Movable type single screw compressor

A single-screw compressor and compressor technology, which is applied in the field of locomotive power gas, compressor, and air compression, can solve the problems that there are no relevant literature reports, and achieve the goals of solving liquid hammer phenomenon, high efficiency, and improving service performance and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

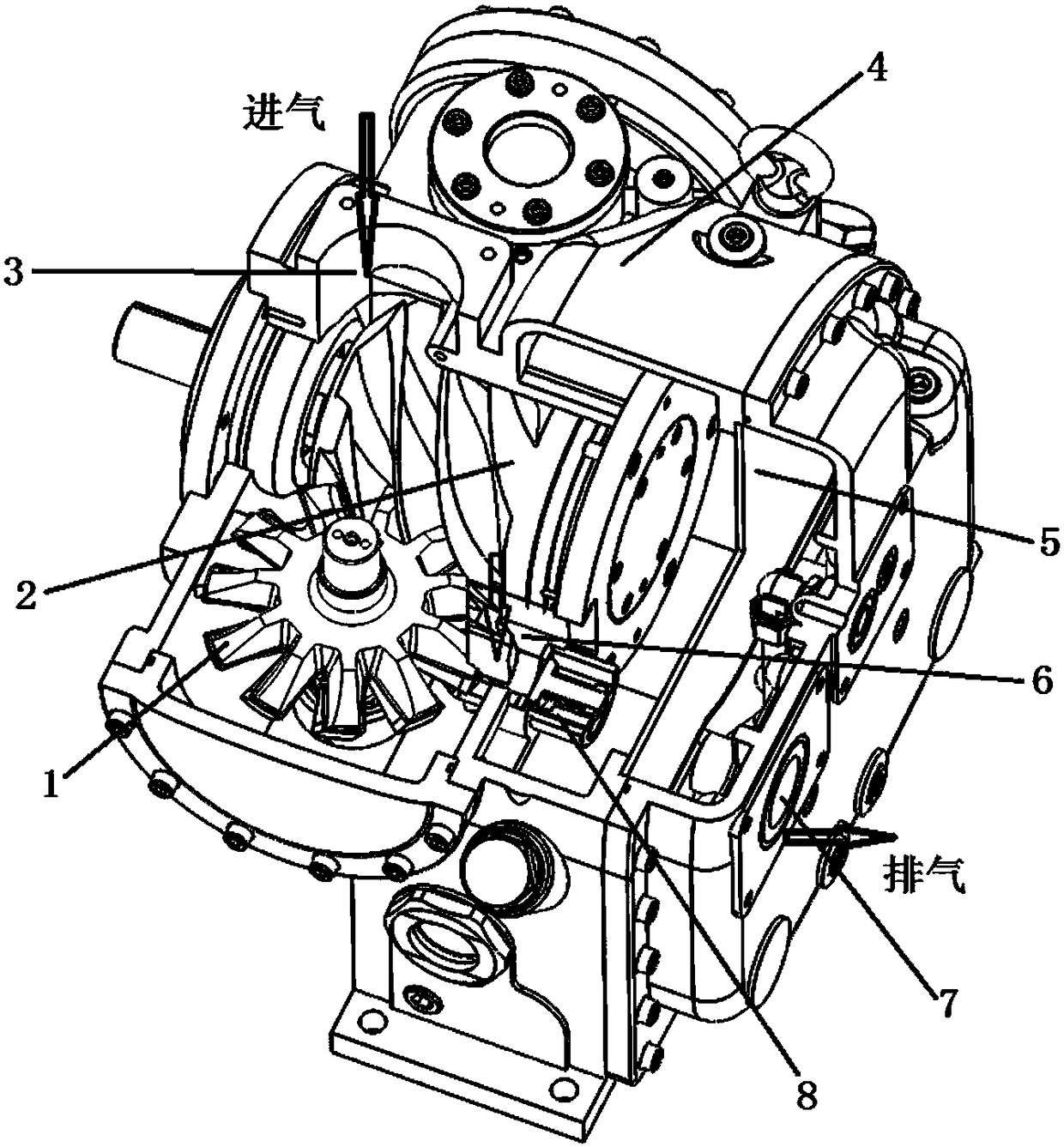

