High-pressure-difference intelligent regulating valve

A technology of intelligent adjustment and high pressure difference, applied in the direction of lift valve, sliding valve, valve details, etc., can solve the problems of unstable flow, pressure adjustment, damage to valve sealing performance, easy wear of valve seat and valve core, etc., to improve processing. The effect of precision and processing efficiency, prolonging service life, avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

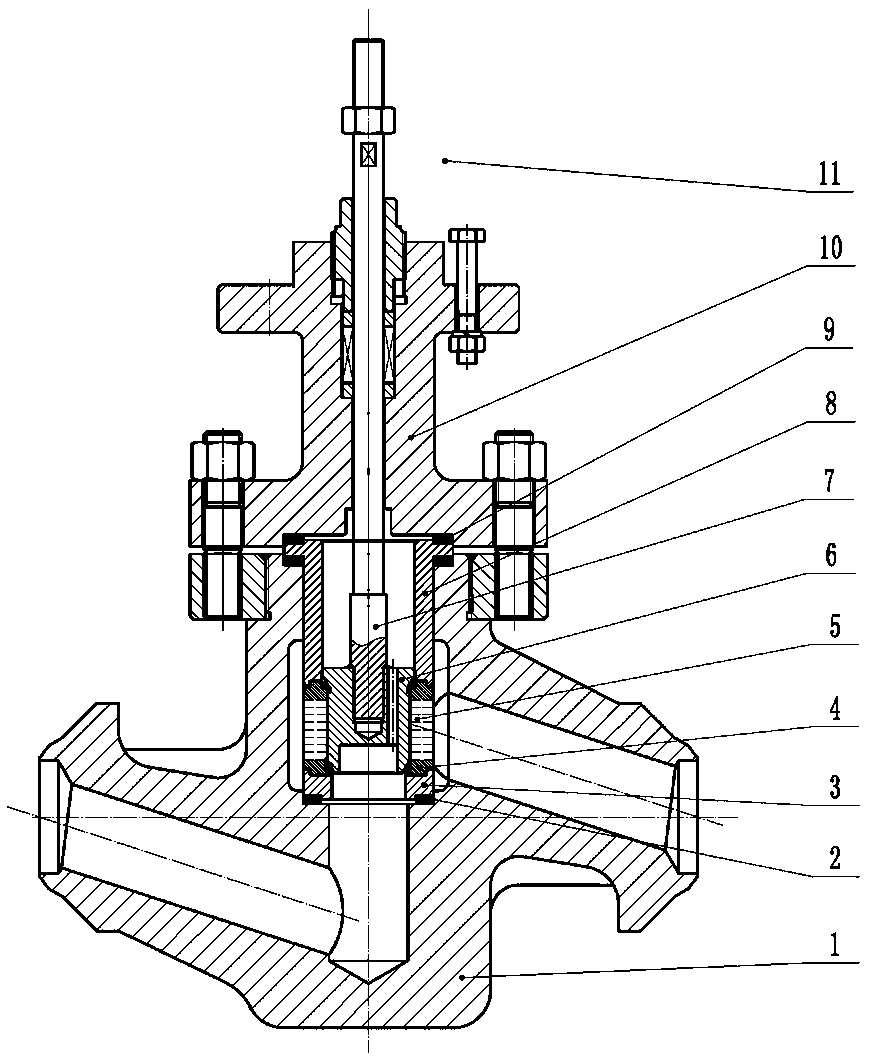

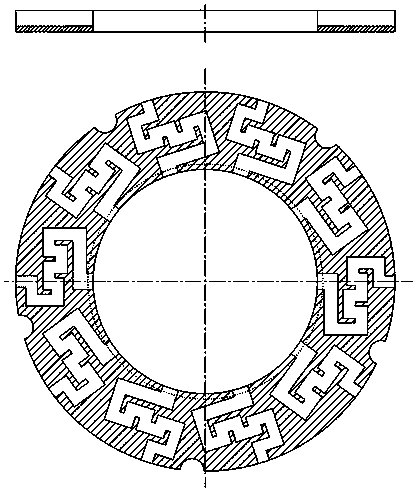

[0018] As shown in the figure, a high-pressure differential intelligent regulating valve includes a valve body 1, a valve cover 10 is arranged above the valve body 1, a valve stem 7 is installed in the valve hole on the valve cover 10, and a valve core 6 is connected to the lower end of the valve stem 7. , the upper end of the valve stem 7 is connected with an external actuator 11 that can drive the valve core 6 to move up and down through the valve stem 7; an S-shaped flow channel is arranged inside the valve body 1, and a valve seat 4 is installed in the S-shaped flow channel, and the flow channel inlet is surrounded by On the side wall of the valve seat 4, the outlet is arranged at the bottom of the valve seat 4; a mounting seat 3 is arranged below the valve seat 4, a pressure sleeve 8 is arranged above the valve seat 4, and a labyrinth valve sleeve assembly 5 is installed on the middle section of the side wall of the valve seat 4. The assembly 5 includes a number of circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com