Transportation and overhauling device for nuclear industry

A maintenance device and nuclear industry technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as difficult handling, motor needs to be replaced, and the quality of objects to be transferred is large, so as to achieve the effect of reducing the number of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

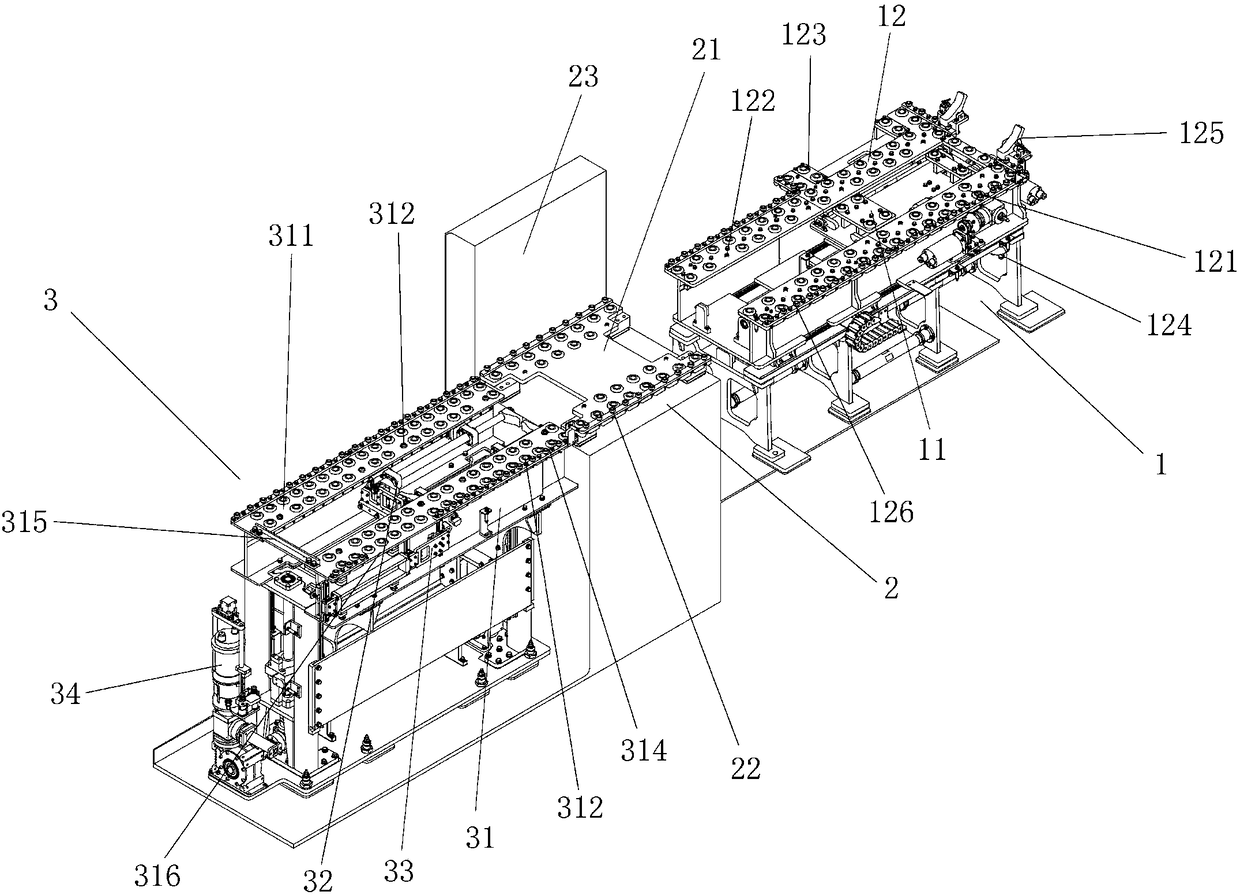

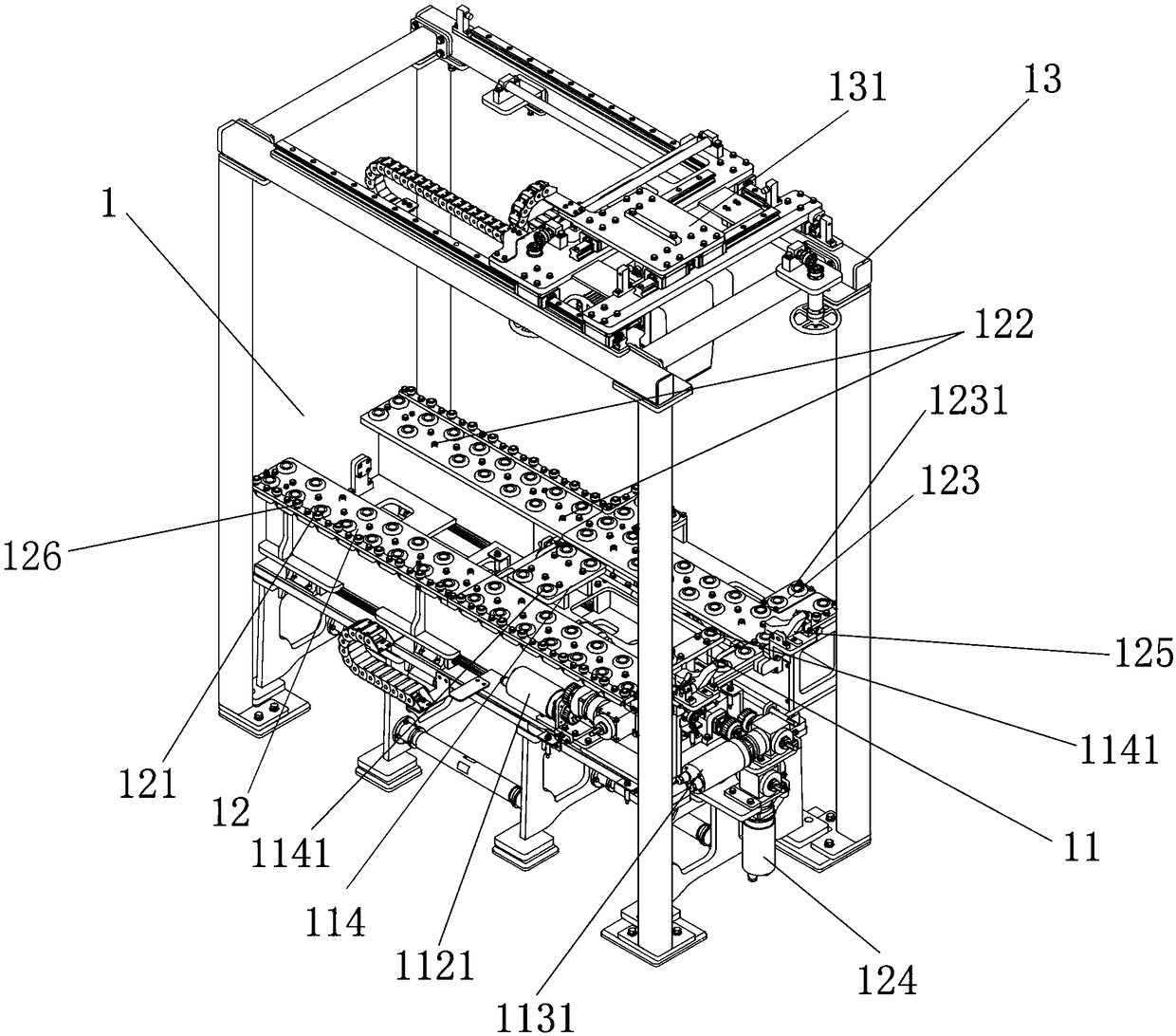

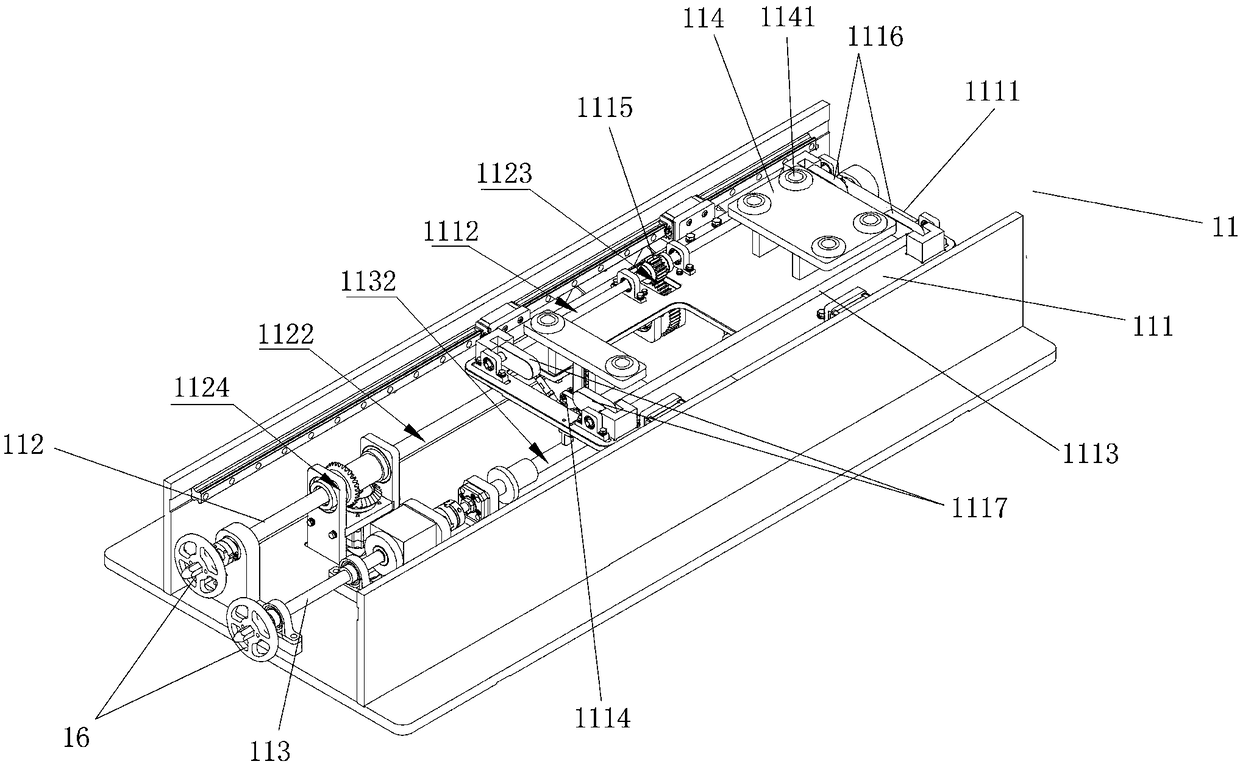

[0047] like figure 1 As shown, this embodiment consists of a conveying section 1, an unpowered section 2 and a corresponding section 3 arranged in turn, wherein the unpowered section 2 is provided with a wall 23 around it (only one wall is shown in the figure), wherein the conveying section 1 and the The first wall is between the unpowered section 2, and the second wall is between the unpowered section 2 and the connecting section 3. In the non-working state, the first wall and the second wall are both closed. When the power section 2 transports the nuclear equipment, the first wall is opened, the third motor 124 drives the transport section 1 to translate and dock with the unpowered section 2, the nuclear equipment enters the unpowered section 2, and the second wall opens after the first wall is closed, The vertical elevating mechanism 34 drives the connecting section 3 to rise up to dock with the unpowered section 2 and take out the nuclear equipment therefrom. The conveyin...

Embodiment 2

[0058] like figure 2 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that the first motor 1121 drives the rotating shaft 1122 horizontally.

Embodiment 3

[0060] This embodiment is basically the same as Embodiment 1, except that the rotating shaft 1122 is a hexagonal steel, and the rotating member 1123 is a hexagonal nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com