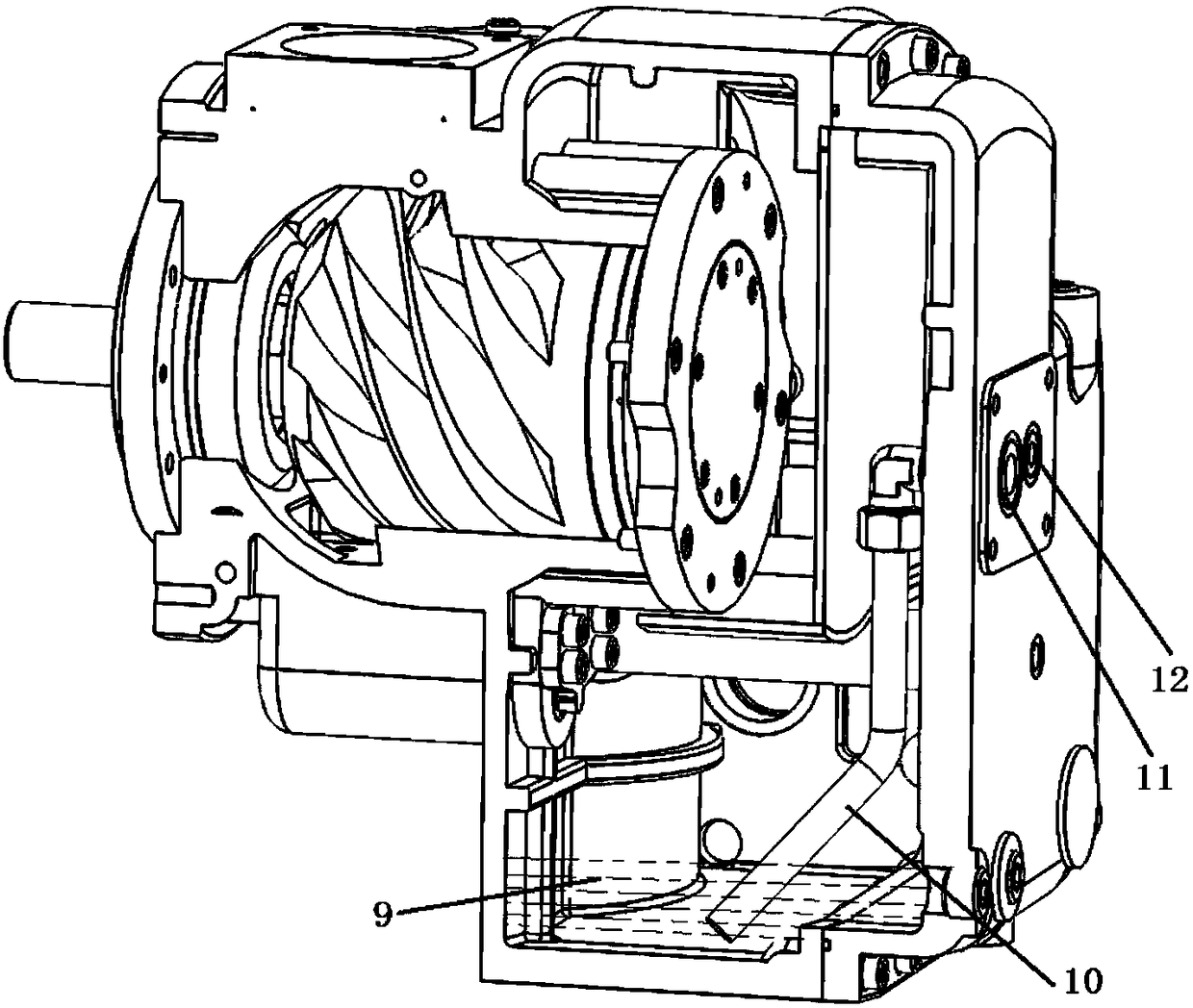

[0037] Such as Figure 1 to Figure 2As shown, a mobile single-screw compressor, the specific mechanism includes: 1. Star wheel; 2. Screw; 3. Compressor air inlet; 4. Compressor shell; 5. Oil separation device; Valve installation hole; 7. Compressor exhaust hole; 8. One-way valve; 9. Oil pool; 10. Oil suction pipe; 11. Compressor oil outlet hole; 12. Compressor oil inlet hole.

