Pulse discharge ozone generation apparatus

A generation device and pulse discharge technology, applied in the direction of ozone preparation by discharge method, ozone preparation, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of low efficiency of ozone generator, achieve light weight, save water cooling system , The effect of increasing equipment reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

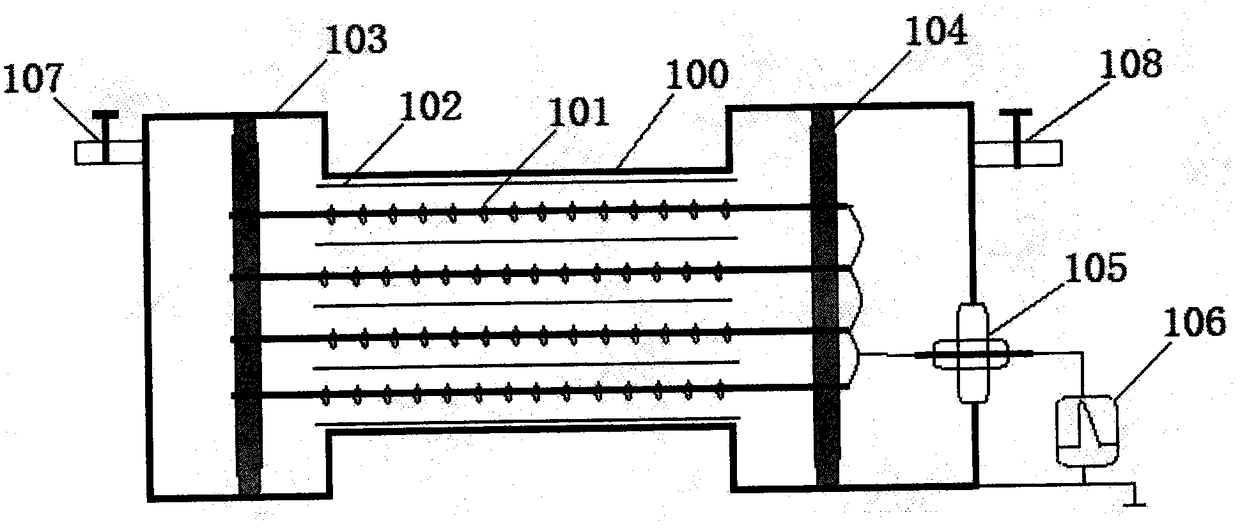

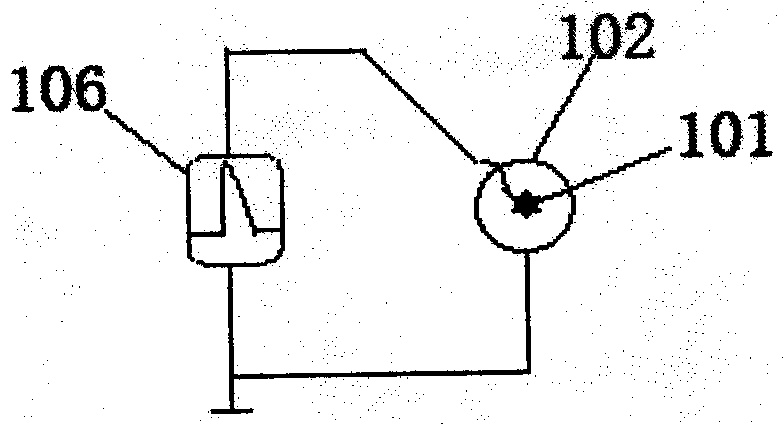

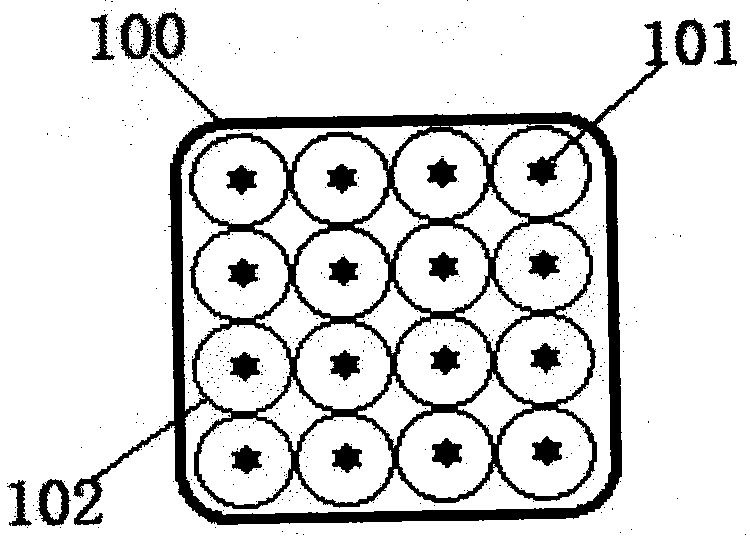

[0021] Refer to attached figure 1 , 2 Given in and 3 are detailed descriptions of specific embodiments of the present invention. It is characterized in that a metal ground electrode 102 in the form of a honeycomb and a rod-shaped metal high voltage electrode 101 with multiple tines are arranged in a stainless steel shell 100 . The high voltage electrode 101 and the ground electrode 102 are made of 316L stainless steel.

[0022] The housing 100 is provided with an oxygen inlet 108 and an ozone outlet 107 , as well as a high-voltage insulator connection end 105 .

[0023] The rod-shaped metal high-voltage electrode 101 with multiple tines is supported, fixed and positioned by an insulating material 104. There is a certain gap between the tines of the electrode 101 and the ground electrode 102 of the honeycomb cylinder, and the distance between the gaps is greater than 20mm.

[0024] The housing 100 is made of stainless steel with large dimensions (such as 103) at both ends an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com