Shot blasting machine

A technology of shot blasting machine and friction plate, which is applied in the direction of abrasive jetting machine tools, metal processing equipment, used abrasive processing devices, etc., can solve the problem of long time-consuming recycling work, improve the effect of rust removal and reduce the time-consuming recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

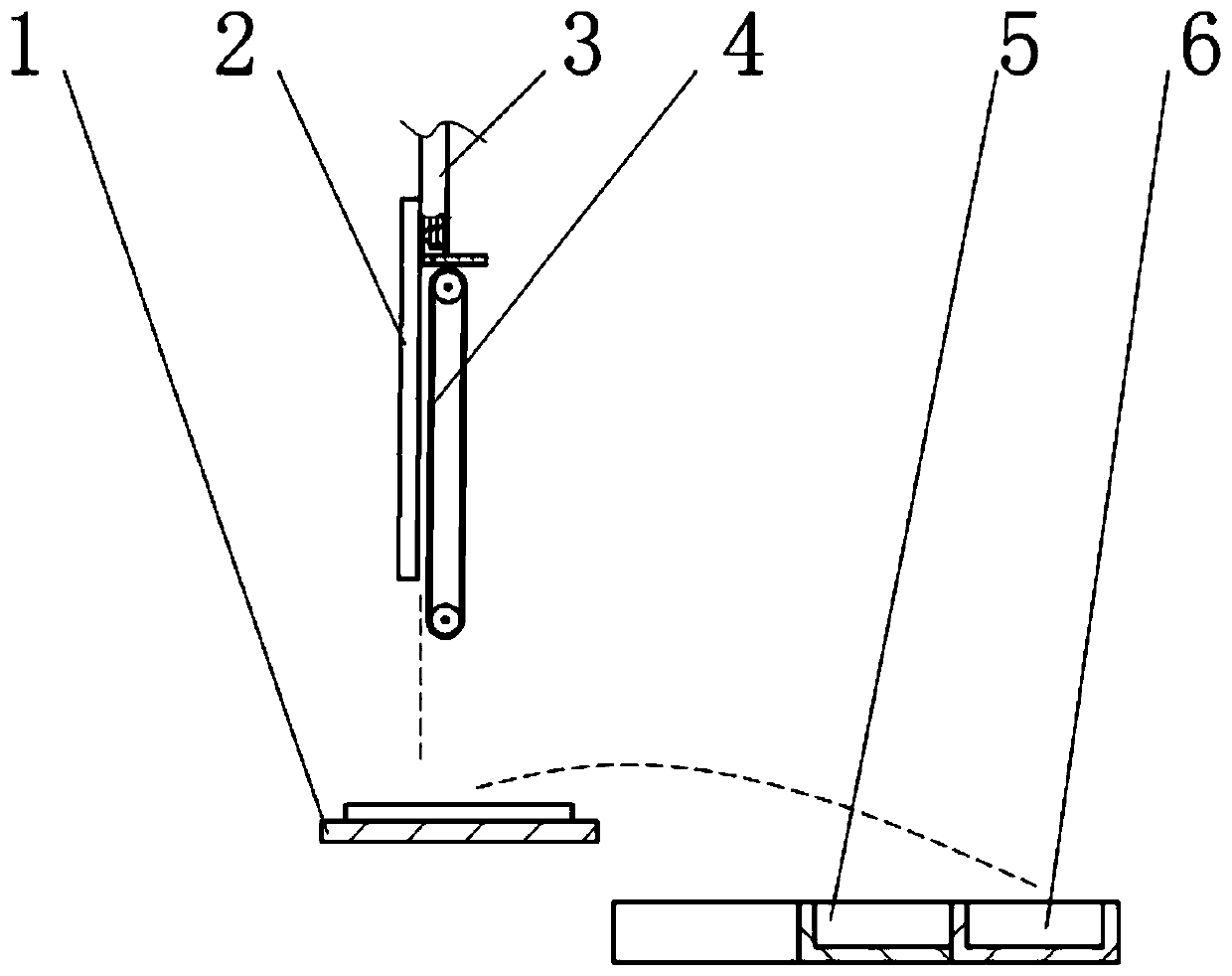

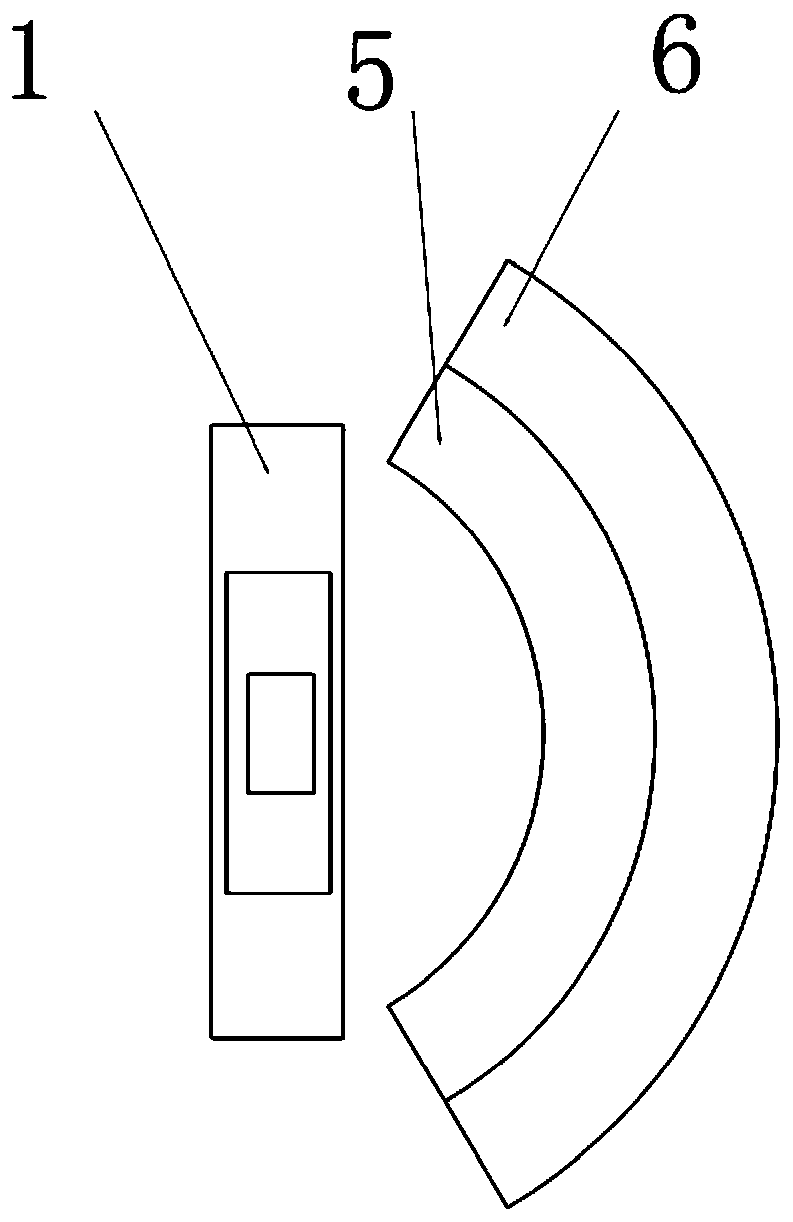

[0017] Embodiment: the shot blasting machine in this scheme, as figure 1 and figure 2 As shown, it includes a vertical acceleration device, a conveying device 1 for conveying products, and a recovery device, and the accelerating device is located above the conveying device 1 . The acceleration device includes a friction plate 2 and an acceleration conveyor belt. The friction plate 2 is made of elastic materials such as rubber or nylon, and the acceleration conveyor belt is located on one side of the friction plate 2 . The acceleration conveyor belt includes an acceleration belt, a driving roller and a driven roller. The acceleration belt is sheathed on the driving roller and the driven roller. The acceleration belt is parallel to the friction plate 2 , and there is an acceleration gap between the acceleration belt and the friction plate 2 . Cotton cloth is fixedly connected to the side of the friction plate 2 close to the acceleration belt, and a number of accelerated abrasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com