Making method of three-layer seamless composite waterproof shoe

A manufacturing method and technology of waterproof shoes, applied in the direction of bonding shoe parts, shoe-making machinery, footwear, etc., can solve the problems of incompleteness, weak and unreliable manufacturing process of three-layer waterproof shoes, etc., and achieve high protection, Remarkable waterproof and moisture-permeable effect, good firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

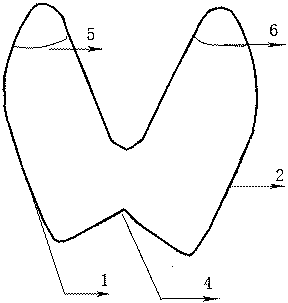

[0058] 1B: Turn the one-piece structure inside out, the reverse side of the weft stitch is outside, and the front side is inside;

[0059] 1C: Sew up the opening of the front head (6) of the second sock part;

[0060] 1D: From the opening of the front head (5) of the first sock part, pass the foot mold through the inside of the first sock part and insert it into the inside of the second sock part. The foot mold is a shoe last with a shape and dimensions are consistent with said first sock portion and said second sock portion;

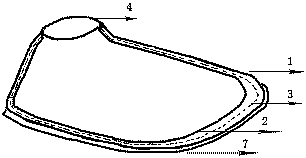

[0061] 1E: placing the seamless sock-shaped waterproof and moisture-permeable PU membrane sleeve (3) outside the second sock part (2);

[0062] 1F: Turn the first sock part (1) backwards and put it on the outside of the PU film sleeve (3) and the second sock part (2);

[0063] 1G: Sew the opening of the front head (5) of the first sock part to form a three-layered sock with the interlayer containing the PU film sleeve (3);

[0064] 1H: heating and se...

Embodiment 1

[0079] Make three-layer waterproof shoes of the present invention according to the following steps:

[0080] 0A: Knit the head 5 of the first sock on the single-needle bed hosiery machine. The veil of the sock is made of cotton and nylon fibers, and the bottom yarn is made of leather-core low-melting yarn (melting point 80~130°C);

[0081] 0B: knitting the sock face 8 and sock sole 10 of the first sock part 1 by unidirectional rotation of the needle cylinder;

[0082] 0C: The reciprocating rotation of the needle cylinder first gradually reduces the knitting needles participating in knitting, and then gradually increases the knitting needles participating in knitting, so as to knit the heel 12 of the first sock;

[0083] 0D: The needle cylinder rotates in one direction to knit the first sock part and the second sock part sock tube 4, and the middle part of the sock tube is lined with elastic or spandex (the opening of the sock is formed here when double-layer socks are turned o...

Embodiment 2

[0097] Before or at the same time as making the three-layer waterproof shoes of the present embodiment, the PU film cover 3 can be prefabricated, and this step (step 1E-0) includes the following sub-steps:

[0098] 1E-01: Do double-sided dot-like glue coating on the PU film on the compound machine;

[0099] 1E-02: Two layers of dotted glued PU film are pressure-heated under the sock-shaped mold. The heat source used is high-frequency electromagnetic wave (high frequency wave), and the pressure of the mold on the PU film is 0.1~8kg / cm 2 , the characteristic polar covalent bonds of the glue-coated molecules and polymers of the PU film heat up to the welding temperature under the action of high-frequency waves, resulting in bonding and fixing;

[0100] 1E-03: Cut the laminated double-layer film at the central line of the sock-shaped rubber coating below the heat-sealing temperature of the PU film to obtain a sock-shaped seamless PU film sleeve 3 with an opening at the ankle.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Hydrostatic pressure | aaaaa | aaaaa |

| Hydrostatic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com