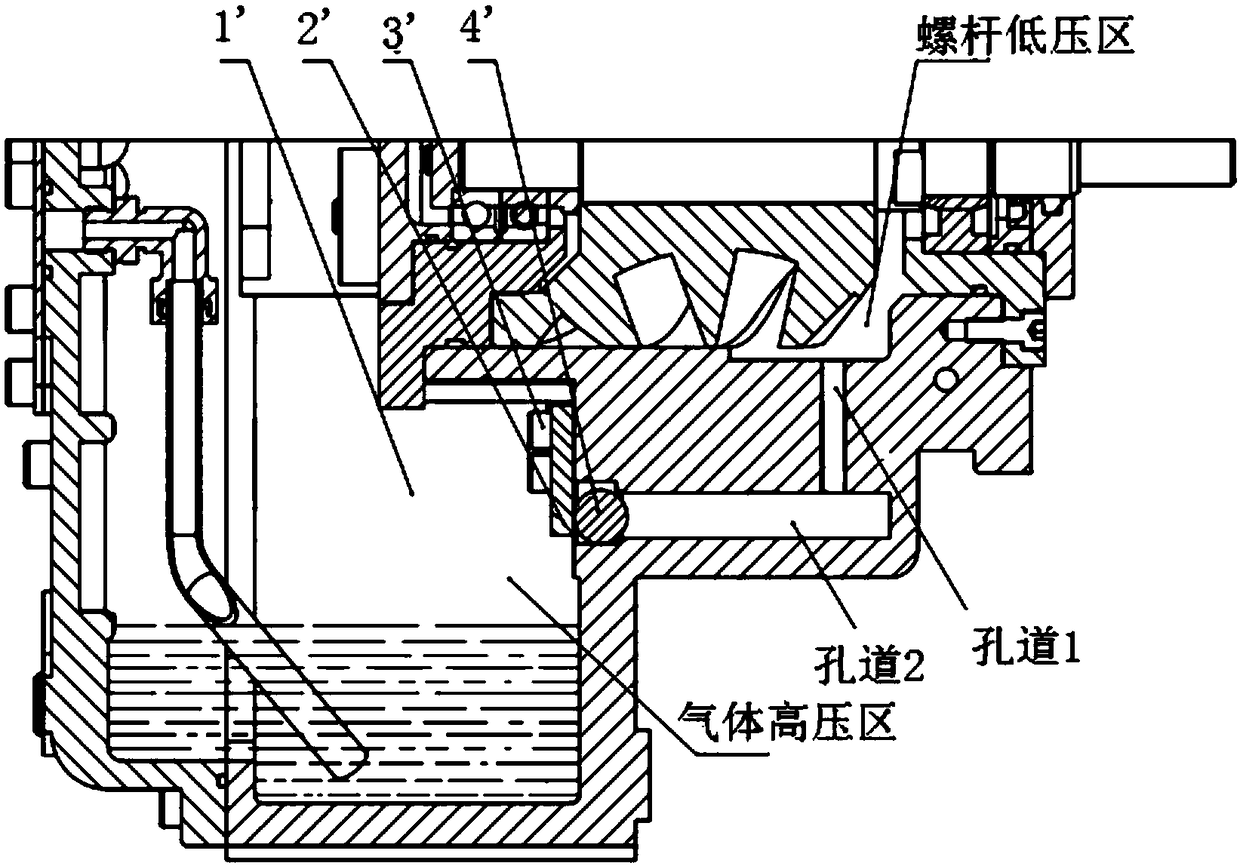

[0038] It consists of a screw 2 and two star wheels 1. The two star wheels 1 in the figure are arranged symmetrically, and the other star wheel is on the other side of the screw rod. The one-way valve is built in the compressor shell and connected to the air outlet after the meshing and compression of the screw 2 and the star wheel 1 to prevent the backflow of the gas in the high-pressure chamber, and to protect the compressor and drive the compressor motor. An oil separation device 5 is arranged inside the compressor housing 4, which can separate the gas-liquid two-phase matter from the one-way valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com