Forged pipe fitting trimming-free precision forging technology

A flash-free, precision forging technology, used in manufacturing tools, forging/pressing/hammering machinery, forging furnaces, etc., can solve the problem that heating furnaces cannot cope with different specifications of bars, product quality cannot meet customer requirements, and cannot be eliminated. Bar segregation, looseness and other problems, to achieve better forging effect, improve work efficiency, and save processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

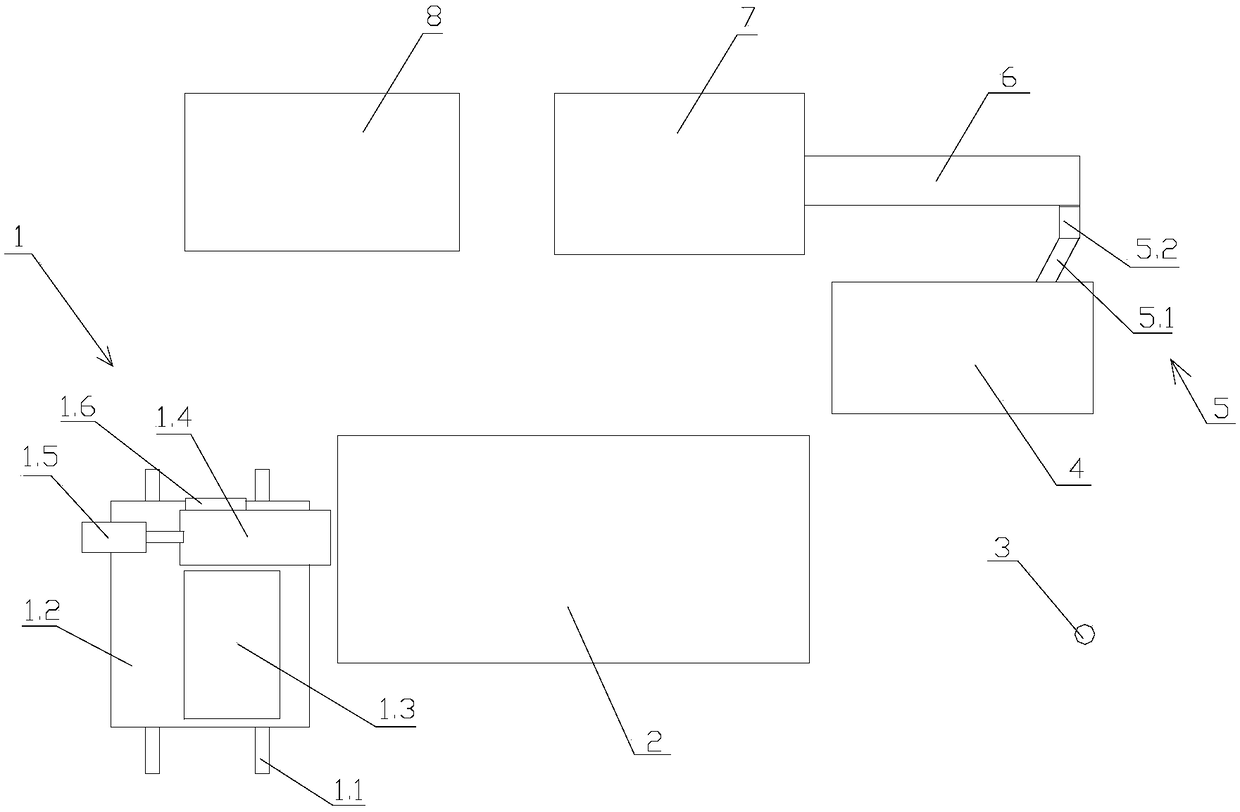

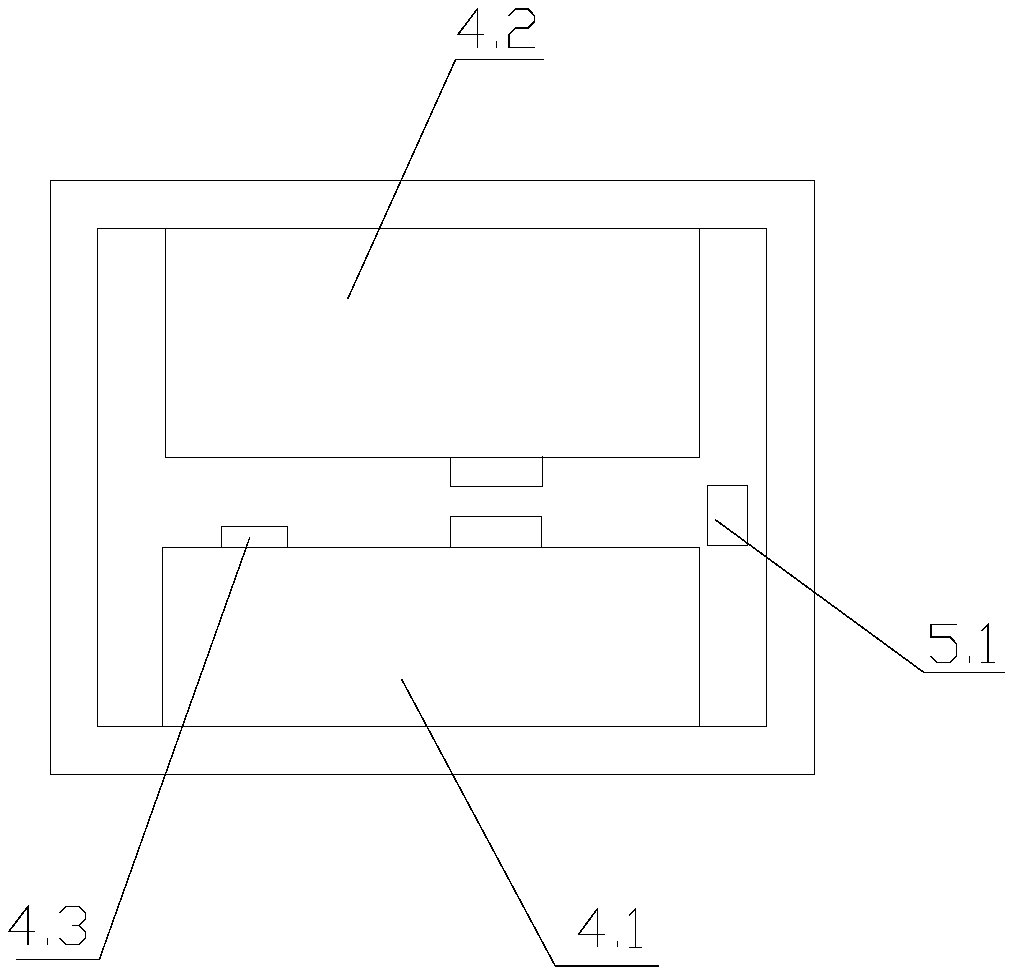

[0028] see Figure 1~3 , the present invention relates to a process for precision forging of forged pipe fittings without flash. The process is realized through a production line for precision forging of forged pipe fittings without flash. 2. Furnace path 2.1 The feeding mechanism 1 at the feed inlet, the charging mechanism 1 includes two rails 1.1 installed in parallel on the ground, and the rails 1.1 are slidably provided with a sliding plate 1.2, and the sliding plate 1.2 is equipped with a feed channel 1.3 arranged obliquely, and the bottom discharge end of the feed channel 1.3 is provided with a feed chute 1.4, and the length direction of the feed trough 1.4 is perpendicular to the length direction of the feed channel 1.3, and the feed trough 1.4 The feed opening of the furnace channel 2.1 facing the heating furnace 2 (preferably, there are multiple furnace channels 2.1, and each furnace channel 2.1 has a different diameter, so that it is convenient to place bars of diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com