Two-degree-of-freedom microgripper

A technology of micro-clamping and degree of freedom, which is applied in the direction of collets, micro-manipulators, manipulators, etc., can solve the problems of limiting the application range of micro-grippers and failing to meet the application fields of micro-grippers, and achieve measurement and real-time feedback , Improve static and dynamic characteristics, improve clamping stability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

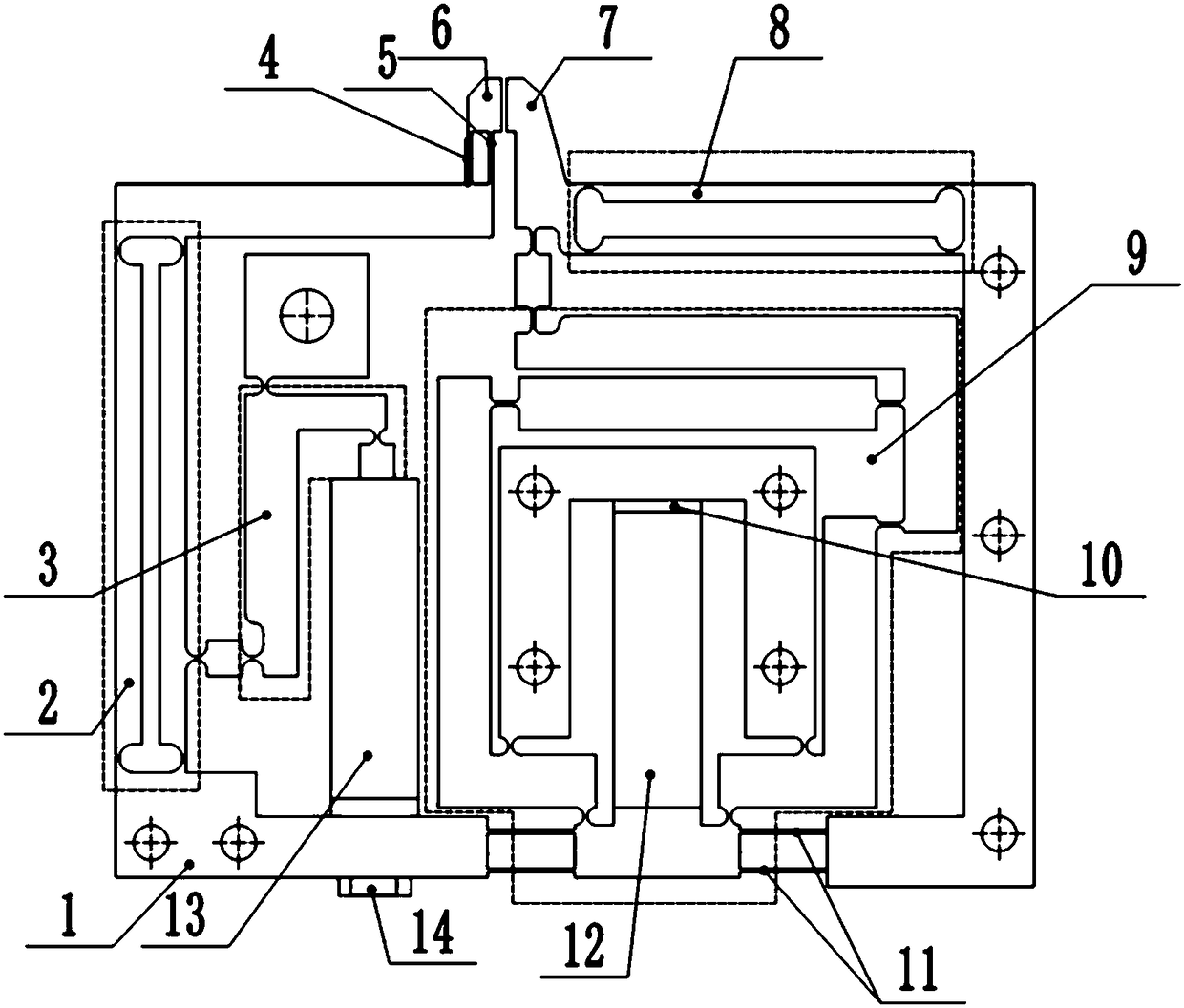

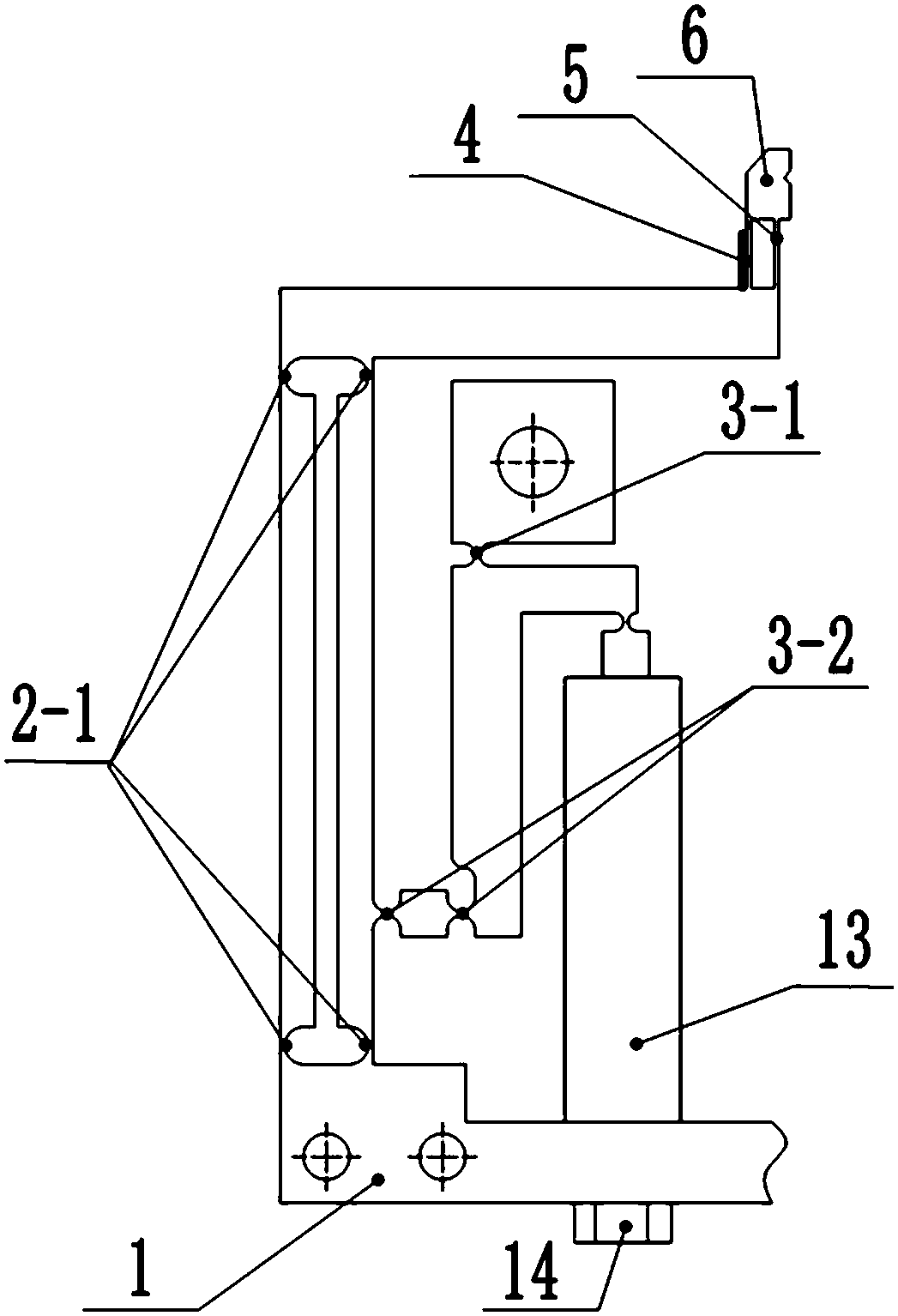

[0020] see Figure 1 to Figure 5 , a two-degree-of-freedom micro-gripper, which is integrally formed by plate wire cutting, including a lever displacement amplification mechanism 3, a differential displacement amplification mechanism 9 and a base body 1, a lever displacement amplification mechanism 3 and a differential displacement The enlargement mechanism 9 is respectively located on the left and right sides of the holder.

