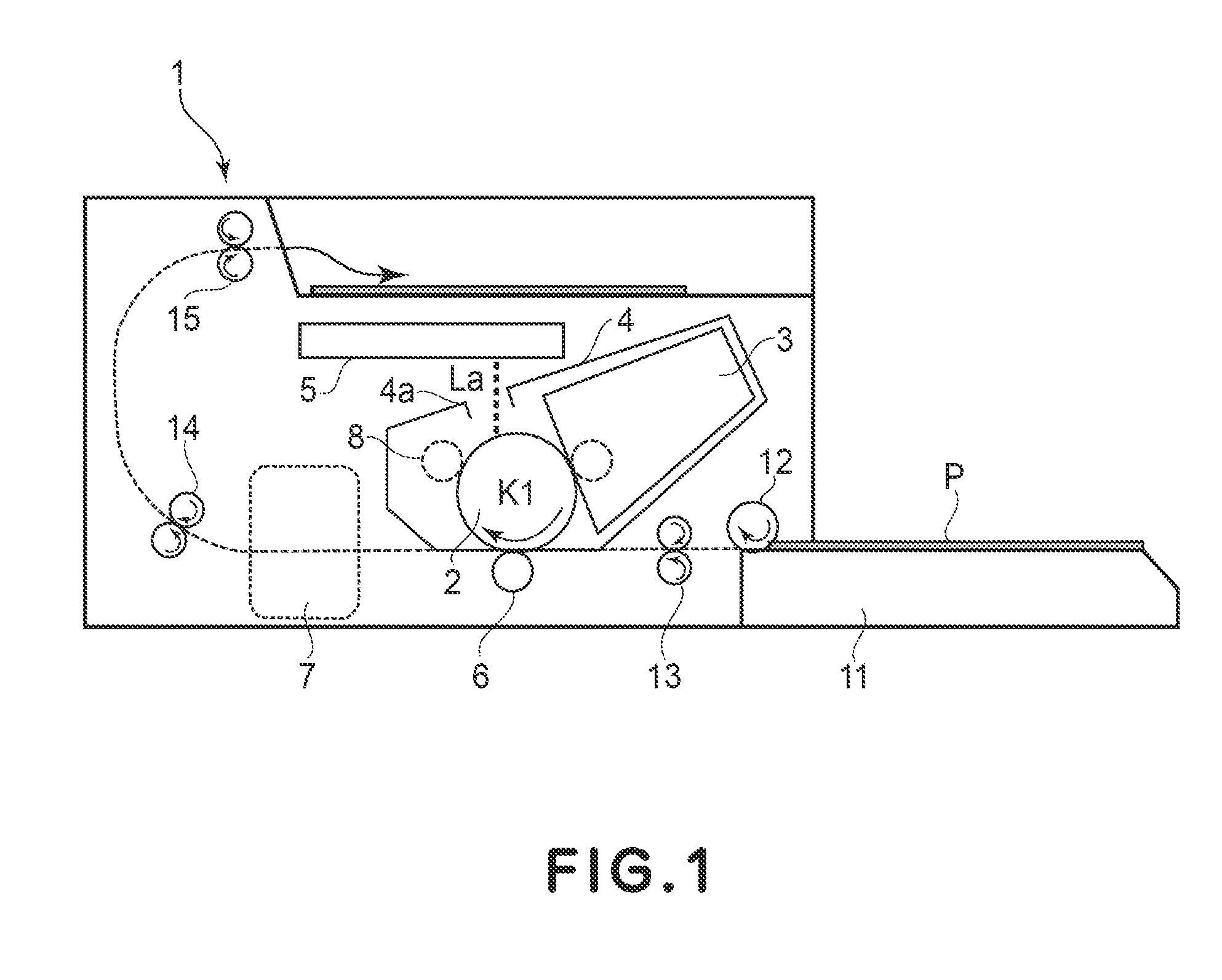

A color image forming apparatus includes one image bearing member, an image forming unit configured to successively form images with toners in plural different colors on the image bearing member per color, a revolving intermediate transfer member, and a transfer unit configured to successively transfer the images on the image bearing member onto the intermediate transfer member in a superimposed relation in a transfer section. Images are transferred in a superimposed relation by executing control such that, when formation of the next image is not started at a due timing of starting the formation of the next image, a timing at which transfer is started after the formation of the next image and a timing at which a leading end of the previously transferred image reaches the transfer section are matched with each other by temporarily changing the revolving speed of the intermediate transfer member or stopping it.

Owner:CANON KK

Ink-jet printer

There is provided an ink-jet printer comprising: a recording head, an electric power supply, and a controller which is configured: to determine an ink amount in which an ink is jetted by the recording head in a flushing processing; in a case that the determined ink amount is less than a first ink amount, to boost a driving voltage of the electric power supply to a target voltage value, in accordance with a predetermined first voltage boosting pattern; and in a case that the determined ink amount is not less than the first ink amount, to boost the driving voltage to the target voltage value, in accordance with a predetermined second voltage boosting pattern in which a voltage boosting time is shorter than that in the first voltage boosting pattern. Accordingly, it is possible to shorten FPOT while reducing the load on the constitutive elements of the ink-jet printer.