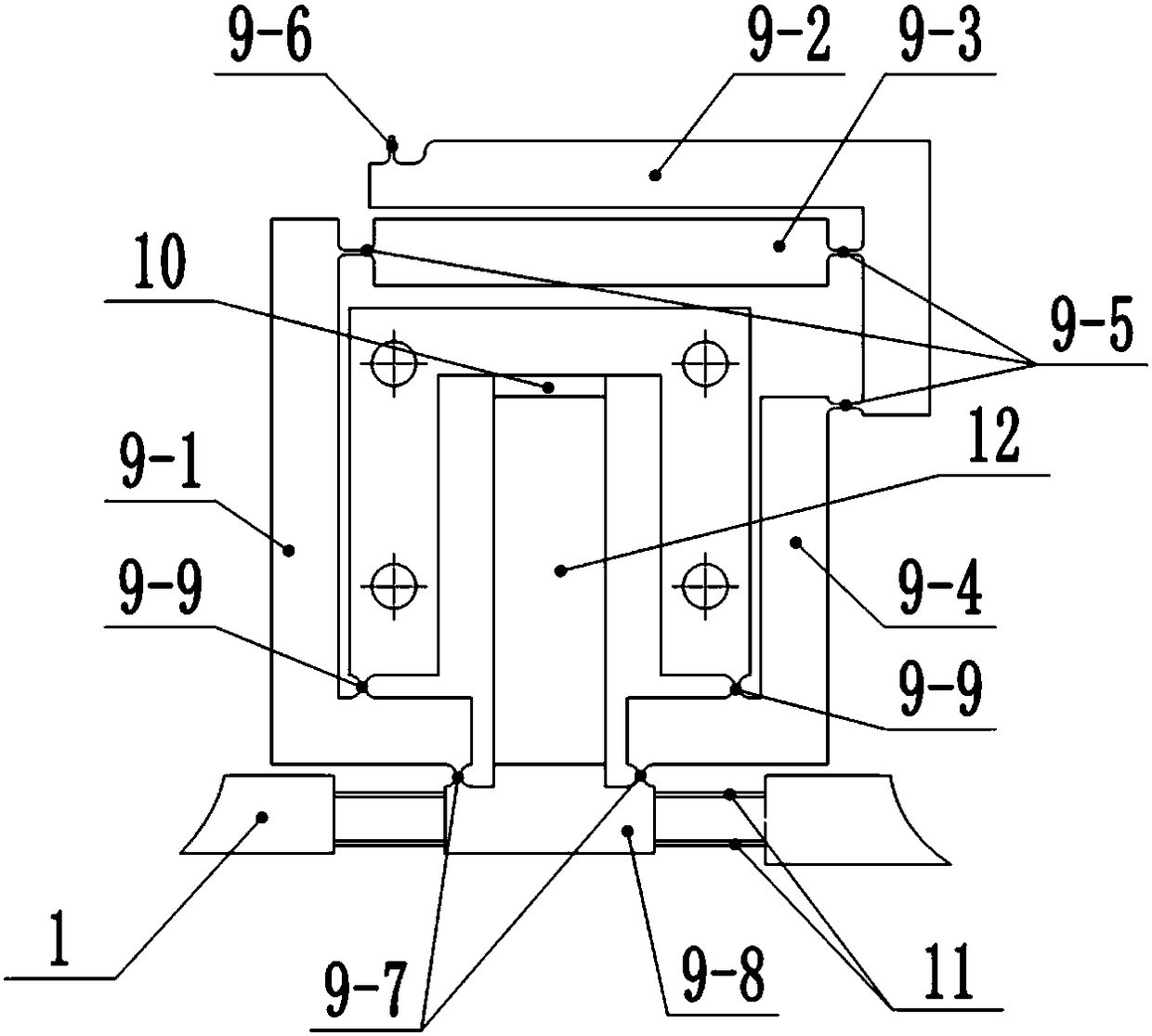

[0021] The differential displacement amplifying mechanism 9 is provided with an input rod 9-8 connected to the substrate 1, an L-shaped rod 9-1, 9-2, 9-4 and a connecting rod 9-3 parallel to the X axis; the input rod A flexible parallel double-plate mechanism I11 connected with the base body 1 is formed at both ends of the member 9-8, and a piezoelectric ceramic driver I12 is provided between the input rod member 9-8 and the base body 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com