Owner:BROTHER KOGYO KK

Image forming apparatus

ActiveUS20190250542A1Shorten the timeShorten FPOTElectrographic process apparatusImage formationEngineering

Owner:CANON KK

Image forming apparatus

PendingUS20220350273A1Shorten FPOTPrevent movementElectrographic process apparatusCorona dischargeImage formationEngineering

An image forming apparatus includes a photosensitive member, a charging member, an exposure unit, a developing unit including a developing member, a motor, a contact and separation unit, a controller, an acquiring portion for acquiring information on a switching time which is a time required for switching a state of the developing member from a separated state to a contact state by executing a contact operation by the contact and separation unit, and a setting portion for setting, on the basis of the information on the switching time acquired by the acquiring portion, a start timing which is a timing when the contact operation by the contact and separation unit is started in a preparation operation and which is a timing before a region on the photosensitive member exposed to light in a light emission period reaches a developing position.

Owner:CANON KK

Image forming apparatus for controlling speed of intermediate transfer member according to image

InactiveUS8224200B2Reduce lost timeShorten FPOTElectrographic process apparatusColor imageImage formation

A color image forming apparatus includes one image bearing member, an image forming unit configured to successively form images with toners in plural different colors on the image bearing member per color, a revolving intermediate transfer member, and a transfer unit configured to successively transfer the images on the image bearing member onto the intermediate transfer member in a superimposed relation in a transfer section. Images are transferred in a superimposed relation by executing control such that, when formation of the next image is not started at a due timing of starting the formation of the next image, a timing at which transfer is started after the formation of the next image and a timing at which a leading end of the previously transferred image reaches the transfer section are matched with each other by temporarily changing the revolving speed of the intermediate transfer member or stopping it.

Owner:CANON KK

Image forming apparatus and process cartridge

InactiveUS9081359B2Improve usabilityShorten FPOTElectrographic process apparatusImage formationMechanical engineering

An image forming apparatus, having process cartridges each including a photosensitive drum and a developing roller, includes a movable member movable between an inside and an outside of a main assembly of the image forming apparatus in a movement direction crossing a longitudinal direction of the photosensitive drum, and a mounting portion for supporting the process cartridges, wherein the process cartridges are detachably mountable to the mounting portion from a direction crossing the longitudinal direction and the movement direction. In addition, and an interrelating member, movable in interrelation with movement of the movable member, moves the developing roller relative to the photosensitive drum so that a distance between a rotation center of the photosensitive drum and a rotation center of the developing roller is decreased with respect to the movement direction when the movable member is moved from the inside to the outside of the main assembly.

Owner:CANON KK

Ink-jet printer

There is provided an ink-jet printer including: a recording head; a power supply; and a controller. In a case that the controller obtains a maintenance instruction, the controller performs: boosting driving voltage to a target voltage value, in accordance with a first pattern; and applying the driving voltage to at least one of driving elements. In a case that the controller obtains an image recording instruction, the controller performs: boosting the driving voltage to the target voltage value, in accordance with a second pattern having a voltage boosting time shorter than the first pattern; and recording an image on a sheet by selectively applying the driving voltage, boosted to the target voltage value, to the driving elements.

Owner:BROTHER KOGYO KK

Ink-jet printer

ActiveUS10099491B2Shorten FPOTShorten the time for a preparing processingPower drive mechanismsOther printing apparatusEngineeringElectrical and Electronics engineering

There is provided an ink-jet printer including a conveyer, a recording head, a carriage, an ink receiver and a controller. The controller executes: receiving a recording instruction; determining an ink amount to be jetted in a flushing process; moving the carriage in a first orientation up to a returning position corresponding to the ink amount; moving the carriage in a second orientation opposite to the first orientation from the returning position to a sheet facing area; executing a flushing processing; and executing recording. The returning position is located at a first position downstream from the sheet facing area in the first orientation, under a condition that the determined ink amount is less than a threshold value; and the returning position is located at a second position downstream from the first position in the first orientation, under a condition that the determined ink amount is not less than the threshold value.

Owner:BROTHER KOGYO KK

Image forming apparatus

ActiveUS11199797B2Reduce the fixing-set markShorten FPOTElectrographic process apparatusImage formationEngineering

Owner:CANON KK

Ink-jet printer

There is provided an ink-jet printer including: a recording head; a power supply; and a controller. In a case that the controller obtains a maintenance instruction, the controller performs: boosting driving voltage to a target voltage value, in accordance with a first pattern; and applying the driving voltage to at least one of driving elements. In a case that the controller obtains an image recording instruction, the controller performs: boosting the driving voltage to the target voltage value, in accordance with a second pattern having a voltage boosting time shorter than the first pattern; and recording an image on a sheet by selectively applying the driving voltage, boosted to the target voltage value, to the driving elements.

Owner:BROTHER KOGYO KK

Image recording apparatus

ActiveUS10730286B2Slow velocityKeep for a long timeSpacing mechanismsPower drive mechanismsRadiologyImage recording

Owner:BROTHER KOGYO KK

Stream printing method for handling large print jobs to achieve reduced first-page-out time

ActiveUS9489156B1Shorten FPOTImprove printing efficiencyDigitally marking record carriersDigital computer detailsData fileMonitoring system

A stream printing method implemented in a print server and a printer for handling printing of large files. The print server divides the input data file into a plurality of data chunks, and transfers them sequentially to the printer. The printer sequentially rips the data chunks and prints them. The print server dynamically monitors the system performance factors to measure, for each data chunk, the time required to extract the data chunk from the data file, the time required to transfer the data chunk to the printer, the time required to rip the data chunk, and the time required to print the data chunk. The sizes of the data chunks are calculated using these performance factors and the chunk size of a previous data chunk.

Owner:KONICA MINOLTA LAB U S A INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com